PRE-RELEASE

Input shaft

| Input shaft |

| 1. |

Mount the shaft in a vice with protective jaws.

|

|

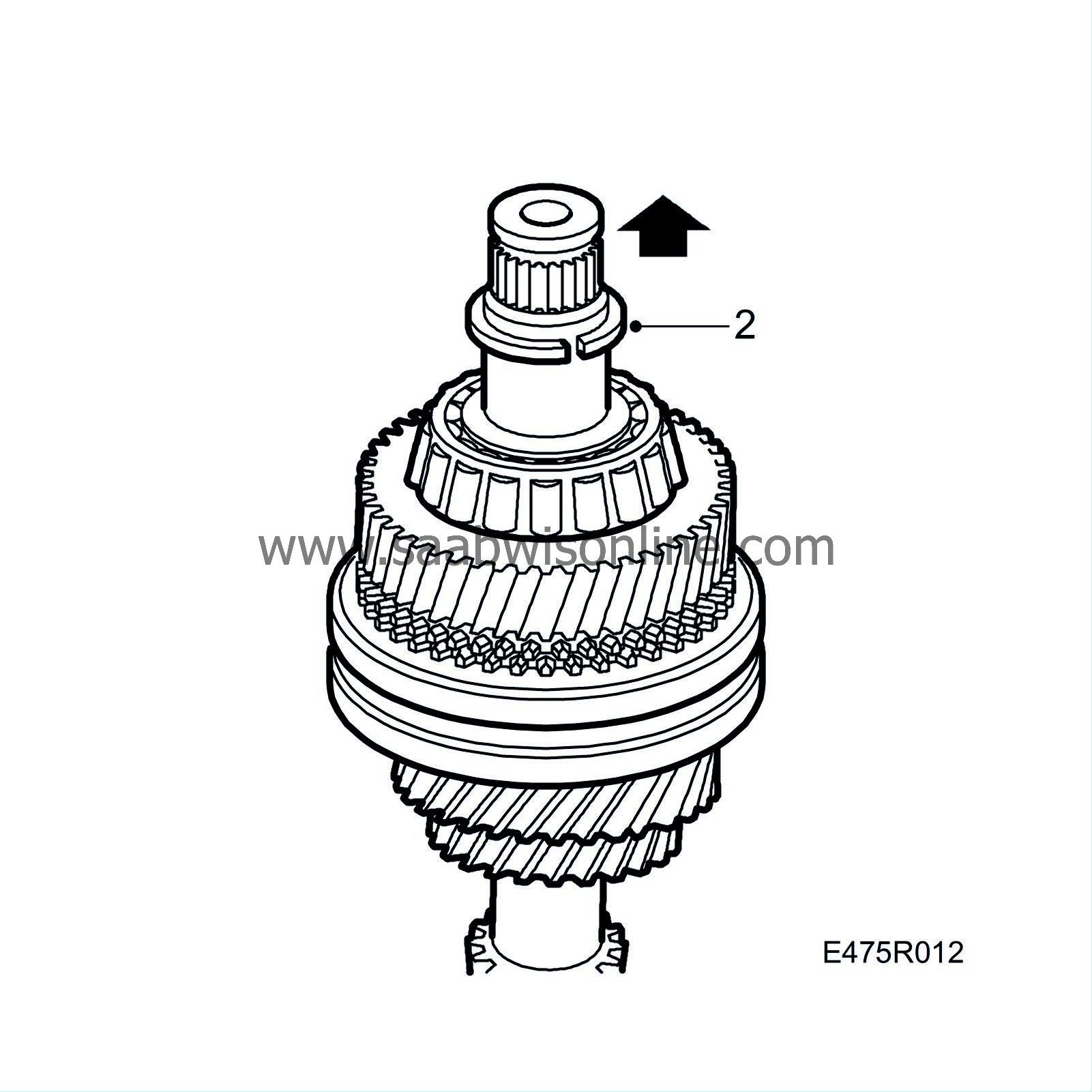

| 2. |

Remove the circlip.

|

|

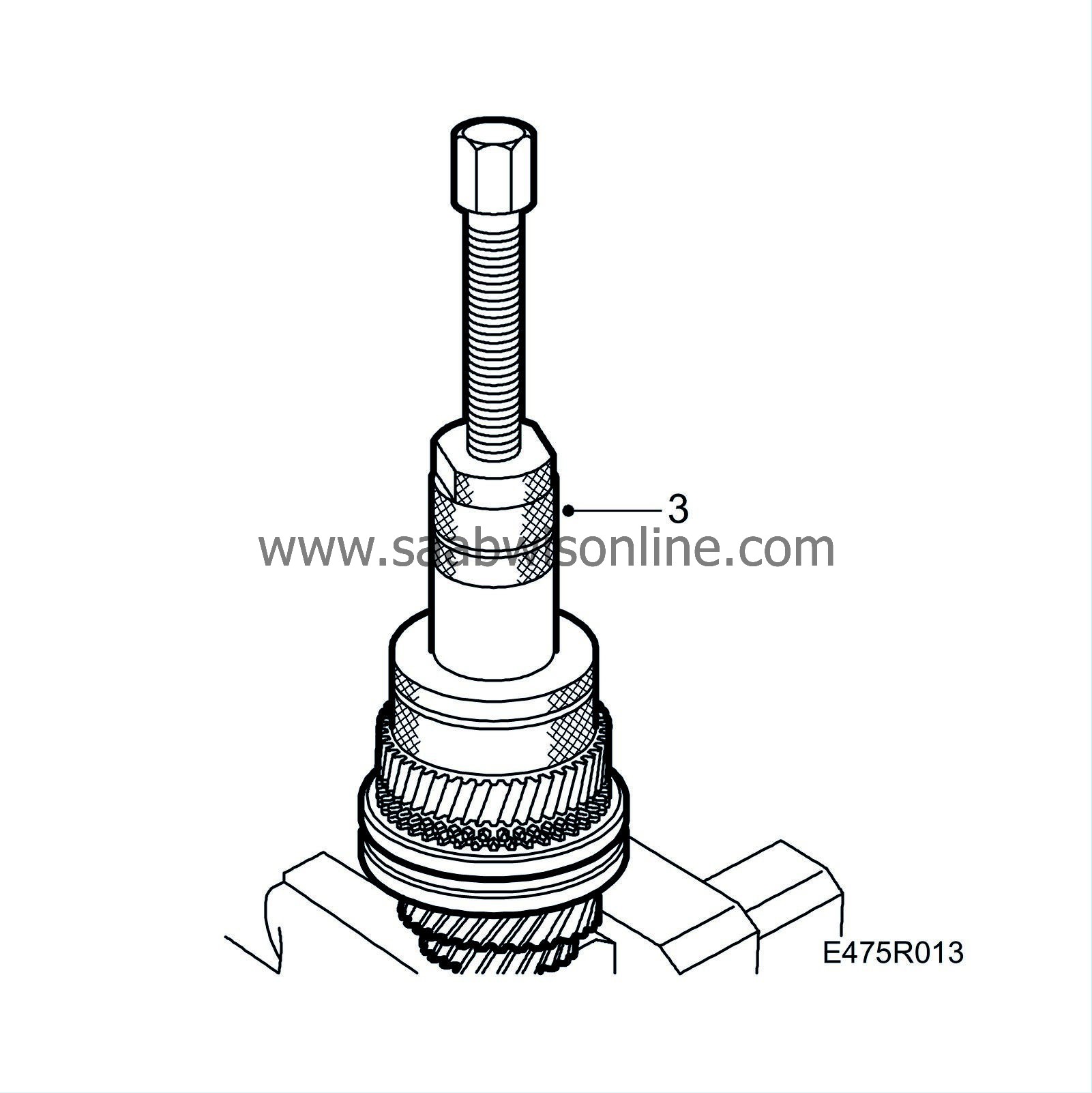

| 3. |

Press the bearing off the shaft. Use

87 92 152 Puller

and

87 91 642 Basic tool

.

