PRE-RELEASE

Rear bumper abutment, 5D

| Rear bumper abutment, 5D |

| To remove |

Certain welded joints on the car may be MIG brazed with bronze as the filling material. A MIG brazed seam may be recognized from the gold colour of the joint. A MIG brazing must always be replaced by a new MIG brazing.

|

|||||||

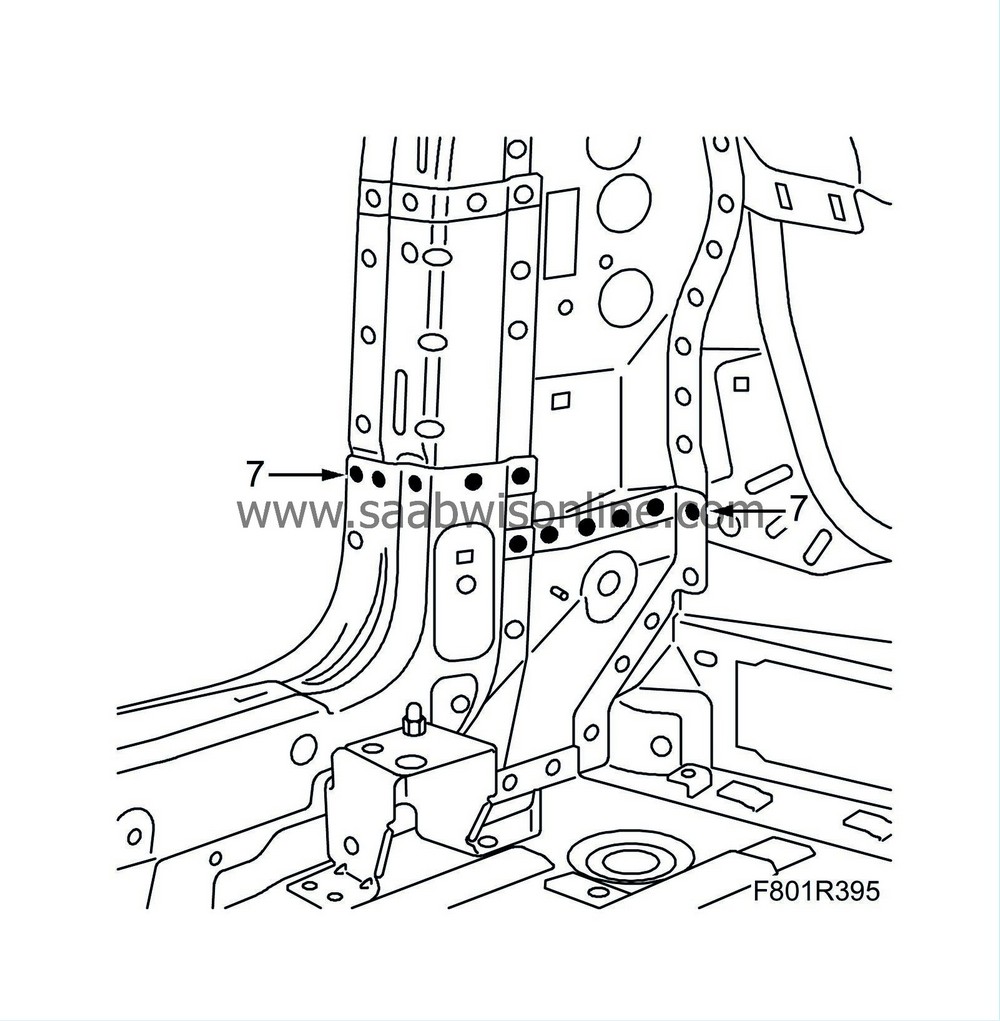

| 1. |

Drill out the spot-welds in the luggage compartment.

