PRE-RELEASE

Inner, lower A-pillar with sill, 4D

| Inner, lower A-pillar with sill, 4D |

| Replacement |

Certain welded joints on the car may be MIG brazed with bronze as the filling material. A MIG brazed seam may be recognized from the gold colour of the joint. A MIG brazing must always be replaced by a new MIG brazing.

|

|||||||

| 1. |

Remove

Outer A-pillar with reinforcement, 4D

.

|

|

| 2. |

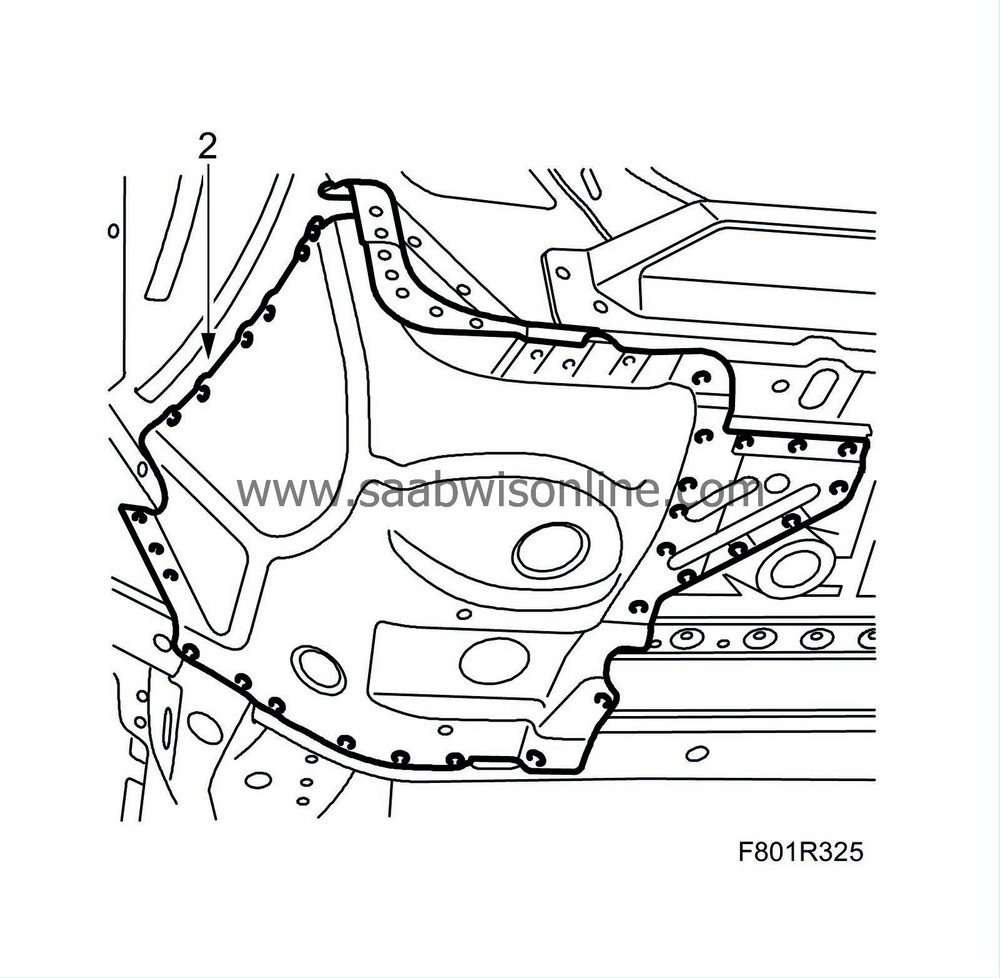

Drill out the spot welds on the front transverse reinforcement.

|

|

| 3. |

Drill out the spot welds from the inside as illustrated. Drill straight through the panels. The drill holes are useful for fitting.

|

|

| 4. |

Tap loose the front transverse reinforcement.