|

||||||||||

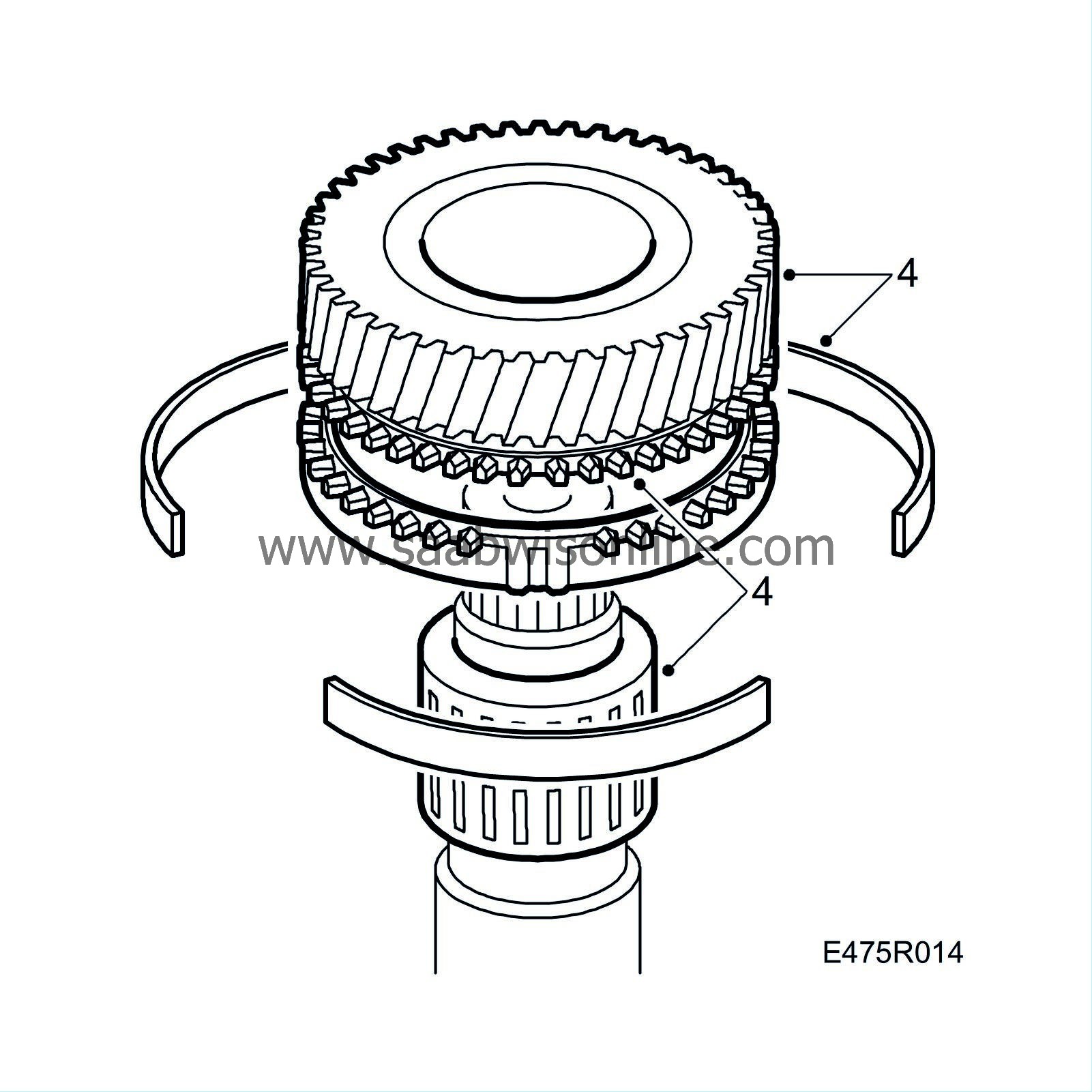

| 4. |

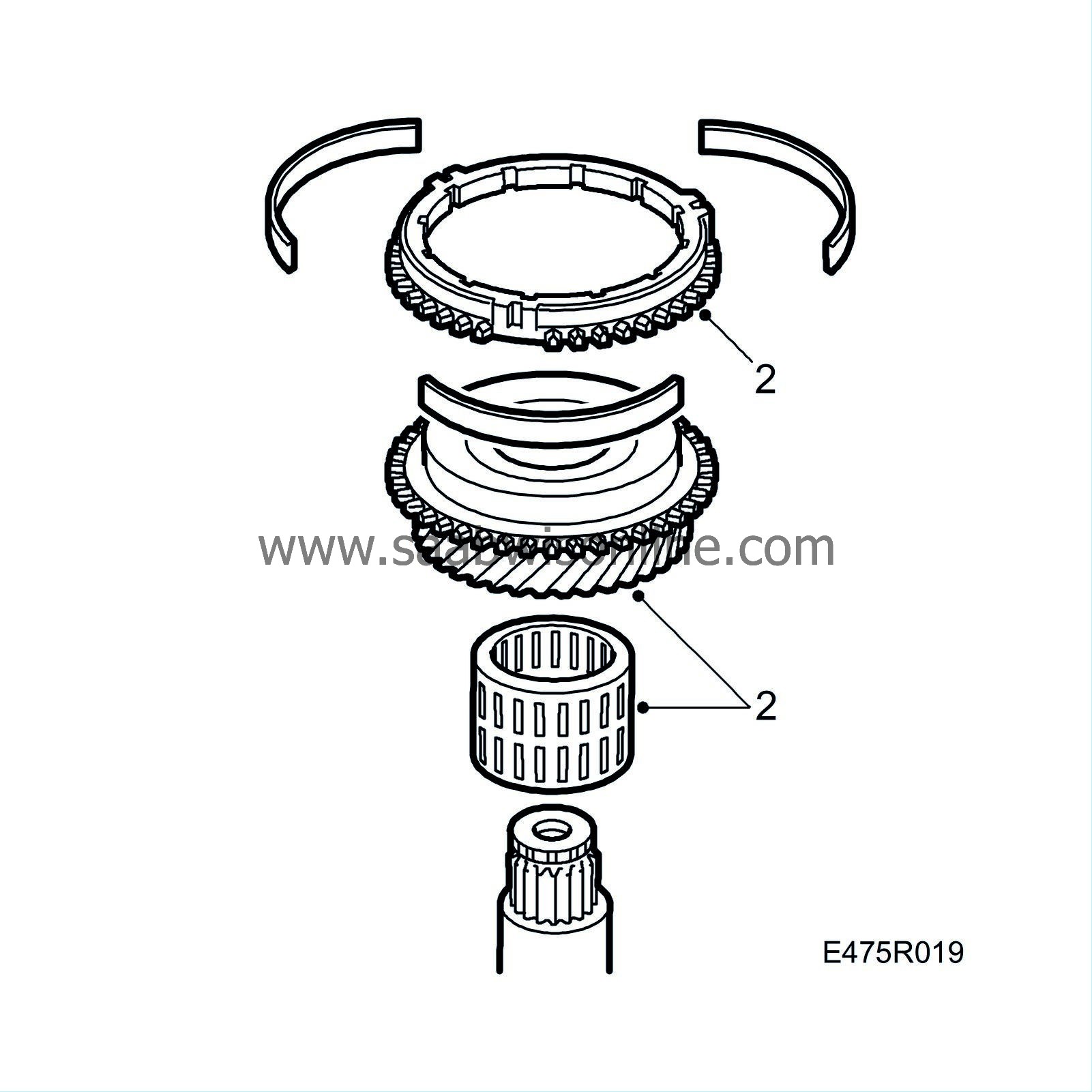

Lift off the 4th gear pinion, synchromesh and needle bearing. Keep the leaf springs in a safe place.

