Engine torque coordination

|

|

Engine torque coordination

|

|

Engine torque coordination, general

|

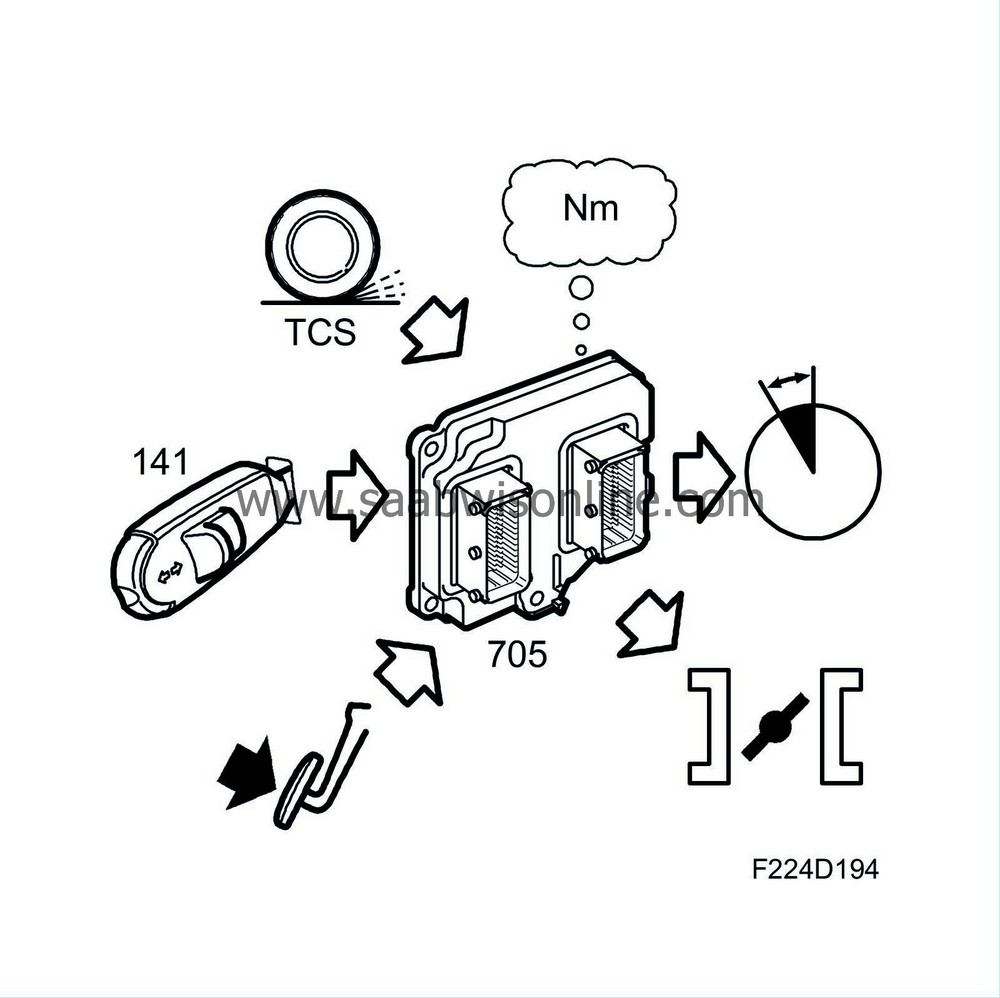

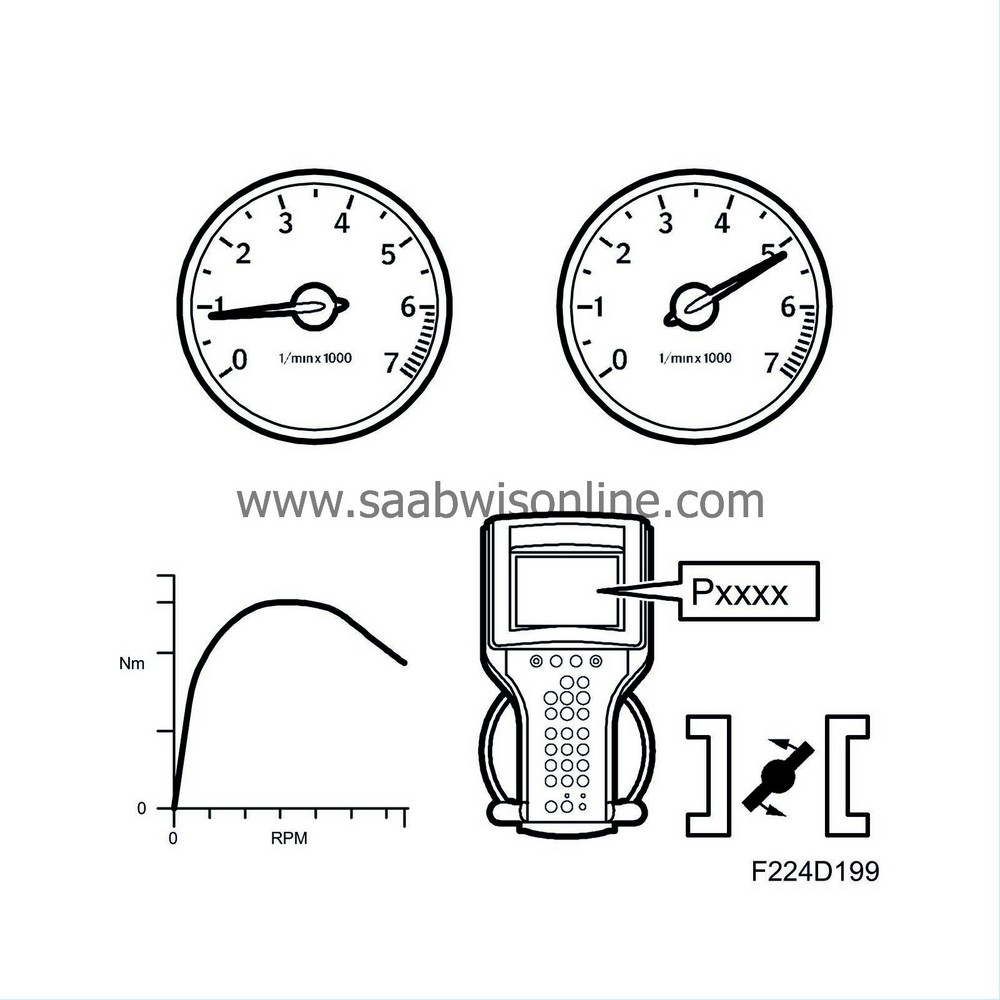

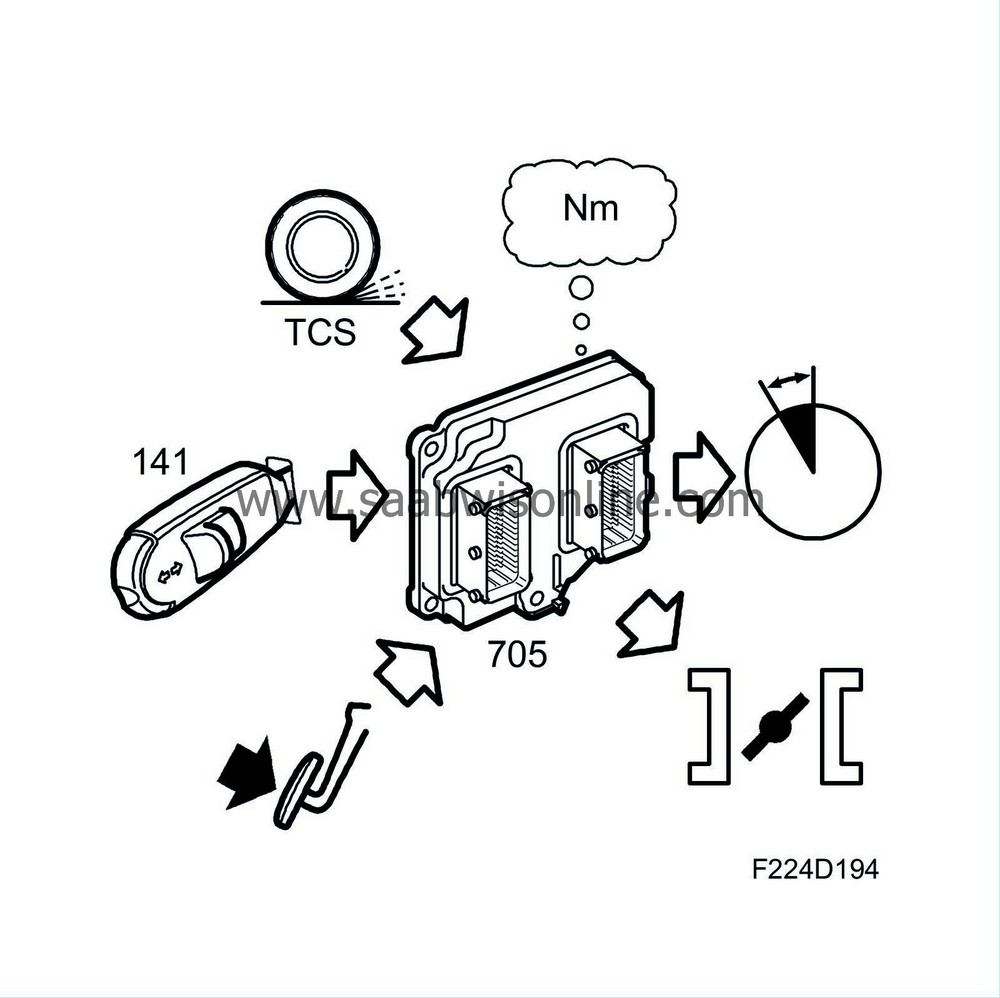

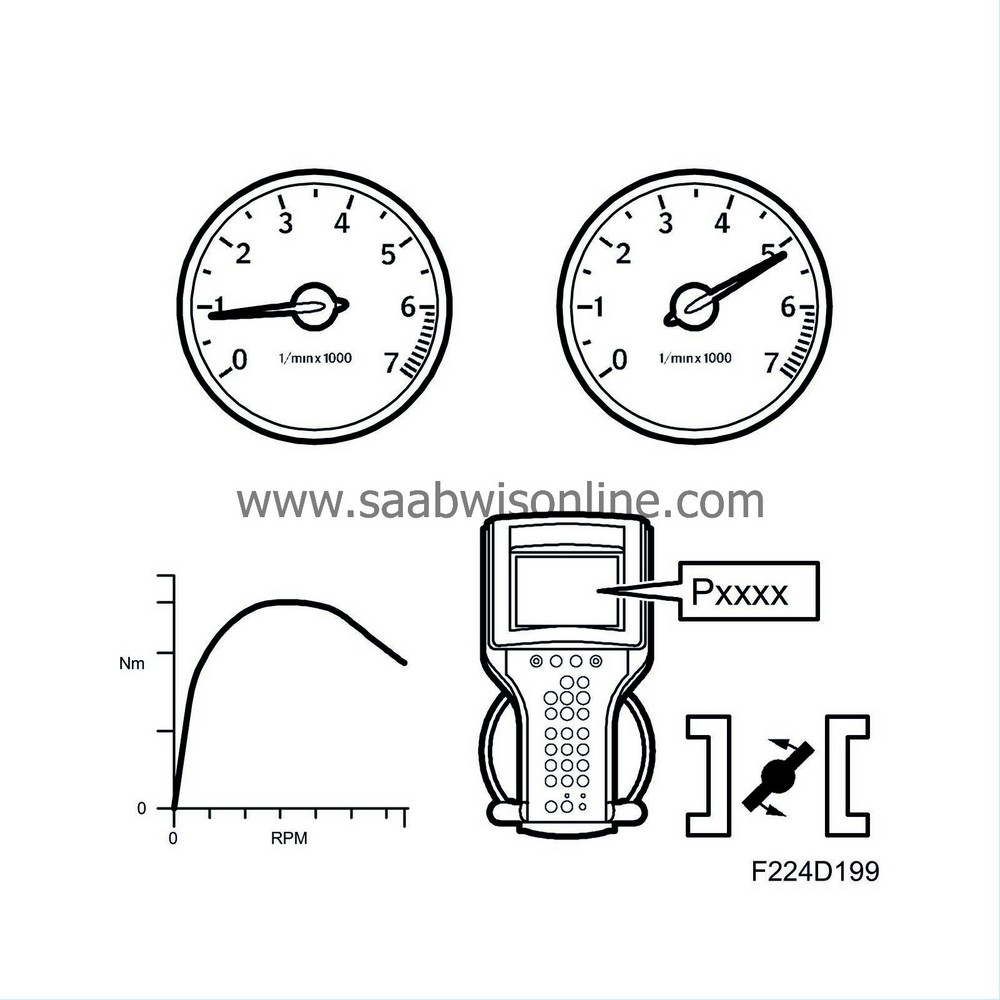

Engine torque coordination is used to coordinate the different cases of torque request to and within the system and to take into account the relevant limitations and make sure the engine delivers the correct engine torque. The engine torque is calculated by ECM, which regulates the engine torque by adjusting the throttle (air mass per combustion), but also by regulating the ignition timing.