|

|

| 5. |

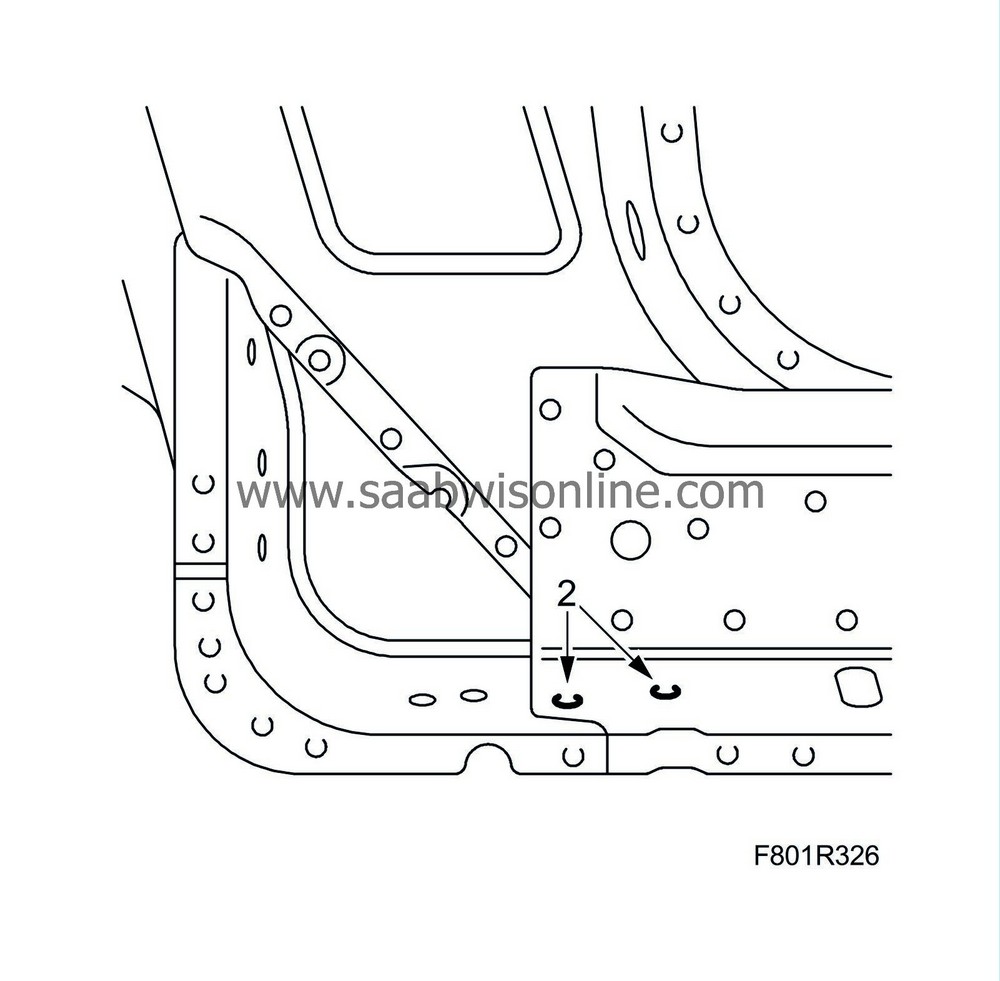

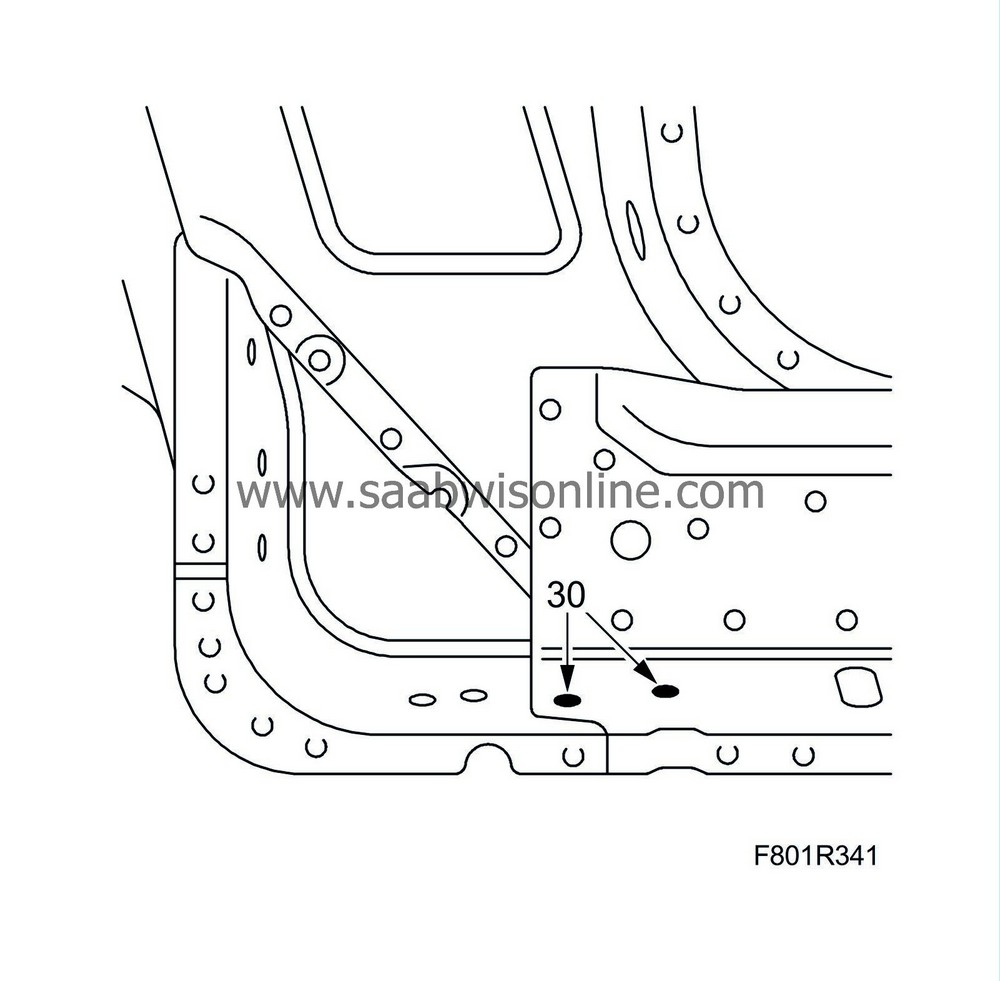

Cut the centre sill as illustrated.

|

|

| 6. |

Drill out the spot welds.

|

|

| 7. |

Tap loose the centre sill.

|

|

| 8. |

Cut the inner sill as illustrated.

|

|

| 9. |

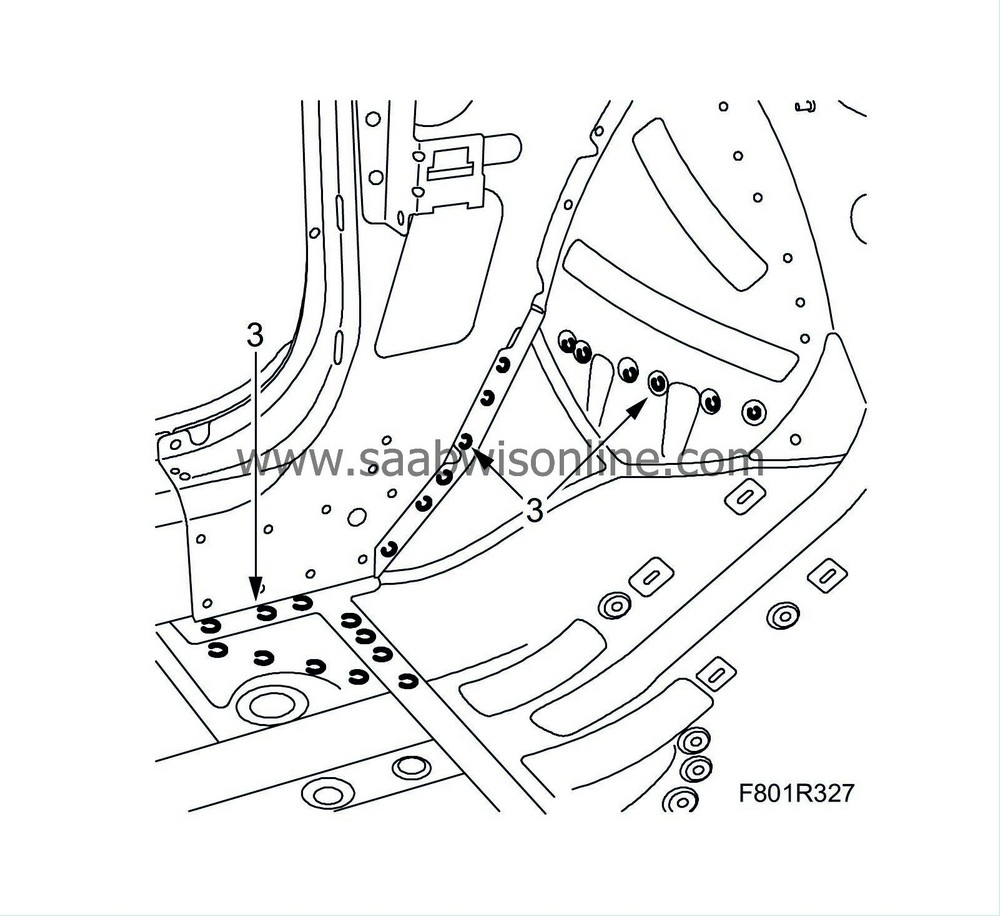

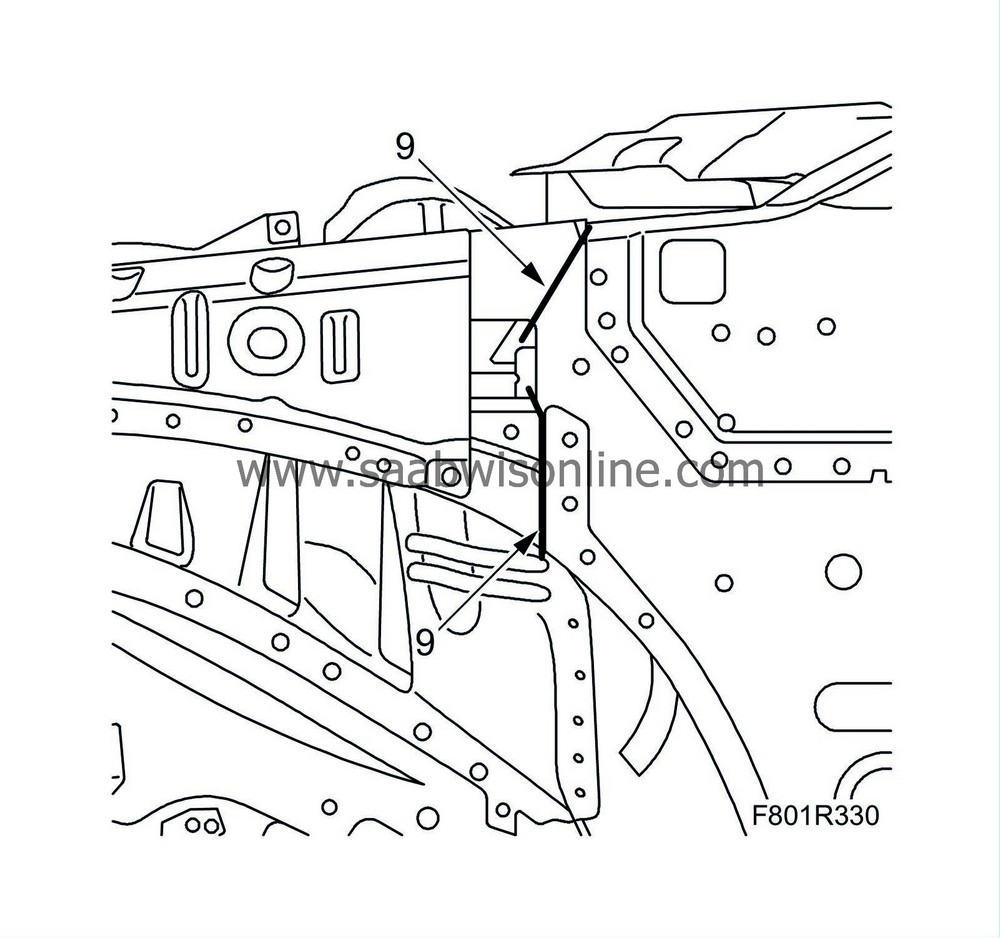

Cut the inner, lower A-pillar as illustrated.