|

|

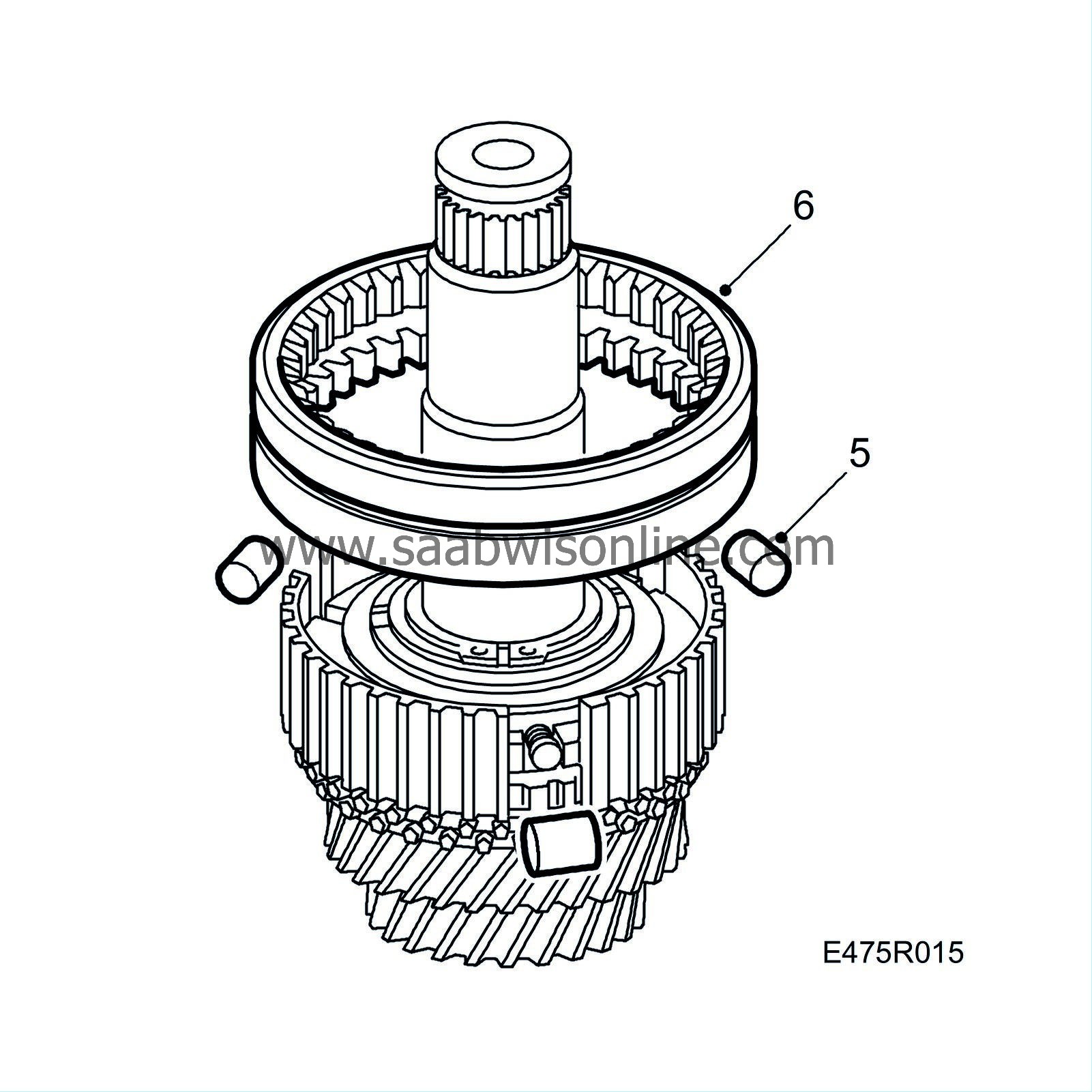

| 5. |

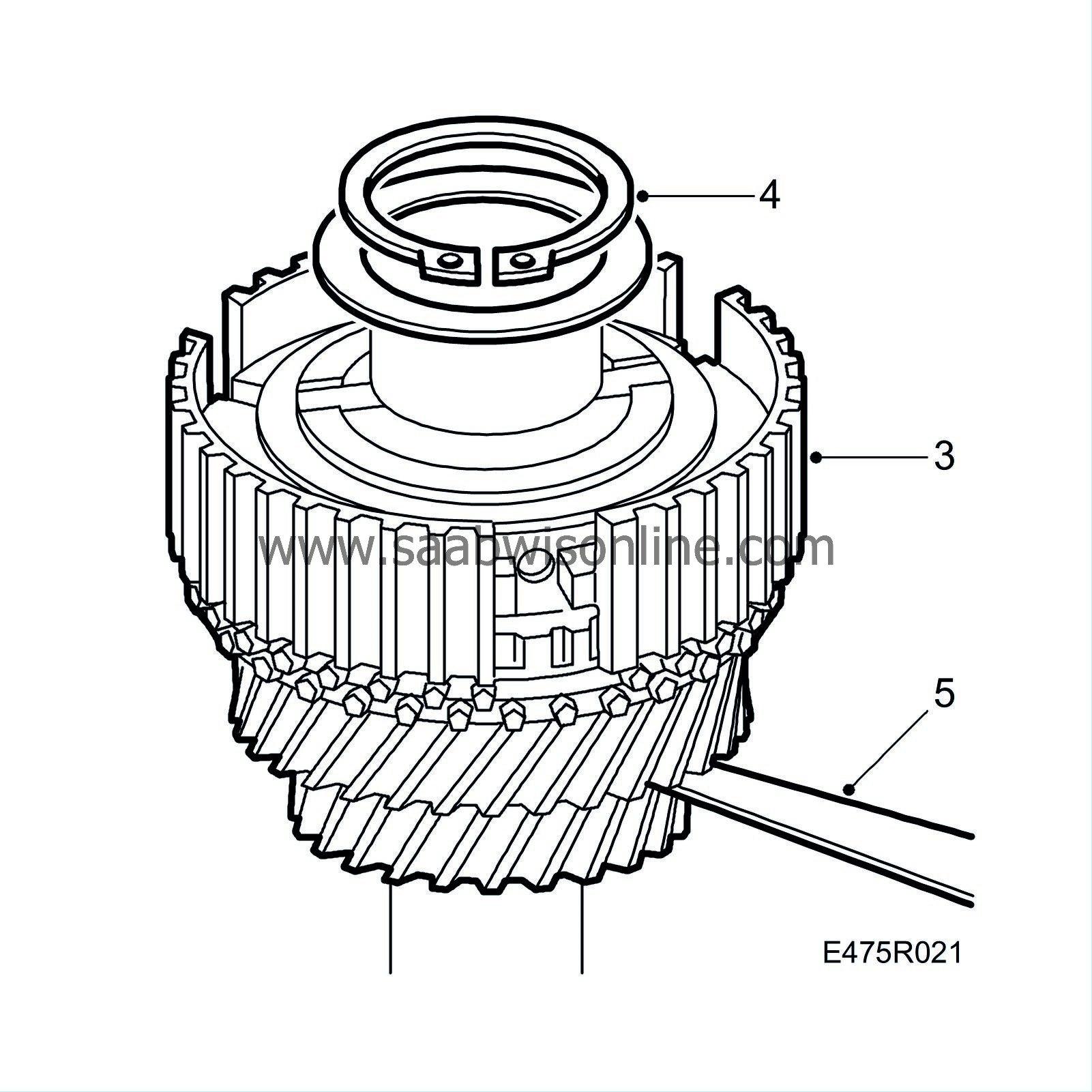

Slightly lift the synchromesh sleeve and hold with your hand so that the spring-loaded rollers do not come out. Keep the rollers in a safe place.

|

|

| 6. |

Lift off the synchromesh sleeve.

