PRE-RELEASE

Front frame member assembly

| Front frame member assembly |

Some weld joints on the car may be MIG brazed, with brazing material of bronze wire. An MIG braze can be identified by its yellow colour. Always replace an MIG braze with another MIG braze.

|

|||||||

| To remove |

| 1. |

Position the car in the alignment jig.

|

|

| 2. |

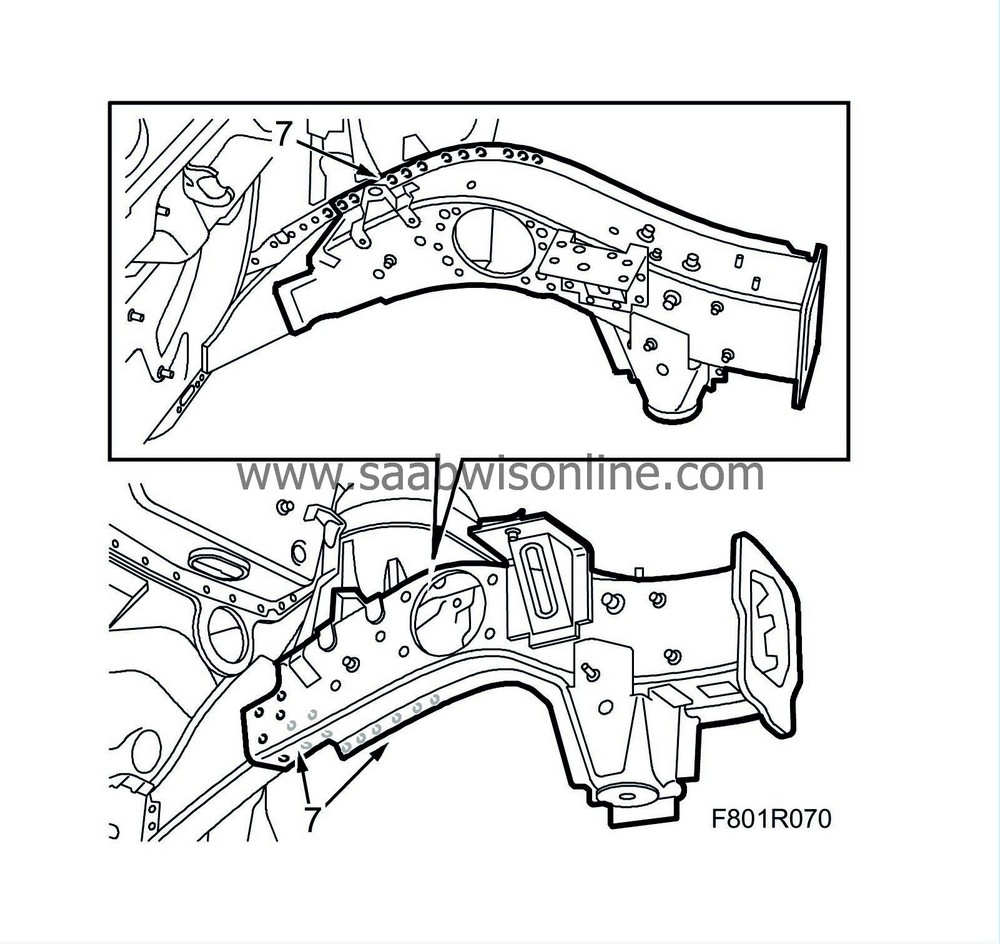

Drill out the spot welds on the wheel housing member.

|

|

| 3. |

Grind away the welds on the wheel housing member.

Some cars : Note that the seam welds are MIG brazed. Tap out the component. |

|||||||||

| 4. |

Remove the bumper member with integrated collision box

and

the headlight frame

.

