PRE-RELEASE

Injector (206), Z19DTH

| Injector (206), Z19DTH |

| To remove |

|

||||||||||||||||||||||

| Important | ||

|

Be very thorough in terms of cleanliness when working in the fuel system. Malfunctions can also occur due to very small dirt particles. Prevent dirt from entering the fuel system by cleaning the hoses and plugging the pipes and lines upon removal using 93 161 370 Plug set. Store the components so that contaminants cannot enter. |

||

|

|||||||

| Important | ||

|

If the injectors are to be refitted, mark the injectors so that they can be refitted to the same cylinder. |

||

| 1. |

Open the bonnet.

|

|

| 2. |

Remove the upper engine cover and insulation.

|

|

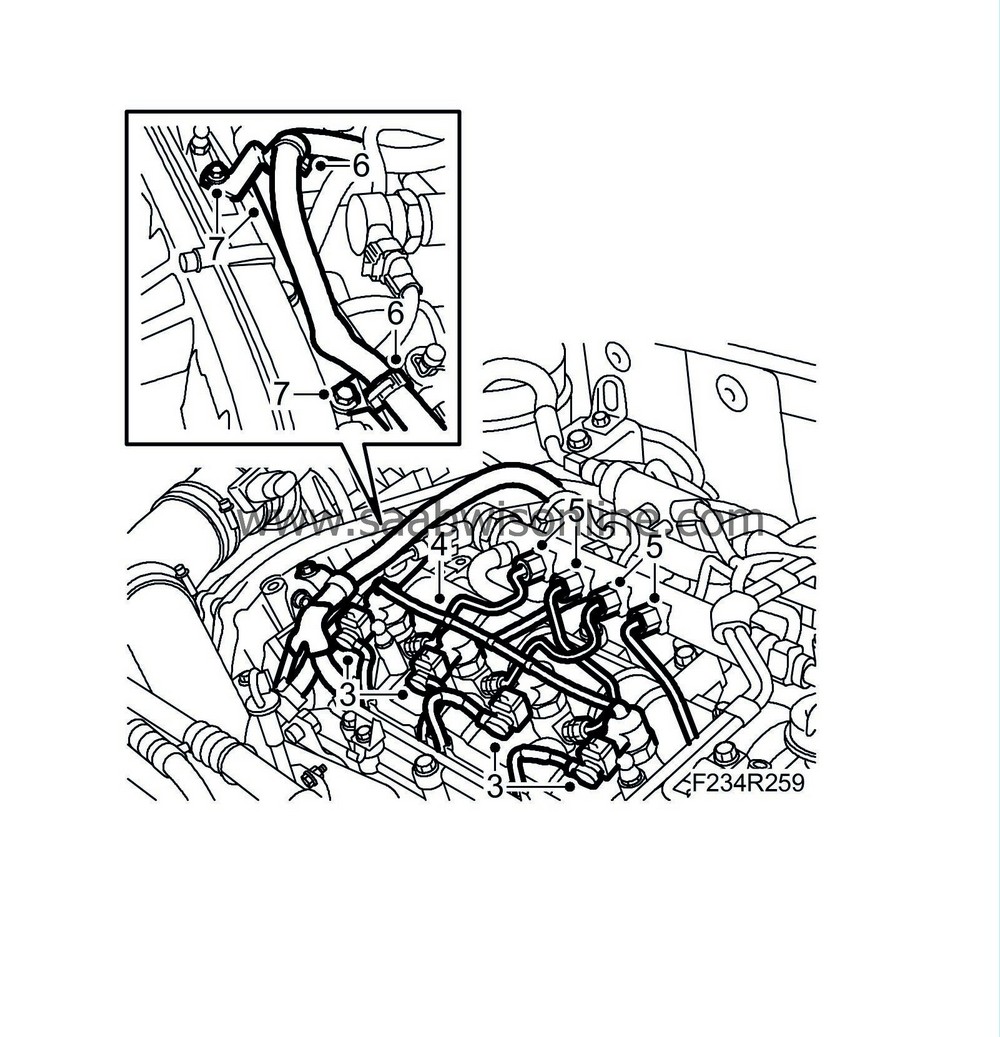

| 3. |

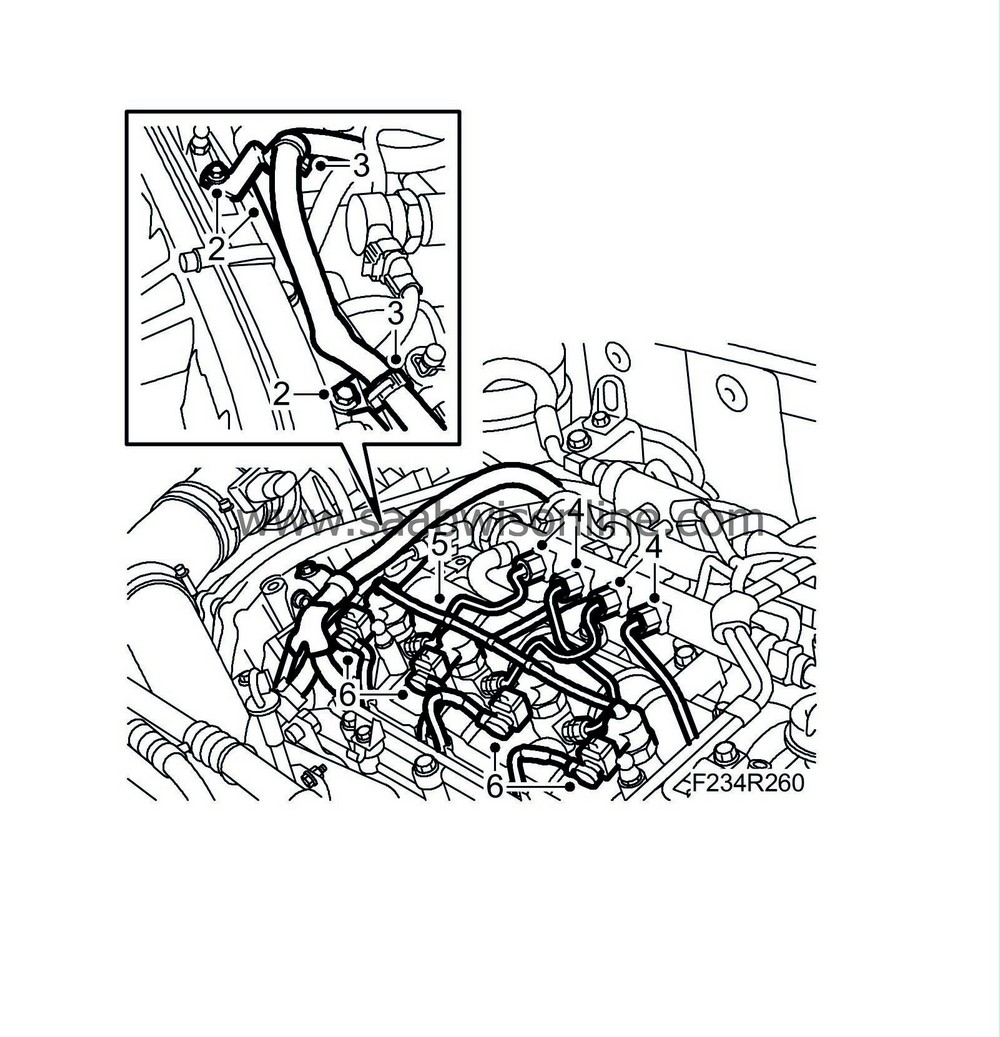

Remove the connectors from the injectors.

|

|

| 4. |

Remove the fuel return hoses.

|

|

| 5. |

Remove the fuel pipes from the injectors and fuel rail. Hold the injector with a spanner when detaching the pipe.