|

|

| 10. |

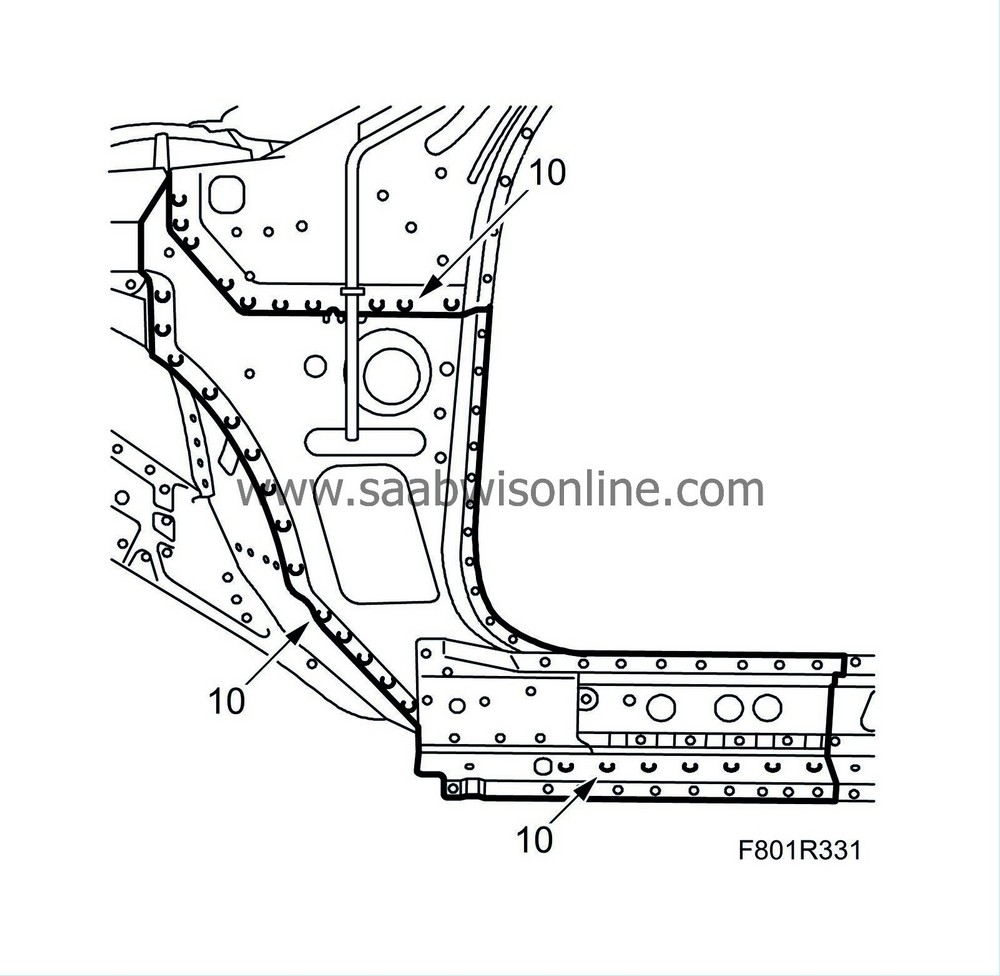

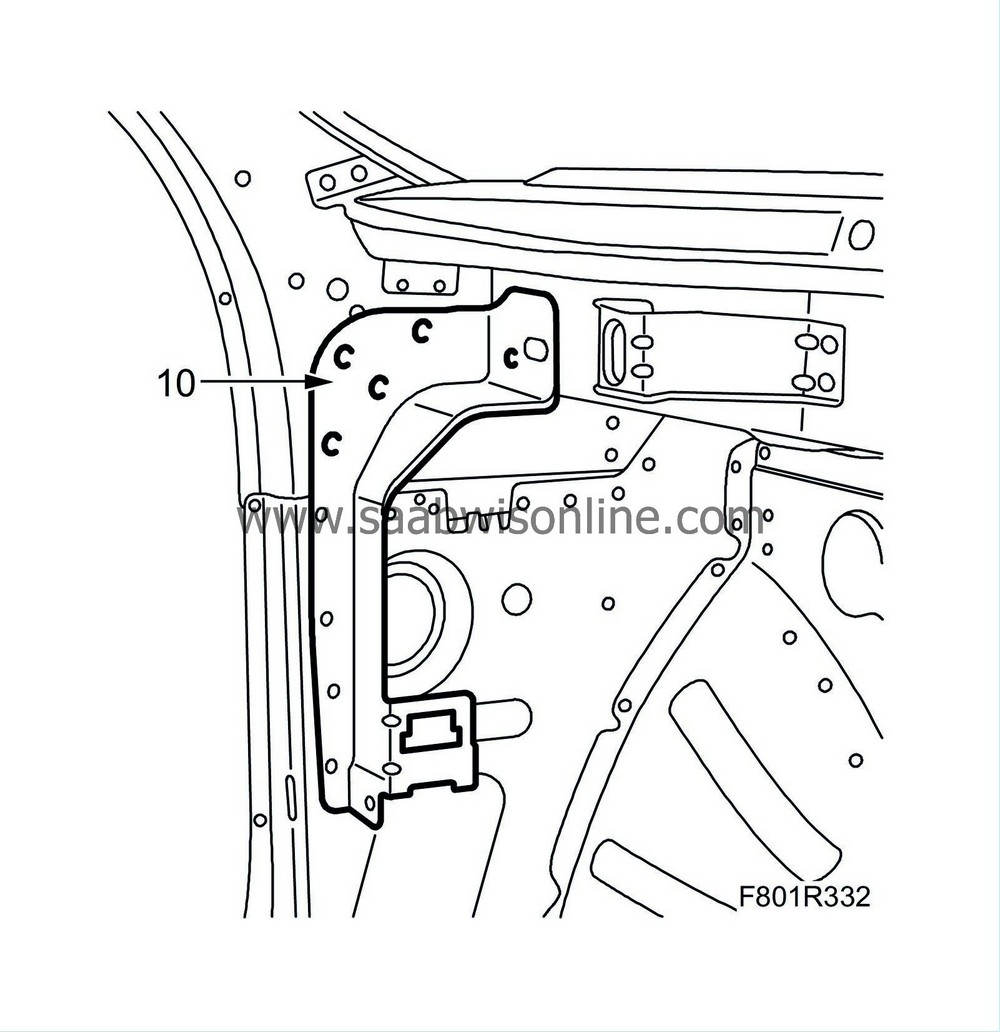

Drill out the spot welds and grind down the MIG brazing.