|

|

| 5. |

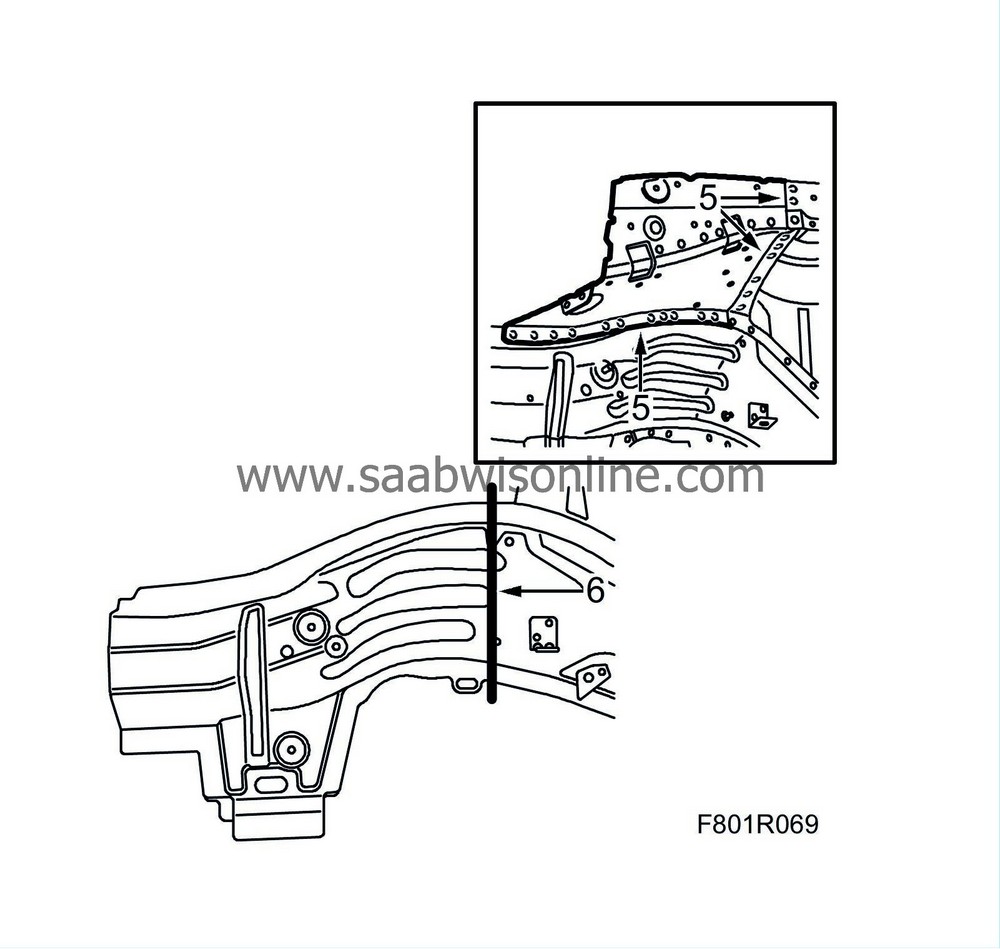

Drill out the spot welds of the front section of the wheel housing. Tap the part out.

