PRE-RELEASE

Short description

| Short description |

| Description |

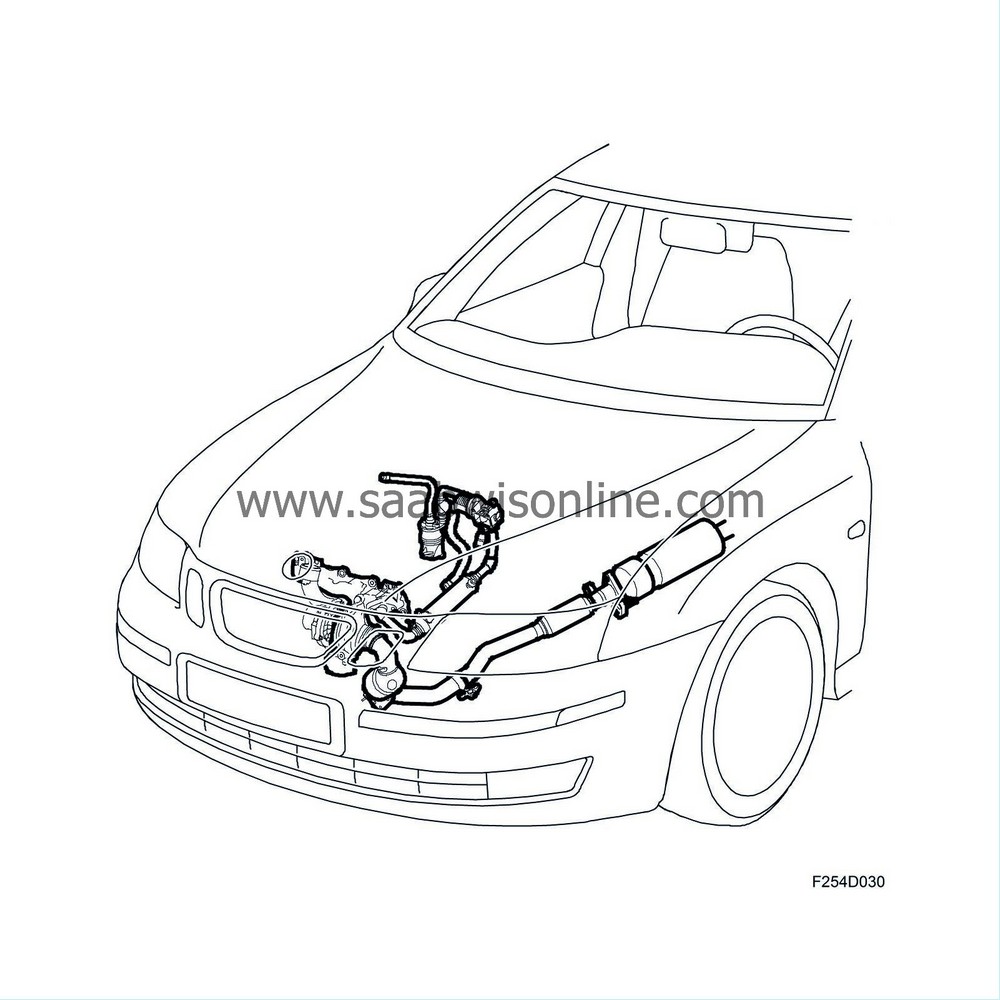

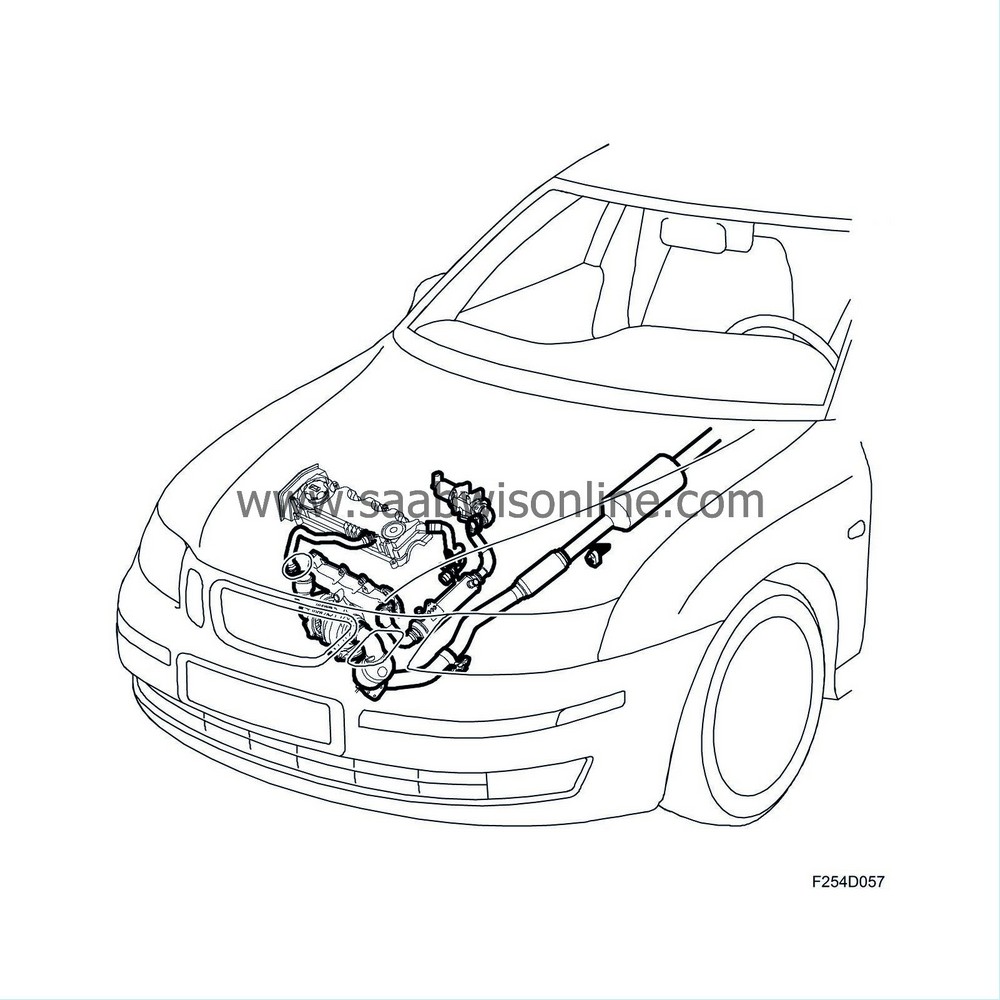

The exhaust emission control system comprises the following sub-systems:

| • |

Catalytic converters

|

|

| • |

Particle trap (cars with particle trap)

|

|

| • |

Crankcase ventilation

|

|

| • |

EGR system

|

|

| • |

Oxygen sensor (cars without particle trap)