|

||||||||||

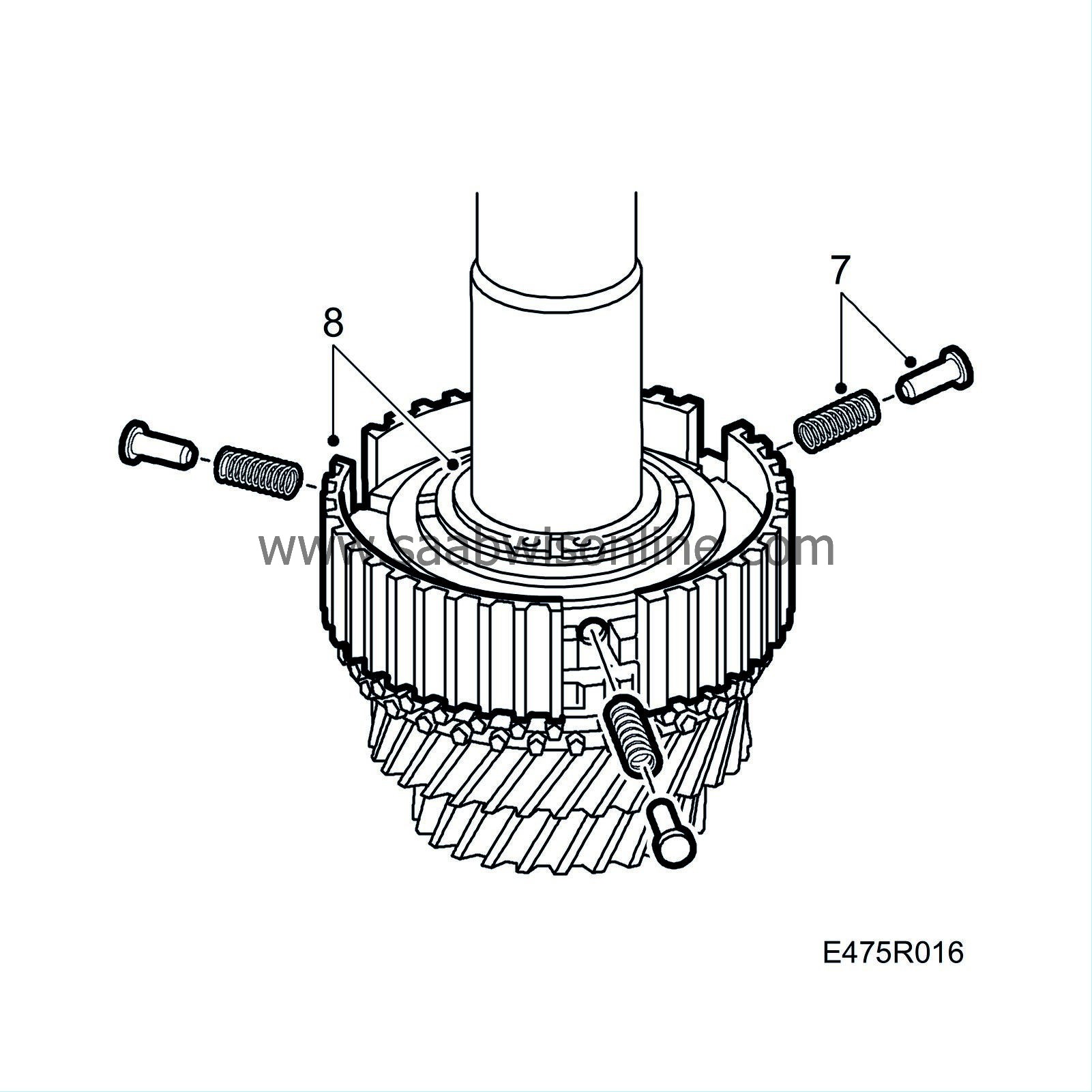

| 7. |

Keep springs and plungers.

|

|

| 8. |

Remove the washer and circlip which secure the synchromesh hub. Remove the hub and keep the leaf springs.

|

|

| 9. |

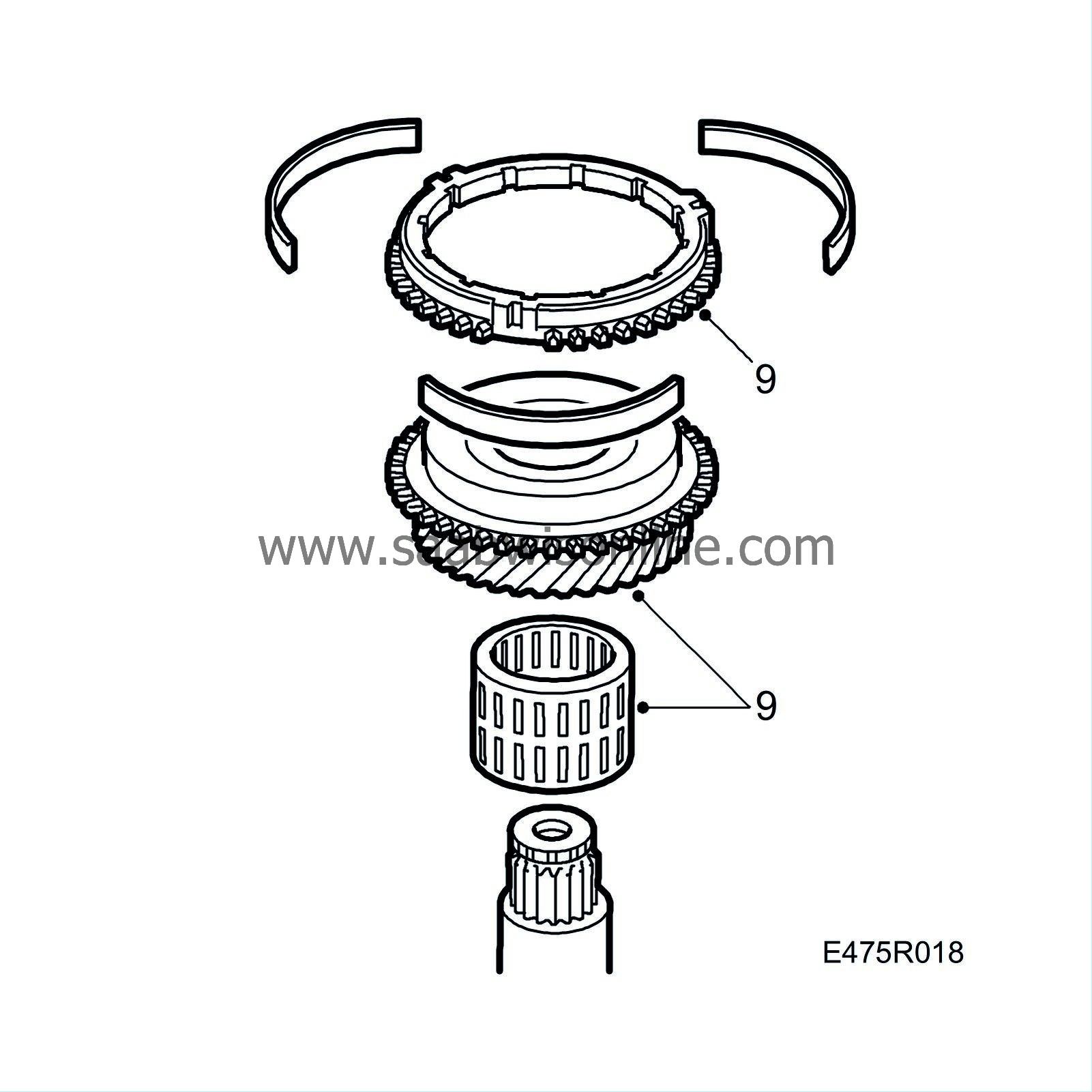

Lift off the 3rd synchromesh, pinion and needle bearing.

|

|

| 10. |

Check the condition of all input parts in terms of wear. Replace damaged or defective parts.

|

|

| To assemble |

Grease all components with manual gearbox oil before fitting, refer to Summary of lubricants and sealants .

| 1. |

Mount the input shaft in a vice with protective jaws.

|

|

| 2. |

Fit the 3rd pinion with needle bearing and baulk ring.

|

|

| 3. |

Fit the synchromesh hub and make sure that the recess for the circlip washer is facing up. Make sure that the hub goes down over the baulk ring, fit the leaf springs. If needed, press with

87 92 202 Sleeve

.