If necessary, drill out the spot welds on the dashboard reinforcement.

|

|

| 11. |

Tap loose the inner, lower A-pillar.

|

|

| 12. |

Align any deformed plates.

|

|

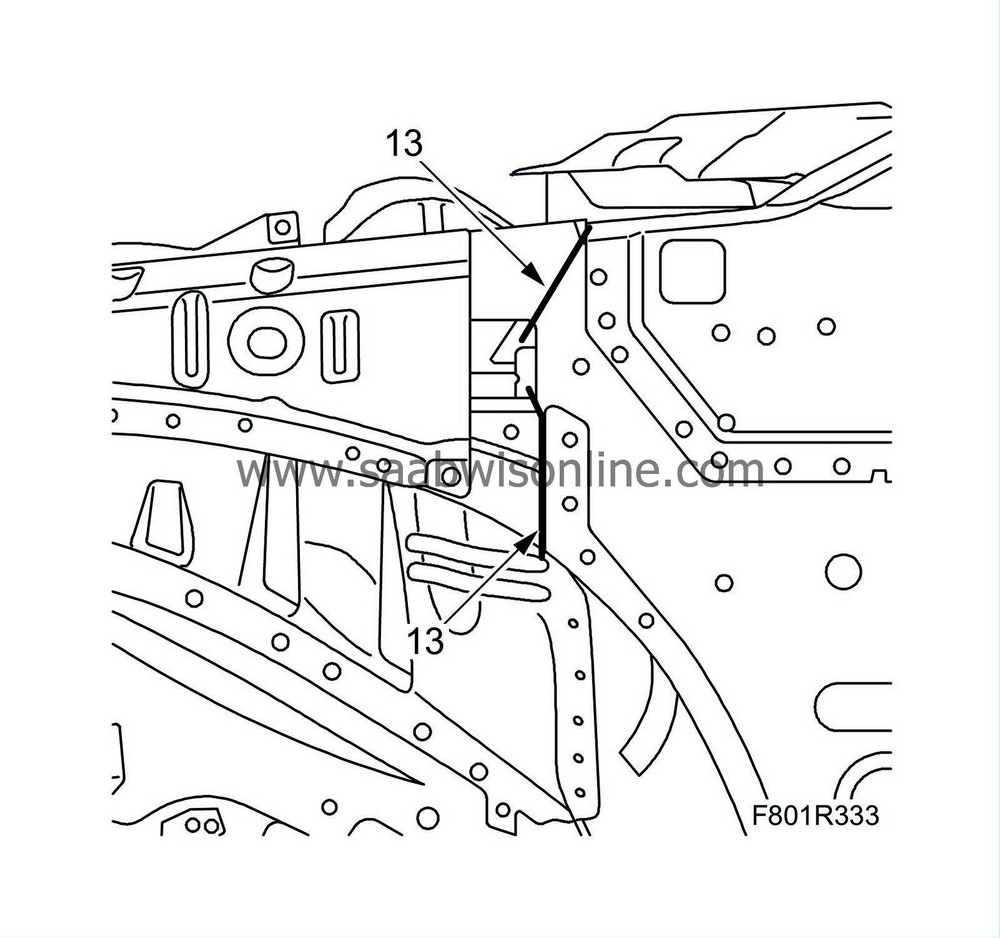

| 13. |

Cut the front edge of the spare part inner, lower A-pillar to roughly the right size. Cut so that it overlaps the previous cut.

|

|

| 14. |

Position the inner, lower A-pillar roughly and secure with welding clamps.

|

|

| 15. |

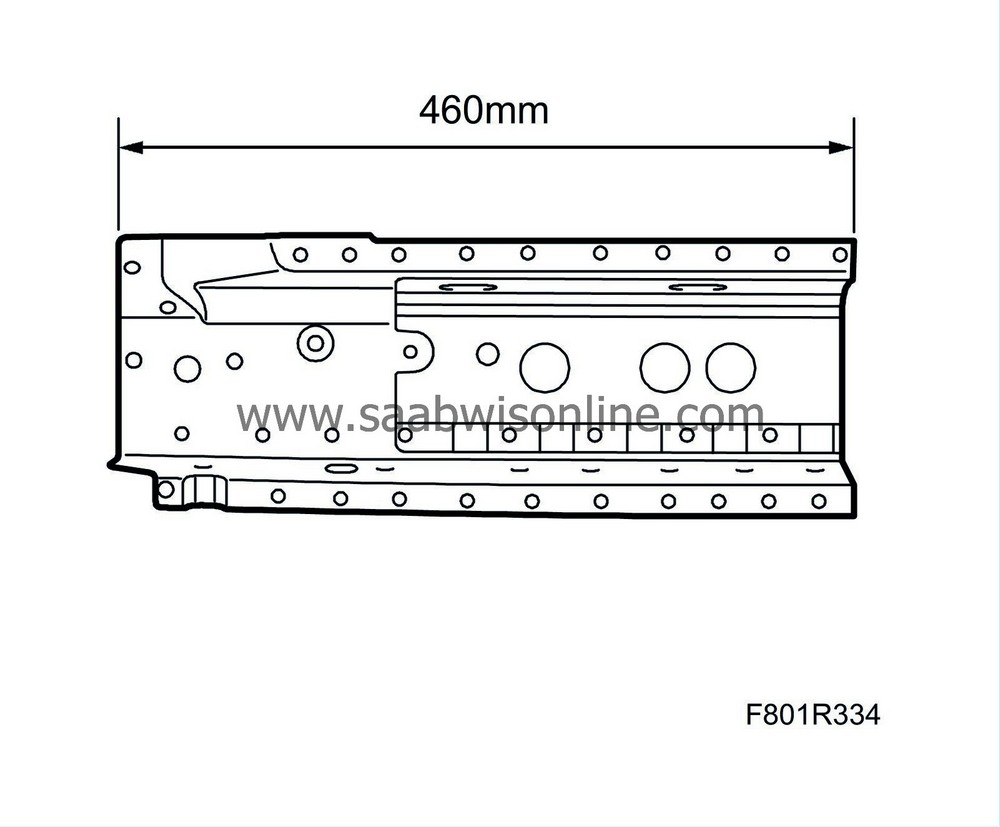

Cut the inner sill (spare part) so that it measures 460 mm.

|

|

| 16. |

Position the inner sill and secure with welding clamps.