|

|

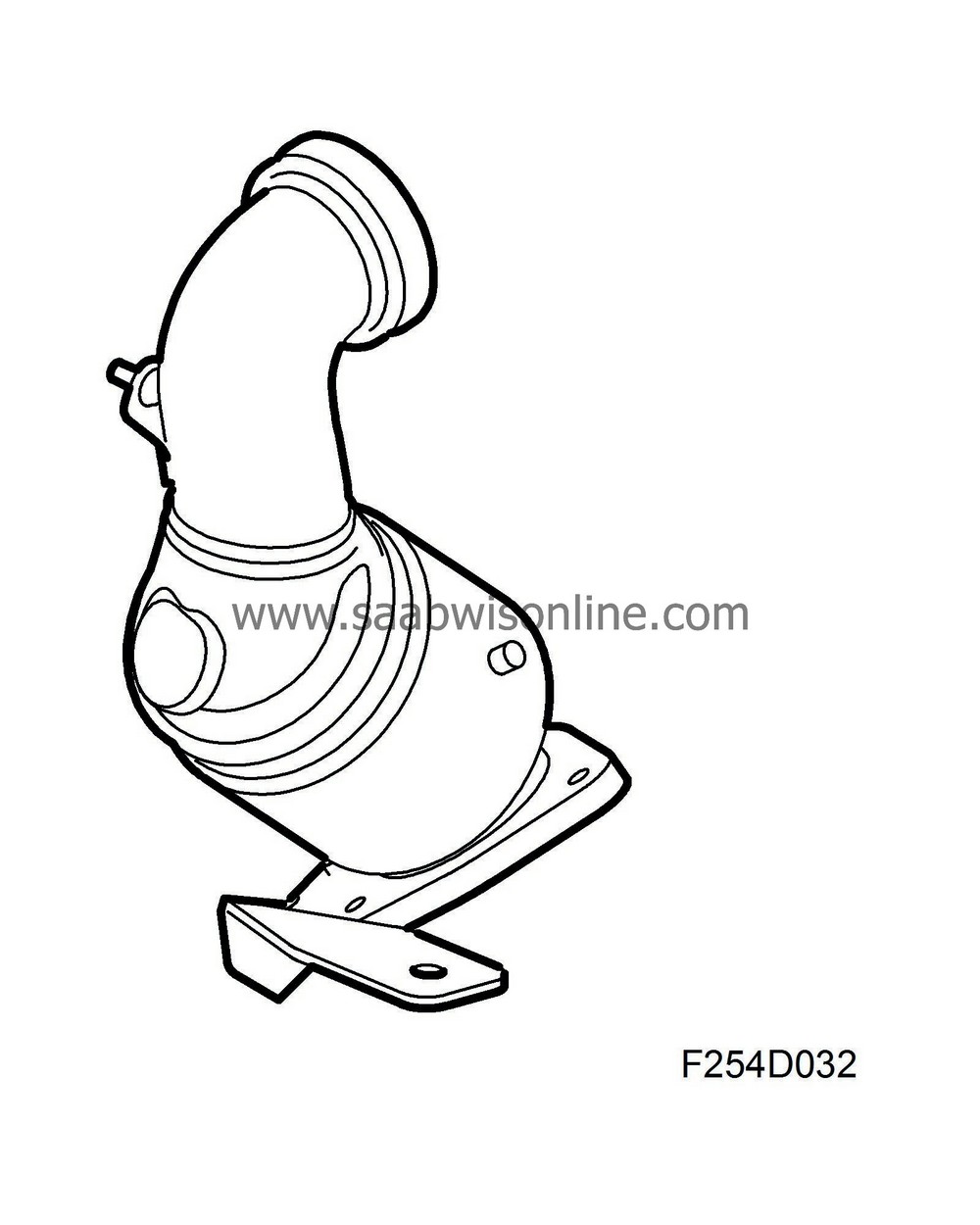

Catalytic converters

Directly after the turbine outlet is the catalytic converter. The proximity to the turbo means the catalytic converter will heat up quickly after starting. On cars equipped with particle trap, the second catalytic converter is integrated in the particle trap. On cars without particle trap, there is a catalytic converter mounted further to the rear on the exhaust system. The catalytic converters reduce emissions of HC and CO.