Generally, torque control can be said to have a slow method of regulating the torque, mass air flow control, and a fast method, ignition timing control.

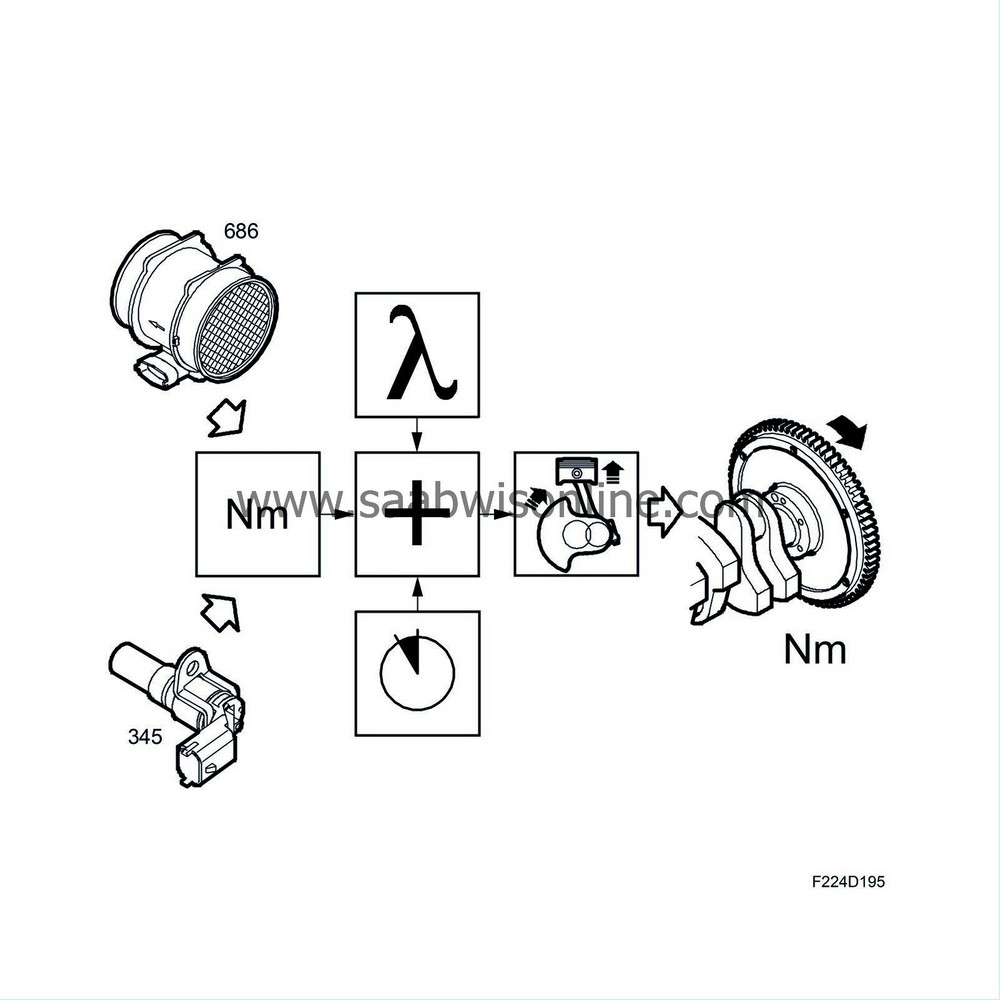

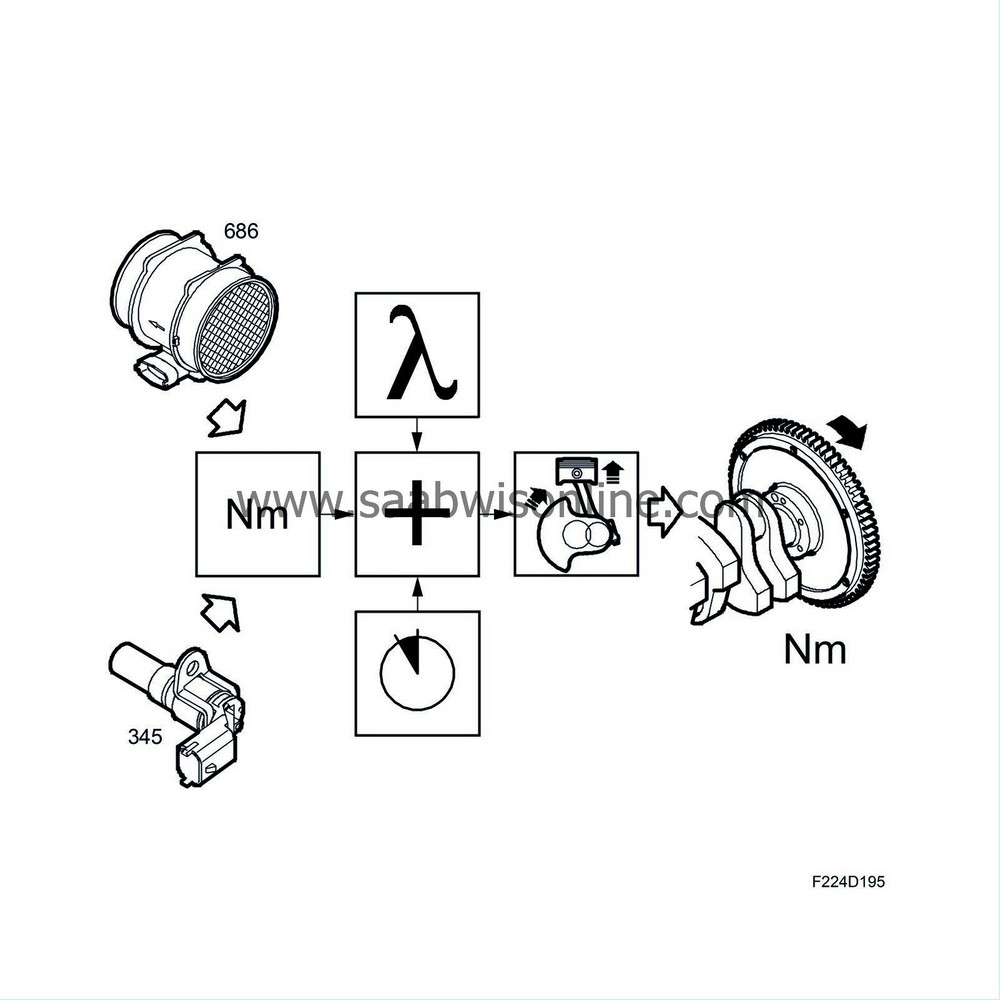

Torque calculation

Engine torque is calculated mainly using load and engine speed but ignition timing and current lambda value will also affect the torque calculation. ECM regulates the engine torque with the throttle (air mass per combustion), but also by regulating the ignition timing.

The calculation also takes into account the torque used by the engine itself, i.e. the internal friction. For this calculation, values for air mass, engine speed and coolant temperature are used.