|

|

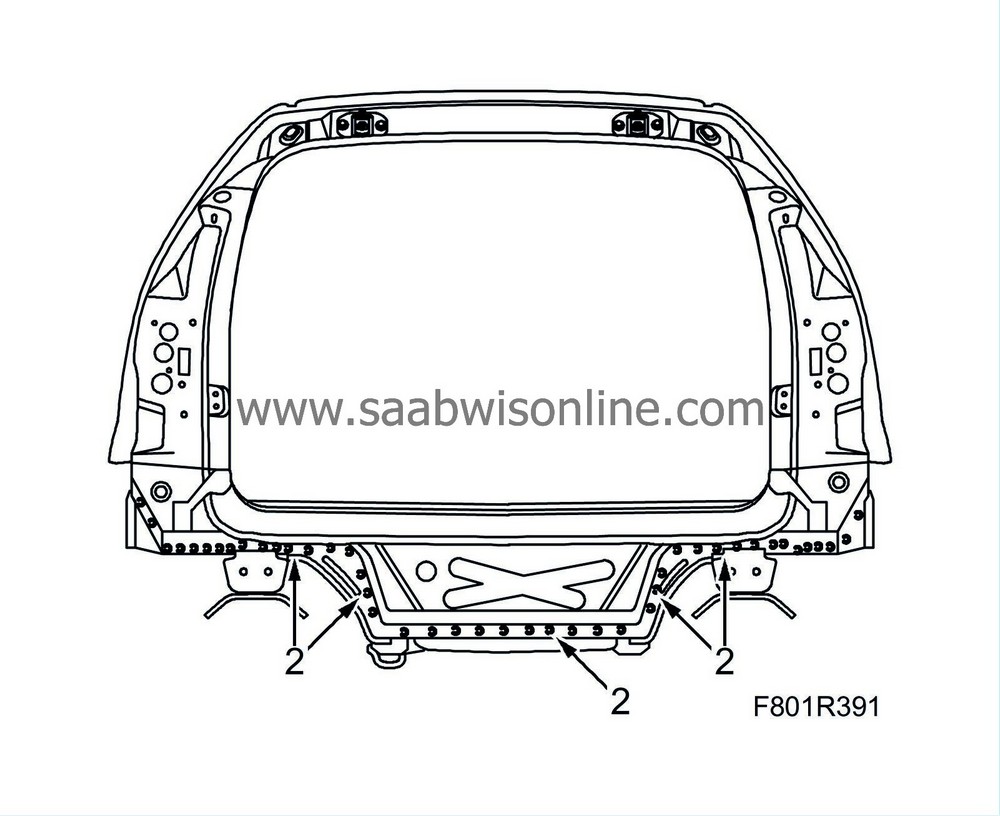

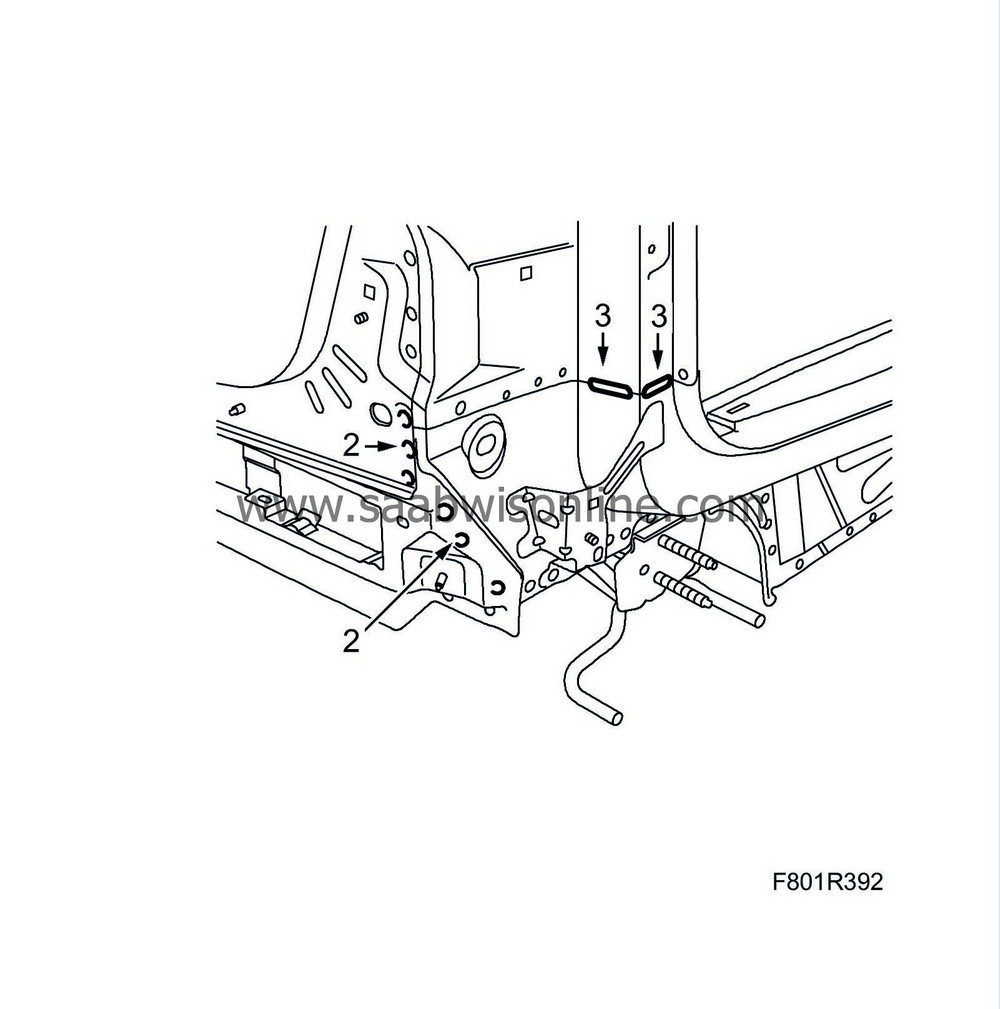

| 2. |

Drill out the spot welds.

|

|

| 3. |

Grind away the MIG brazed seam welds.

|

|

| 4. |

Knock out the rear bumper abutment.

|

|

| 5. |

Align any deformed sheet metal or panels.

