PRE-RELEASE

MIG brazing (EU)

| MIG brazing (EU) |

MIG brazing has been introduced into production as a method of joining, which means a change to the repair methods used by workshops. Some of the welds in the car have been replaced with brazes using bronze wire, so-called MIG brazing. MIG brazes are a gold colour.

|

|||||||

Sheet metal damage where there is MIG brazing involves a new procedure for repairs. Before the Saab workshops have procured new equipment, damaged cars with MIG brazing must be taken to the closest Opel workshop which has MIG brazing equipment. A list of approved MIG brazing equipment is in 1:4 Workshop equipment and in our IRIS database under Service Information - Technical News - Group 8 Body- MIG-Brazing - Opel dealer MIG Brazing equipment. The list in IRIS will be updated regularly and will be found under "What's New?". Where appropriate, where authorized Opel workshops do not have suitable equipment, contact one of the six approved suppliers for support. The list of "MIG- Brazing equipment suppliers" can be found in our IRIS database under Service Information - Technical News - Group 8 Body - MIG-Brazing.

In all cases, 100% pure argon gas must be used and the welding rod must be 1 mm (16-93 180 983).

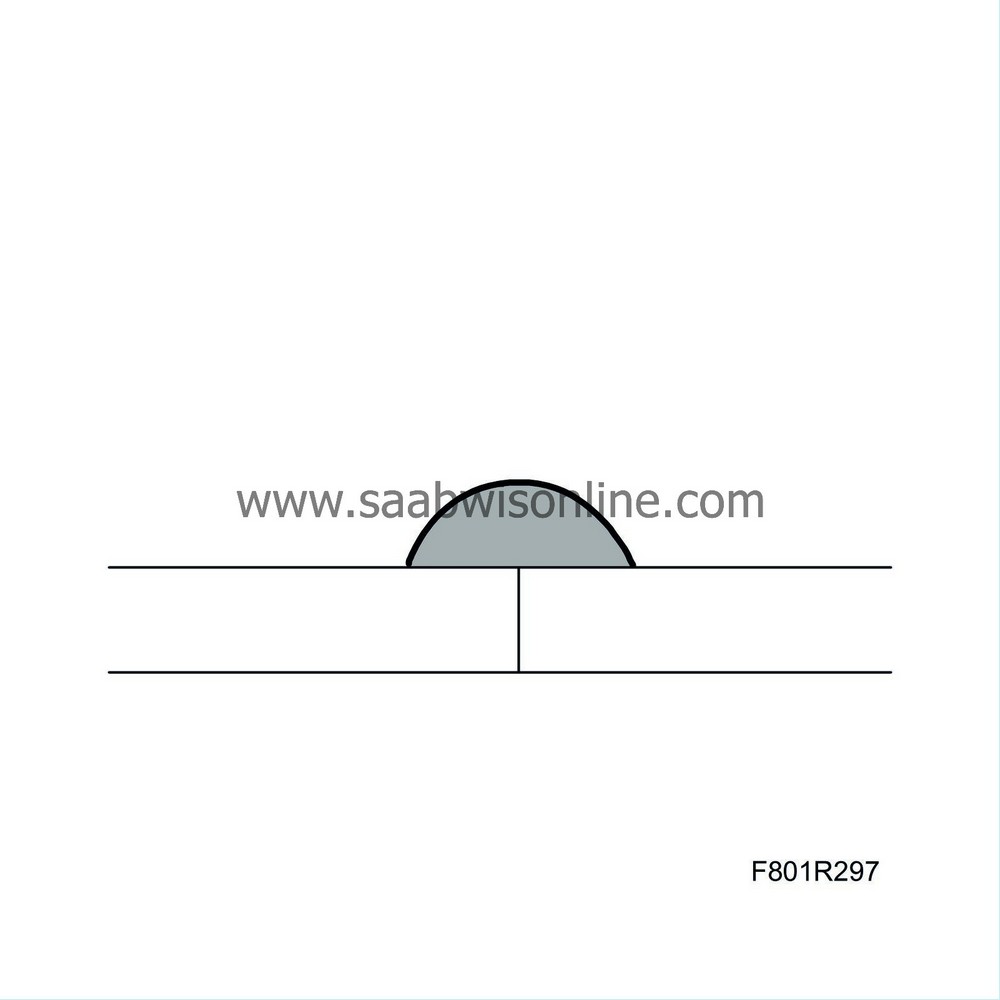

The appearance of a MIG brazing joint differs to a conventional weld joint. However, when welding with low energy the arc is occasionally broken, resulting in stronger sizzling and more spray. A good MIG brazing joint must be evenly rounded.

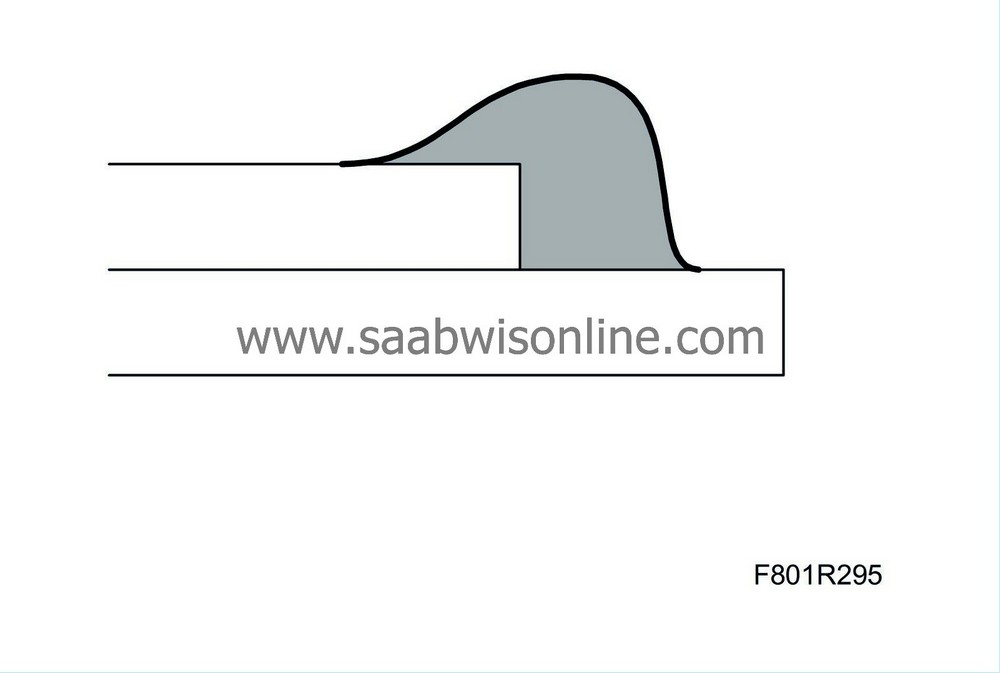

Lap joint:

MIG brazing emits a significant amount of zinc gas in the molten material and brass is formed, with few or no air holes as a result. As MIG brazing is a soldering process where the panels do not need to be melted together, there is also less risk of burning holes. In the cases where grinding is required, the welds are considerably easier to grind. Ensure that the independent workshops which are engaged have access to this information.

Warning

Warning