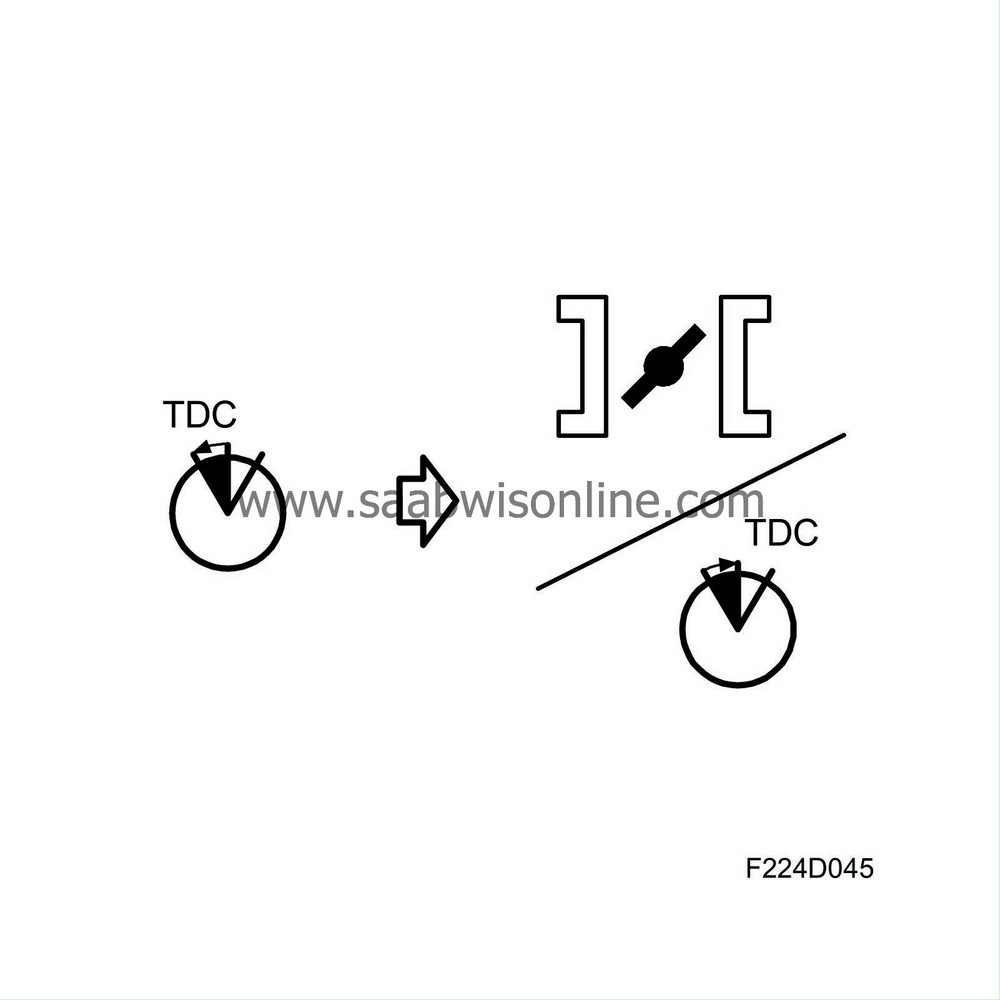

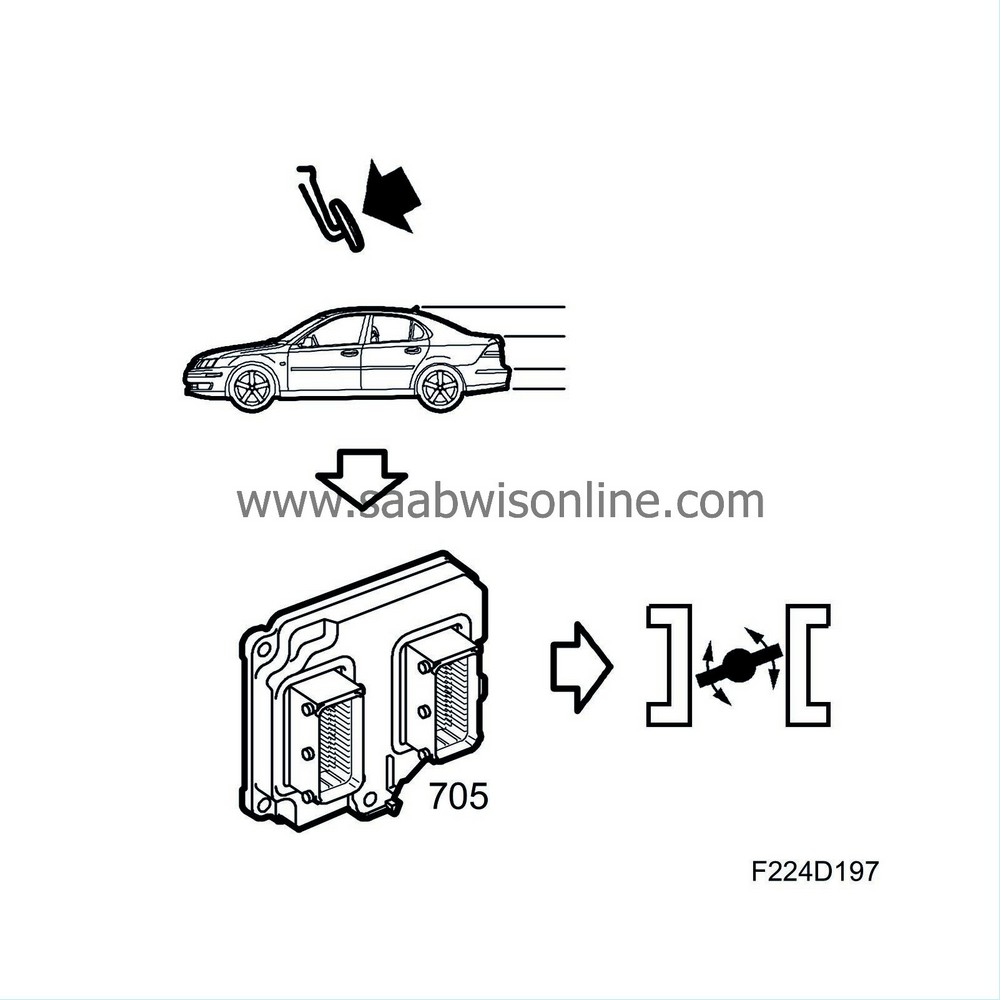

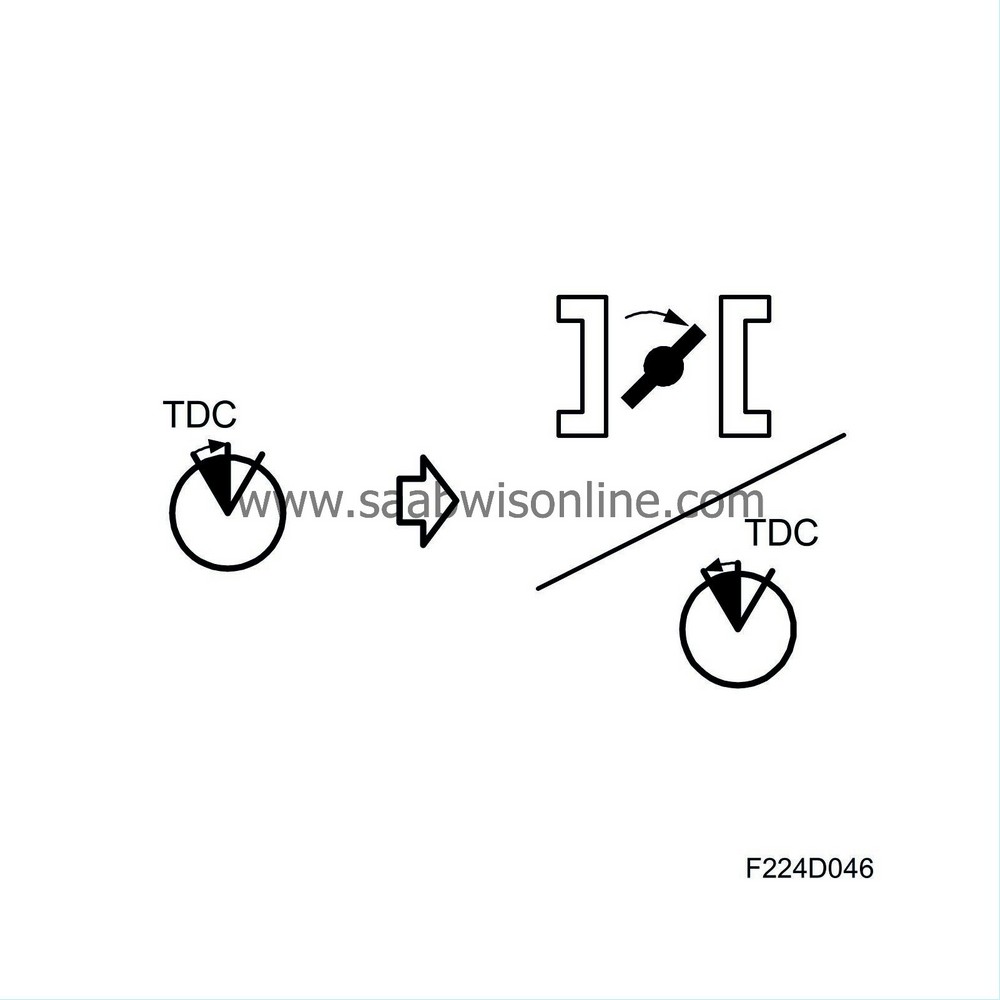

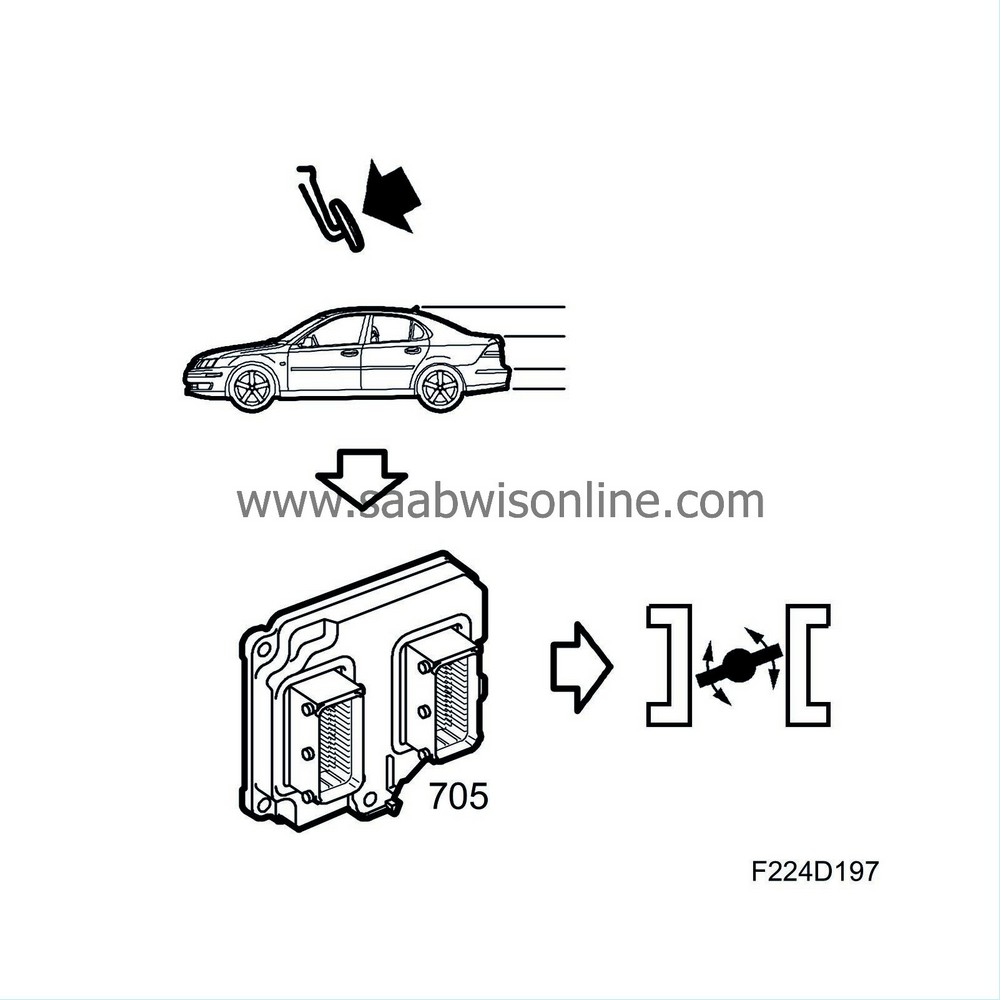

Fast engine torque control, increasing load

The fast type of regulation is used when the engine load changes rapidly, e.g. at idling speed when the A/C compressor is engaged and exerts a load on the engine. The increase torque required from the engine must be compensated quickly with a similar increase in engine torque or the idling speed will drop. This rapid compensation is done by advancing the ignition timing, which gives a higher engine torque.

After the fast compensation, ECM will gradually increase the throttle area in order to get more air mass into the engine while the ignition is retarded slightly. This allows ECM to maintain a torque reserve so that it can again perform fast compensation for changed engine loads.