|

|

| 17. |

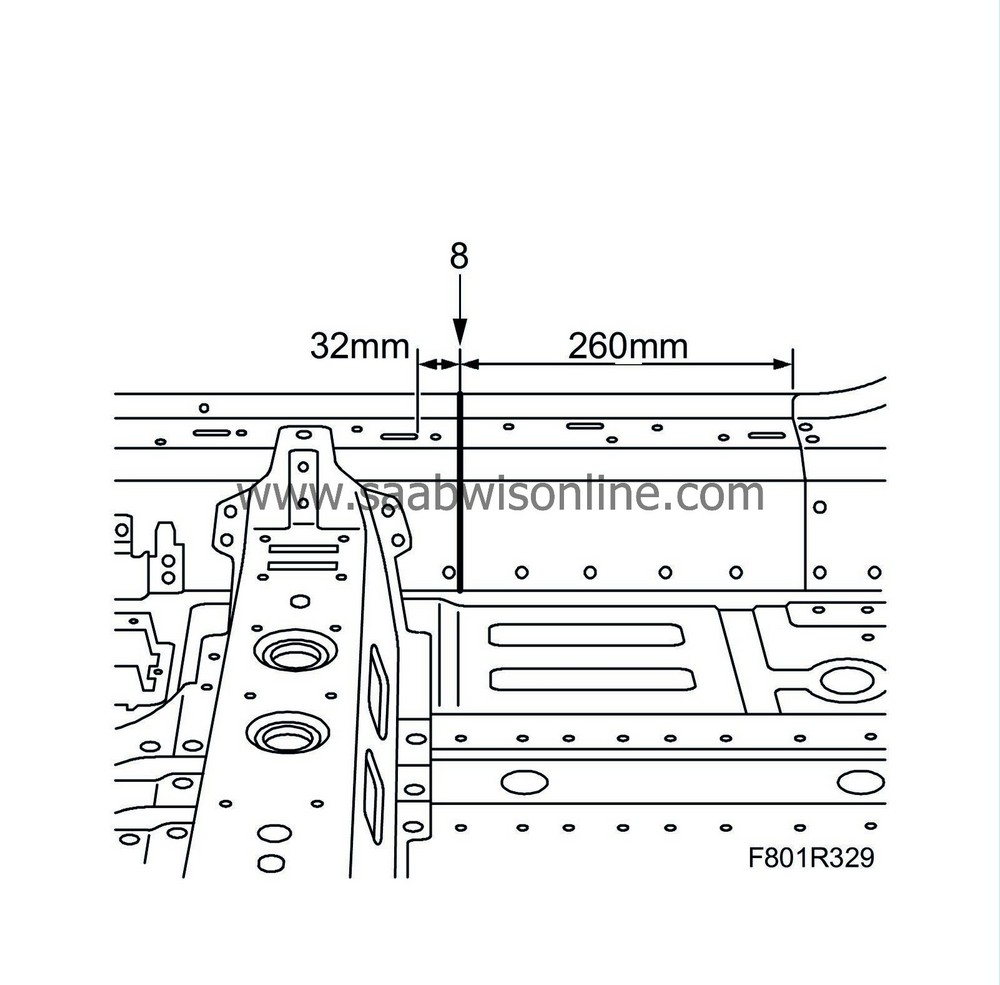

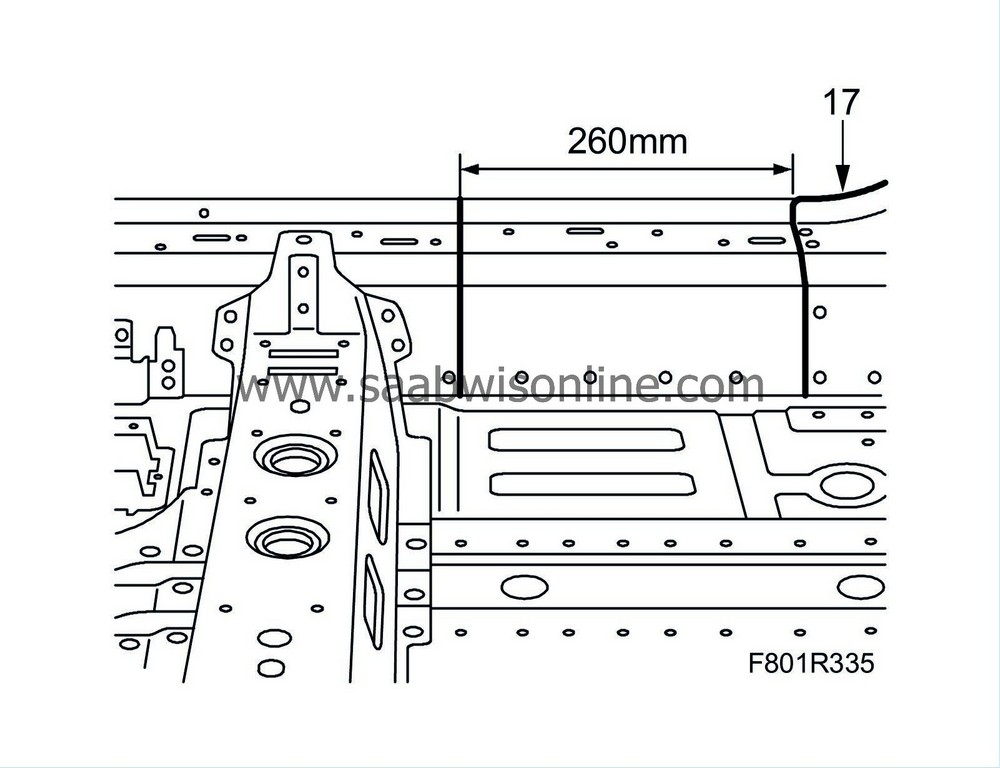

Position the inner, lower A-pillar. It must be 260 mm from the previous cut.

|

|

| 18. |

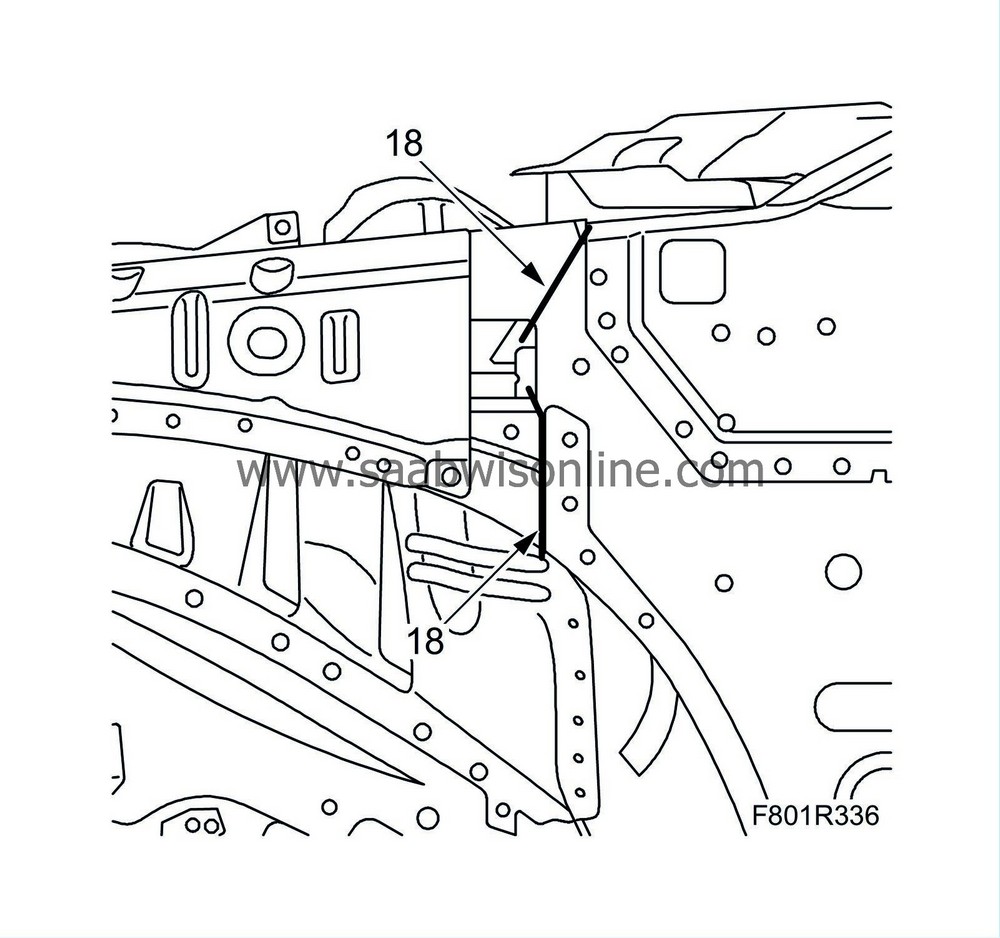

Now cut the front edge of the inner, lower A-pillar so it is edge-to-edge with the previous cut.

|

|

| 19. |

Grind the surfaces which are to be welded.

|

|

| 20. |

Apply welding primer to the surfaces to be spot and plug welded. Use Teroson Zink Spray.