|

|

| 4. |

Fit the washer with a new circlip. The dotted side of the circlip must be facing the hub.

|

|

| 5. |

Check the axial play between 2nd and 3rd gear pinions. The play should be 0.05-0.40 mm.

|

|

| 6. |

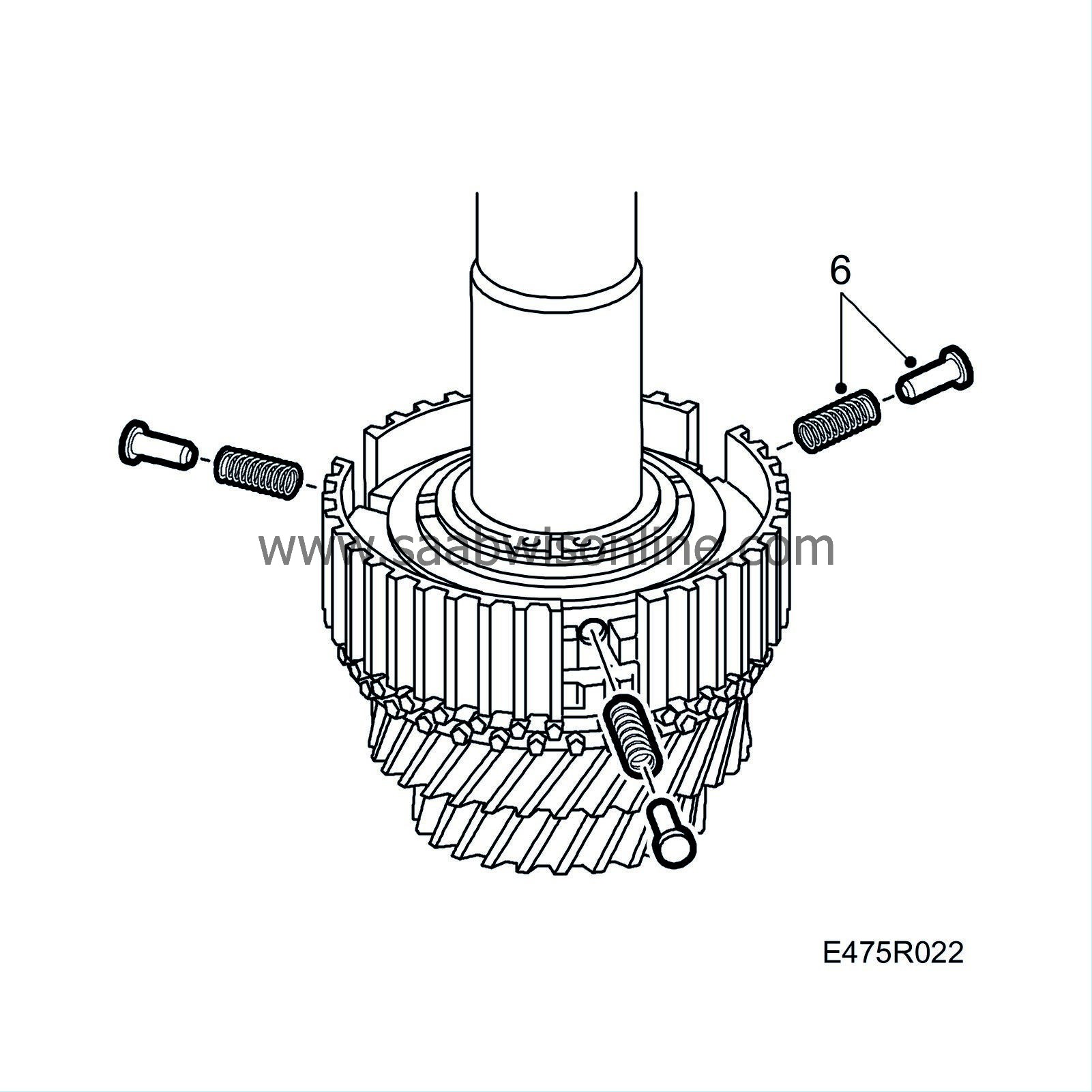

Fit the springs and plungers.

|

|

| 7. |

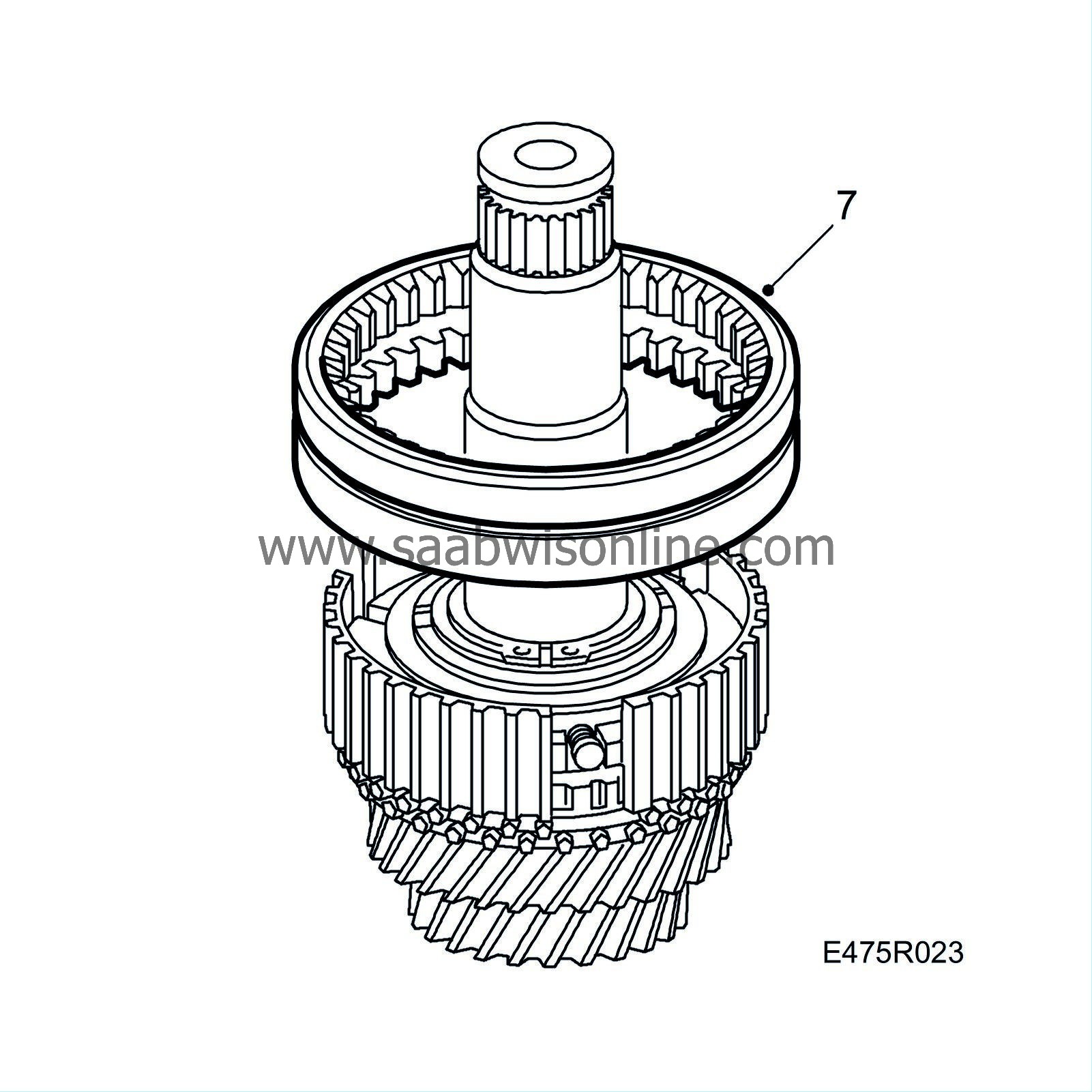

Fit the synchromesh sleeve.

