Checking for leaks in the evaporative emission system

|

|

Checking for leaks in the evaporative emission system

|

|

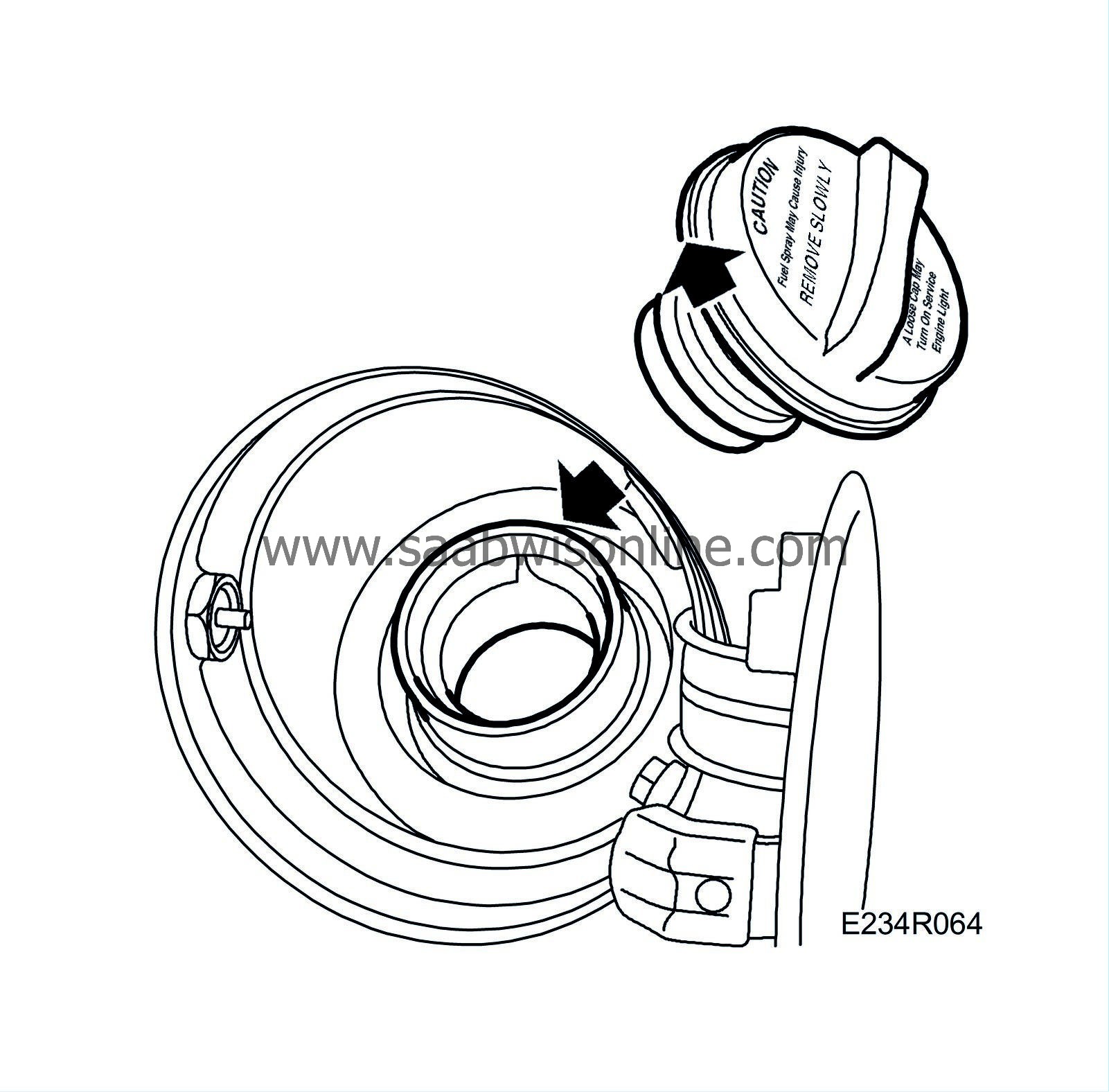

1.

|

The cut-off valve shall remain activated.

|

|

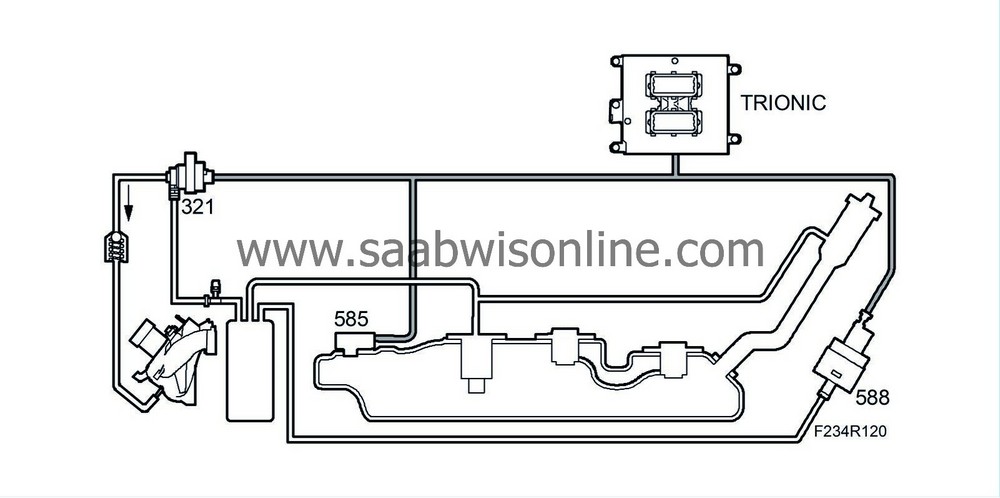

2.