|

|

| 6. |

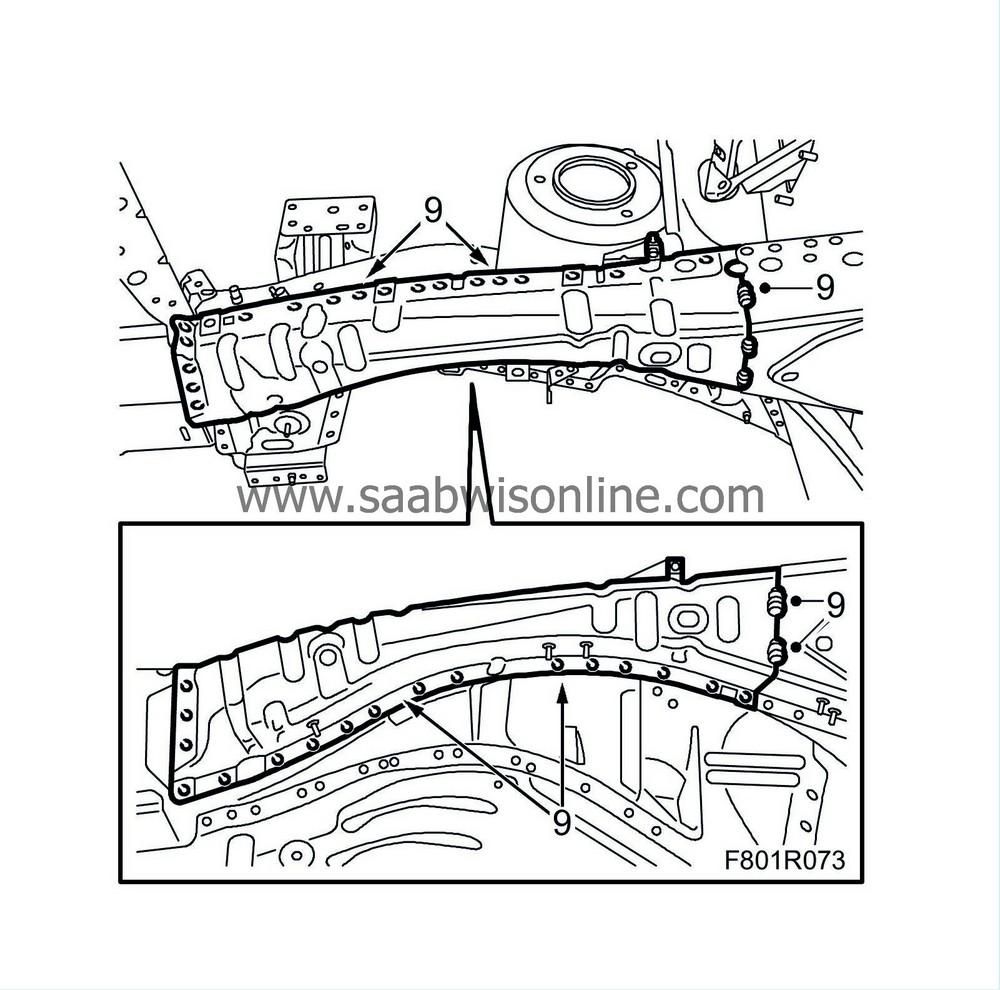

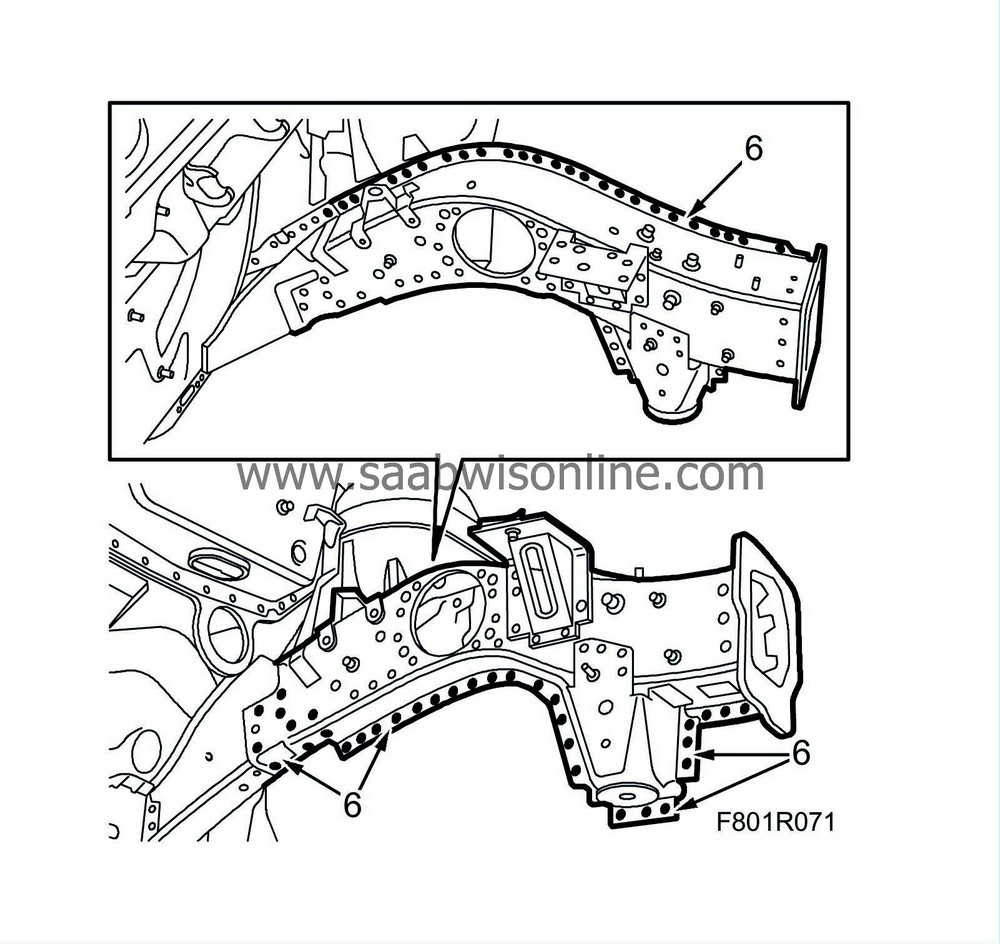

Cut the outer panel as illustrated.