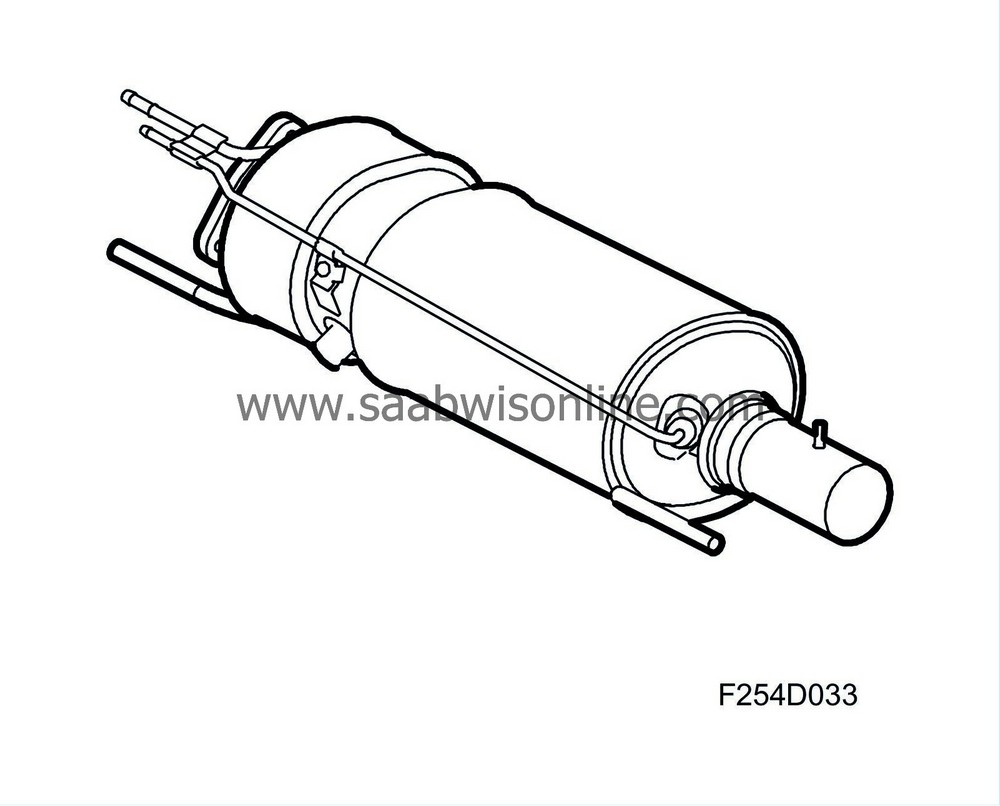

Particle trap (cars with particle trap)

Cars with engine alternative Z19 can be equipped with particle trap, which is used to trap particles of soot in the exhaust. Once the trap is saturated the particles are burned. This is called regeneration.In principle, the particle trap comprises a ceramic body similar to a catalytic converter with a large number of small channels in which particles of soot fasten. A differential pressure sensor measures the drop in pressure across the particle trap and when it exceeds a certain limit, the particle trap is considered to be full and is regenerated. This is normally done fully automatically without the driver noticing. Principally, regeneration is a process where an extra dose of fuel is injected during the exhaust stroke to drastically raise the temperature of the exhaust gas entering the particle trap. The high exhaust temperature burns off the soot and "cleans" the particle trap. This process can take up to 15 minutes to complete. Regeneration can also be activated with the diagnostic tool.

