PRE-RELEASE

Fitting the power train

| Fitting the power train |

| To fit |

|

|||||||

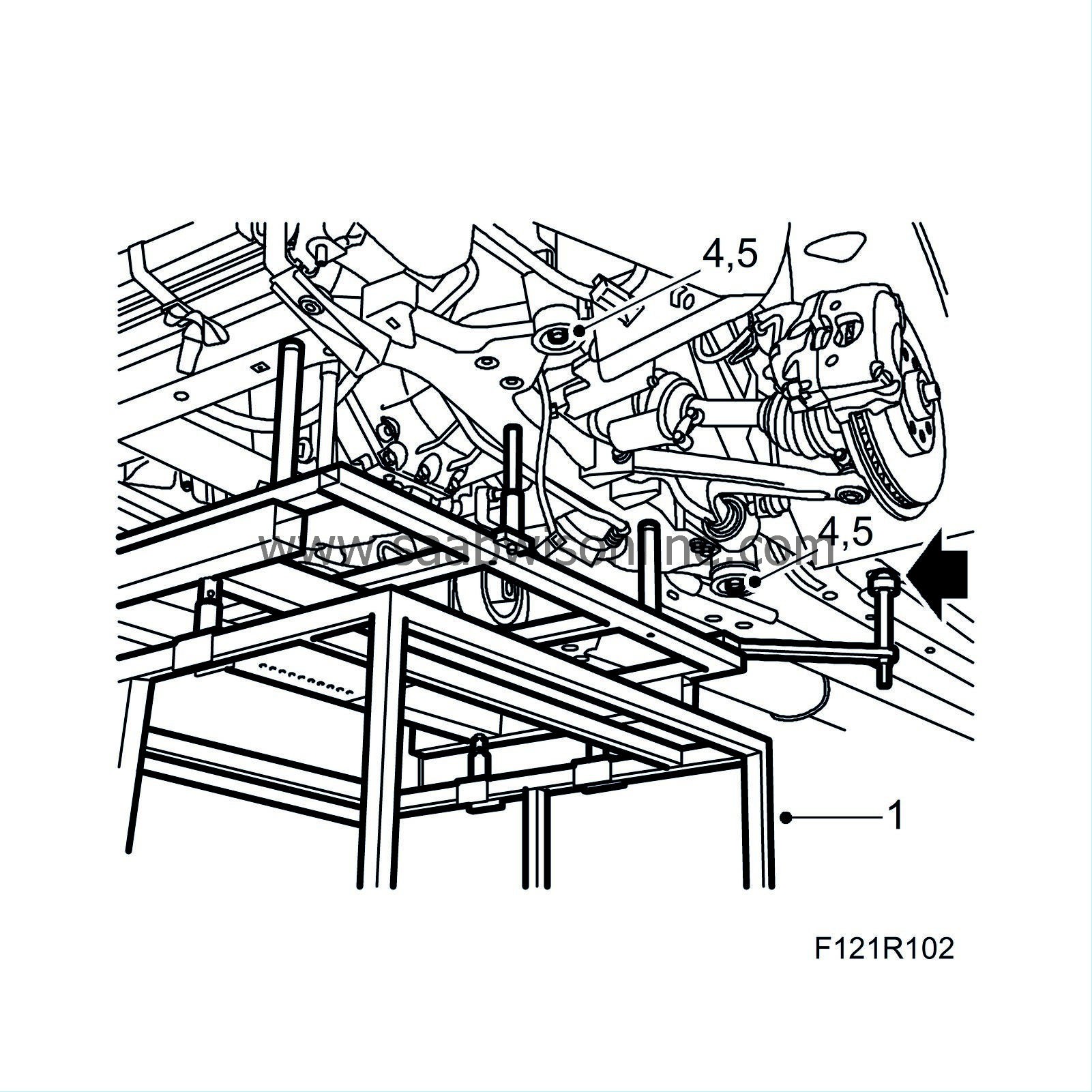

| 1. |

Align the trolley lift with the powertrain and adjust its position in relation to the body. See

Centring tool, engine and subframe.

|

|

| 2. |

Lift up the power train until the inboard drive shaft universal joints are level with the wheel hubs and insert the drive shafts into the hubs. Make sure nothing gets caught or damaged.

|

|

| 3. |

Lift a little higher and position the lower swivel joints to the steering swivel members. If necessary, adjust the trolley lift screws to provide even contact with the body. Check that the guide pins are positioned correctly relative the reference holes in the body.

|

|

| 4. |

Position the bolts and screw them through the subframe into the body.

|

|

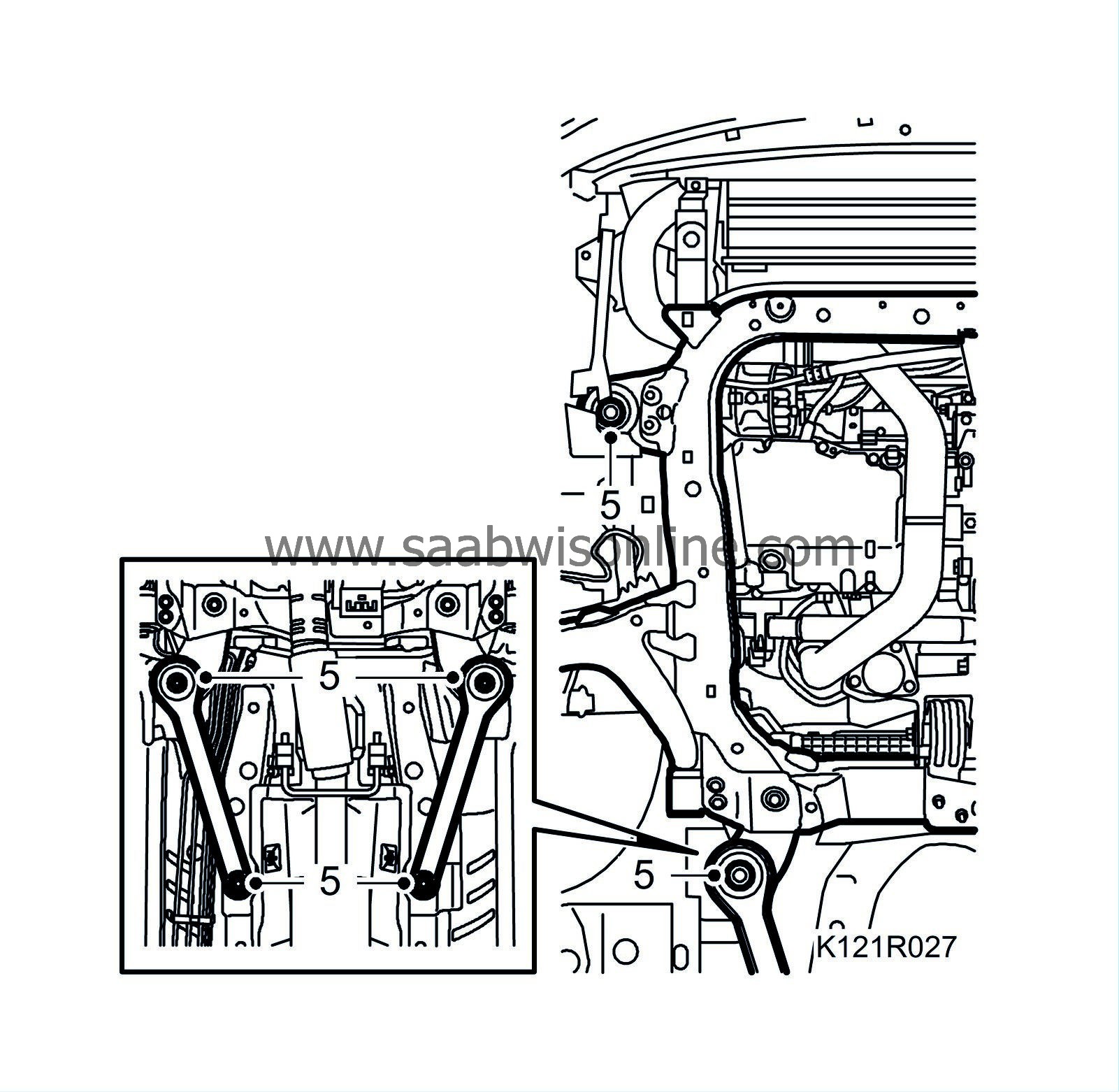

| 5. |

Raise the engine completely and tighten the subframe bolts.

Tightening torque 75 Nm + 135° (55 lbf ft +135°)

|

|

| 6. |

Lower the trolley lift and move it out of the way.

|

|

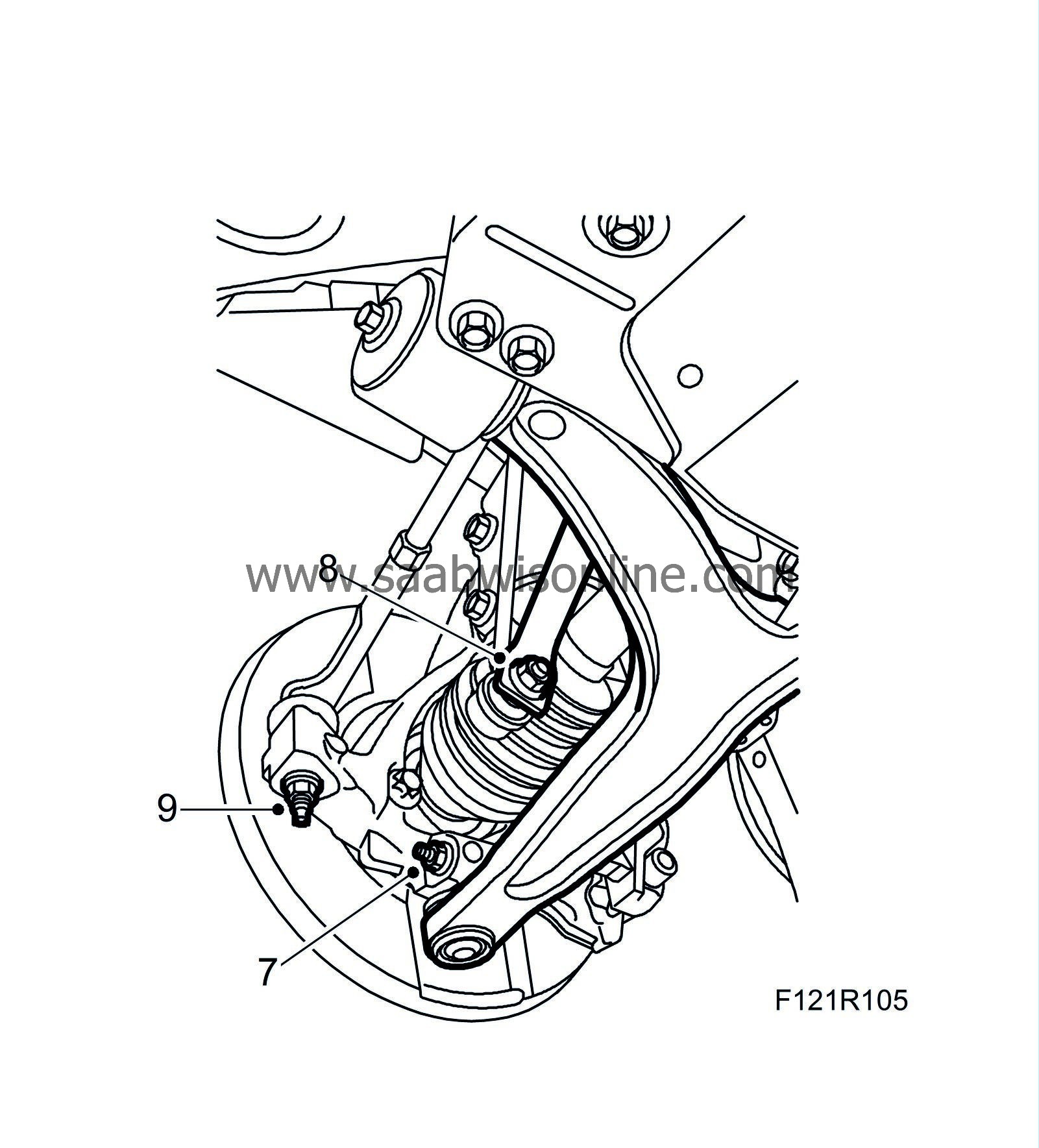

| 8. |

Position the lower anti-roll bar links and tighten them while gripping the flats with a thin spanner.

Tightening torque 64 Nm (47 lbf ft) |

|

| 9. |

Position the outboard steering links and tighten them.

Tightening torque 35 Nm (26 lbf ft) |

|

| 10. |

Plug in the angle sensor connector (option).

|

|

| 11. |

Clean the pipe connections, fit a joint clamp on the front pipe and fit the front exhaust pipe to the catalytic converter, or fit the complete exhaust system. Use a new gasket and new nuts.

Tightening torque 25 Nm (18 lbf ft) |

|

| 12. |

If the pipe was cut, adjust the joint clamp so that the pipe ends are in the centre of the joint clamp. Tighten the joint clamp nuts.

Tightening torque 40 Nm (30 lbf ft).

|

|

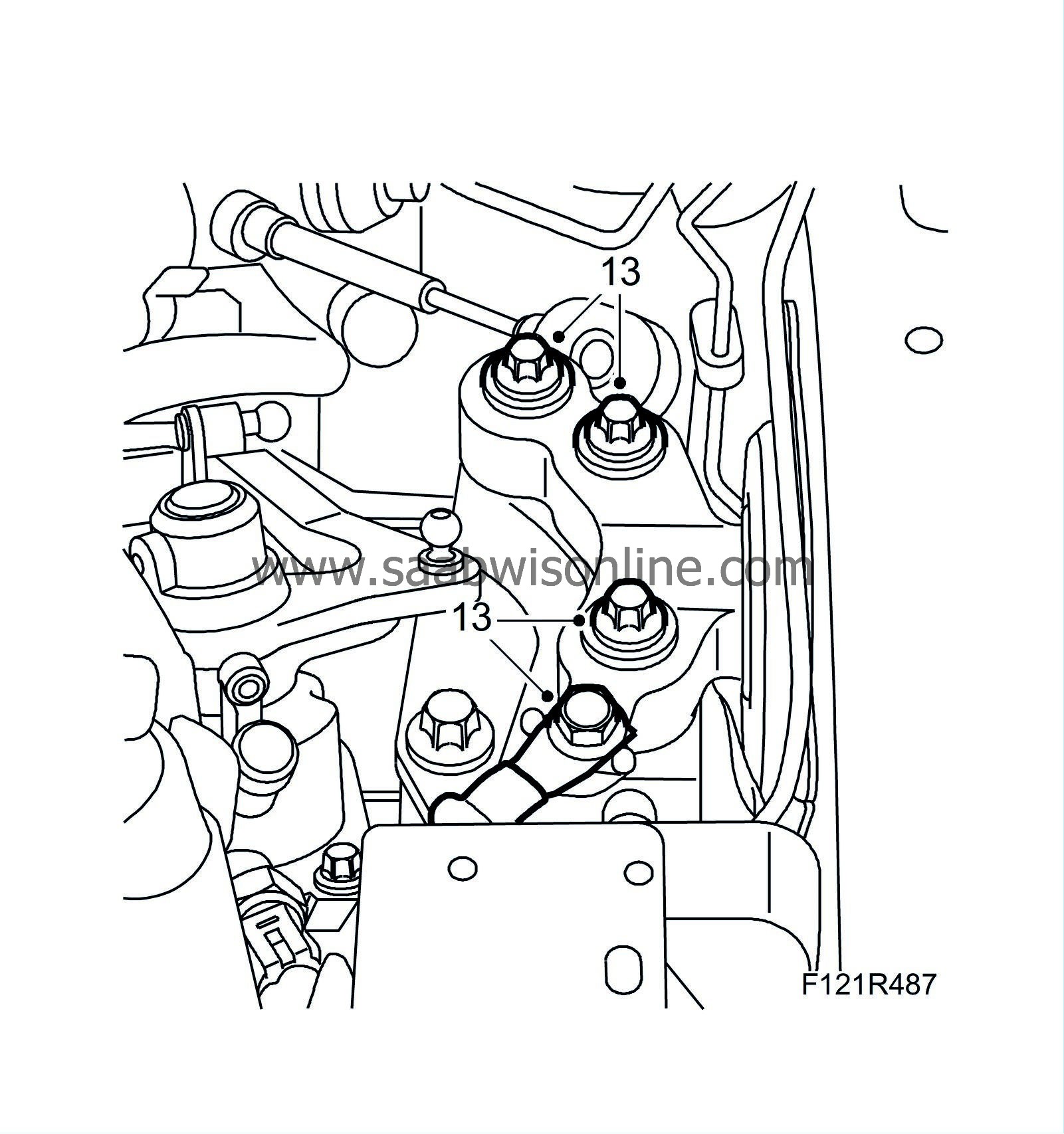

| 13. |

Lower the car and fit the left-hand engine mounting.