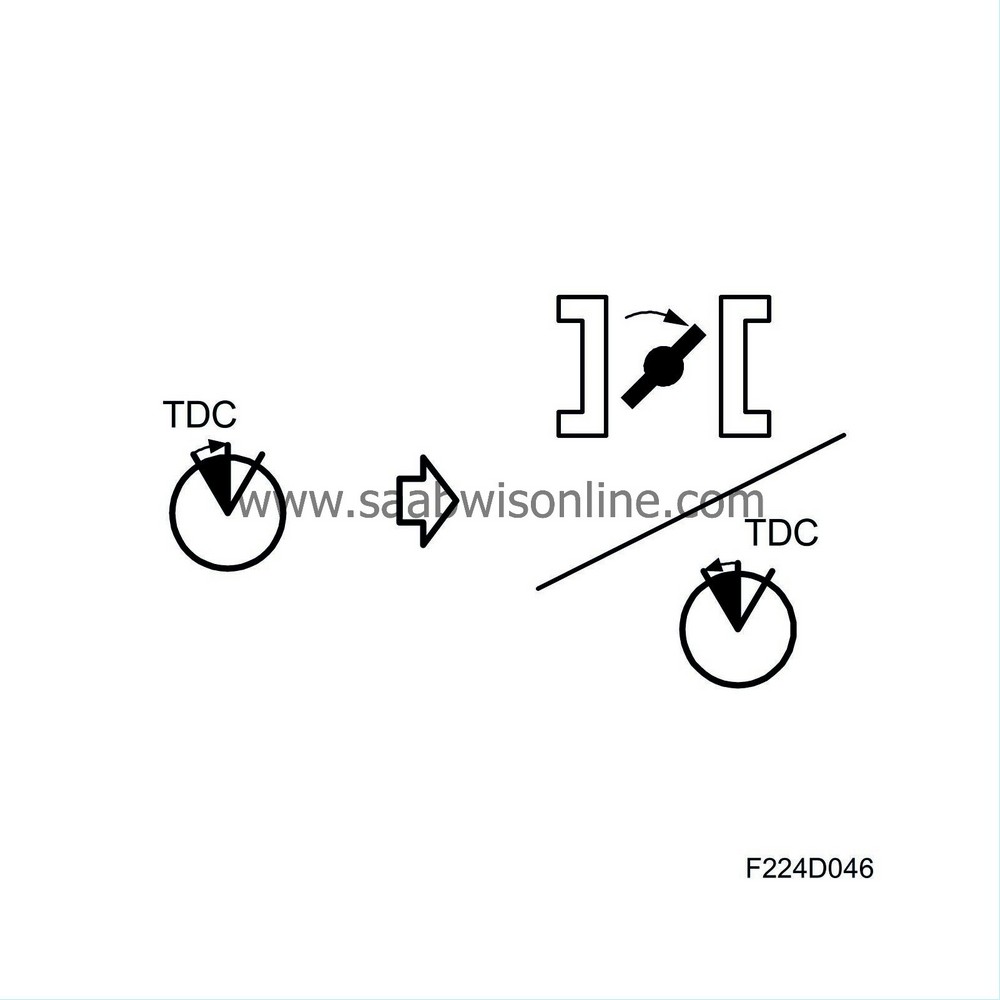

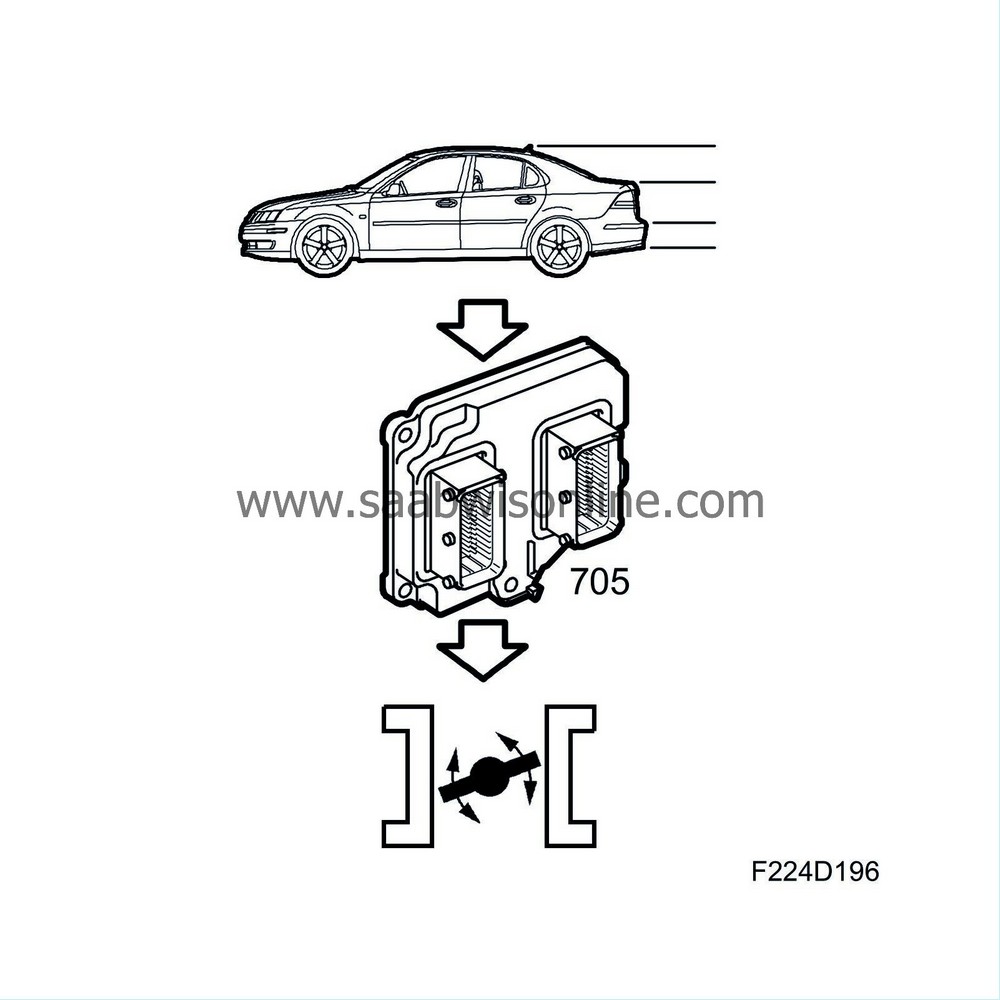

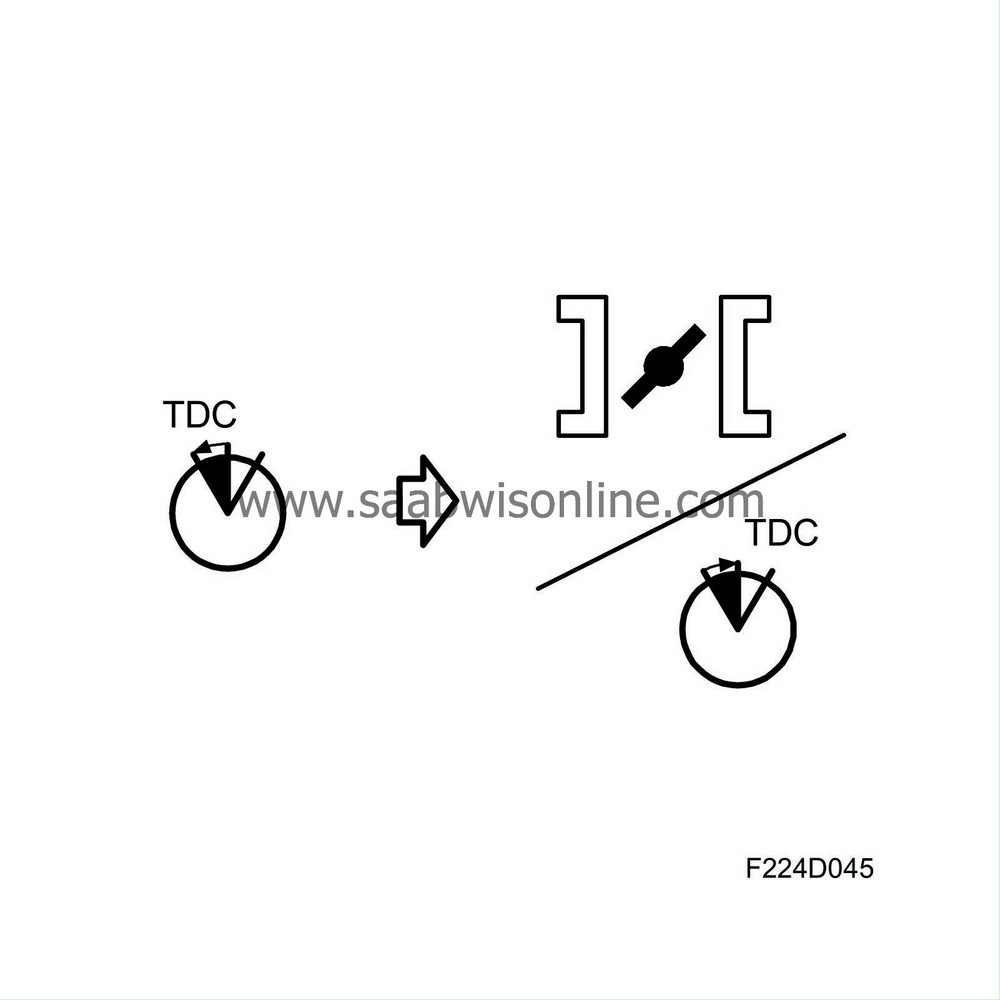

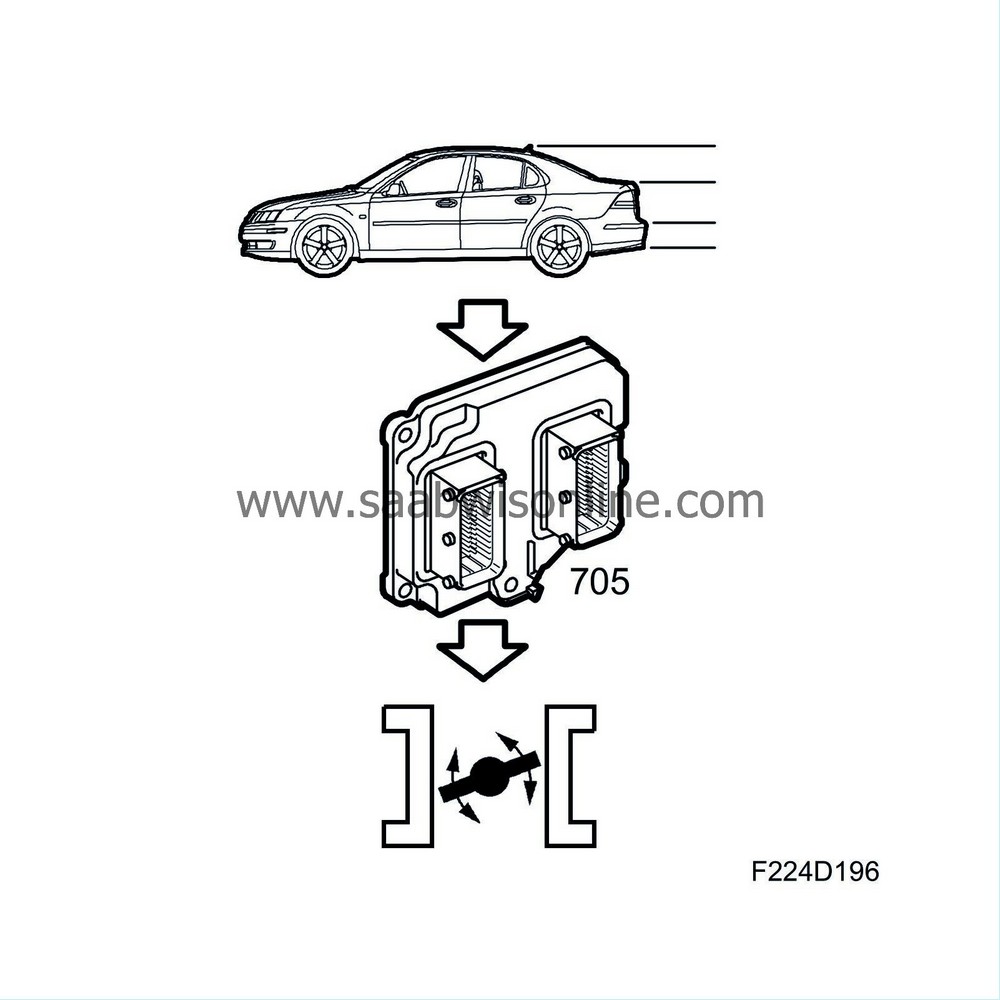

Fast engine torque control, reduced load

This works conversely when the load suddenly drops, e.g. when the A/C compressor is turned off. The engine will then deliver a higher torque than is needed to keep the engine and its auxiliaries running, i.e. generator