|

|||||||||

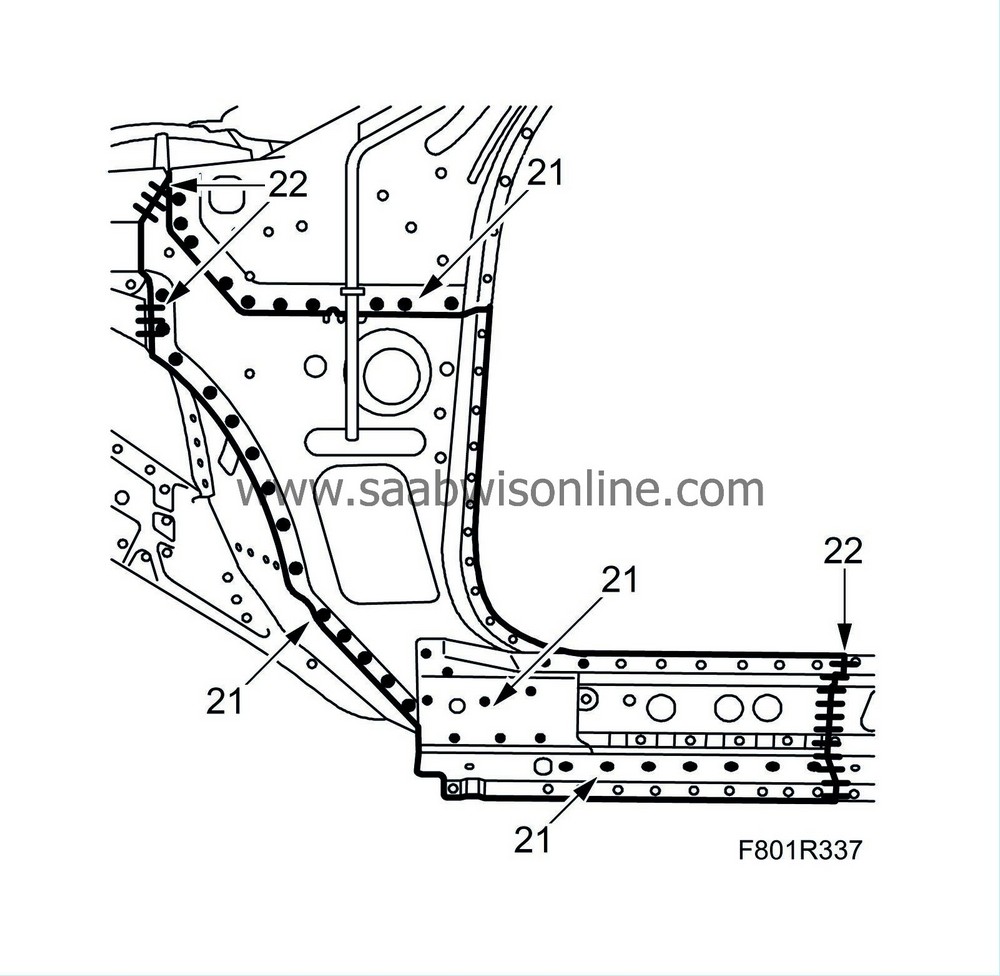

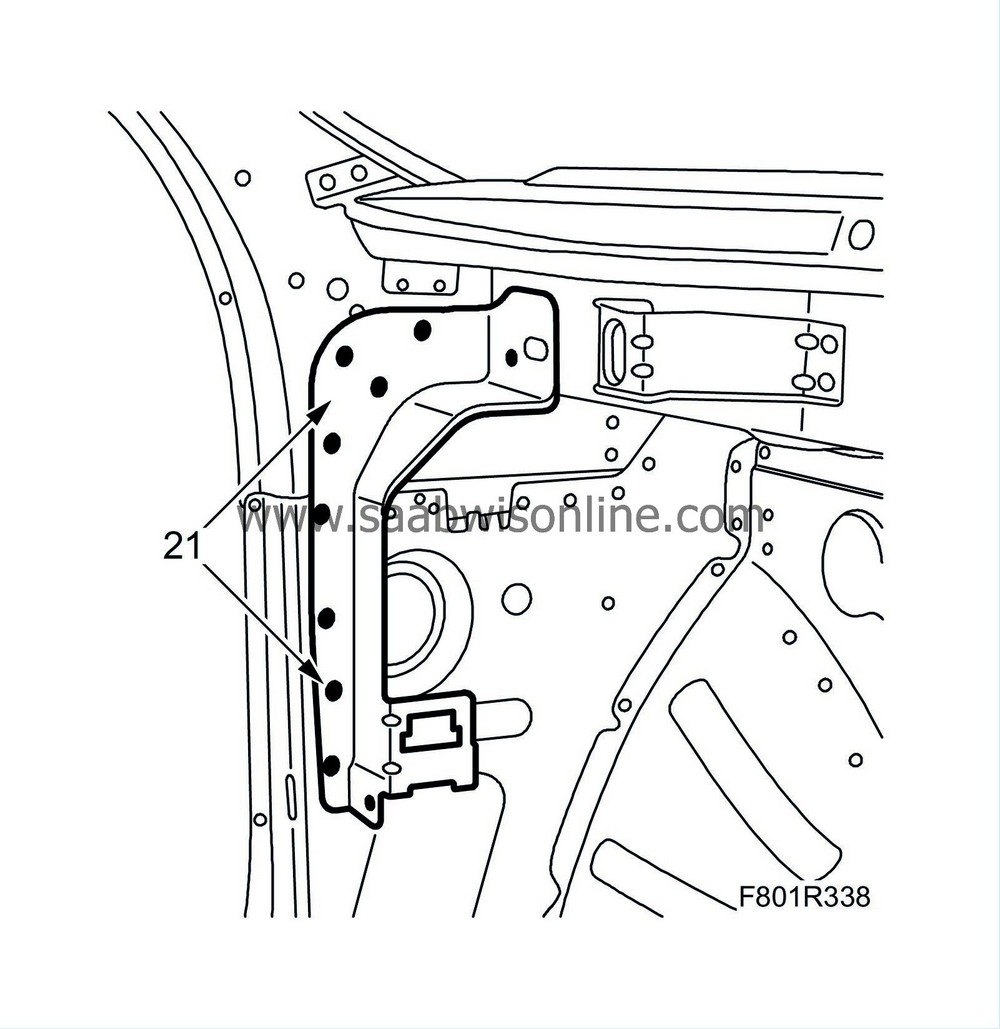

| 21. |

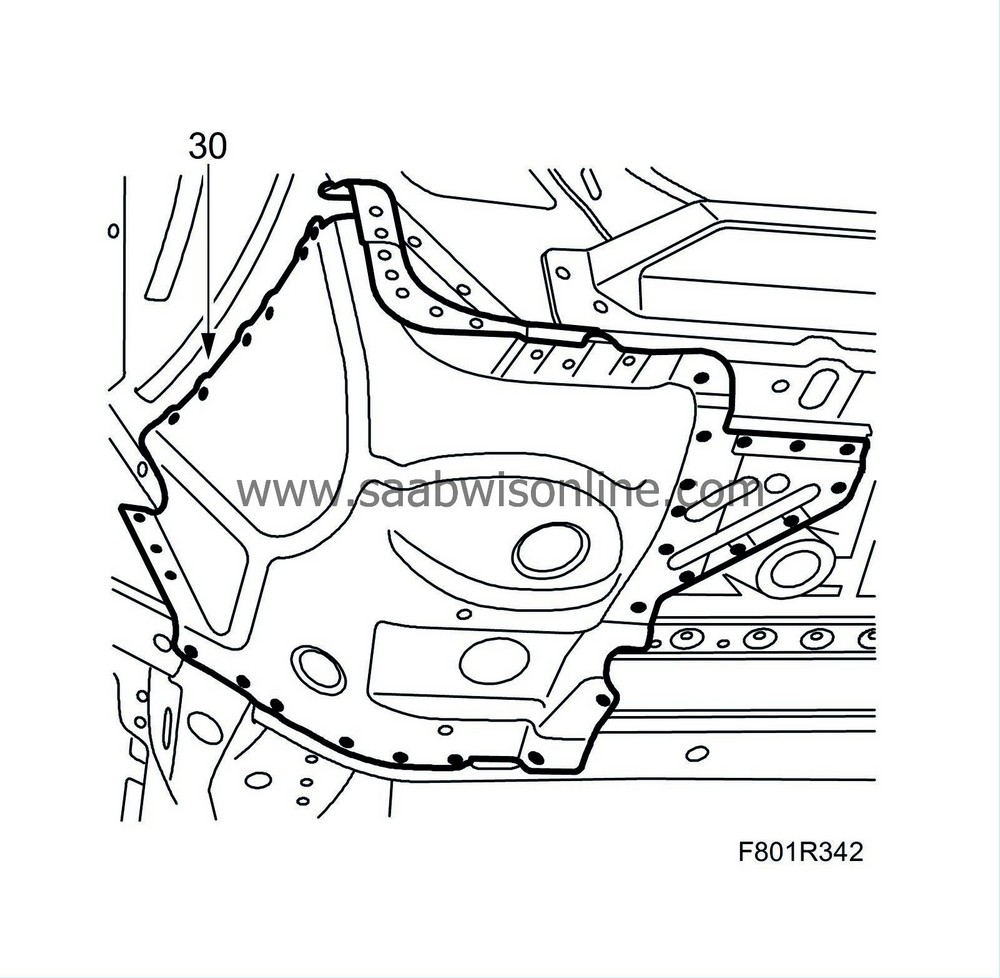

Secure the spare part with spot and plug welds. Replace the MIG brazing.

|

|

| 22. |

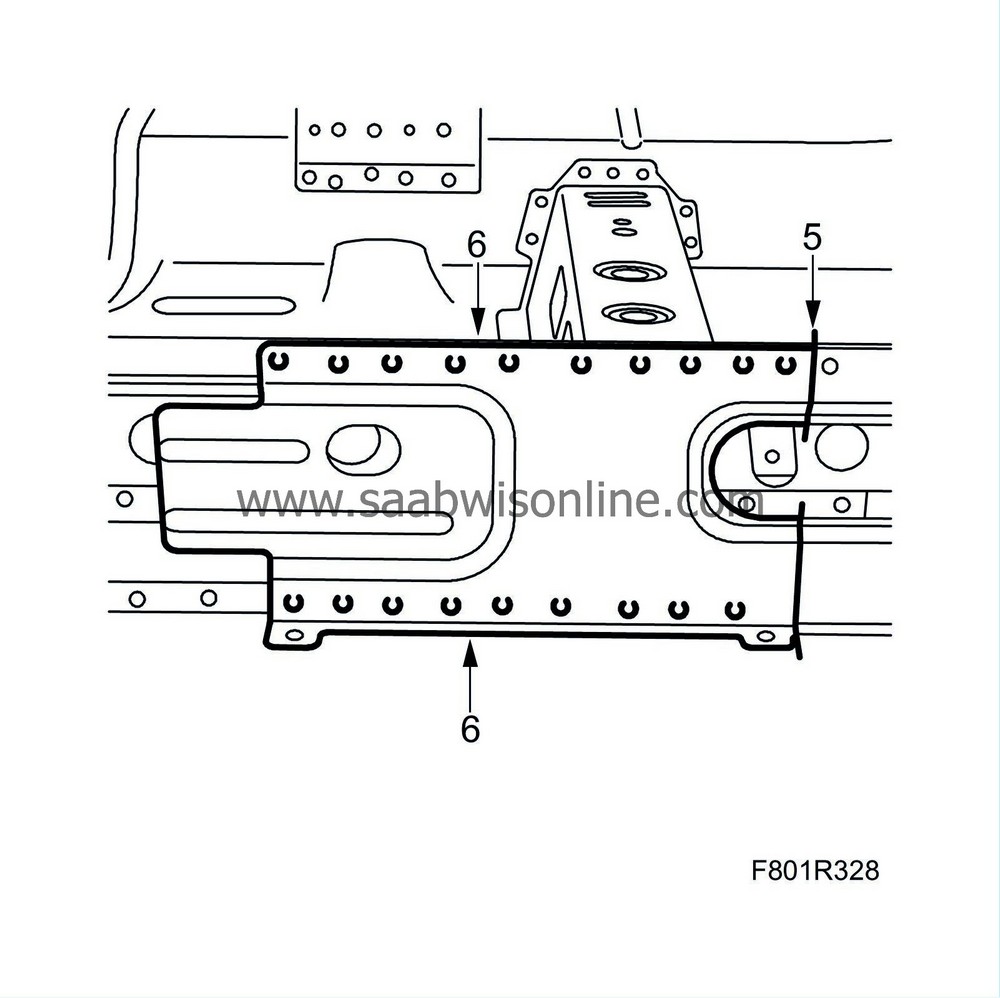