Tightening torque: 70 Nm + 45° (52 lbf ft + 45°)

|

|

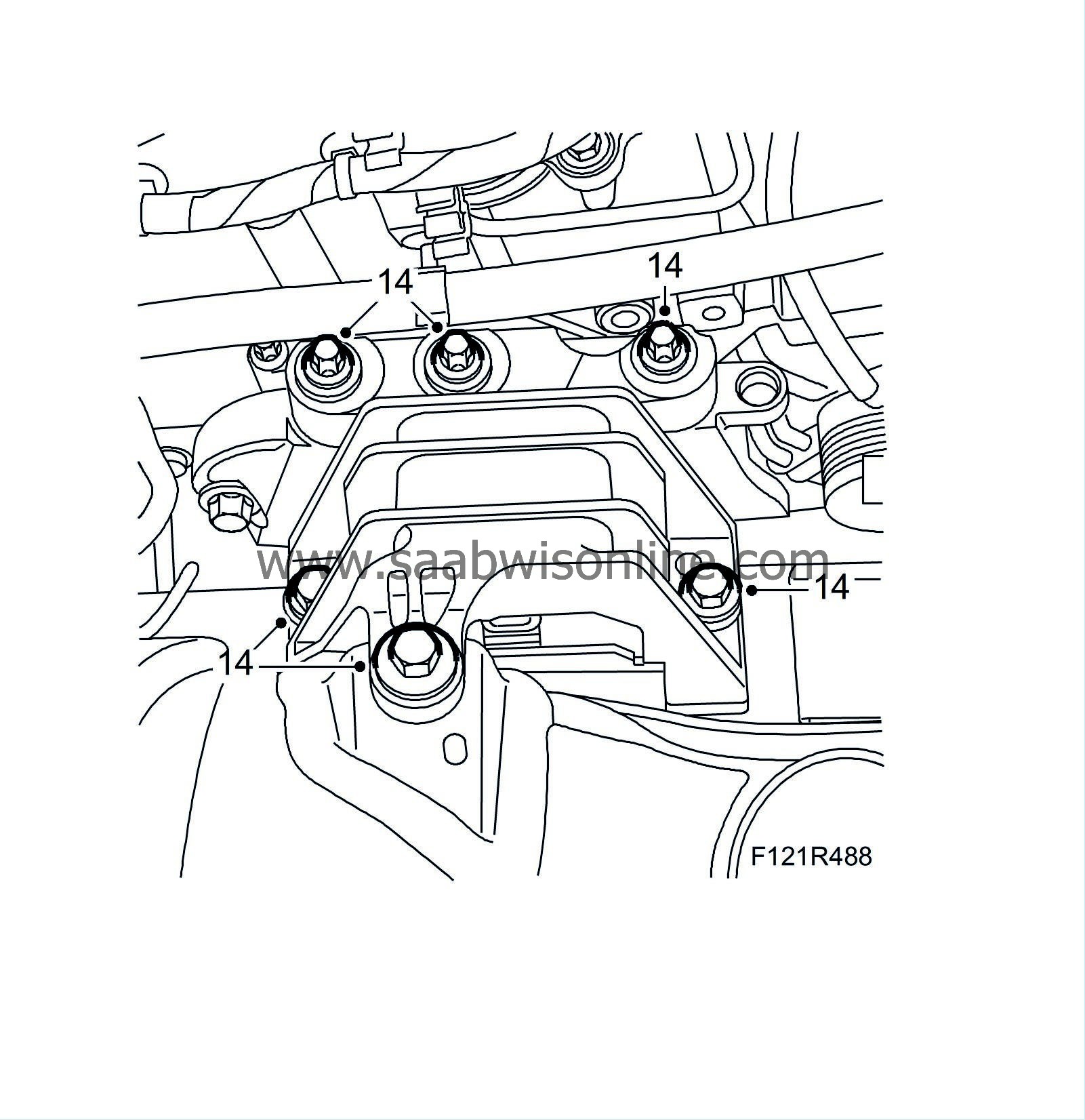

| 14. |

Fit the right-hand engine pad.

Tightening torque 70 Nm + 60° (52 lbf ft + 60°) Tightening torque, engine pad to body 40 Nm + 60° (30 lbf ft + 60°)

|

|

| 15. |

Remove the strap from the radiator member and the A/C compressor.

|

|

| 16. |

Remove the radiator member.

|

|

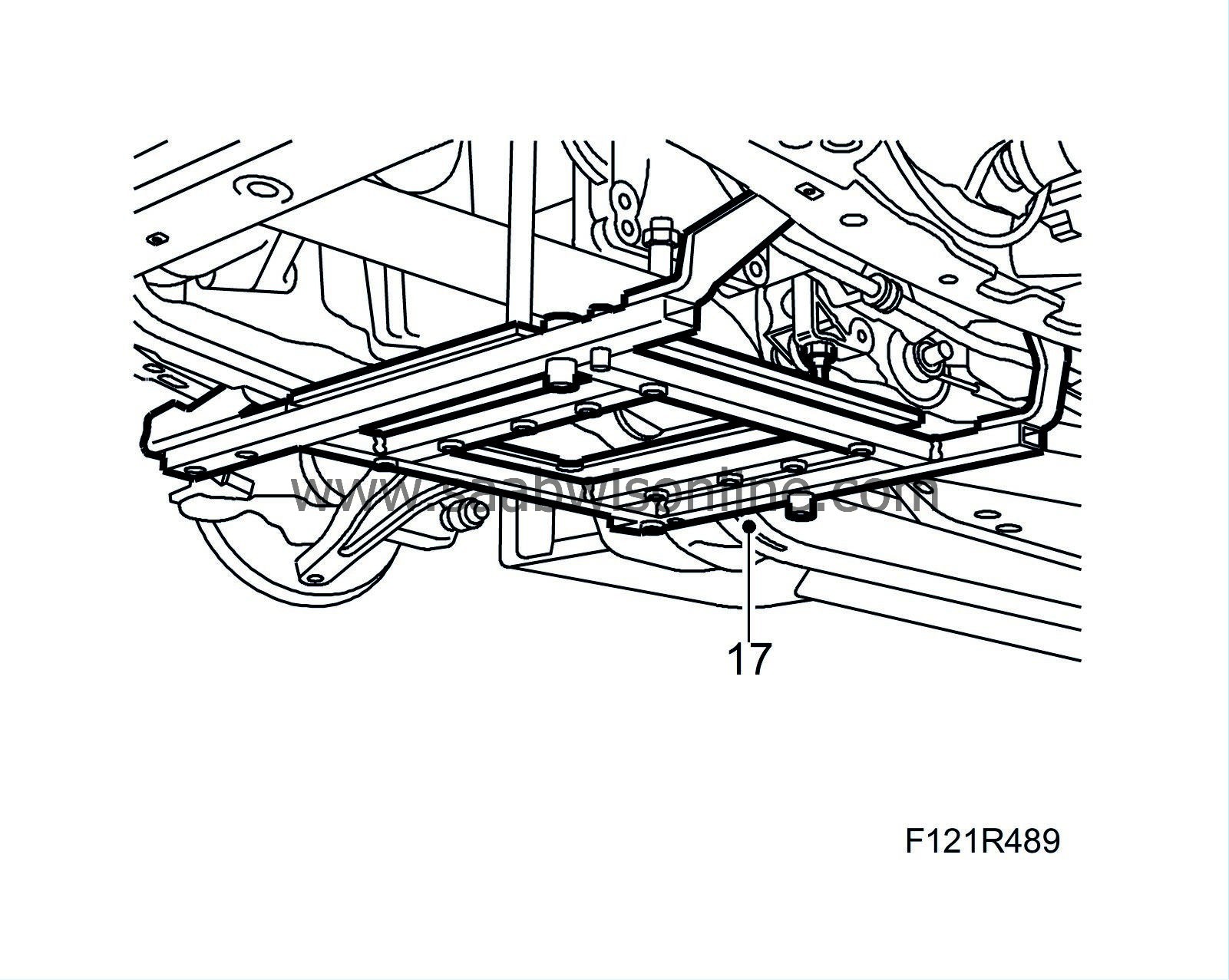

| 17. |

Raise the car, relieve

83 96 152 Engine centring tool kit

and remove it from the subframe.

|

|

| 18. |

Secure the power steering pipe to the subframe with the clips.

|

|

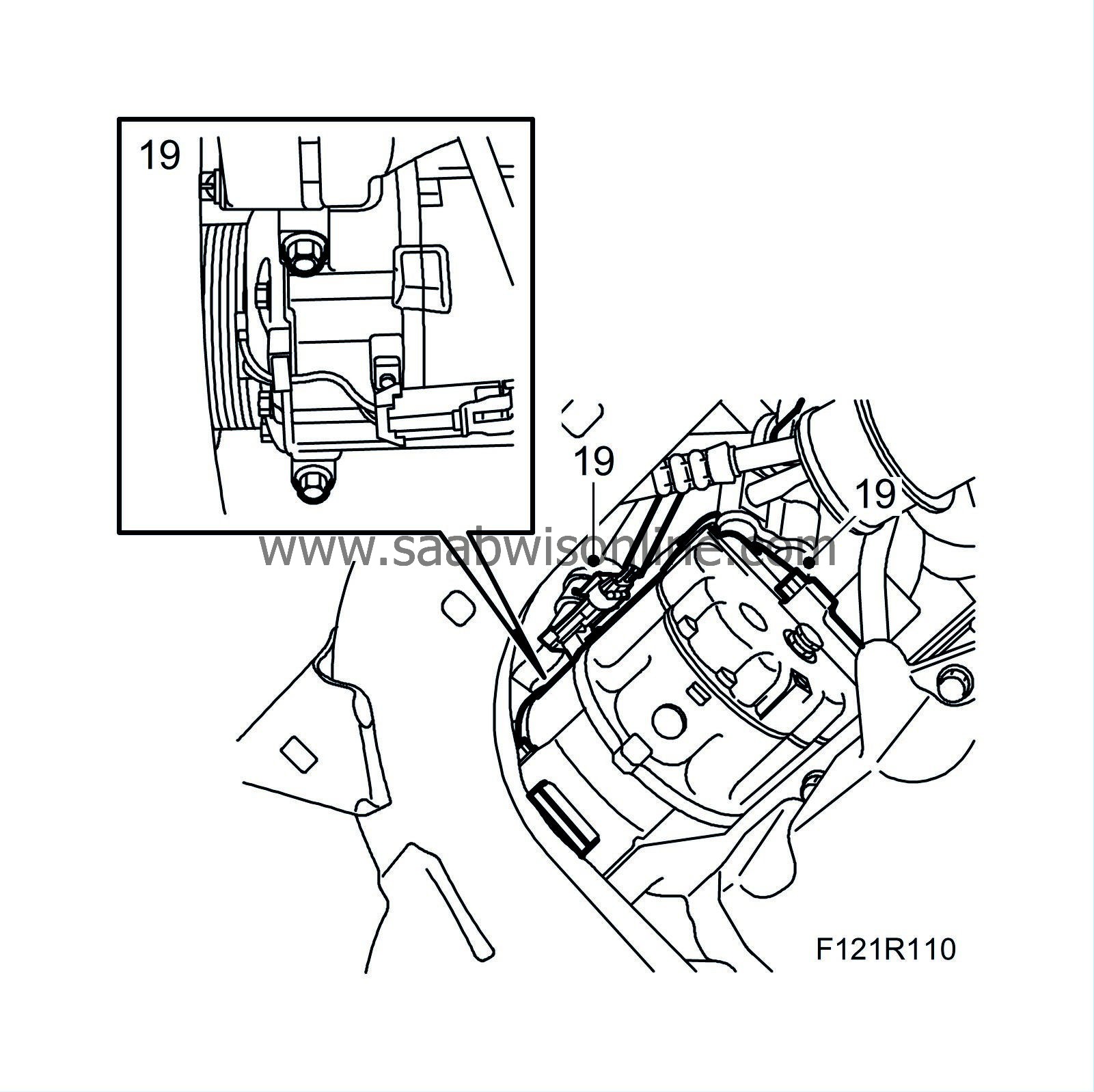

| 19. |

Fit the A/C compressor and plug in the connector.

Tightening torque 20 Nm (15 lbf ft).

|

|

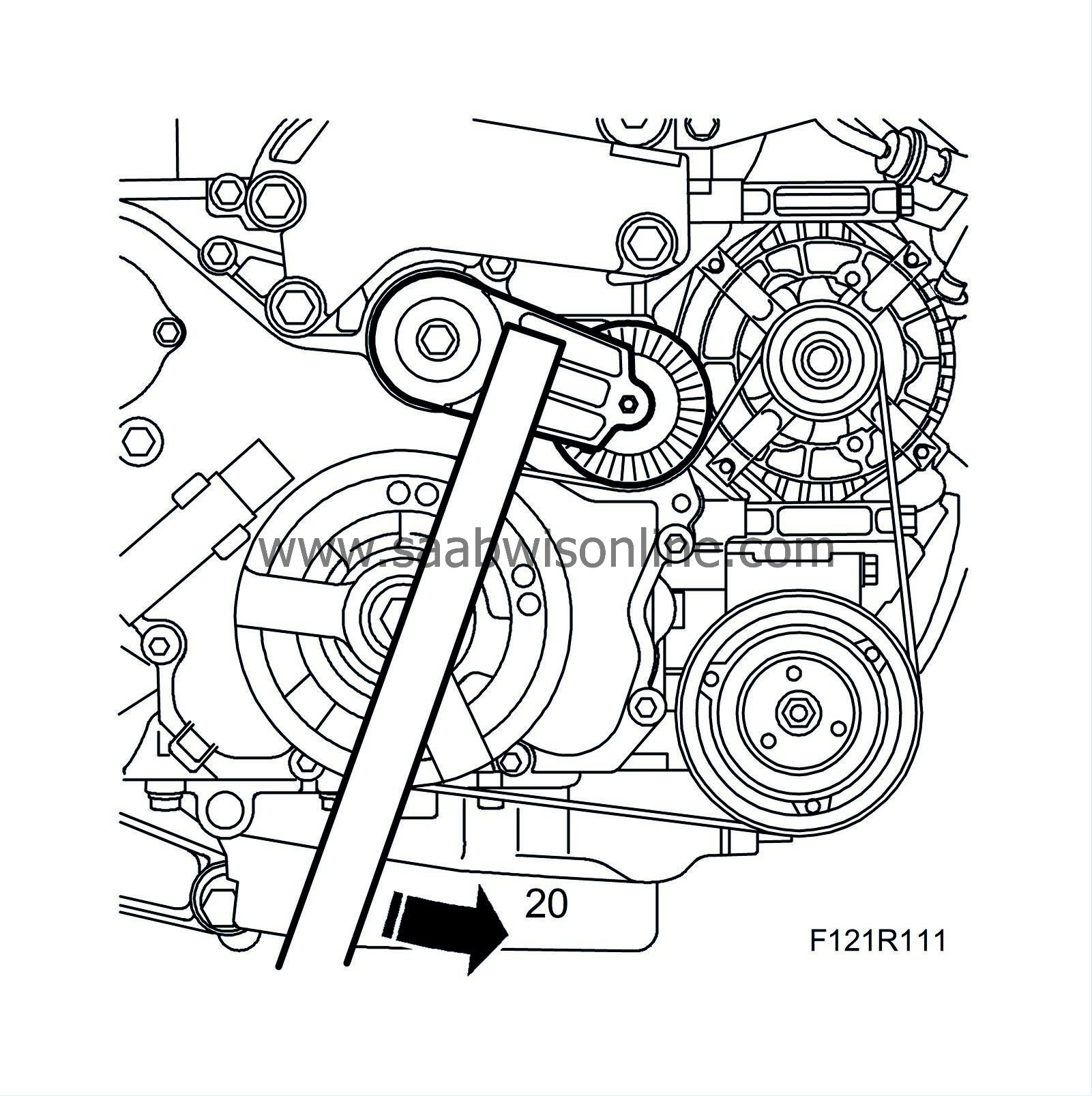

| 20. |

Relieve the multigroove belt and mount it observing the rotation direction noted earlier. Use