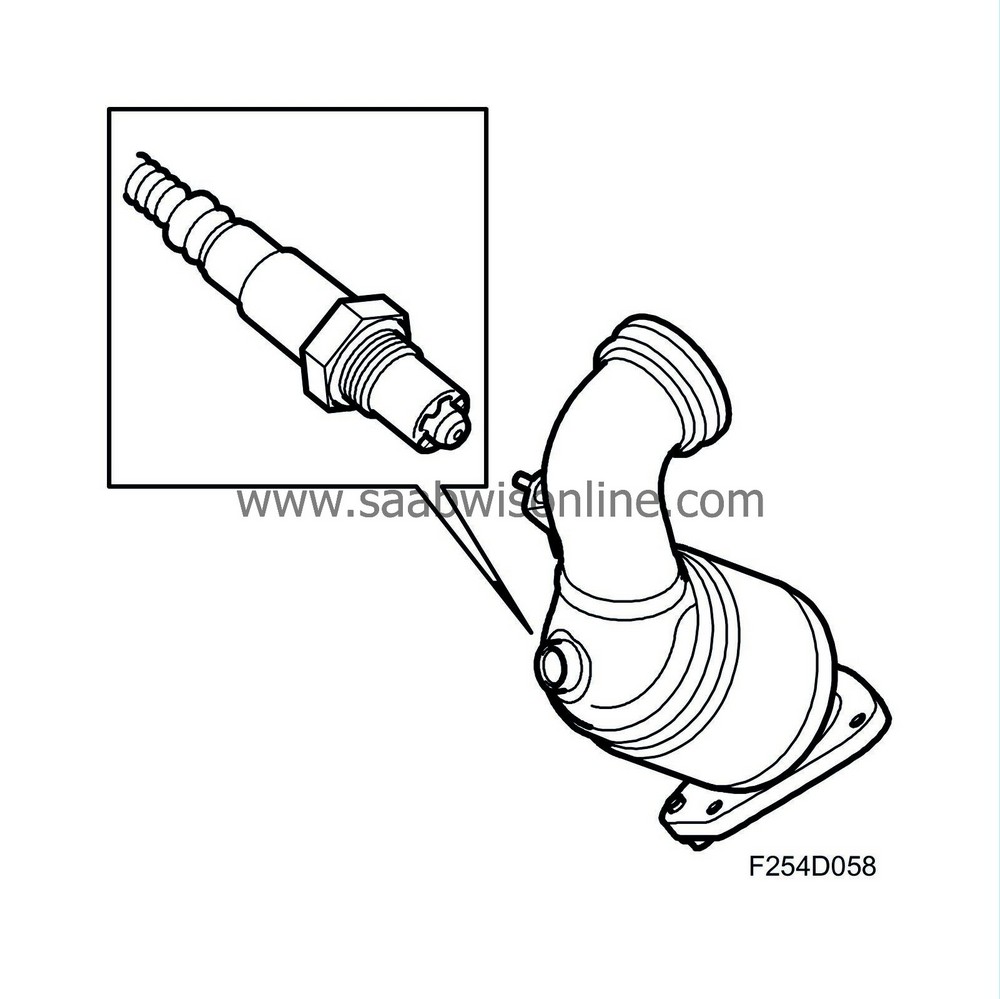

Oxygen sensor (cars without particle trap)

Cars without particle trap are fitted with an oxygen sensor in the inlet to the catalytic converter. The oxygen sensor is broadband type.

Crankcase ventilation, general

The combustion gases passing the piston rings collect in the crankcase and must be led out of the engine through the crankcase ventilation. The reason for this is partly to prevent excessively high pressure in the crankcase and ventilate off the water vapour and hydrocarbons left from the combustion. Since the crankcase gases contain hydrocarbons, they must not be released into the air and must be led back to the cylinders to be burned. This means the crankcase ventilation is a closed system.Crankcase ventilation, Z19DTH