|

|

| 7. |

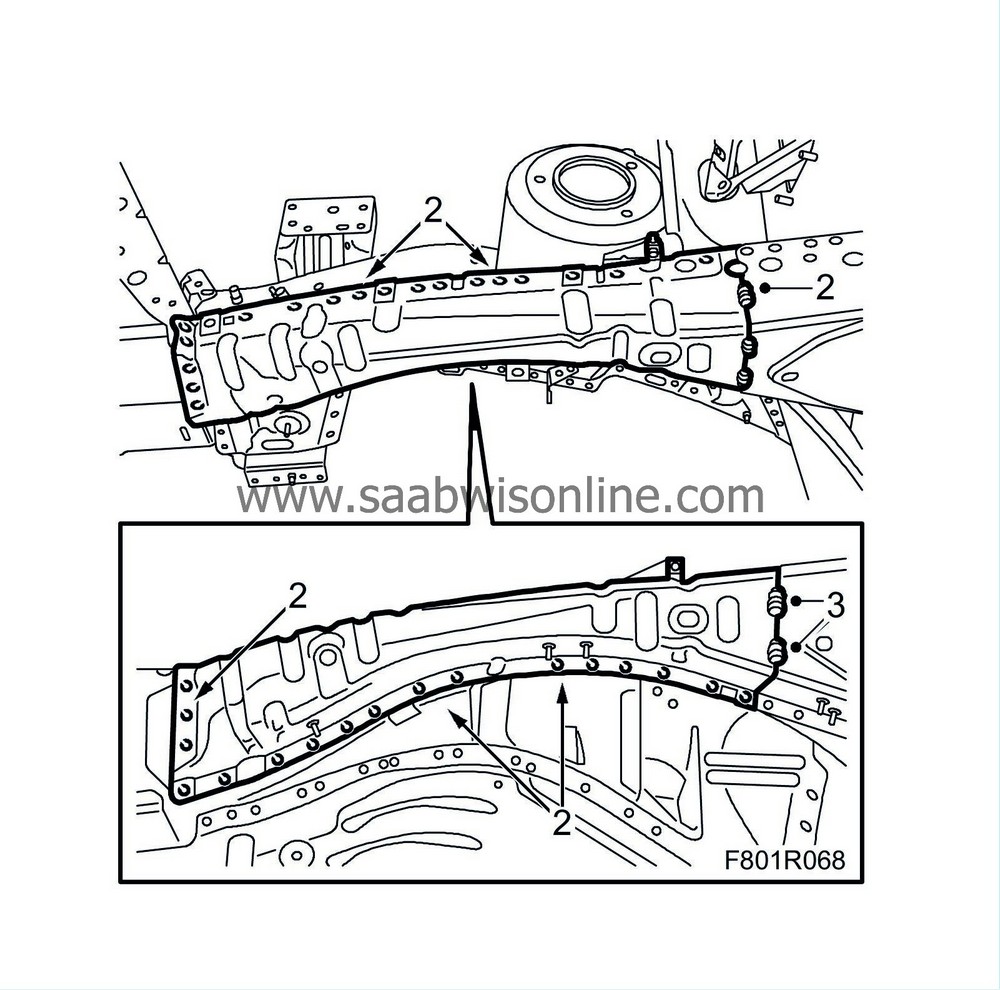

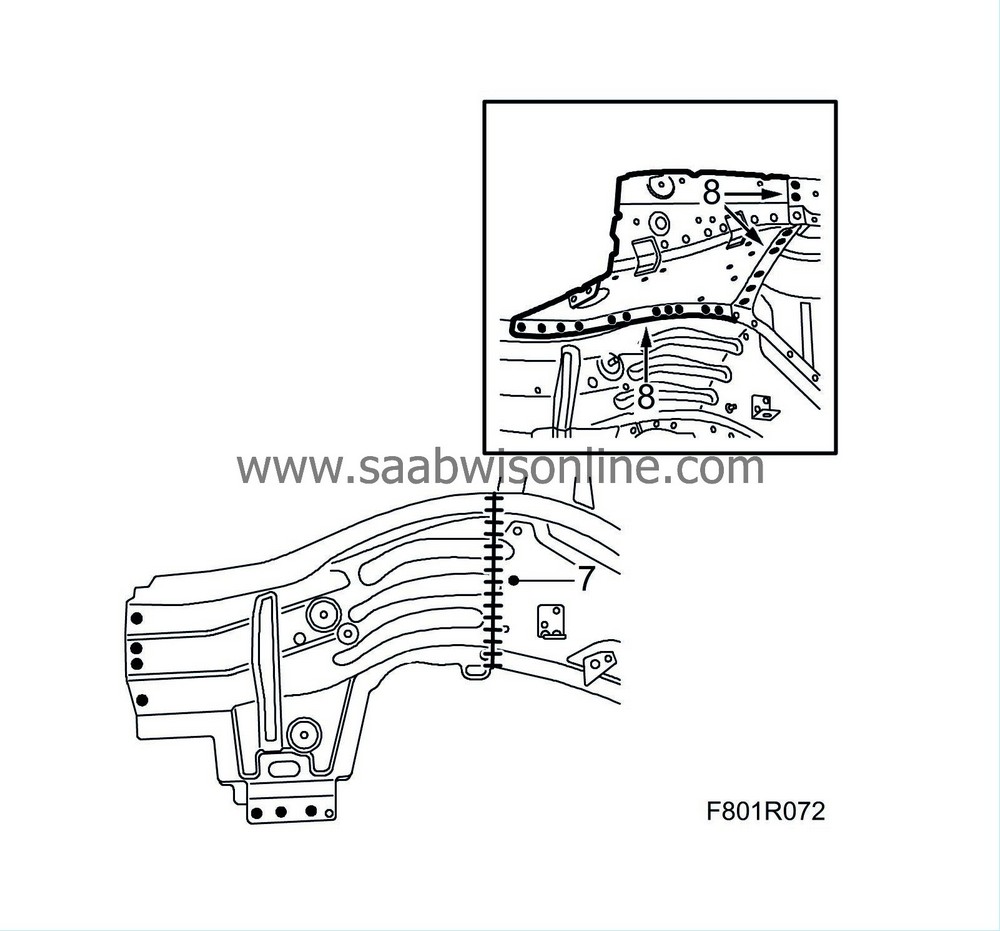

Drill out the spot welds on the front frame member. Some of the spot welds require drilling through two panels as illustrated (shaded grey).

|

|

| 8. |

Tap out the front frame member.

|

|

| To fit |

| 1. |

Straighten and grind all surfaces which are to be welded.

|

|

| 2. |

Apply welding primer to the surfaces that are to be welded.

|

|

| 3. |

Cut the outer panel to fit. Drill holes for plug welds.

|

|

| 4. |

Position the replacement panels and hold in place with some welding clamps.

|

|

| 5. |

Position the parts and align them using the alignment jig's measuring system.

|

|

| 6. |

Weld the parts in place.

|

|

| 7. |

All-weld the joint on the outer panel of the frame member.

|

|

| 8. |

Weld the front section of the wheel housing in place.

|

|

| 10. |

Remove the headlight frame

and

bumper member with integrated collision box

.

|

|

| 11. |

Grind the welds.

|

|

| 12. |

Wash away surplus welding primer. Welding primer reduces the adhesion of paint, filler and sealant.

|

|

| 13. |

Apply primer to all bare metal surfaces.

|

|

| 14. |

Seal joints and seams with sealant.

|

|

| 15. |

Apply underseal after painting. Use Terostat 9320.

|

|

| 16. |

Apply rust protector after painting. Use Terotex HV 400.

|

|

Warning

Warning