83 96 095 Belt circuit relieving tool B207

.

|

|

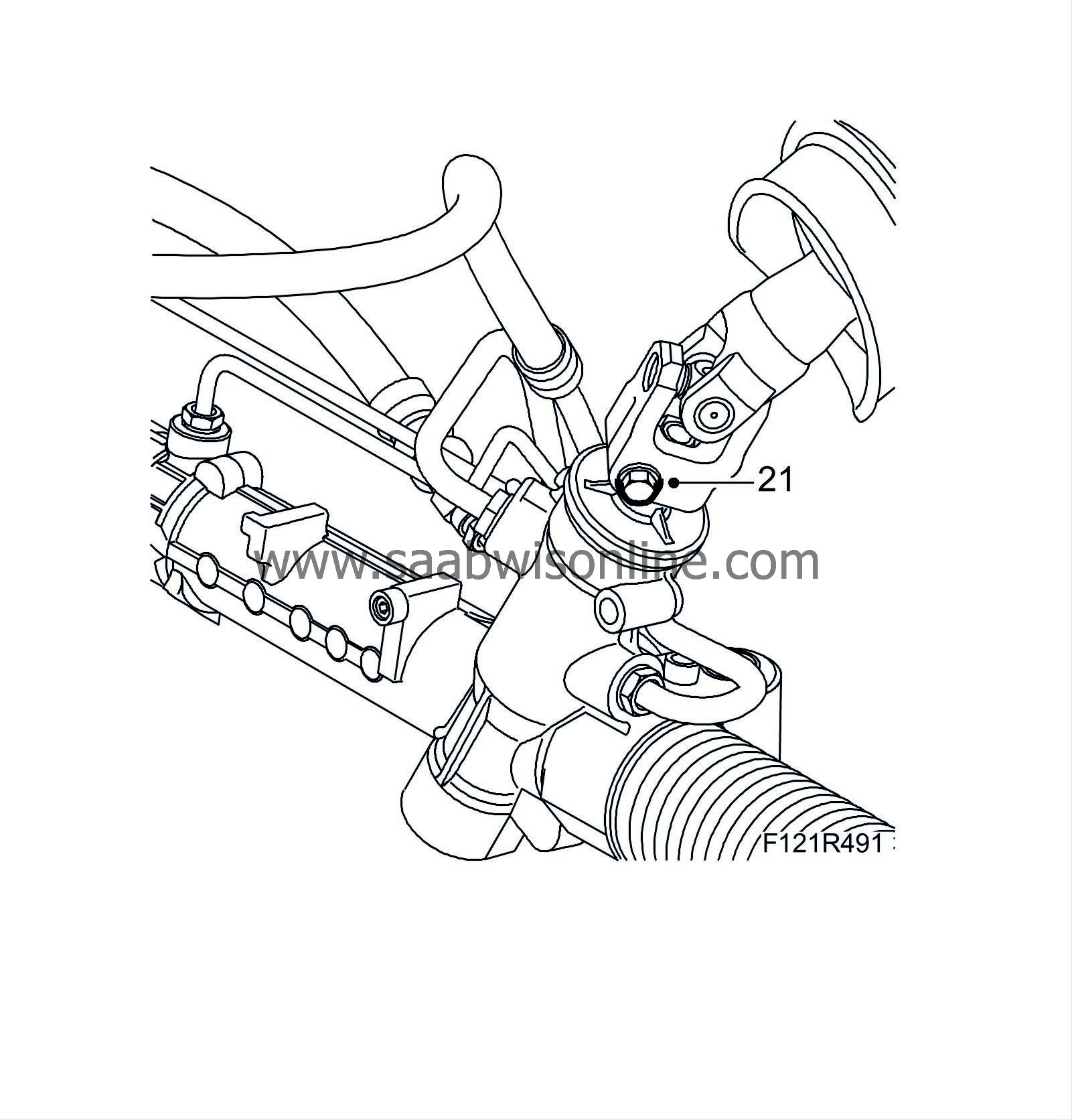

| 21. |

Make sure the steering assembly is in straight-ahead position. Fit the steering shaft to the steering gear. Clean the threads and apply

74 96 268 Thread locking adhesive

to the threads.

Tightening torque 30 Nm (22 lbf ft)

|

|

| 22. |

Lower the car and remove the tape from the steering wheel.

CV:

Fit

Chassis reinforcement, front subframe, CV

|

||||||||||||||||||||||||

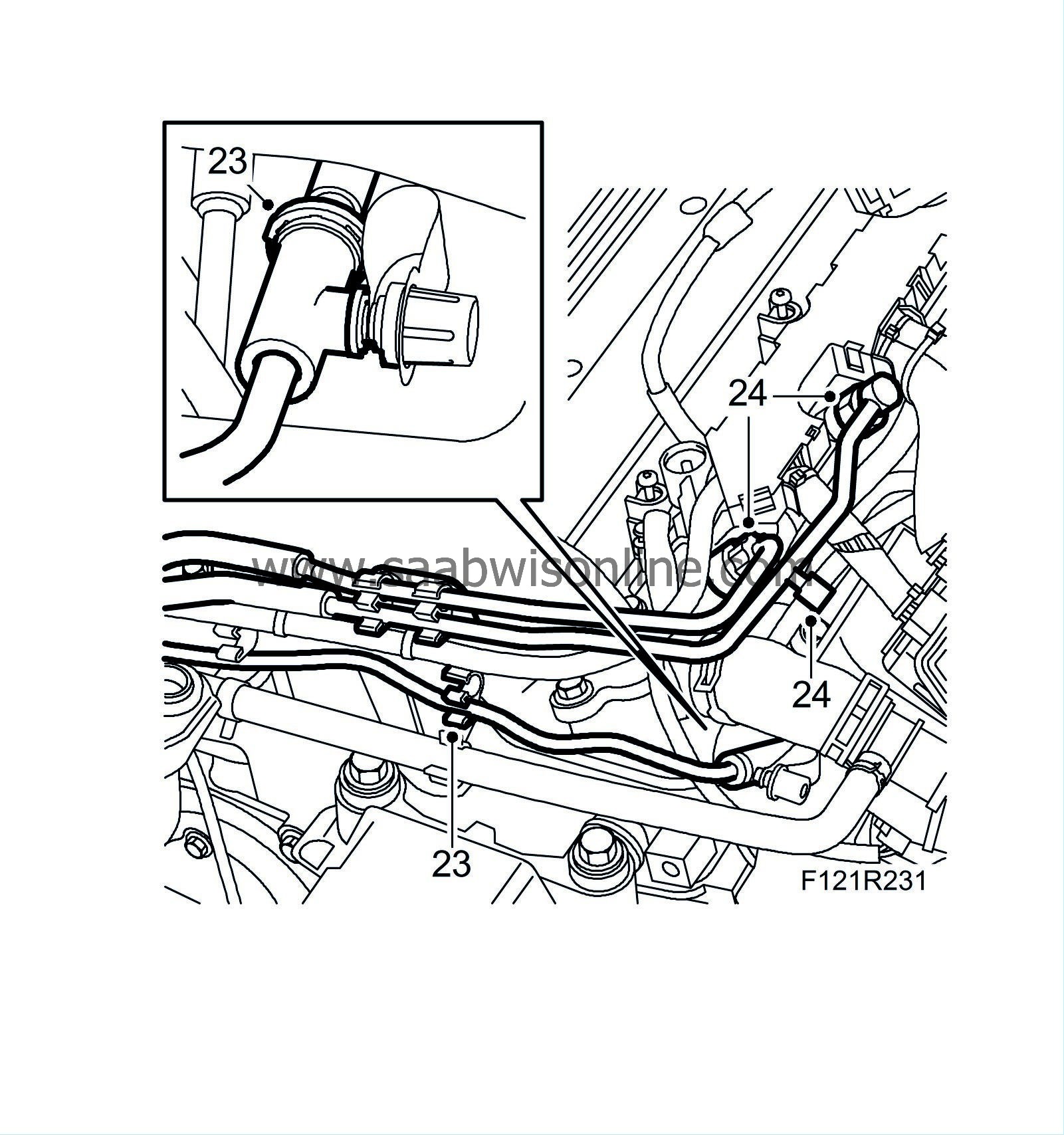

| 23. |

Connect the quick-release coupling on the ventilation line and press the fuel lines and ventilation lines into the clips on the camshaft cover.

|

|

| 24. |

Remove the plugs and connect both fuel lines to the fuel rail while gripping the lower nut. Use new seals.

|

|

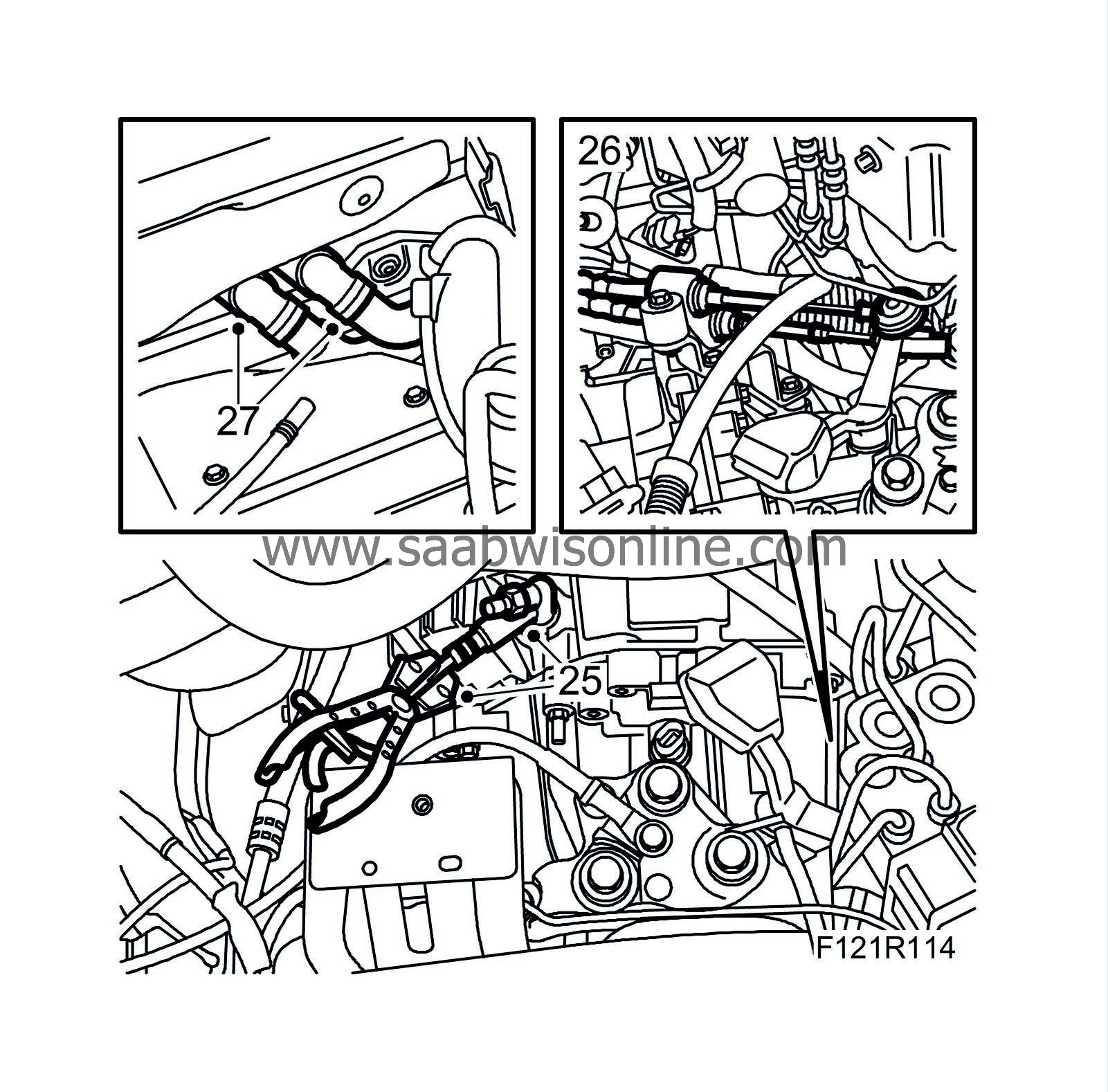

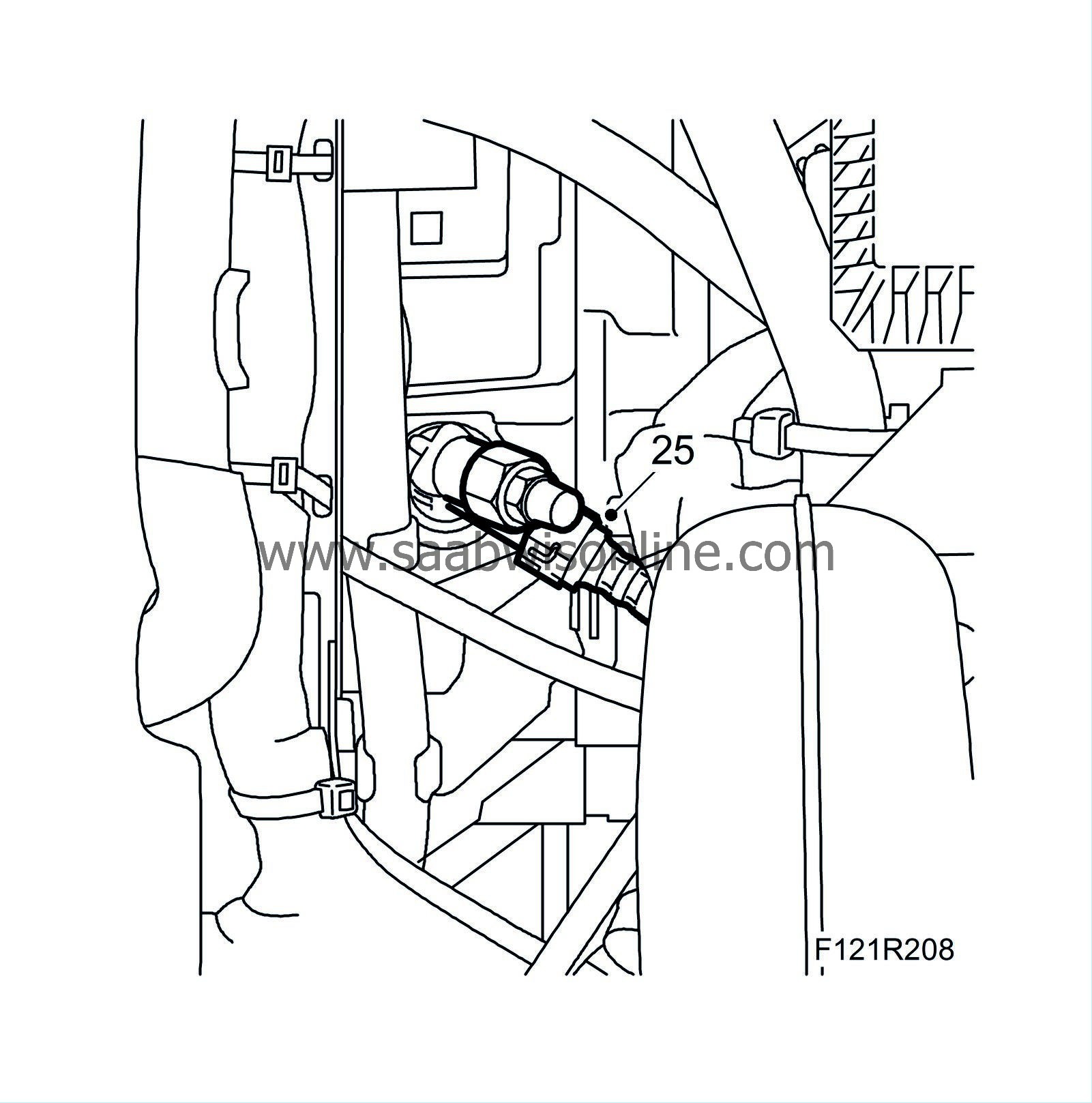

| 25. |

Connect the quick-release coupling to the clutch slave cylinder. Remove

30 07 739 Hose pinch-off pliers

from the clutch hose. The connection must be mounted at the correct angle as illustrated. Make sure the connection is secure.