|

||||||||||

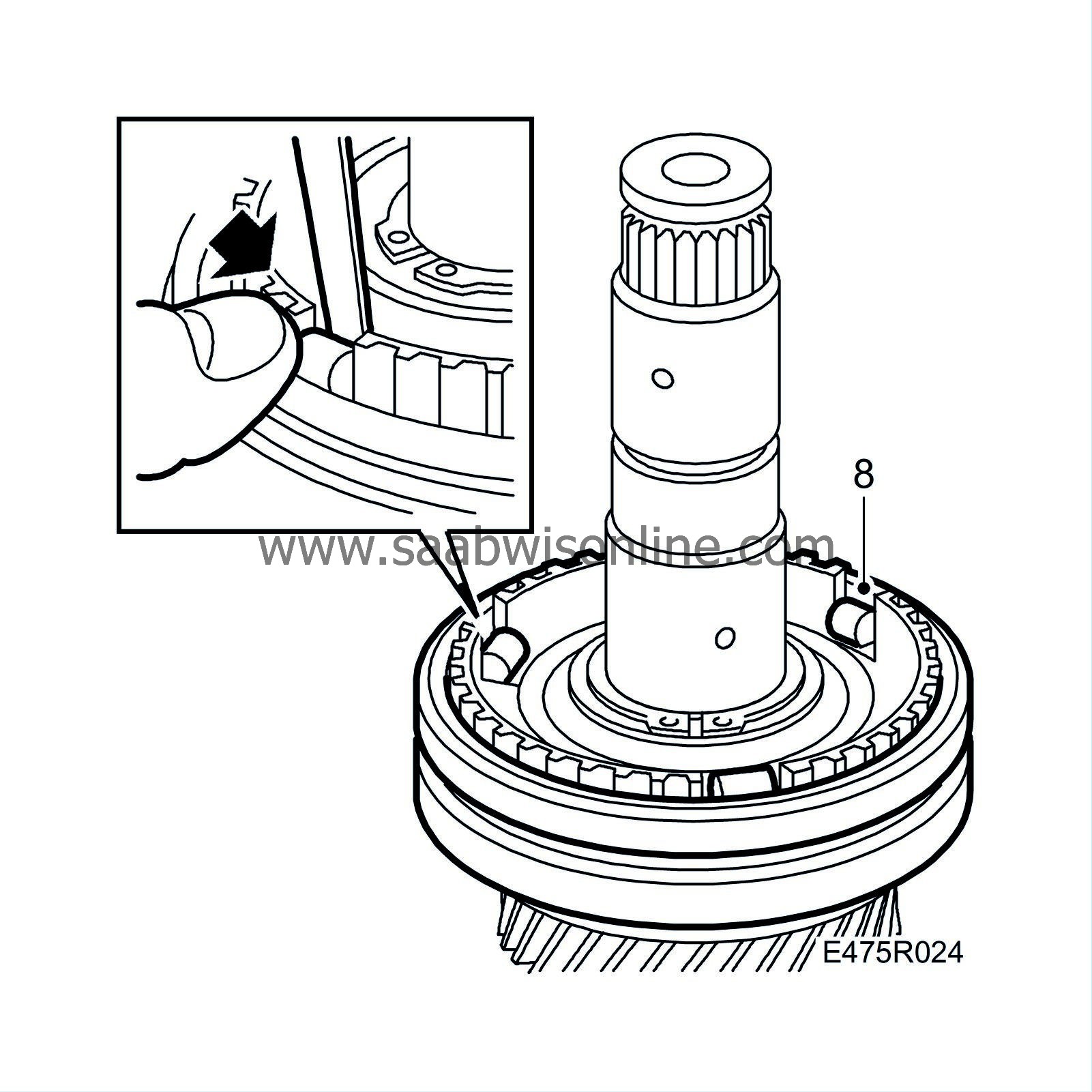

| 8. |

Fit the rollers. The rollers are fitted by pressing in the springs. For example, use a small screwdriver to press in the springs.

|

|

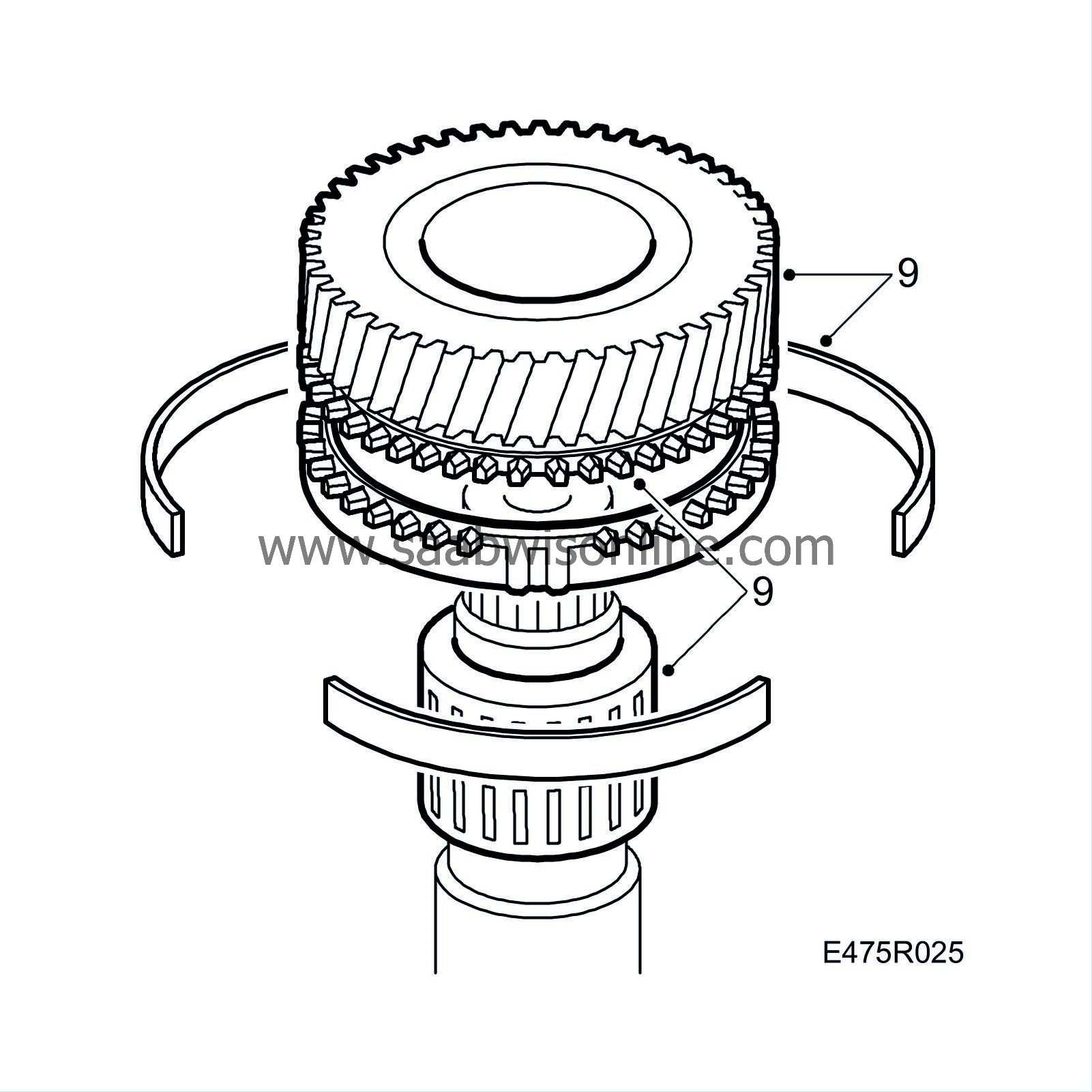

| 9. |

Fit the 4th baulk ring, leaf springs, needle bearing and pinion.