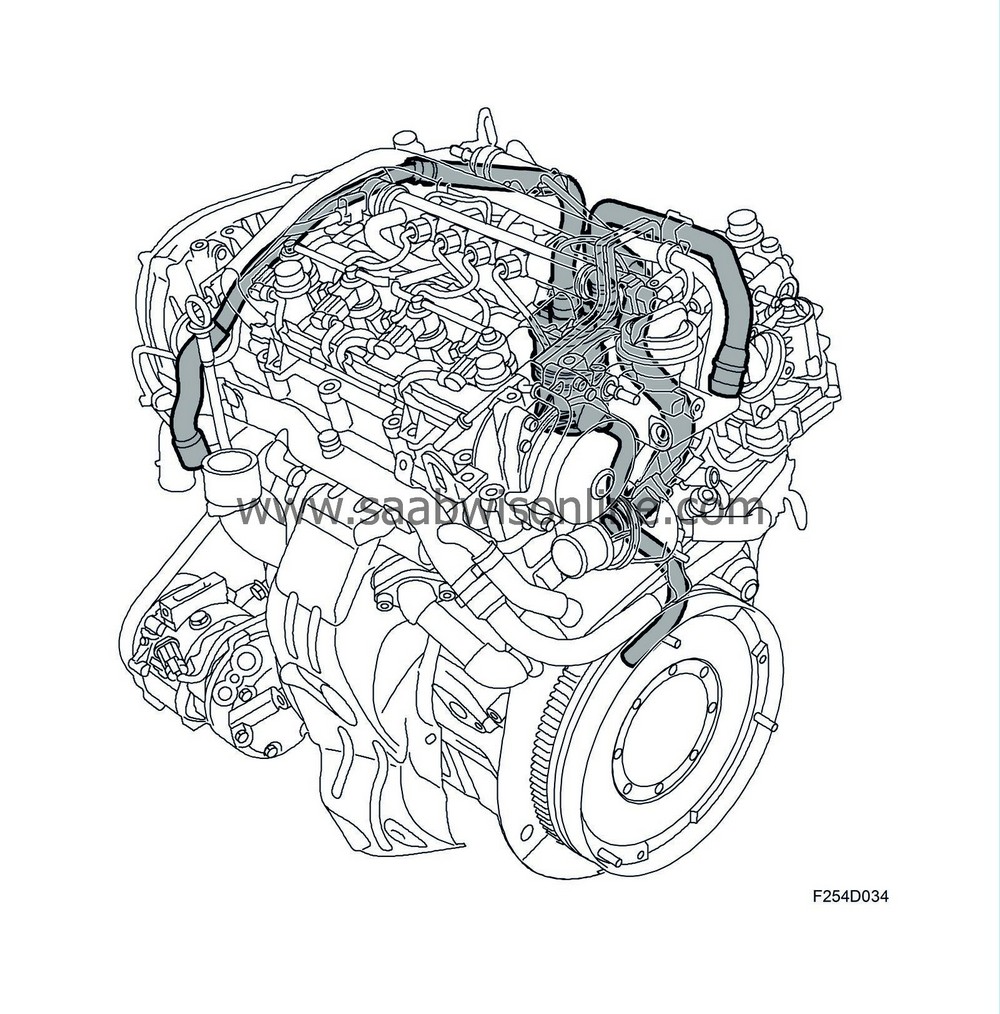

Z19DTH (16V) has an external oil trap. Most of the oil mist coming from the crankcase gases is deposited in the oil trap. The oil passes back into the crankcase and the air is led into the engine induction system for combustion and to be rendered harmless.

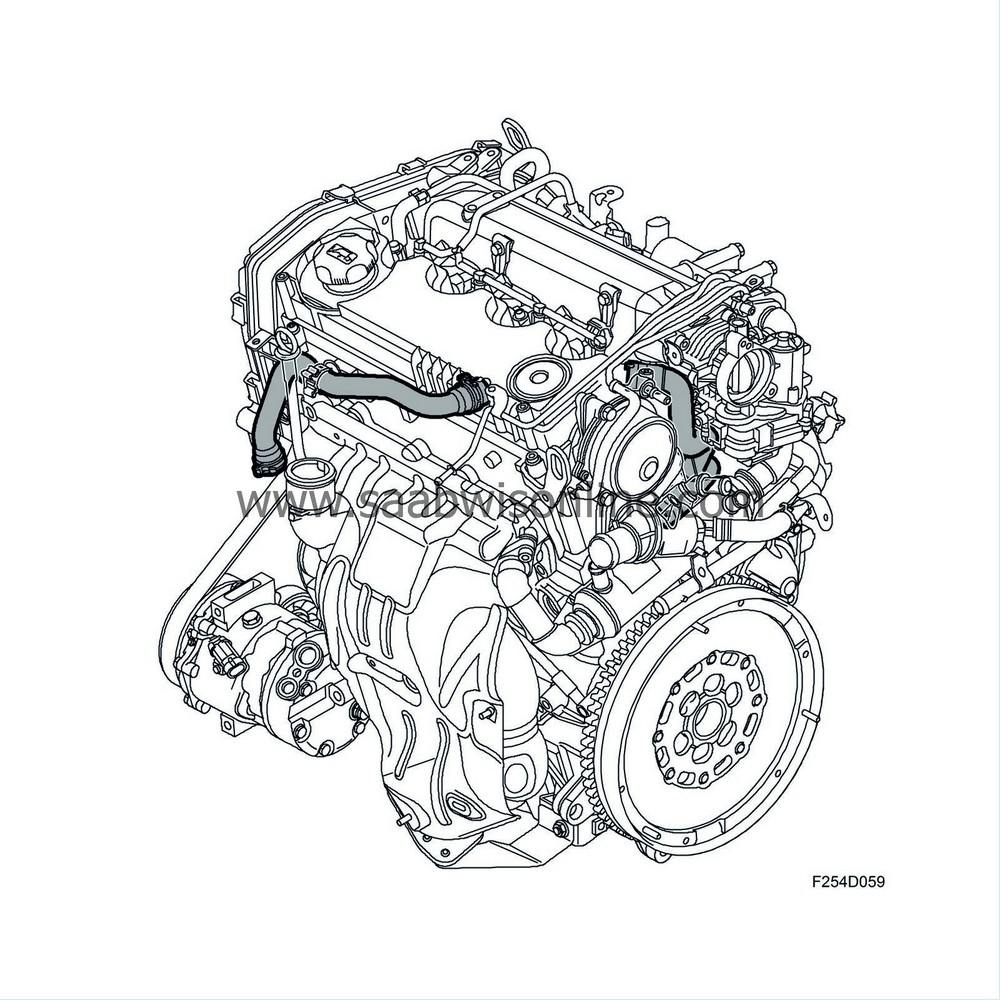

Crankcase ventilation, Z19DT

The engine's crankcase ventilation is fully closed. The ventilation comprises an oil trap integrated in the camshaft cover and a nipple in the engine block that is connected to the crankcase. From the nipple in the engine block there is a hose leading to the oil trap. In the camshaft cover is a connection to the oil trap for ventilating the cylinder head. Drops of oil from the crankcase gases are separated in the oil trap. From the oil trap there is a hose connected to the inlet pipe between the mass air flow sensor and the turbocharger.