|

|

| 26. |

Attach the gear cables to the gearbox.

|

|

| 27. |

Connect the coolant hose quick-release couplings. Change O-rings if necessary.

|

|

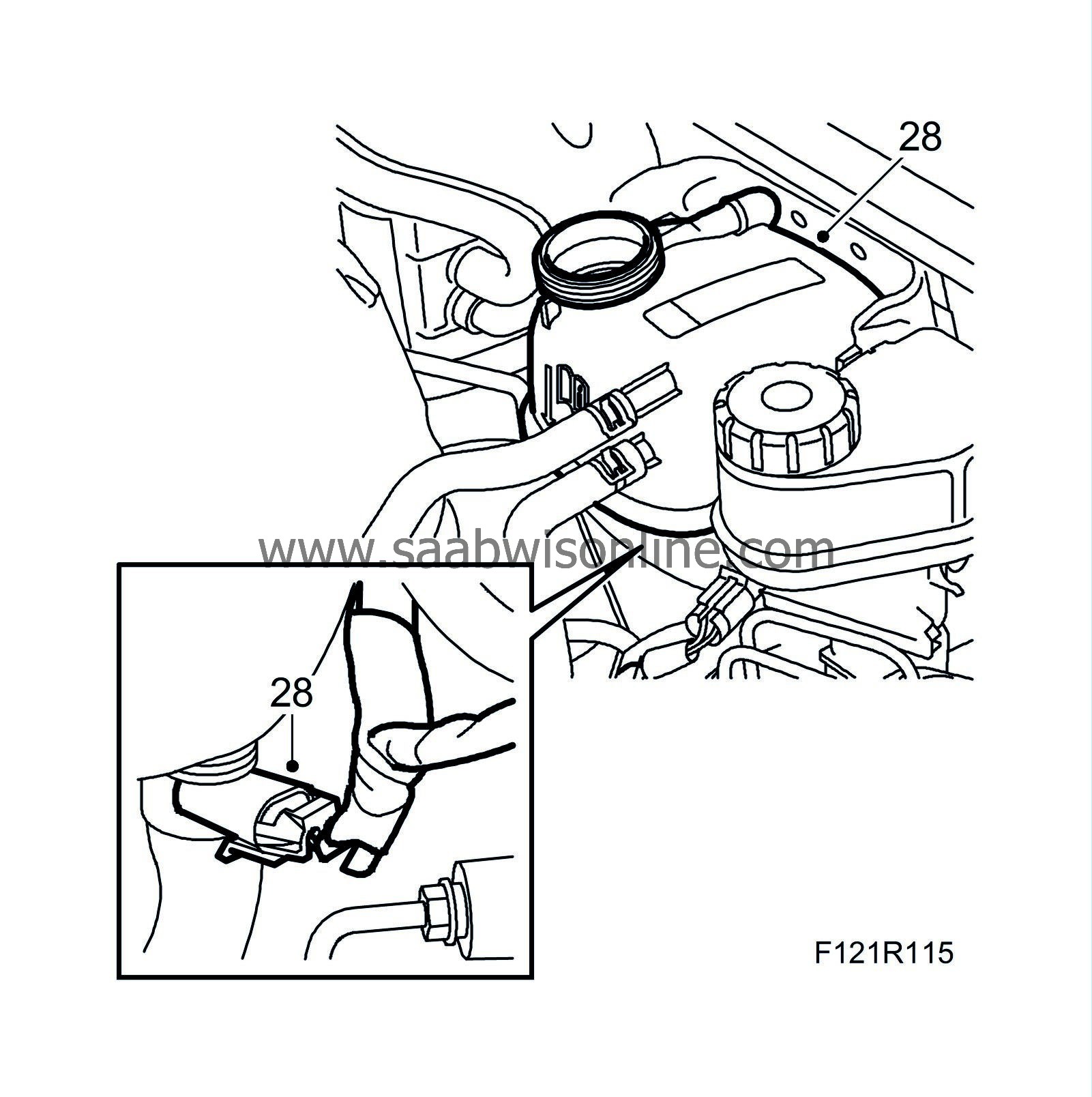

| 28. |

Fit the expansion tank on the body. Plug in the coolant level sensor connector.

|

|

| 29. |

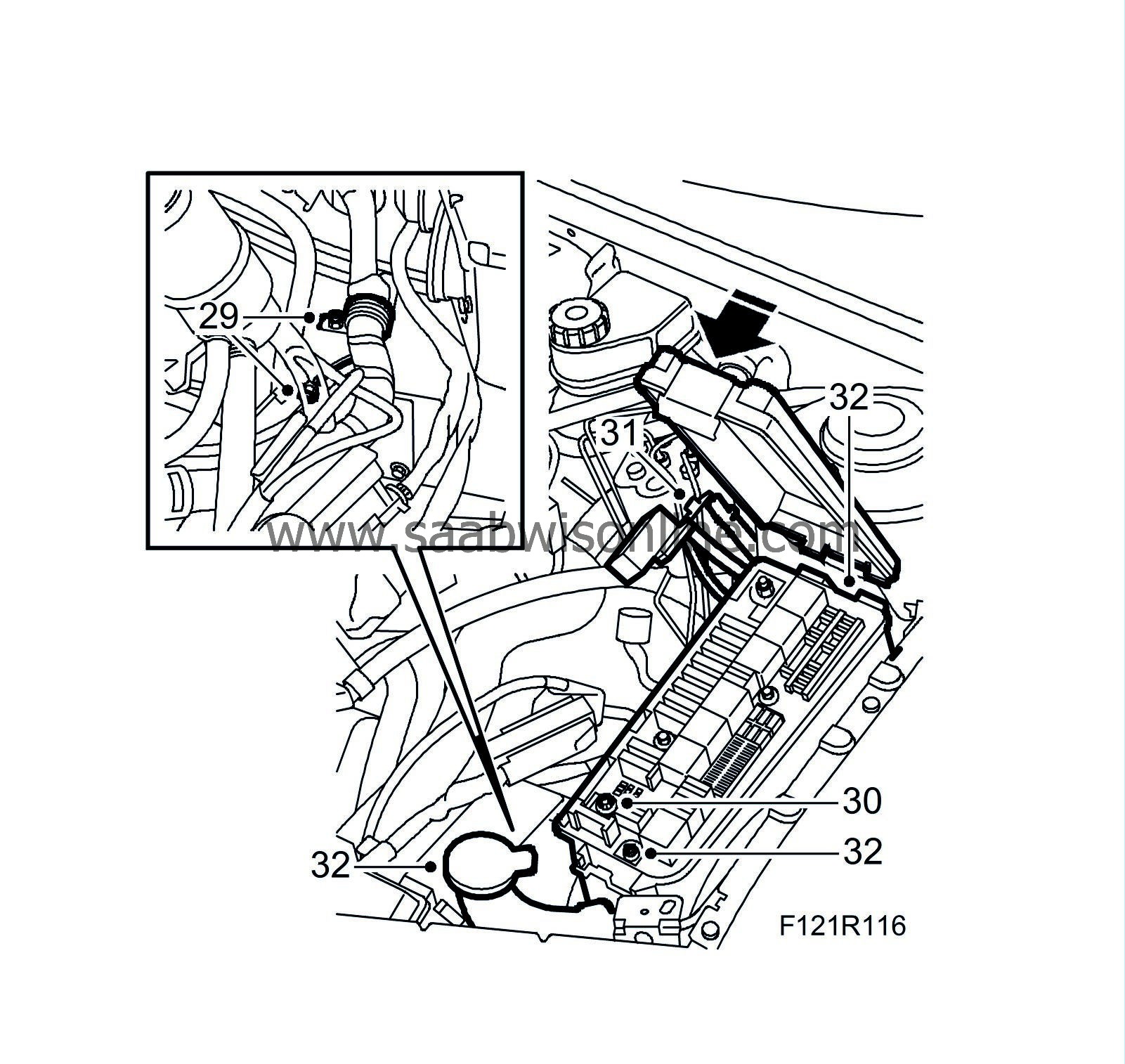

Attach the ground cables and the clamp for the engine harness to the body.

|

|

| 30. |

Fit the retaining bolt for the engine harness connector in the main fuse box.

|

|

| 31. |

Fit the positive cable to the battery's positive terminal.

|

|

| 32. |

Fit the two retaining screws for the main fuse box and the main fuse box cover. Fit the windscreen washer filler pipe.

|

|

| 33. |

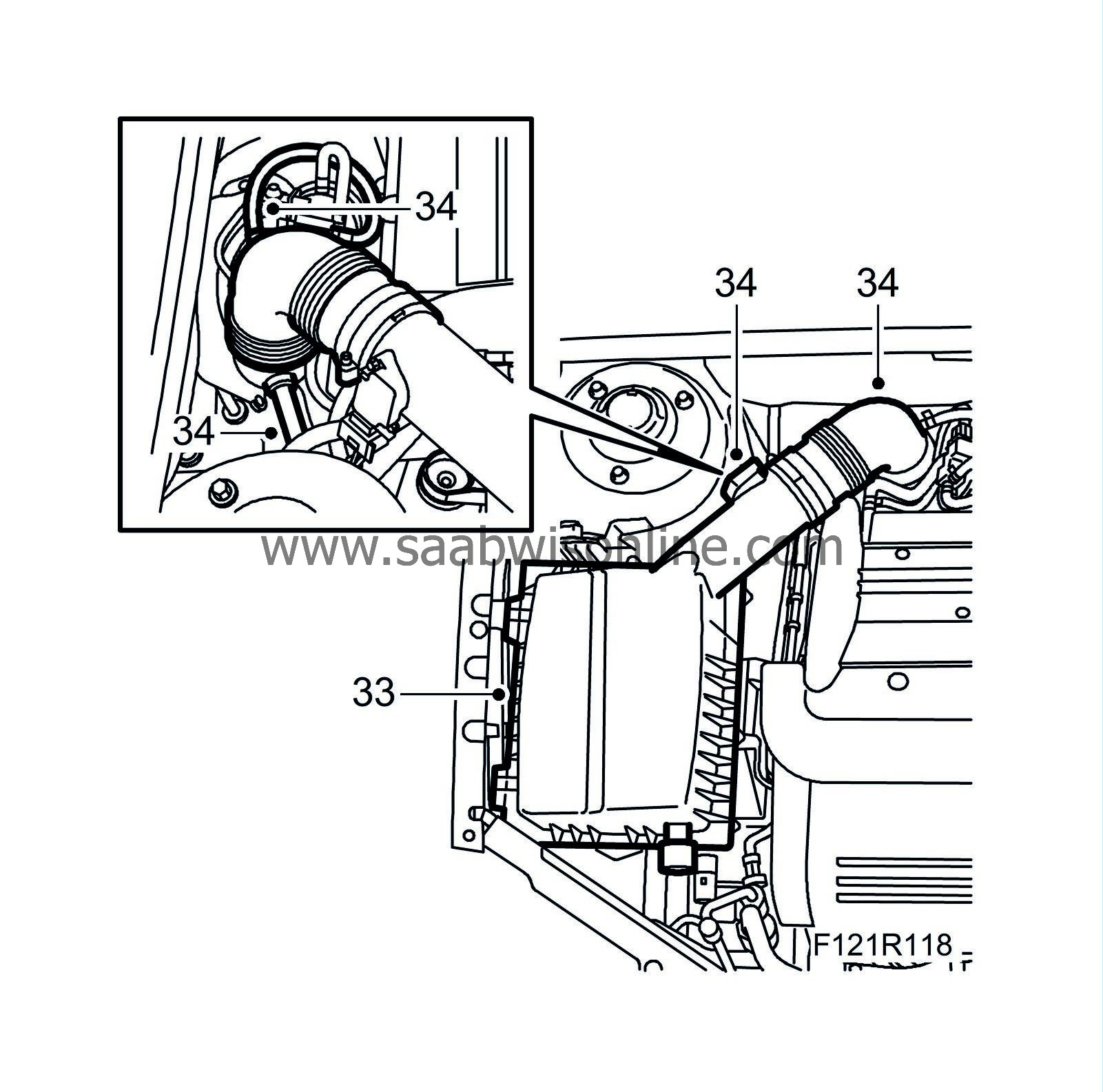

Fit the air filter housing and connect the intake hose. Fit the air filter and the air filter housing cover.

|

||||||||||

| 34. |

Plug in the mass air flow sensor connector. Remove the plug, fit the turbo inlet pipe and connect the hoses to the inlet pipe.