|

|

| 6. |

Undo the cables from the crankcase ventilation pipe.

|

|

| 7. |

Undo the crankcase ventilation pipe.

|

|

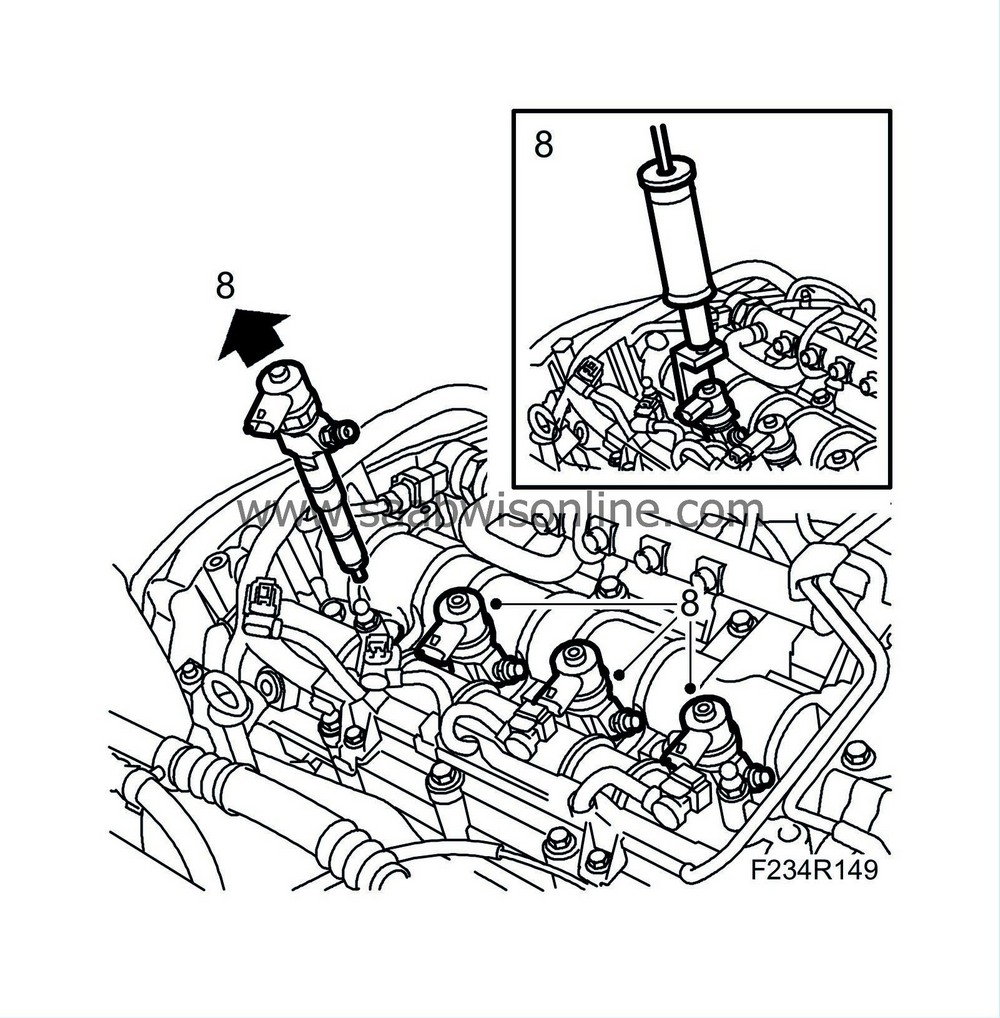

| 8. |

Undo the injector with holder. If the nozzles cannot be lifted by hand, use removal tool:

32 025 013 Injector removal tool

and

83 90 270 Sliding hammer

and

32 025 012 Sliding hammer adapter

.

|

|

| 9. |

Remove the injectors in the following order:

1-2-3-4

|

||||||||||

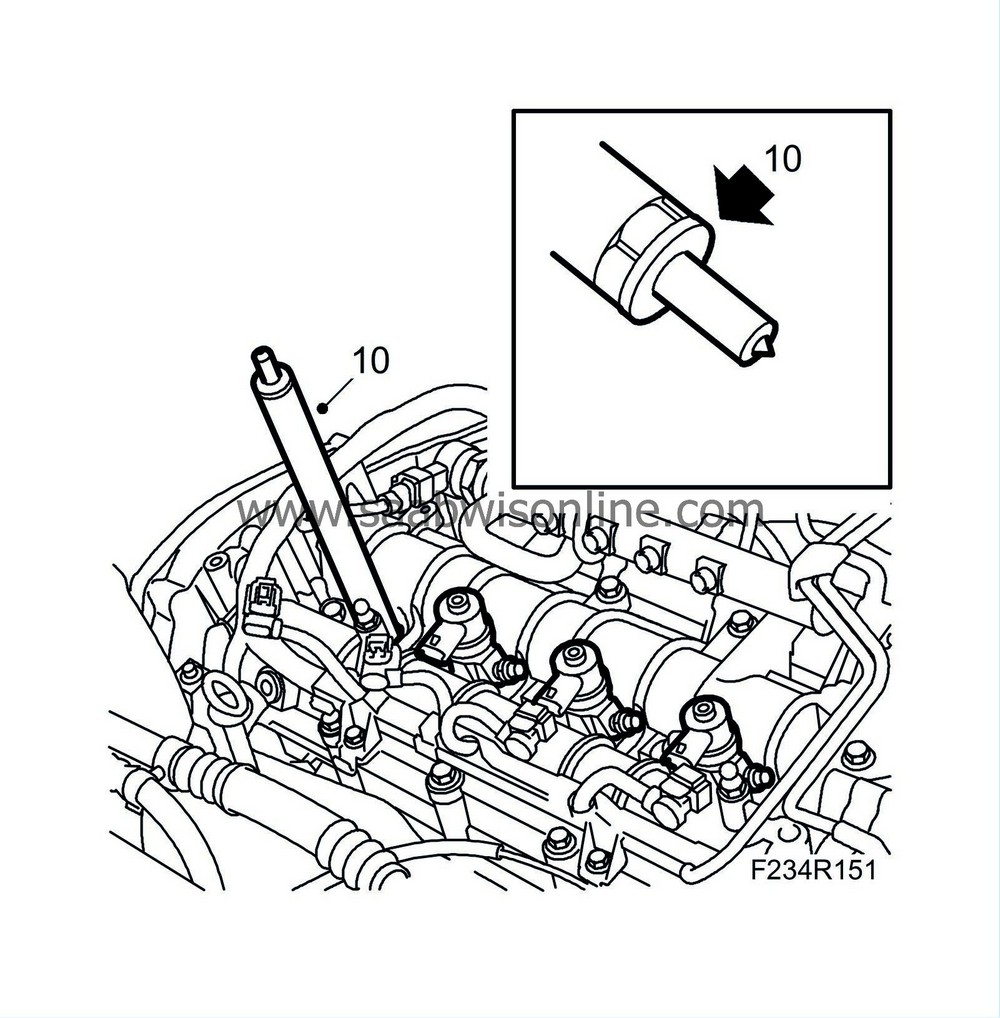

| 10. |

Clean the injector sealing surfaces in the cylinder head. Use

32 025 010 Cleaning tool.