Seam weld as illustrated. Weld the inside and outside of the inner sill.

|

|

| 23. |

Apply primer to the internal seam welds. Use Standox 1k.

|

|

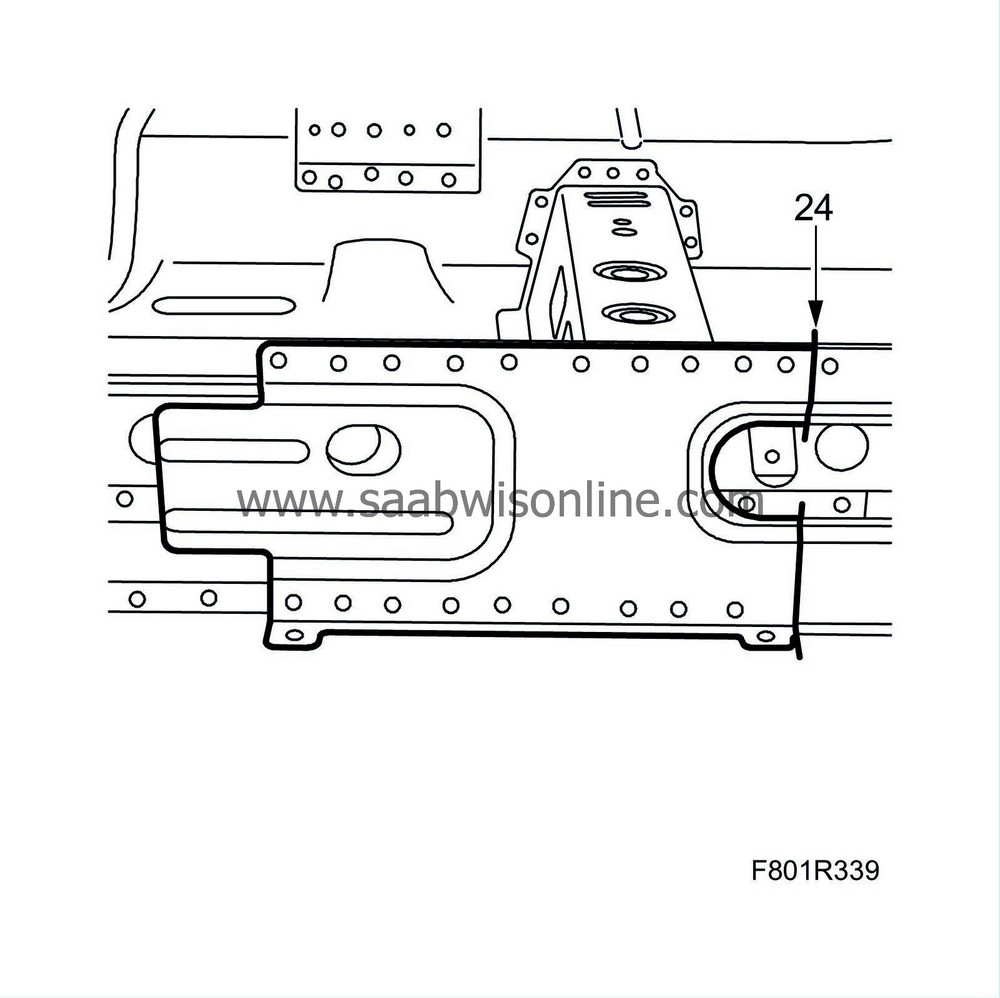

| 24. |

Cut the centre sill so that it matches the previous cut.