|

Detach the line from the EVAP canister purge valve at the intake manifold.

|

|

3.

|

Raise the pressure again, following the instructions in the Kent-Moore manual.

|

|

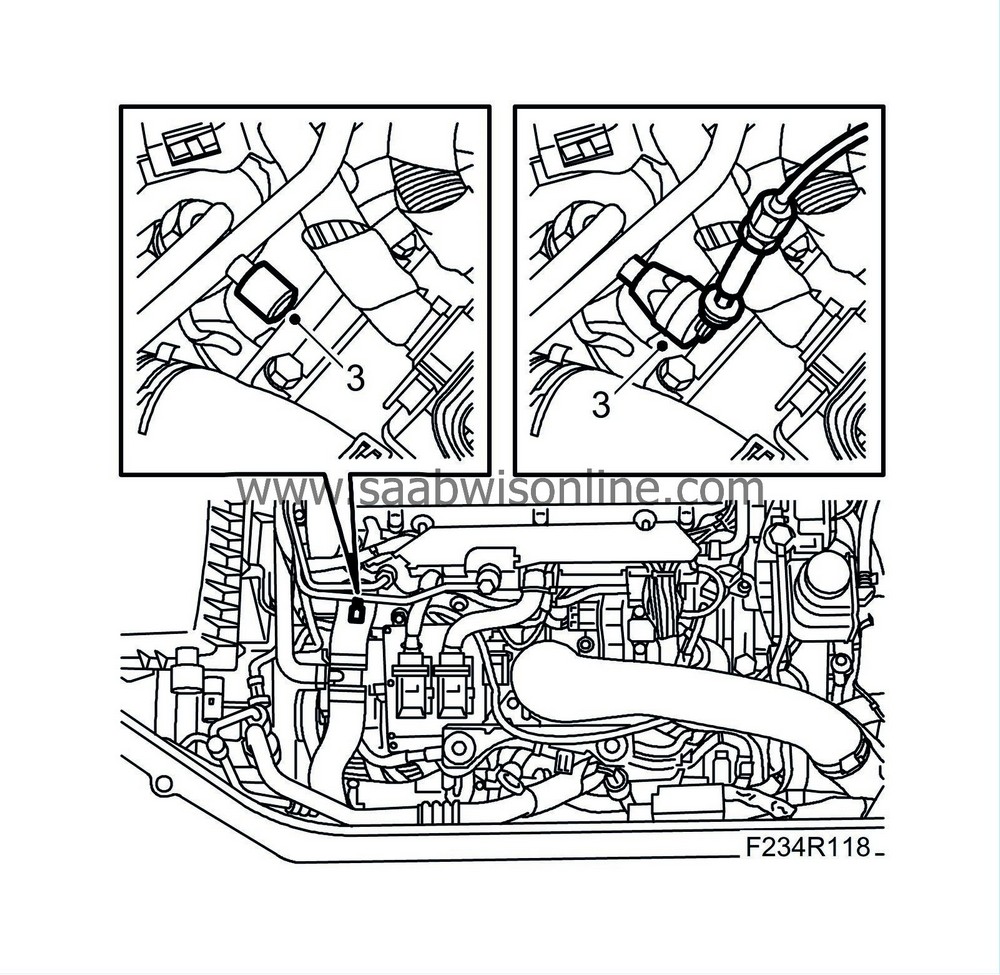

4.

|

Use ultrasonic leak detector J41416 to trace the leak. Start with the line that has been disconnected from the intake manifold and then follow the system lines and components. Make a visual check of the system at the same time.

|

Note

|

|

In order to check for leaks in components on the top of the fuel tank, it may be necessary to lower the tank a bit.

|

|

Note

|

|

Leak detection listening equipment is sensitive to ambient noise, such as exhaust outlet, air-driven machines, use of blower nozzles, leaking pressurised air connections, etc.

|

|

Airflow from the ventilation equipment in the workshop can also affect the equipment.

|

|

All of the items mentioned can cause a similar, but incorrect indication/detection of a leak in the EVAP system.

|

|

|

5.

|

Therefore, always adjust the sensitivity of the ultrasonic leak detector, so that the ambient noise, which often causes interference, is filtered out.

|

Note

|

|

A larger leak, such as a faulty cut-off valve or a loose line, is difficult to detect as it does not give off the ”right noise” to be detected by the ultrasonic leak detector.

|

|

For this reason, it is essential that you make a thorough visual inspection of the system components, to check for leaks not detected by the equipment.

|

|

|

6.

|

Rectify any leaks detected and test the system again.

|

|

7.

|

Restore the car to its normal condition.

|