|

|

| 35. |

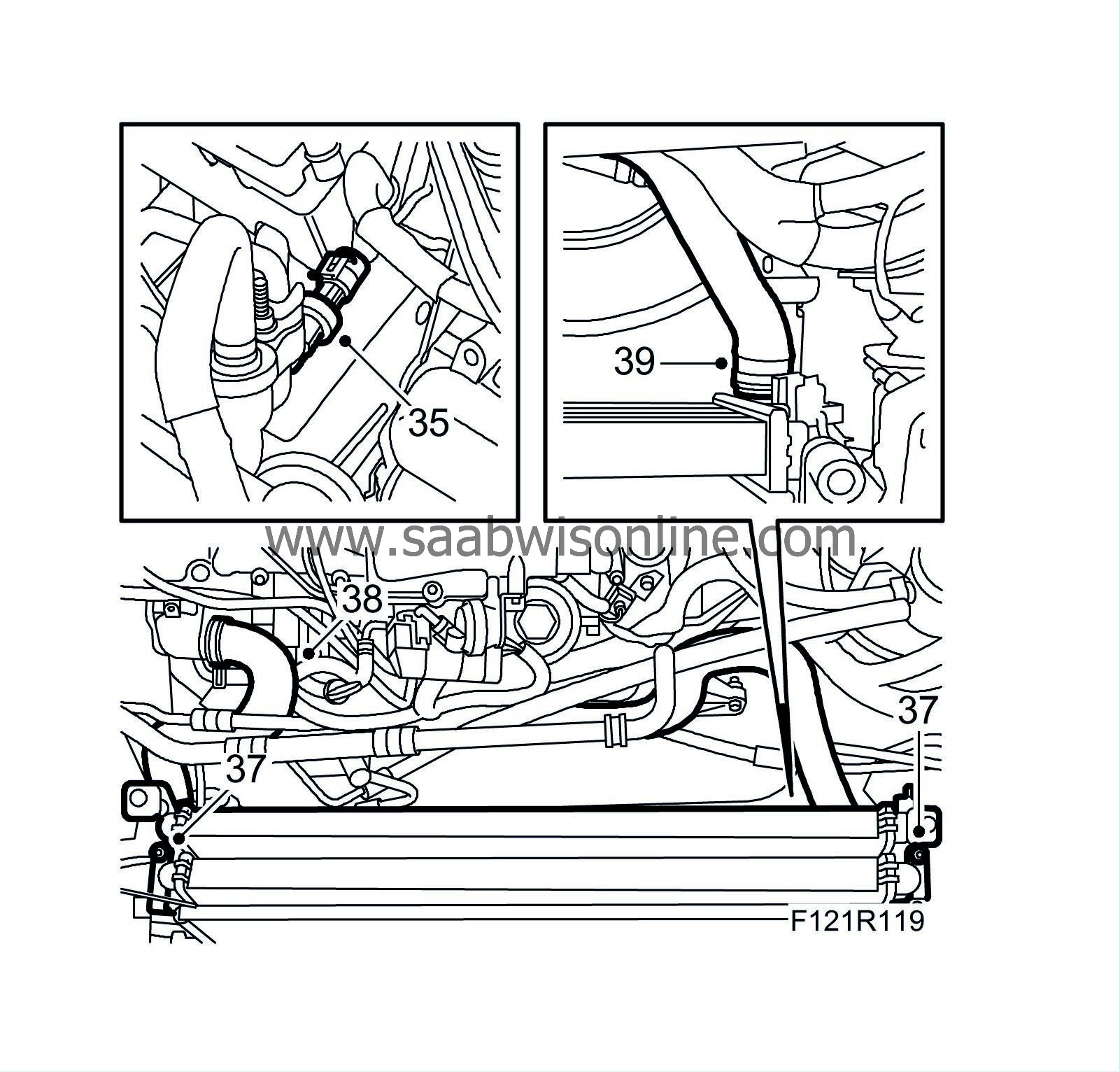

Plug in the connector for the A/C pressure sensor.

|

|

| 36. |

Fit the radiator. Cut off the cable ties.

|

|

| 37. |

Make sure the condenser and charge air cooler hooks are positioned correctly and fit the radiator retaining bolts.

|

|

| 38. |

Fit the upper radiator hose.

|

|

| 39. |

Fit the lower coolant hose.

|

|

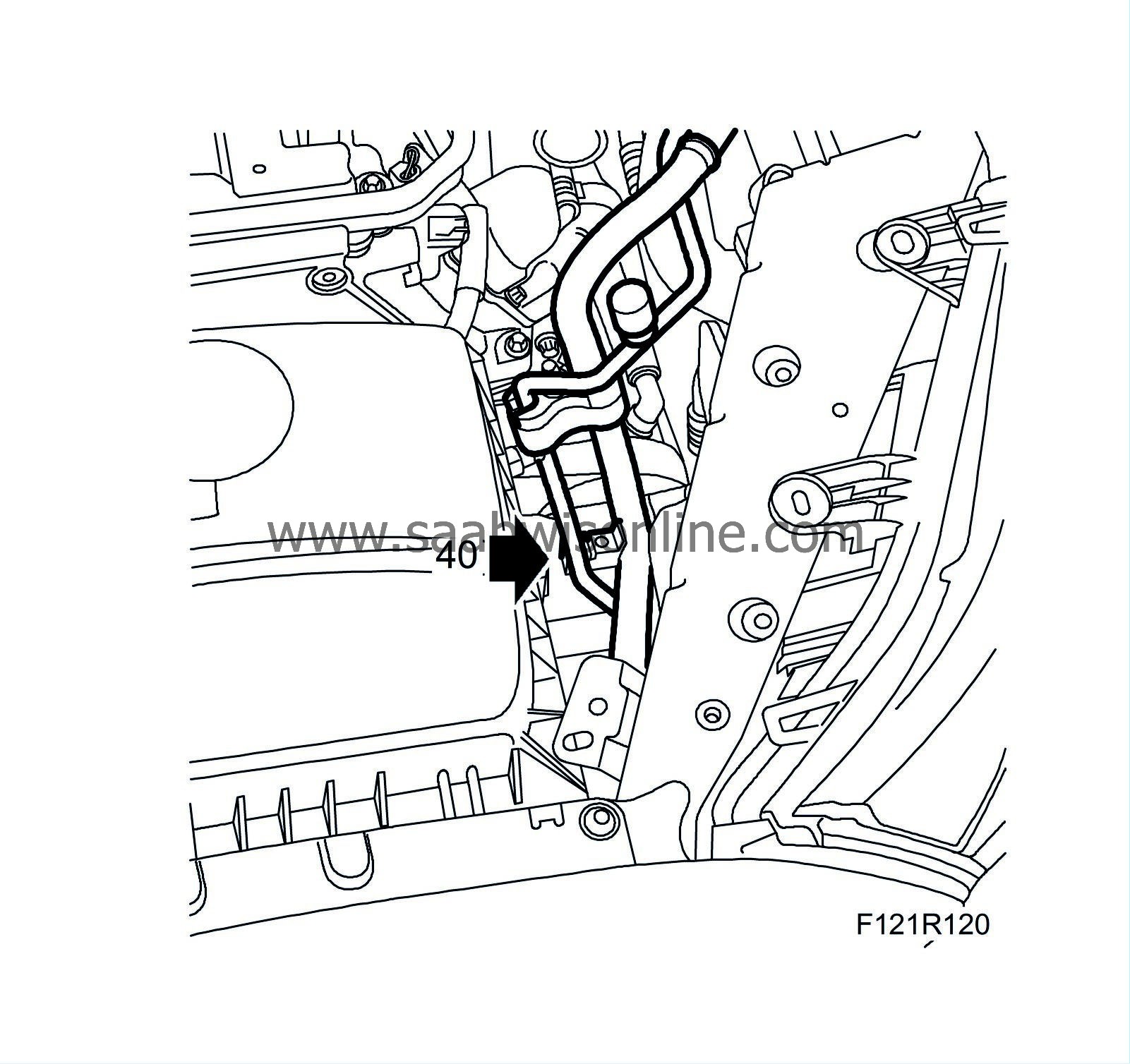

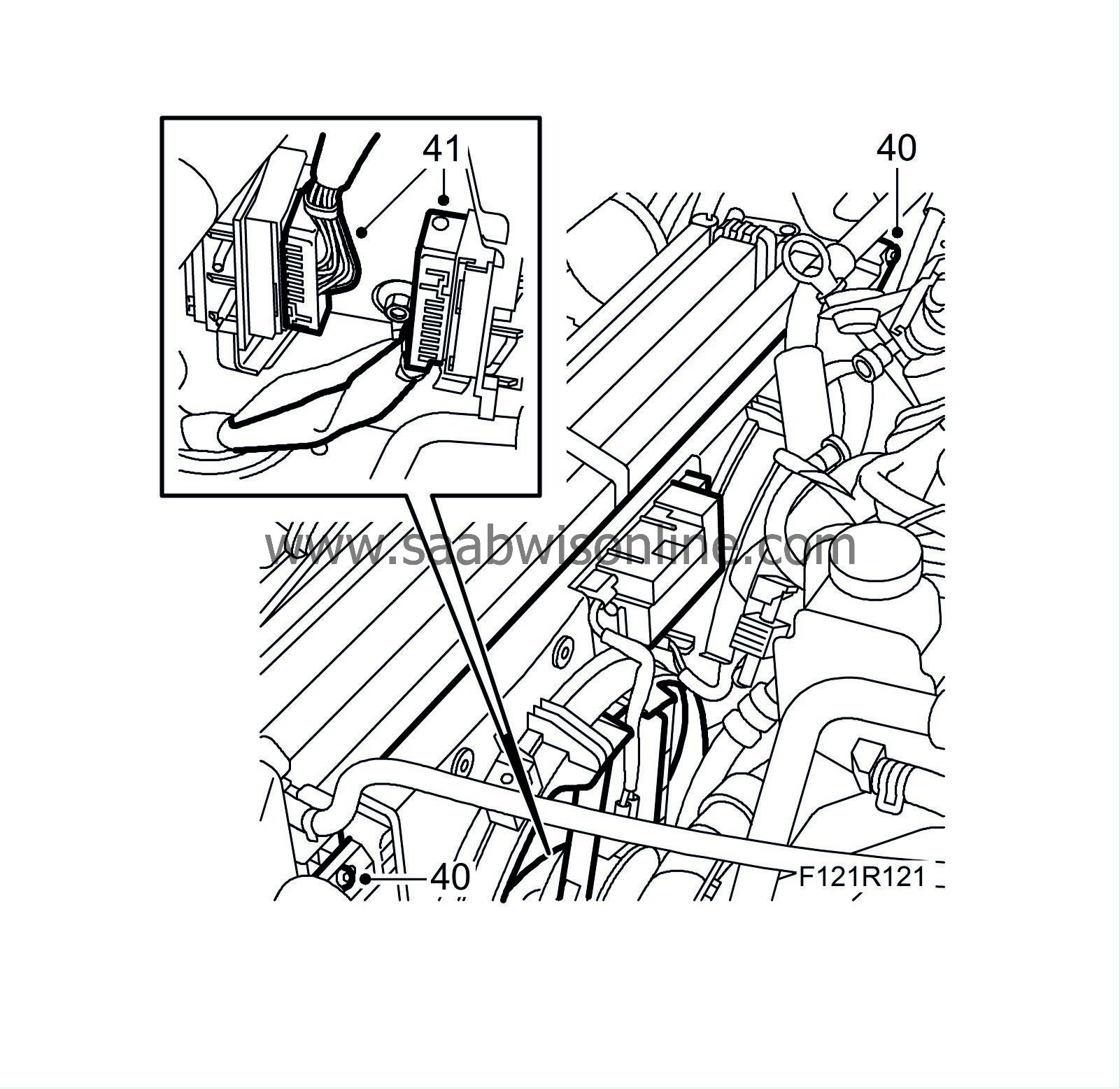

| 40. |

Fit the fan cowling and press the A/C pipes into the retaining clips on the right structural member.

Aut:

Connect the oil pipes from the automatic transmission to the radiator.

|

|

| 41. |

Plug in both connectors on the left structural member.

|

|

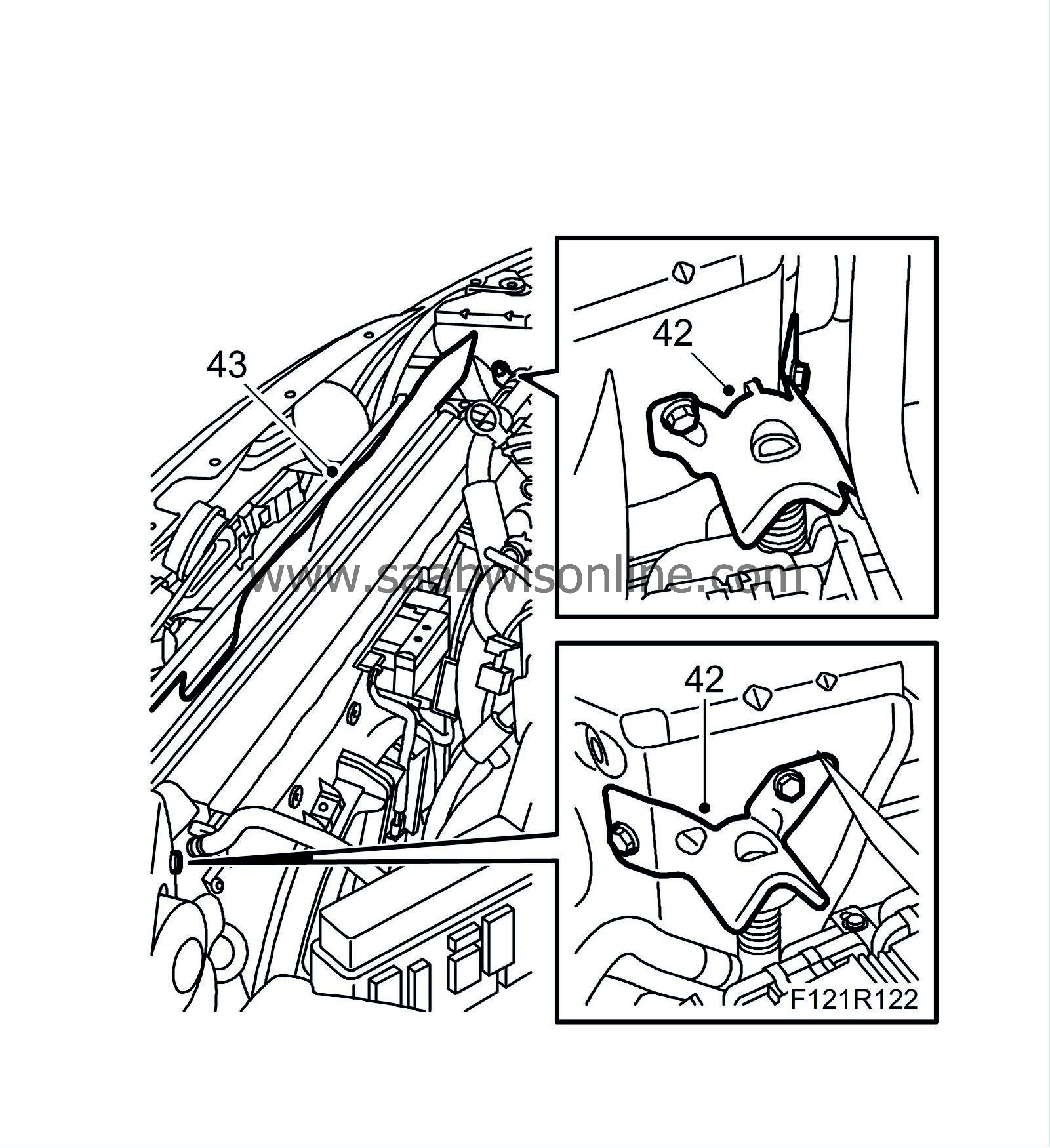

| 42. |

Fit the upper radiator brackets to the body.

|

|

| 43. |

Fit the seal over the radiator core.