|

|

| To fit |

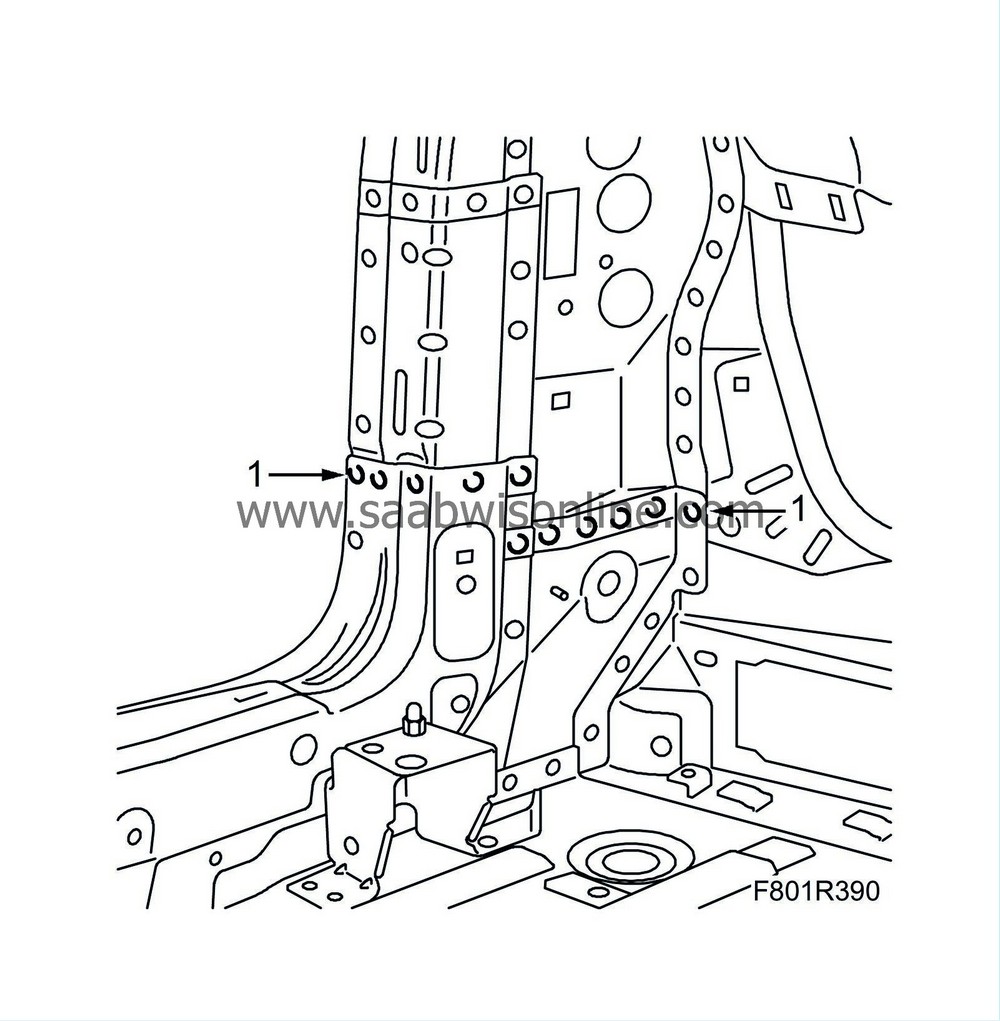

| 1. |

Drill holes for plug-welding in the spare part.

|

|

| 2. |

Grind all surfaces that are to be welded.

|

|

| 3. |

Apply welding primer to the surfaces that are to be welded.

|

|

| 4. |

Put the new rear bumper abutment in place and secure it with a few welding clamps. Check the fit using the alignment bench measuring system.

|

|

| 5. |

Lower the tailgate and check the fit of the rear bumper abutment.