|

|

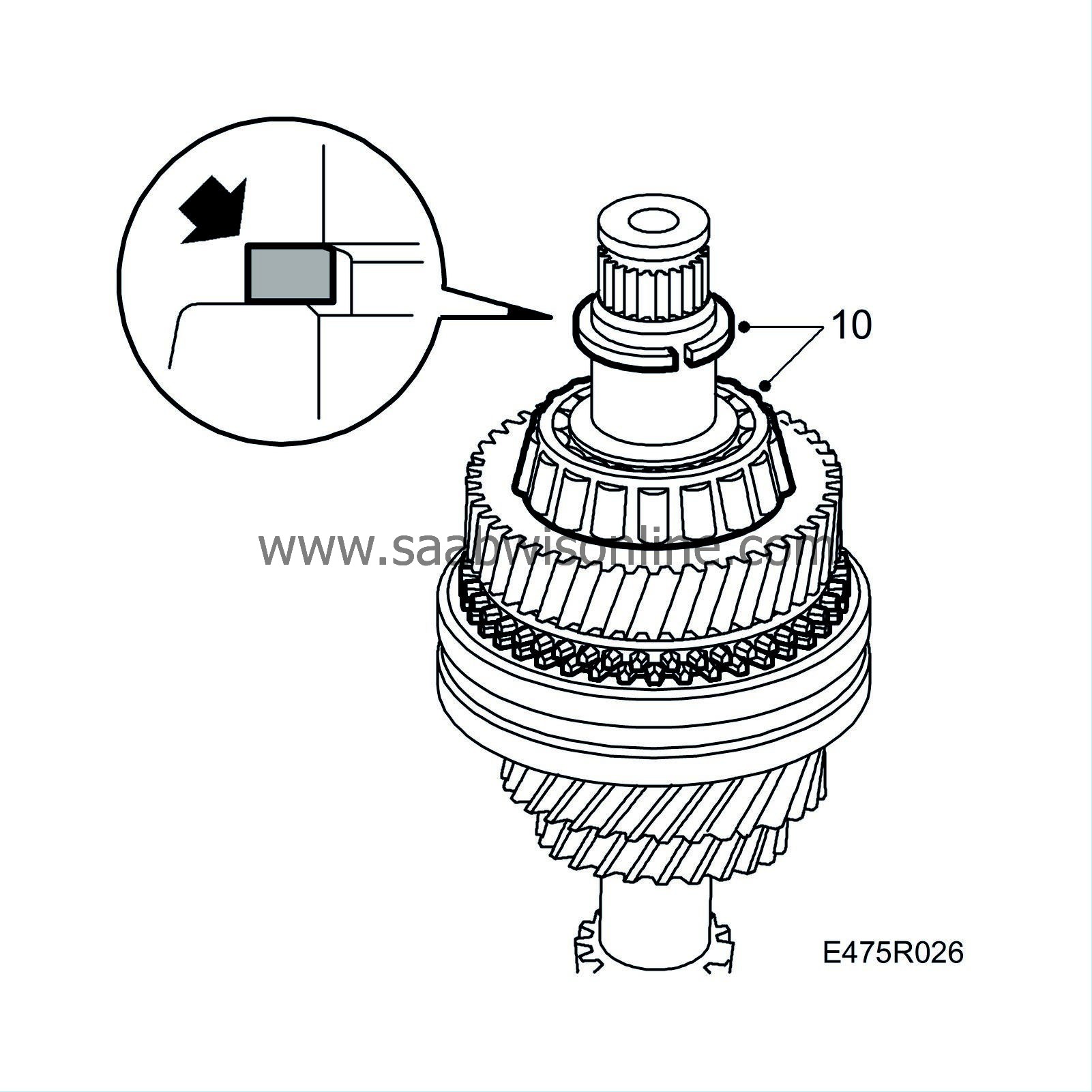

| 10. |

Make sure the bearing is turned the right way round and press in a new bearing closest to the 4th gear pinion. Use the sleeve from

87 91 261 Puller, pinion

. Fit a new circlip with the bevelled edge face up. Carefully tap the circlip into the groove in the shaft with a drift.

|

||||||||||

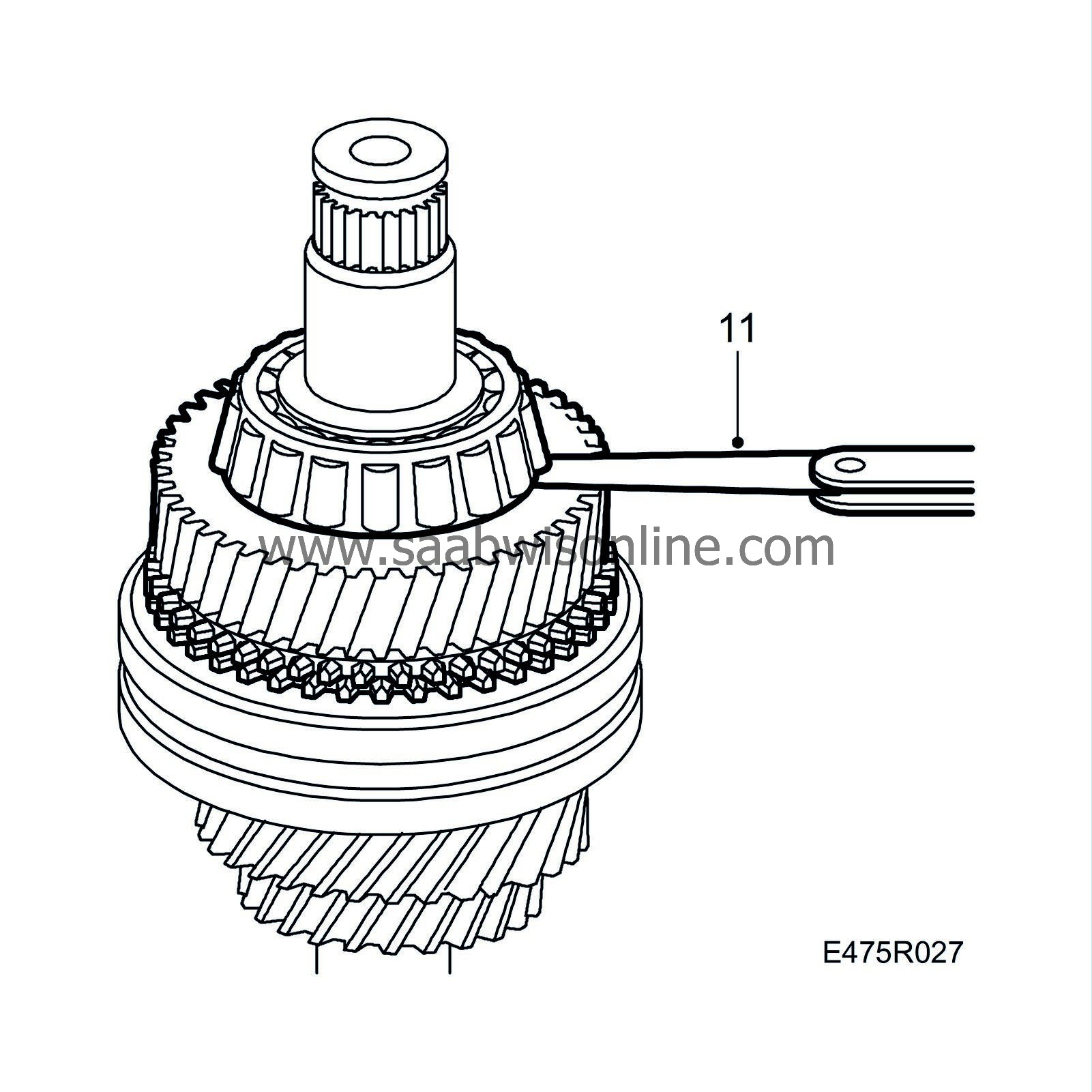

| 11. |

Check the play between bearing and 4th pinion to ensure that the input shaft is correctly fitted. Play should be 0.05-0.40 mm.