|

|

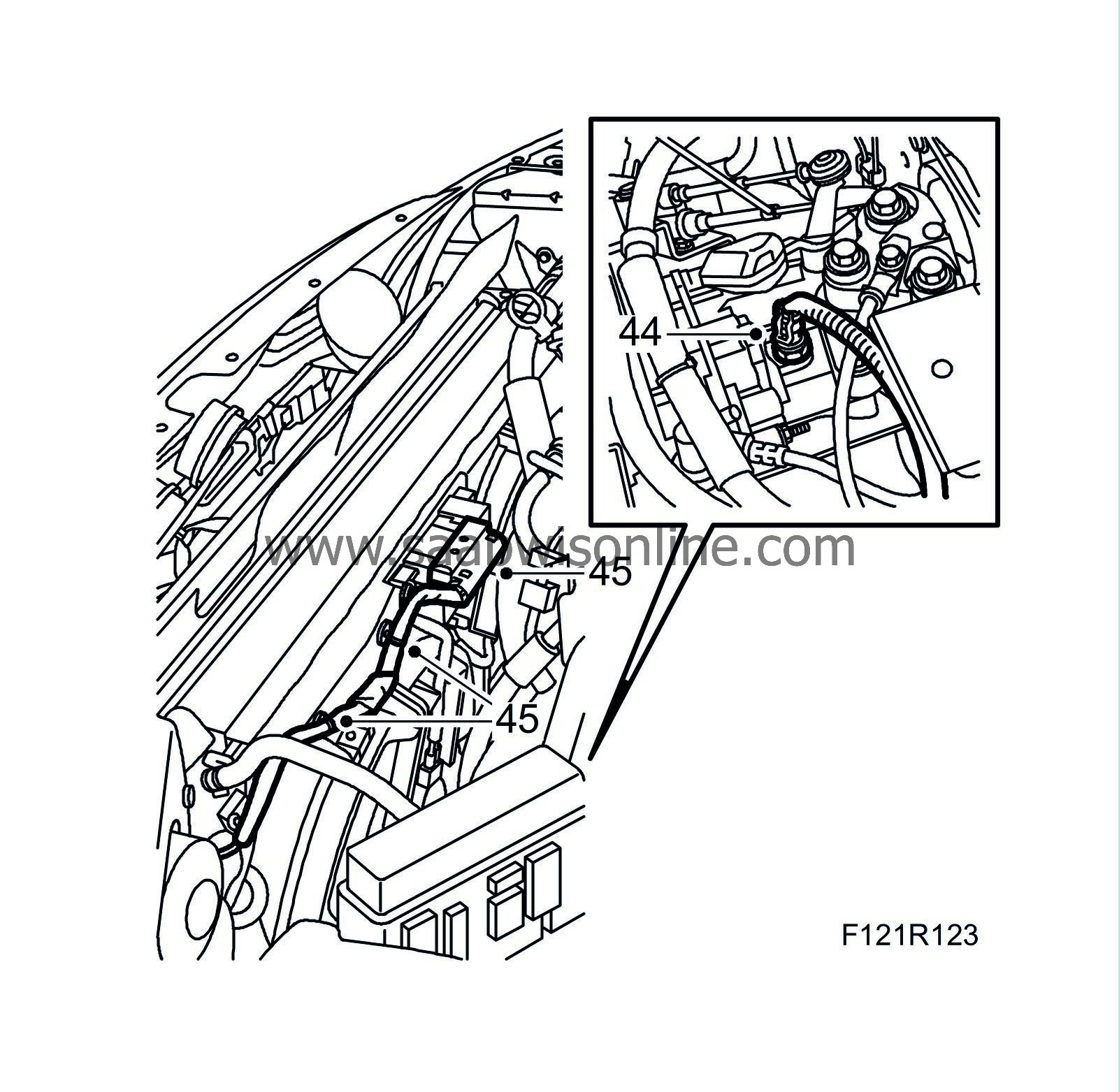

| 44. |

Plug in the reversing light switch connector.

|

|

| 45. |

Plug in the connector and attach the clip securing the cables on the fan cowling.

|

|

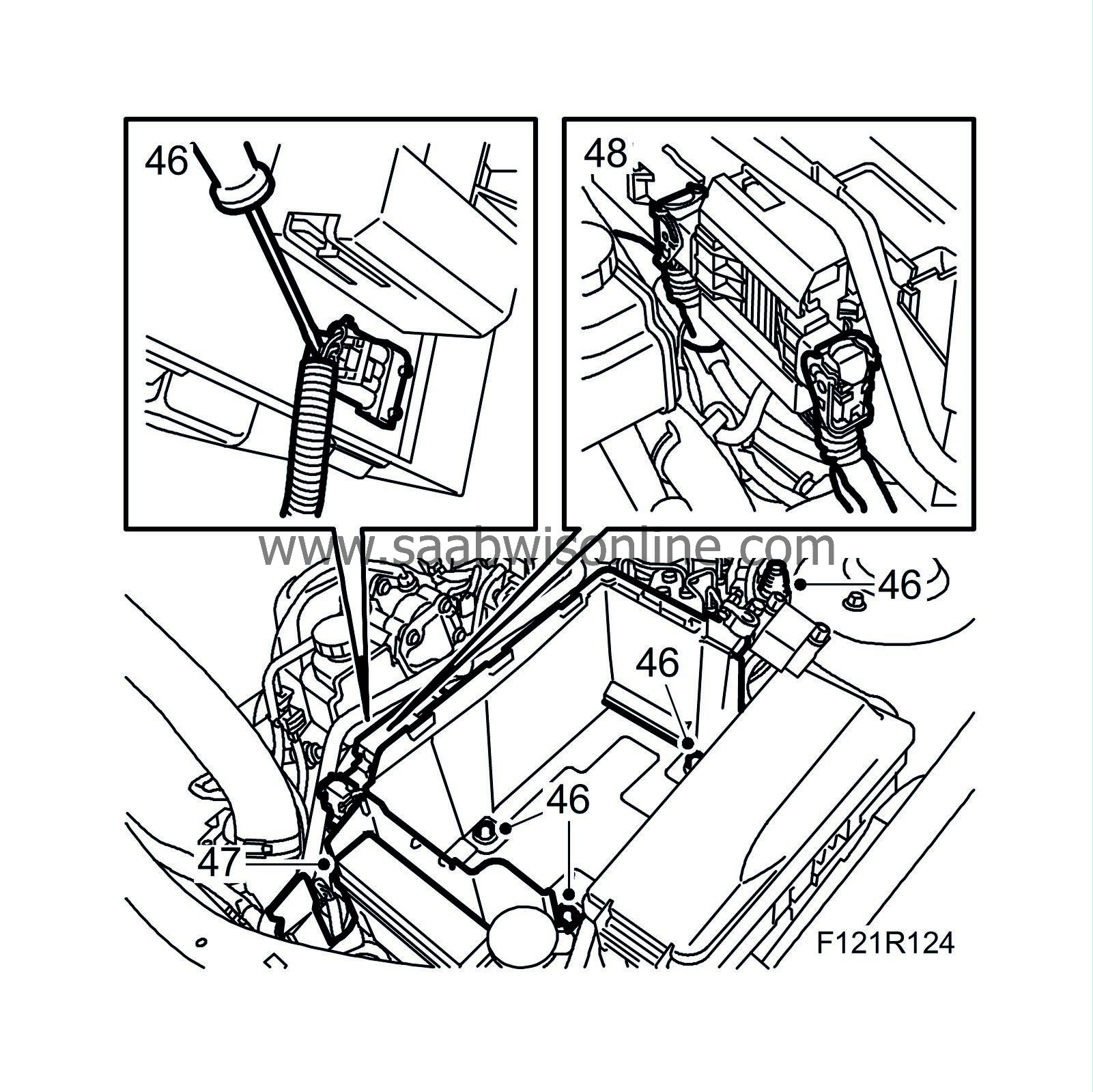

| 46. |

Fit the battery tray and the cable clip. Plug in the bonnet switch connector.

|

|

| 47. |

Fit the main fuse box in front of the battery tray. Plug in the connector under the control module.

|

|

| 48. |

Aut:

Fit the cover with the TCM. Plug in the connector to the control module.

|

|

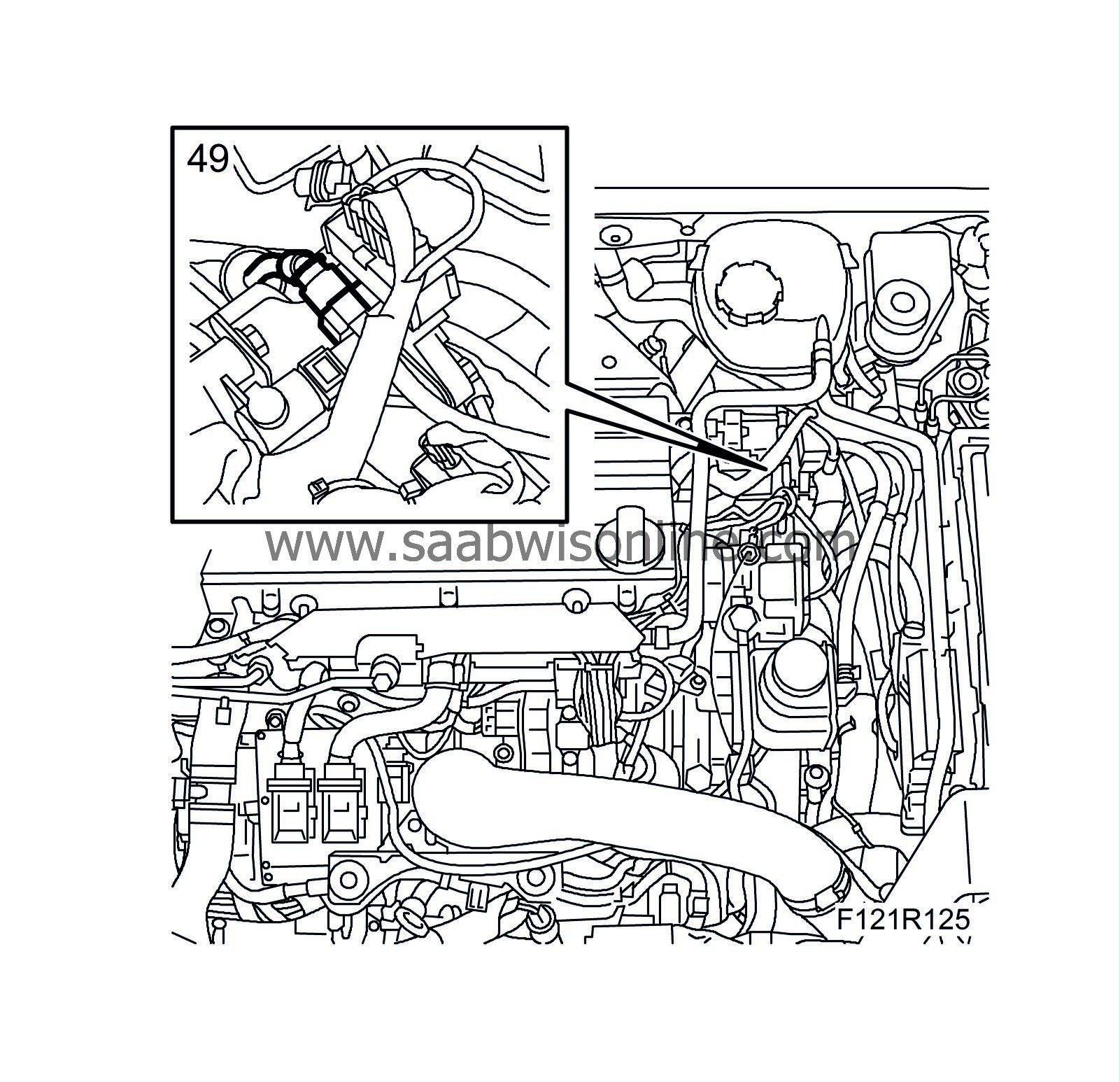

| 49. |

Connect the vacuum hose quick-release coupling to the vacuum pump.

|

|

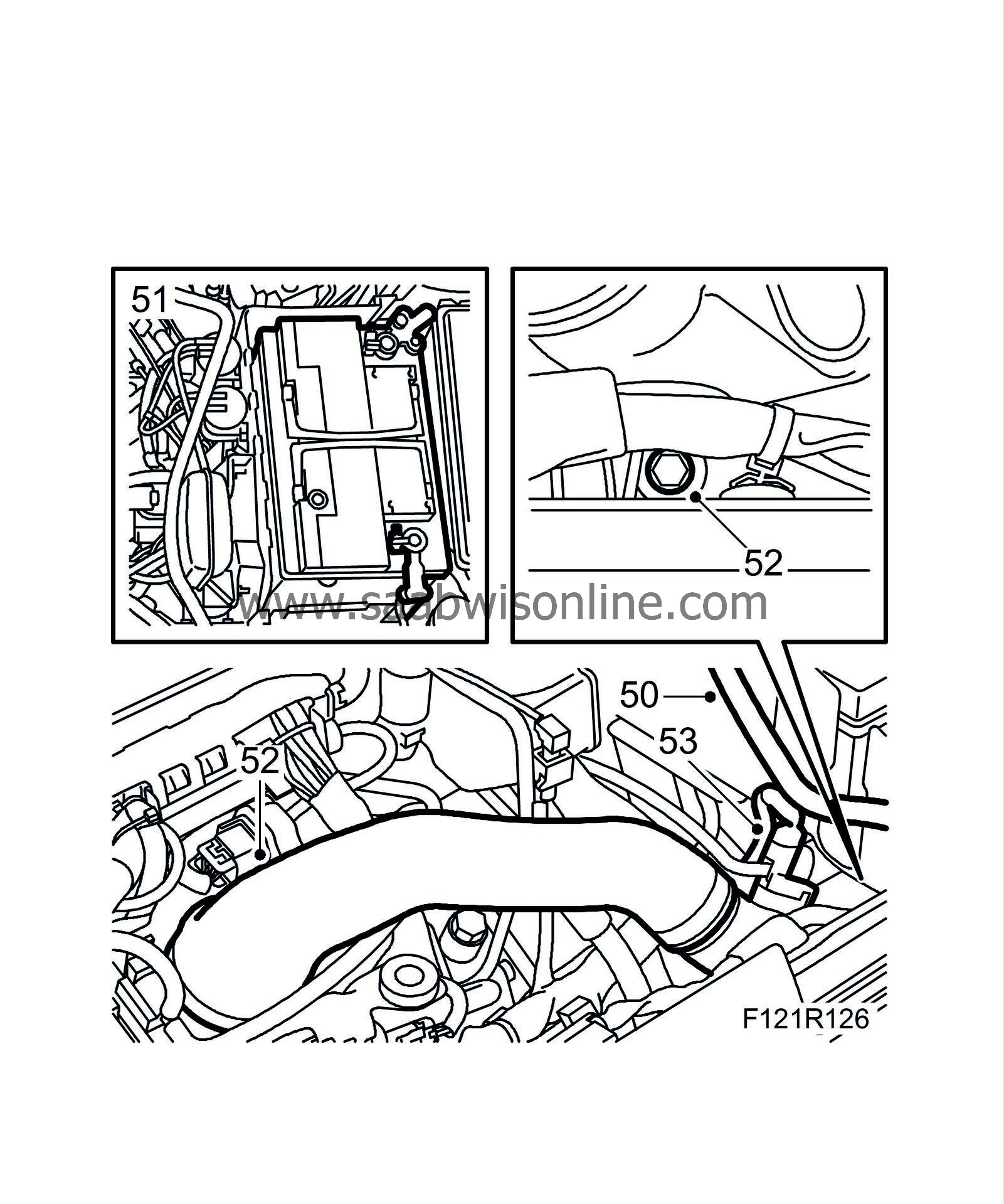

| 50. |

Connect the ventilation hose to the radiator.

|

|

| 51. |

Fit the battery.

|

|

| 52. |

Fit the charge air hose to the throttle body and the upper charge air pipe bracket on the fan cowling.

|

|

| 53. |

Connect the hose to the bypass valve and the connector to the pressure/temperature sensor.