|

|

| 6. |

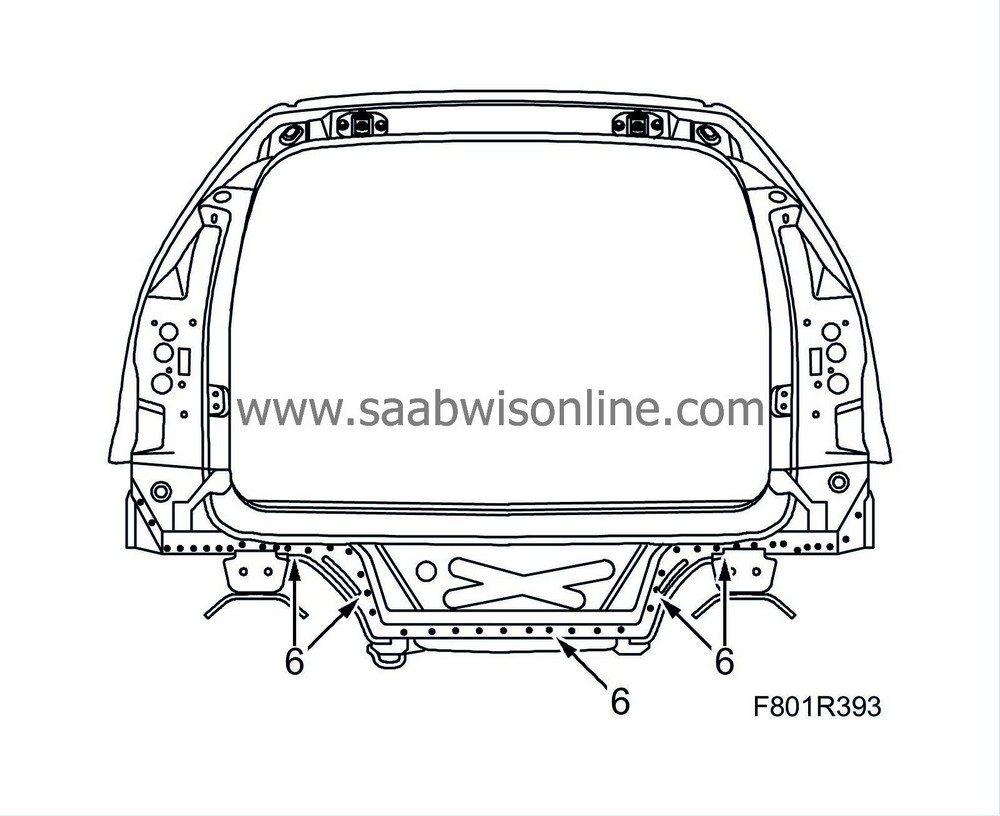

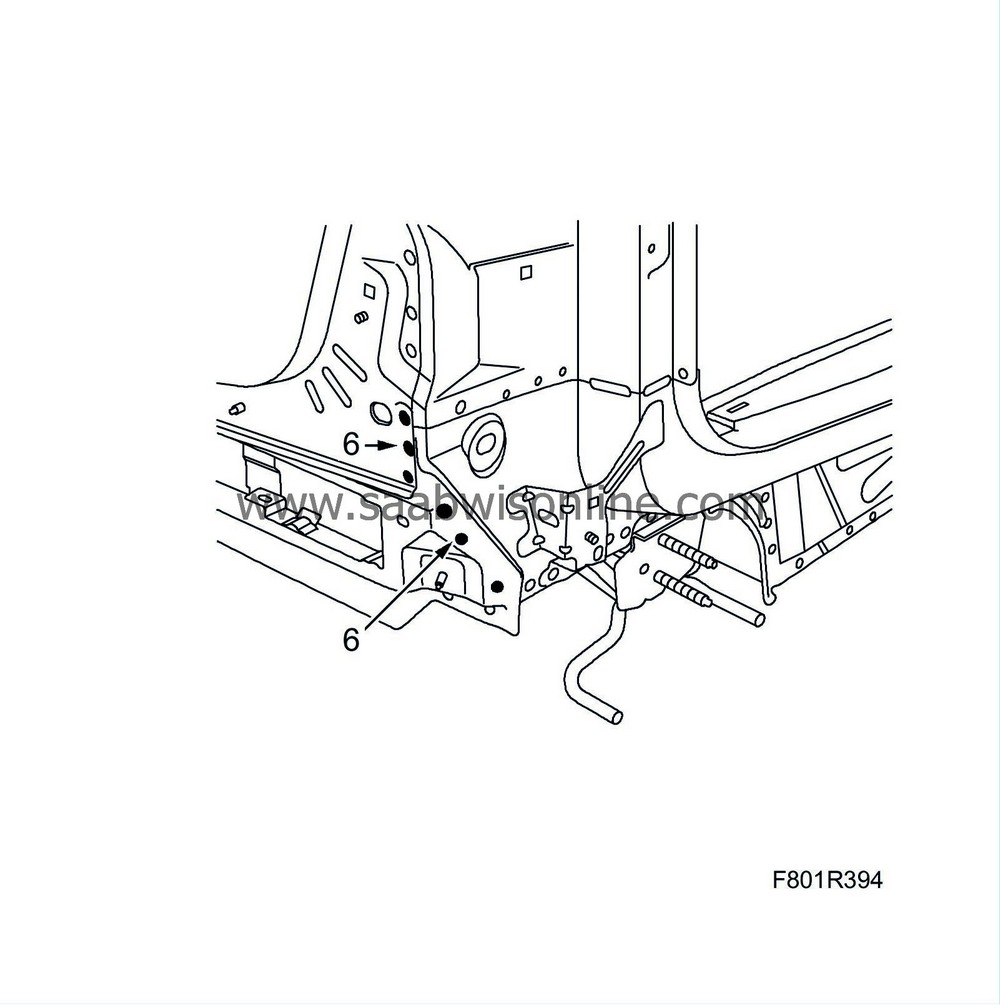

Spot and plug weld on the rear bumper abutment.