|

|

| To fit |

| Important | ||

|

If new injectors are to be fitted, read and make a note of its classification code. The code is to be used when programming using the diagnostic tool. |

||

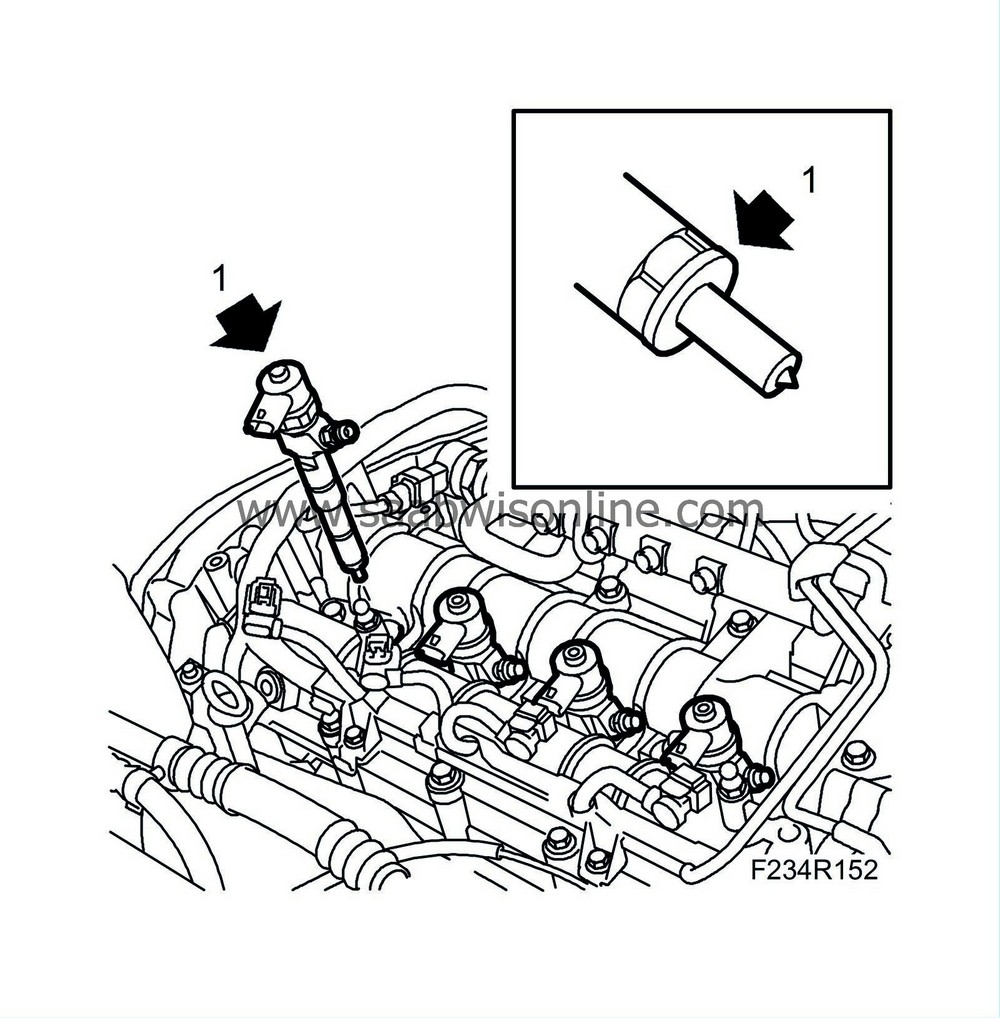

| 1. |

Fit the injectors with new seals in the following order: 4-3-2-1.

Tightening torque 25 Nm (18 lbf ft).

|

|

| 2. |

Fit the crankcase ventilation pipe.

|

|

| 3. |

Fit the cables to the crankcase ventilation pipe.

|

|

| 4. |

Check that the fuel pipe sealing surfaces are not damaged and are clean. Fit the pipes without strain and mount the nuts by hand.

Tightening torque 25 Nm (18 lbf ft). |

|

| 5. |

Fit the fuel return hoses.

|

|

| 6. |

Fit the connectors.

|

|

| 7. |

If new injectors are fitted

: Connect the diagnostic tool for programming. Select Menu - Engine - Engine management system - Adjustment -

Injector Replaced.

|

|

| 8. |

Start the engine and check that the fuel system is not leaking.

Connect the diagnostic tool and erase any diagnostic trouble codes. |

|

| 9. |

Fit the insulation and the upper engine cover.

|

|

Warning

Warning