|

|

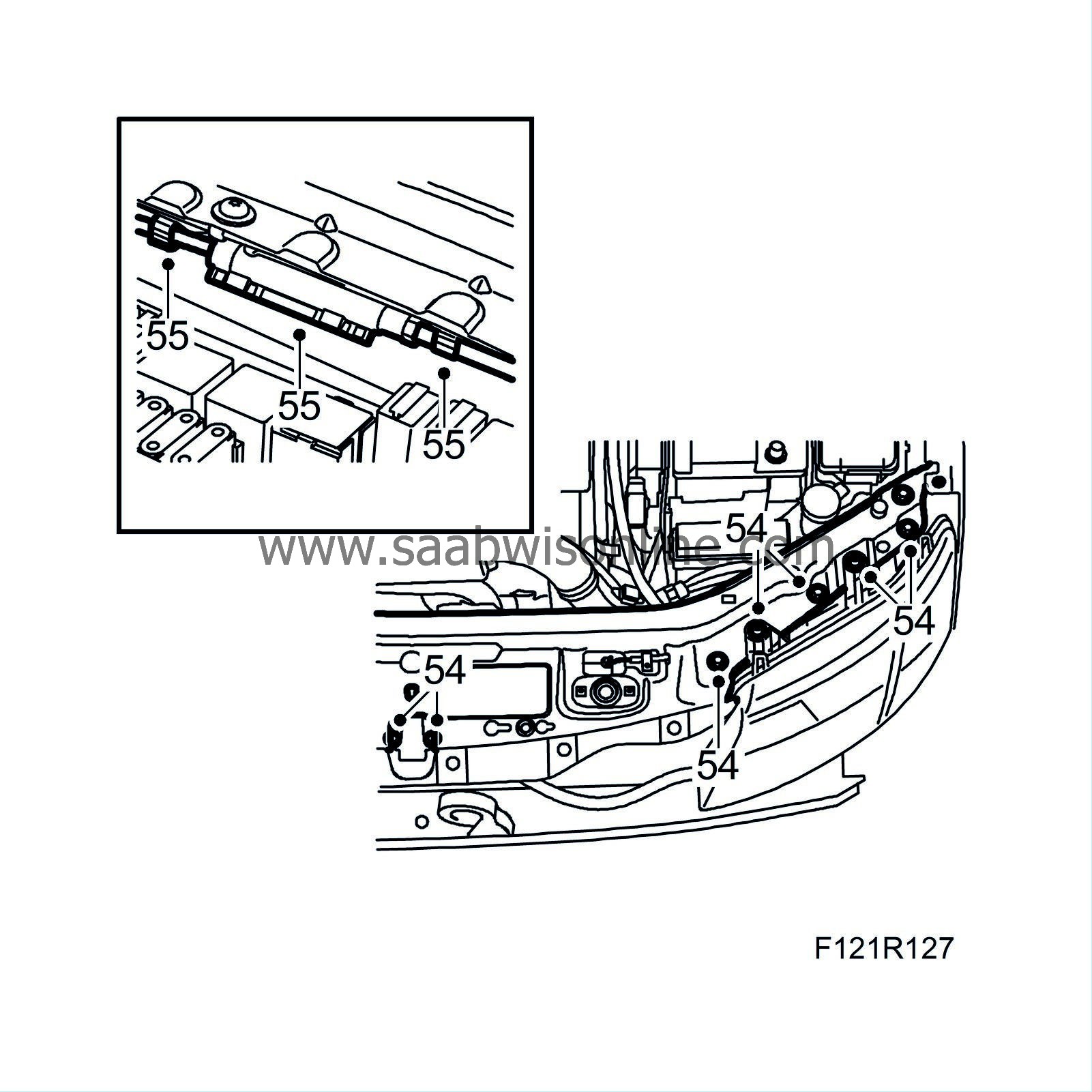

| 54. |

Fit the upper radiator crossmember

|

|

| 55. |

Connect the bonnet cable quick-release coupling and secure it to the body with new clips.

|

|

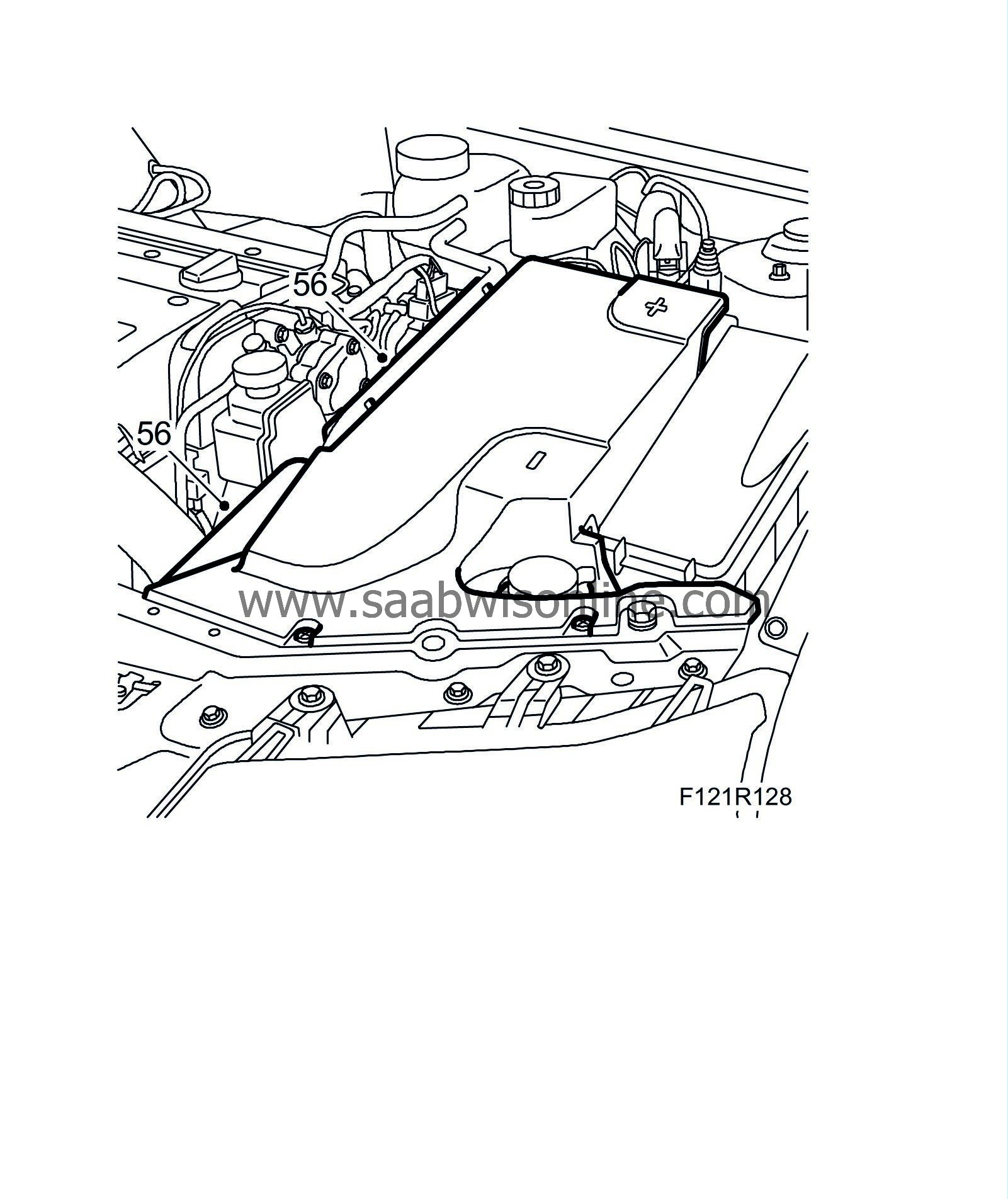

| 56. |

Fit the battery cover and the battery cooler pipe.

|

|

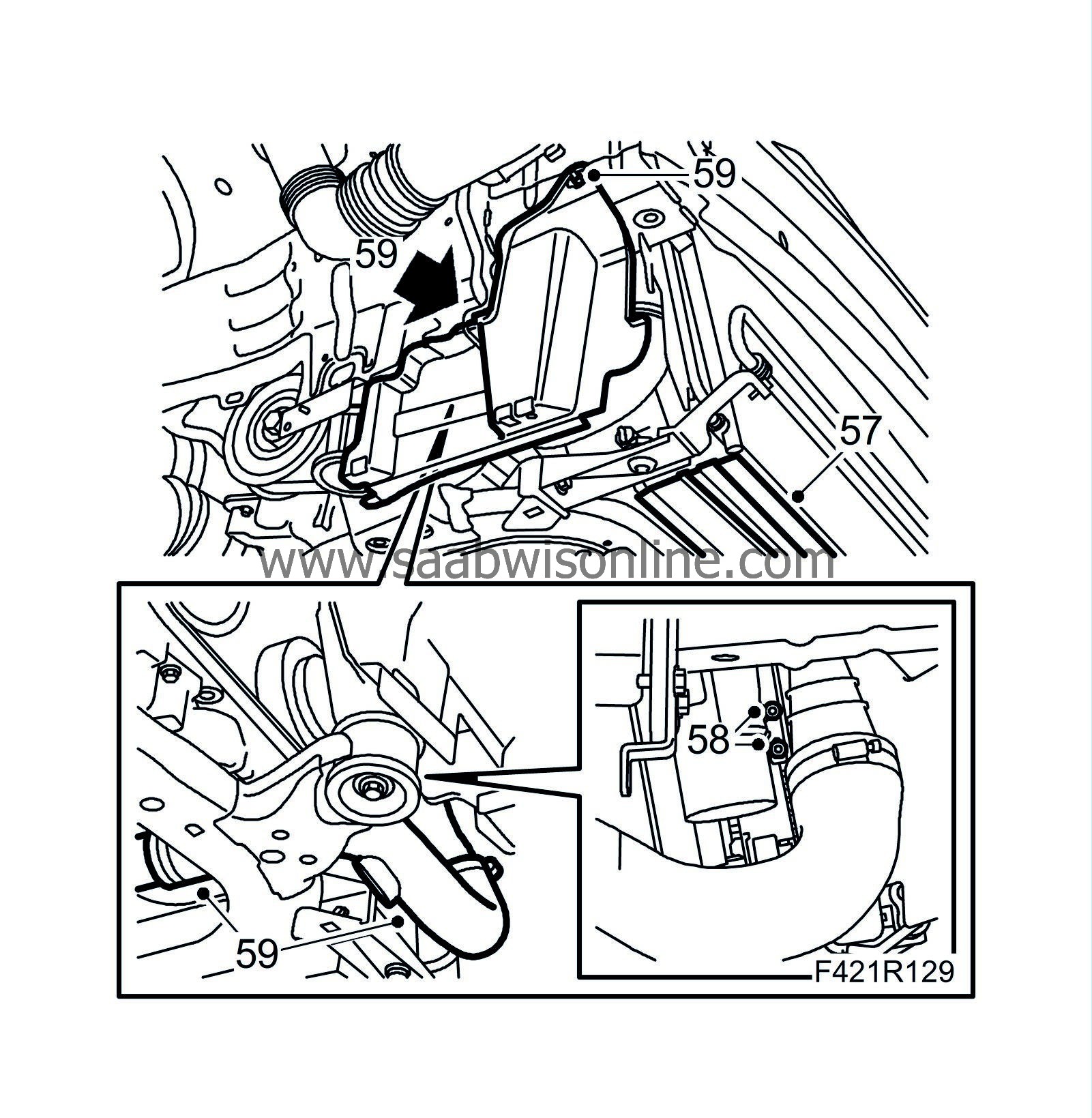

| 57. |

Raise the car and fit the lower seal between the charge air cooler and the radiator.

|

|

| 58. |

Fit the dryer filter bolts to the radiator.

|

|

| 59. |

Fit the hose between the charge air cooler and the charge air pipe and fit the cover on the right-hand side.

|

|

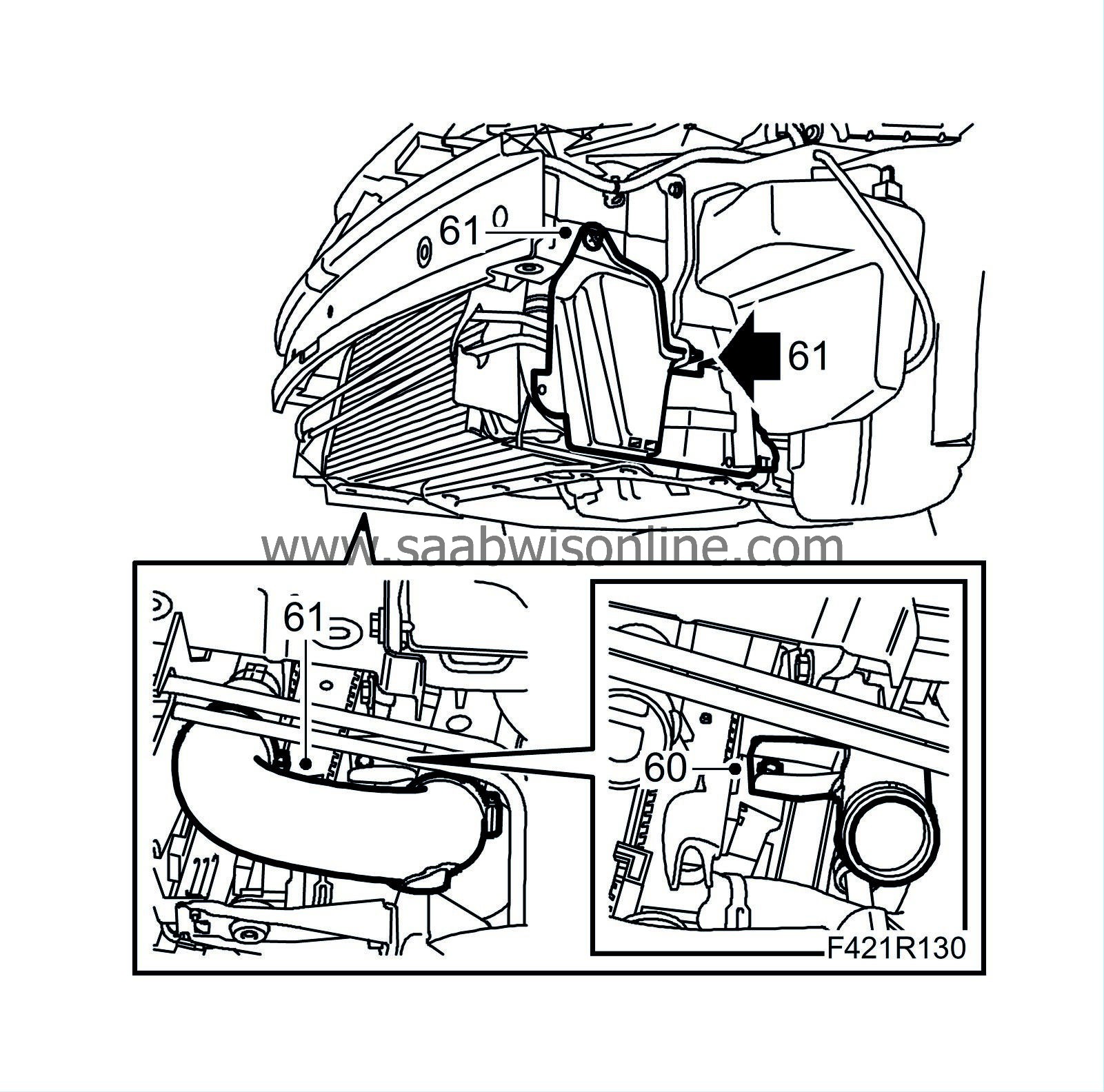

| 60. |

Fit the charge air pipe lower bracket on the fan cowling on the left-hand side.

|

|

| 61. |

Fit the charge air hose between the charge air pipe and the charge air cooler and fit the cover on the left-hand side.