|

|

| Replacement of bearing closest to 1st gear pinion on input shaft |

To remove

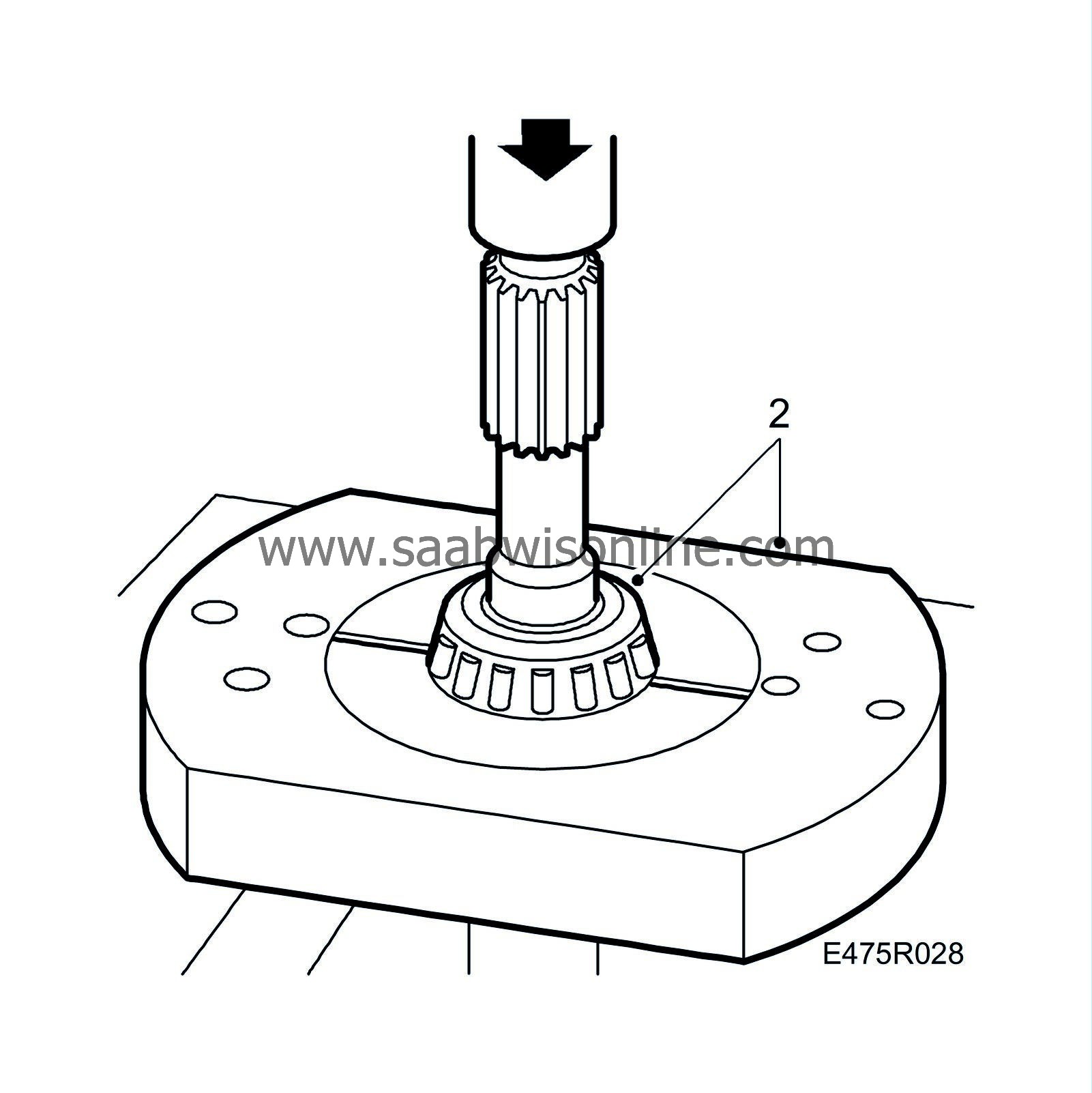

| 1. |

Set up the shaft in a press using

87 91 121 Puller ring, 13 teeth

or

87 92 830 Puller ring, 12-gear manual transmission

and

87 90 636 Fixture

.

|

|

| 2. |

Press the bearing off the shaft.

|

|

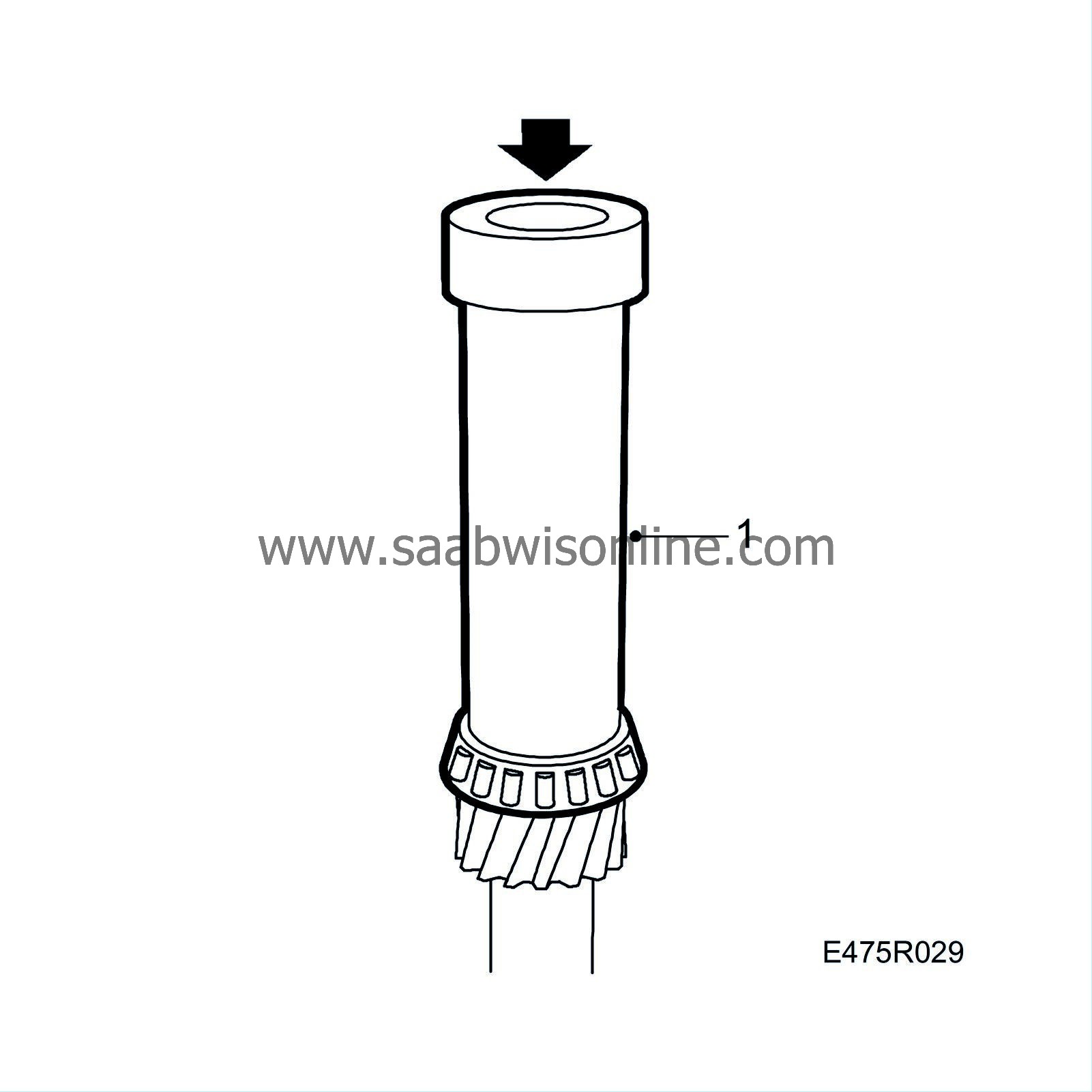

To fit

| 1. |

Fit a new bearing. Take care to turn the bearing the right way round. Press the bearing until it bottoms with the sleeve from

87 91 261 Puller, pinion

.

|

||||||||||