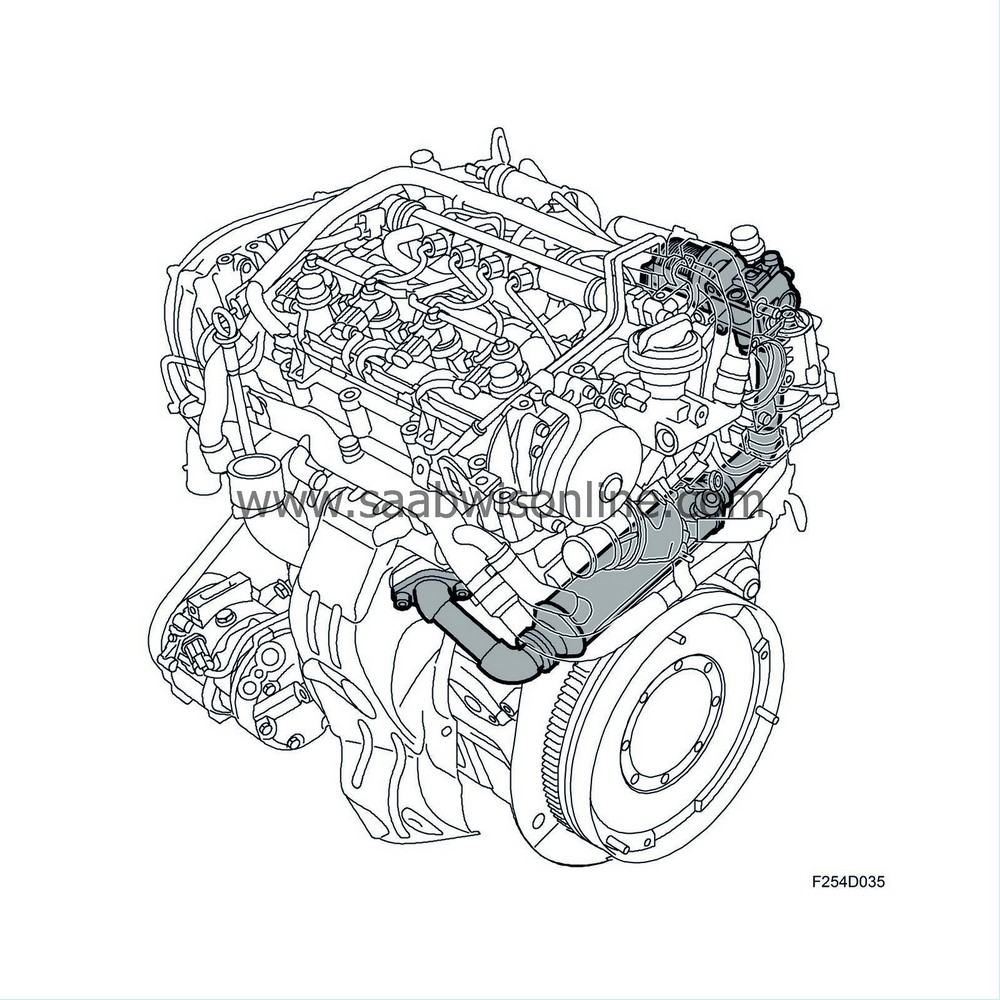

EGR system

To reduce NO x (nitrogen oxides) they must be prevented from arising altogether. This is done by reducing the temperature during combustion. By adding recirculated cooled exhaust gas to the intake air, the combustion temperature can be reduced and therefore also the level of NO x emissions.The following components are included in the EGR system:

| • |

An EGR valve to control the amount of exhaust gas being recirculated.

|

|

| • |

EGR cooler to cool down the exhaust gas.

16V:

8V:

|

|