|

|

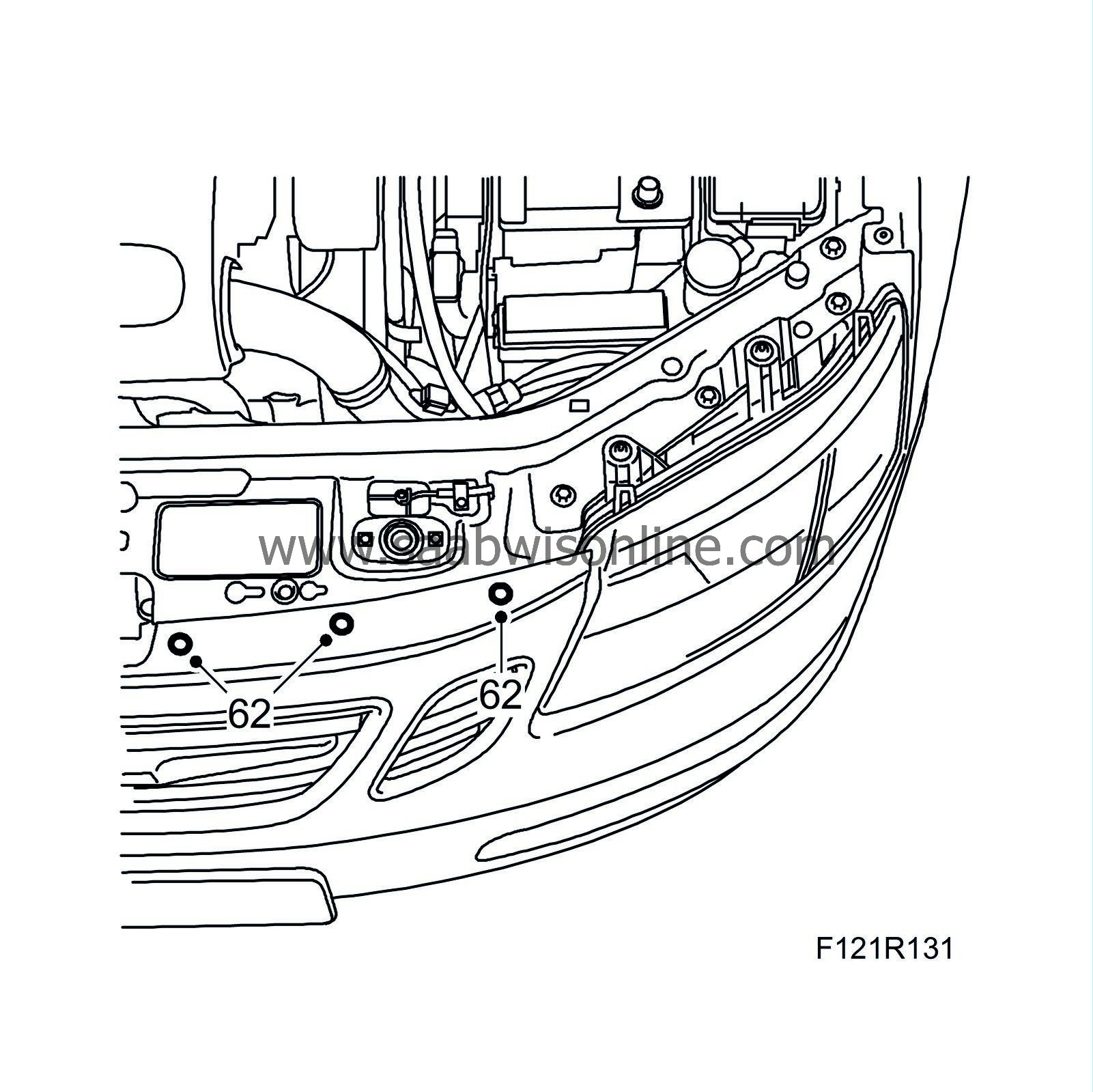

| 62. |

Lower the car slightly and fit the bumper.

|

|

| 63. |

Connect the hose to the headlamp washers.

|

|

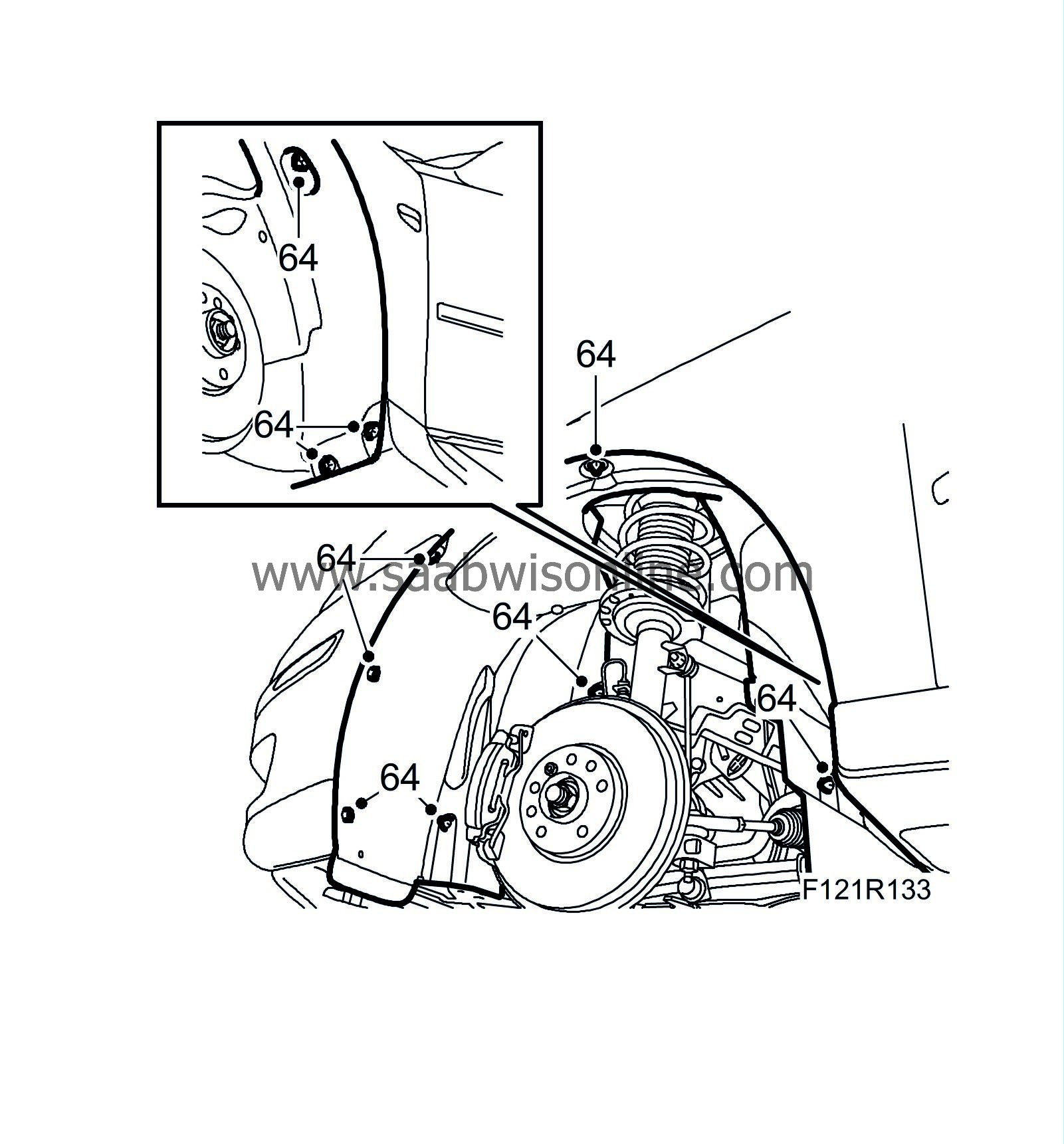

| 64. |

Fit the cover on the gearbox and the wing liners in both front wheel housings.

|

|

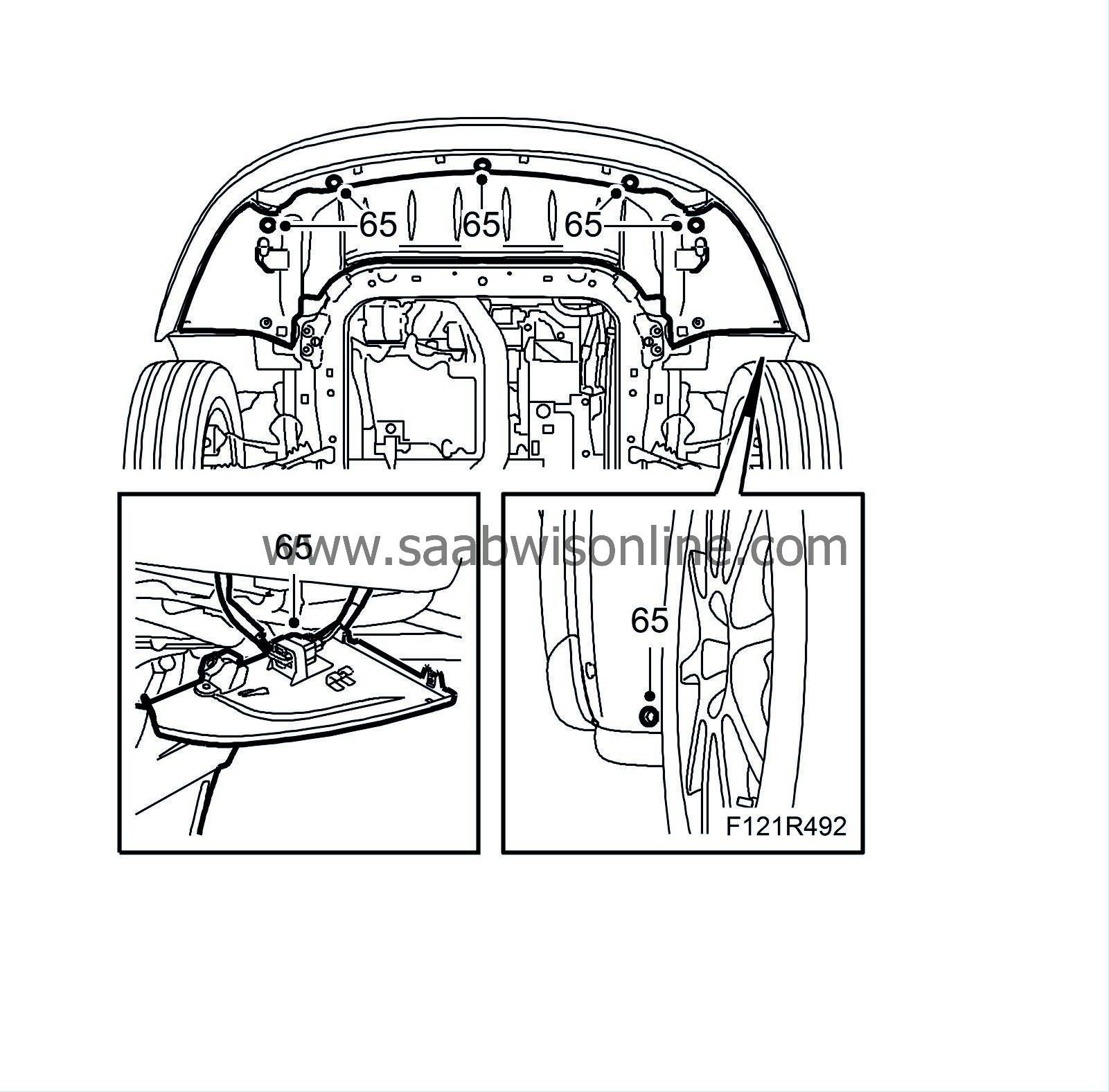

| 65. |

Fit the lower spoiler shield. Plug in and fit the connector.

|

|

| 66. |

Fit the drive shafts and tighten the hub centre nuts.

Tightening torque 230 Nm (170 lbf ft). |

|

| 67. |

Fit the front wheels. See

Wheels.

|

|

| 68. |

Check oil level and top up as necessary. Fill with coolant to approx. 20 mm above the mark on the expansion tank. If a new engine is fitted, follow the instructions given in

Bleeding the cooling system when working on the oil cooler

.

|

|

| 69. |

Top up the washer fluid.

|

|

| 70. |

Bleed the clutch as described under

Bleeding the clutch hydraulic system in situ

.

|

|

| 71. |

Check the level of the automatic transmission fluid.

|

|

| 72. |

Remove the wing covers and restore car electrical functions, see

Procedure after reconnecting the battery

.

|

|

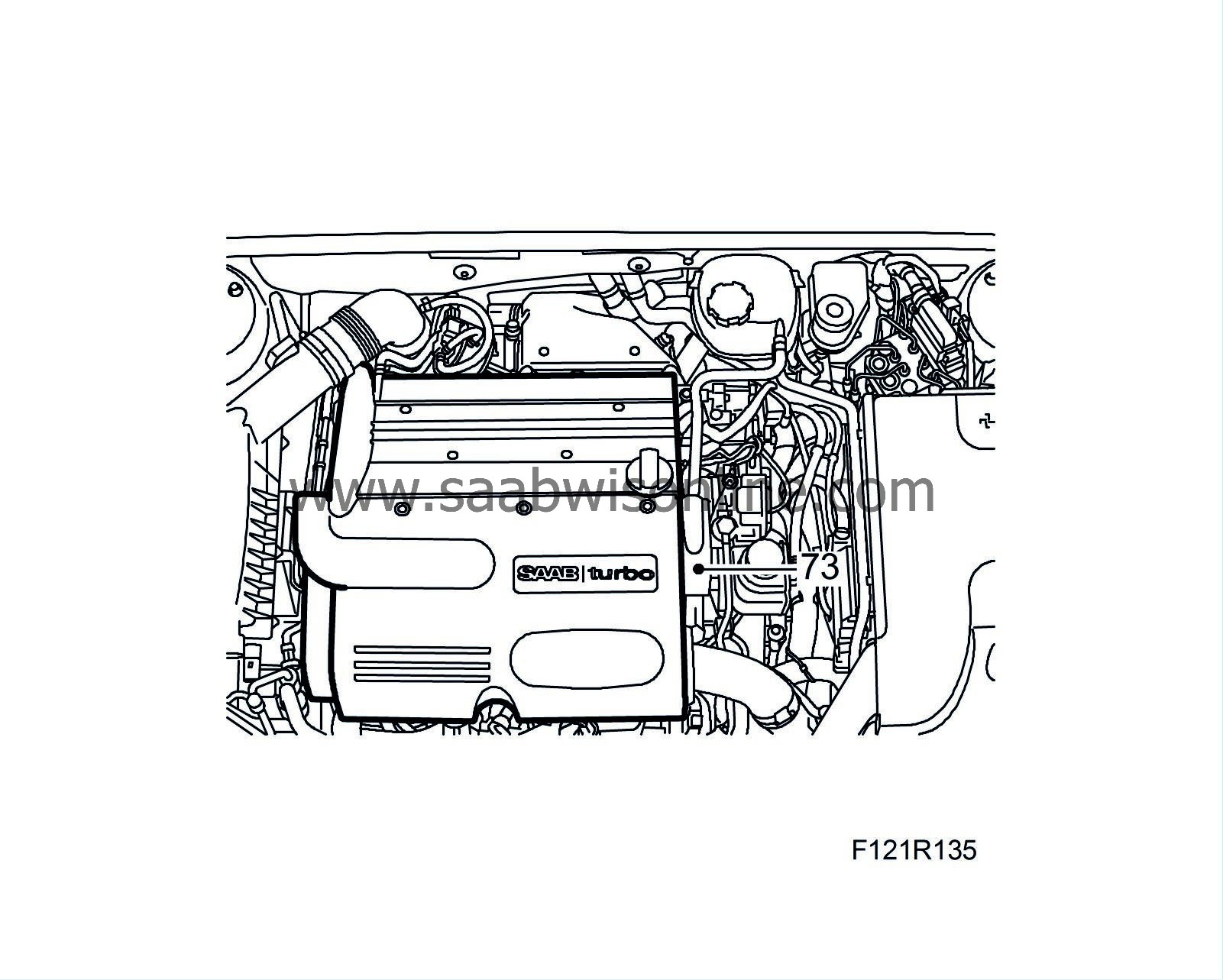

| 73. |

Fit the upper engine cover.

|

|

Warning

Warning