|

|

| 25. |

Grind the surfaces which are to be welded.

|

|

| 26. |

Apply welding primer to the surfaces to be spot and plug welded. Use Teroson Zink Spray.

|

|

| 27. |

Position the centre sill and secure it with welding clamps.

|

|

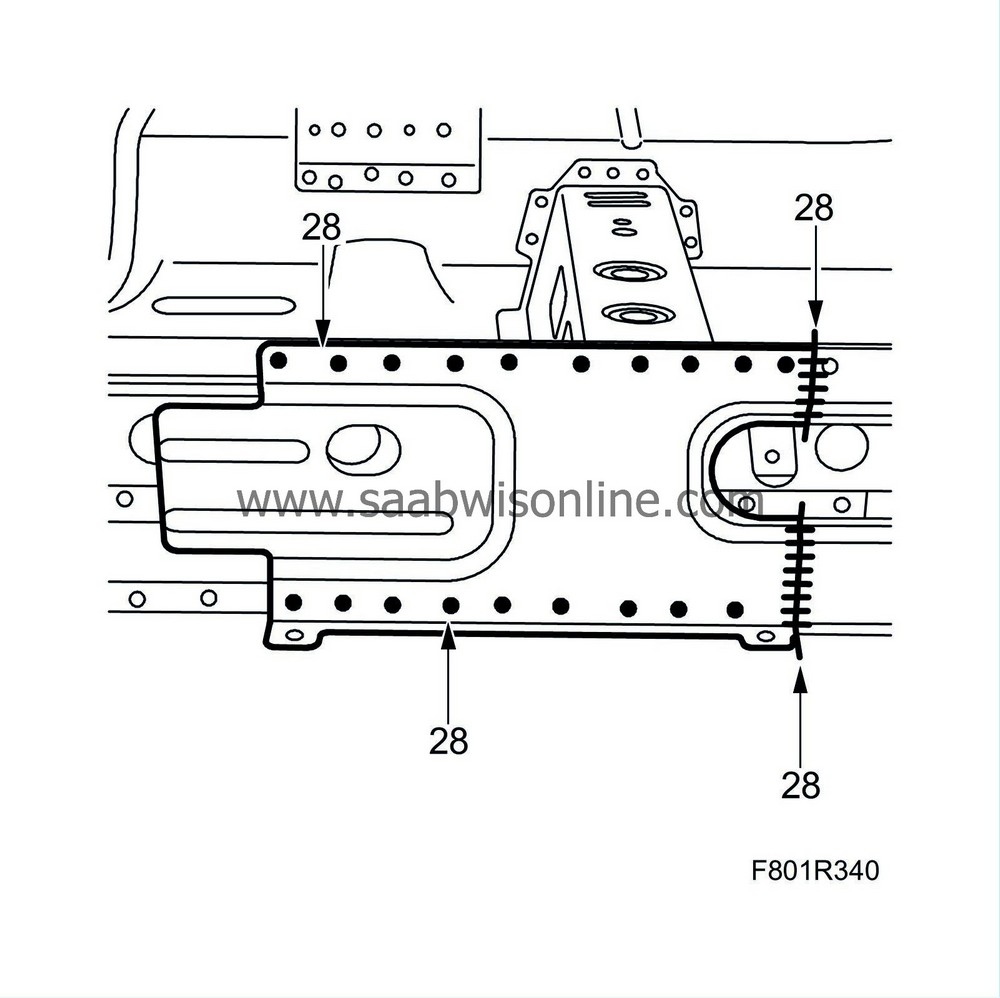

| 28. |

Weld the centre sill in place.

|

|

| 29. |

Smooth off the welds.

|

|

| 30. |

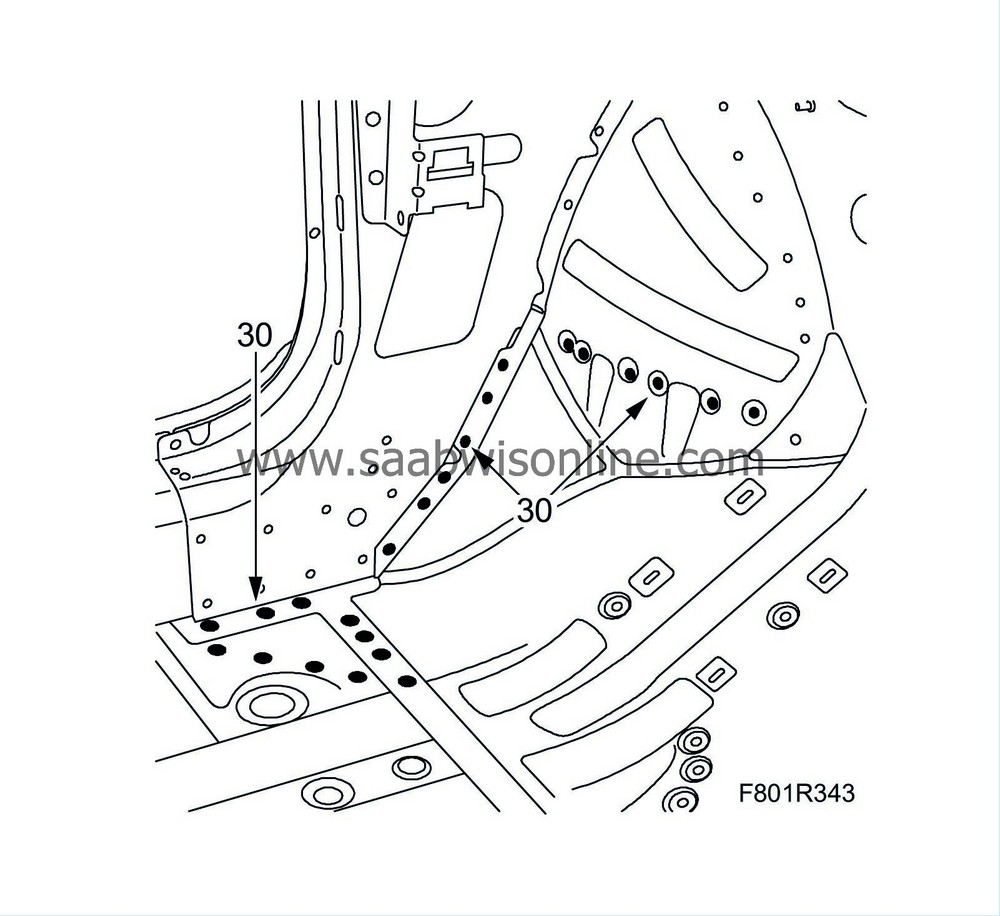

Fit the front transverse reinforcement and support. Use the dill holes from the spot welds.

|

|

| 31. |

Grind the welds and apply rustproofing. Use Terotex HV 400.

|

|

| 32. |

Fit

Outer A-pillar with reinforcement, 4D

|

|

| 33. |

Wash away surplus welding primer. Welding primer reduces the adhesion of paint, filler and sealant.

|

|

| 34. |

Apply primer to all bare metal surfaces. Use Standox 1K.

|

|

| 35. |

Use Terostat 1K-PUR to seal joints and metal folds.

|

|

| 36. |

Apply anti-corrosion agent to internal surfaces after painting. Use Terotex HV 400.

|

|

Warning

Warning