|

|

| 8. |

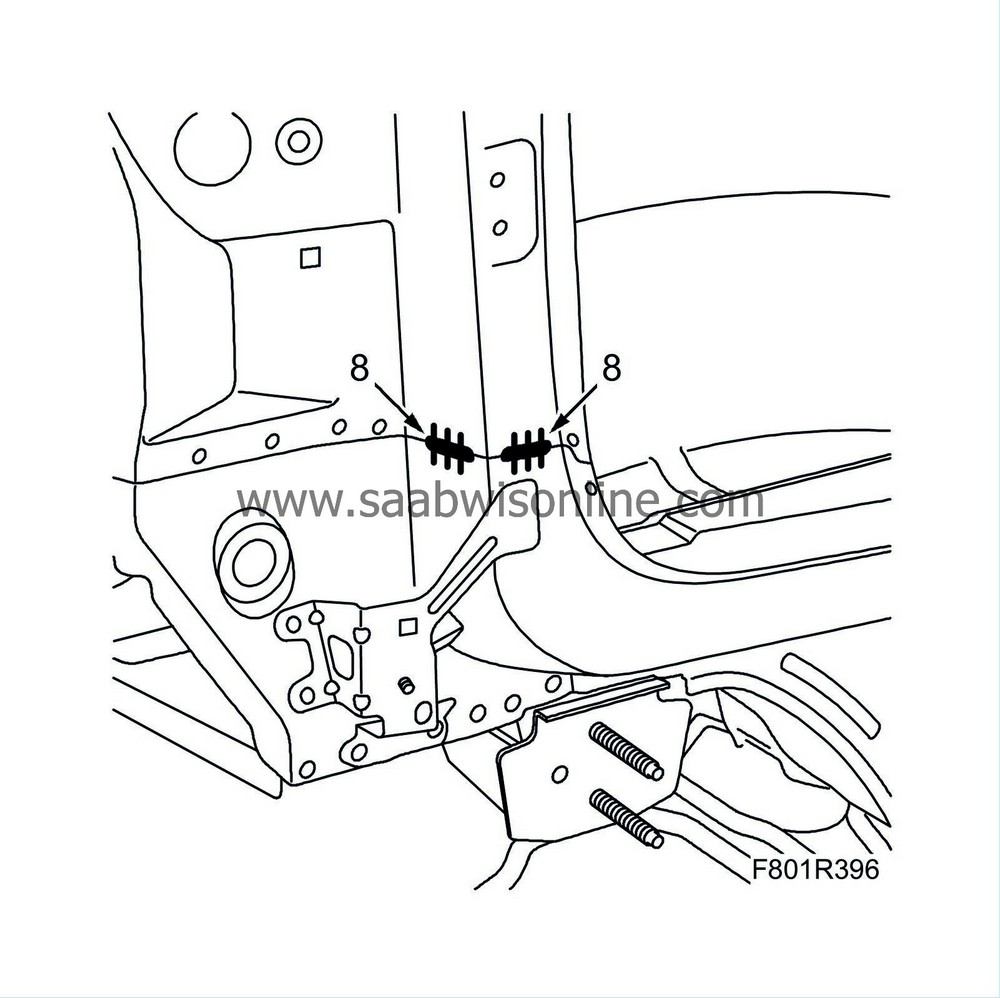

Seam weld on the rear bumper abutment using MIG brazing.

|

|

| 9. |

Grind the welds.

|

|

| 10. |

Wash away surplus welding primer. Welding primer reduces the adhesion of paint, filler and sealant.

|

|

| 11. |

Apply primer to all bare metal surfaces.

|

|

| 12. |

Seal joints and seams with sealant.

|

|

| 13. |

Apply PVC substitute to the bottom of the rear bumper abutment.

|

|

| 14. |

Apply anti-corrosion agent after painting.

|

|

Warning

Warning