and water pump. If the engine torque is not reduced quickly, the idling speed will rise above nominal because the engine is producing "too much torque".

Engine torque is reduced by retarding the ignition slightly, which results in lower engine torque and restores the balance between the torque being produced and the torque being used.

The engine will not be running with an ignition timing that is favourable from the point of view of fuel consumption. ECM will then reduce the throttle area (less air mass to the engine) while the ignition timing is advanced slightly.

Slow engine torque control

Slow engine torque control is used when driving under constant load, i.e. when the load does not vary or varies slowly. In this case, ECM operates mainly with throttle area to regulate the engine torque.

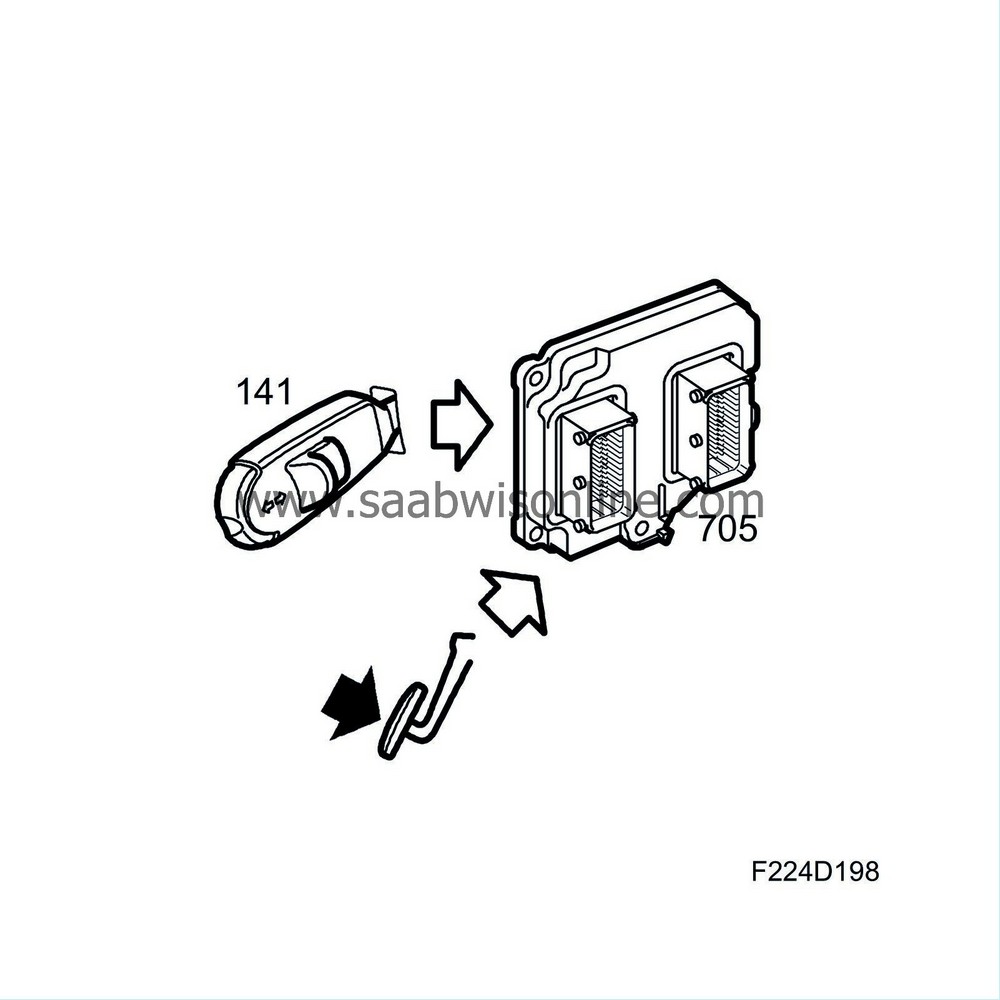

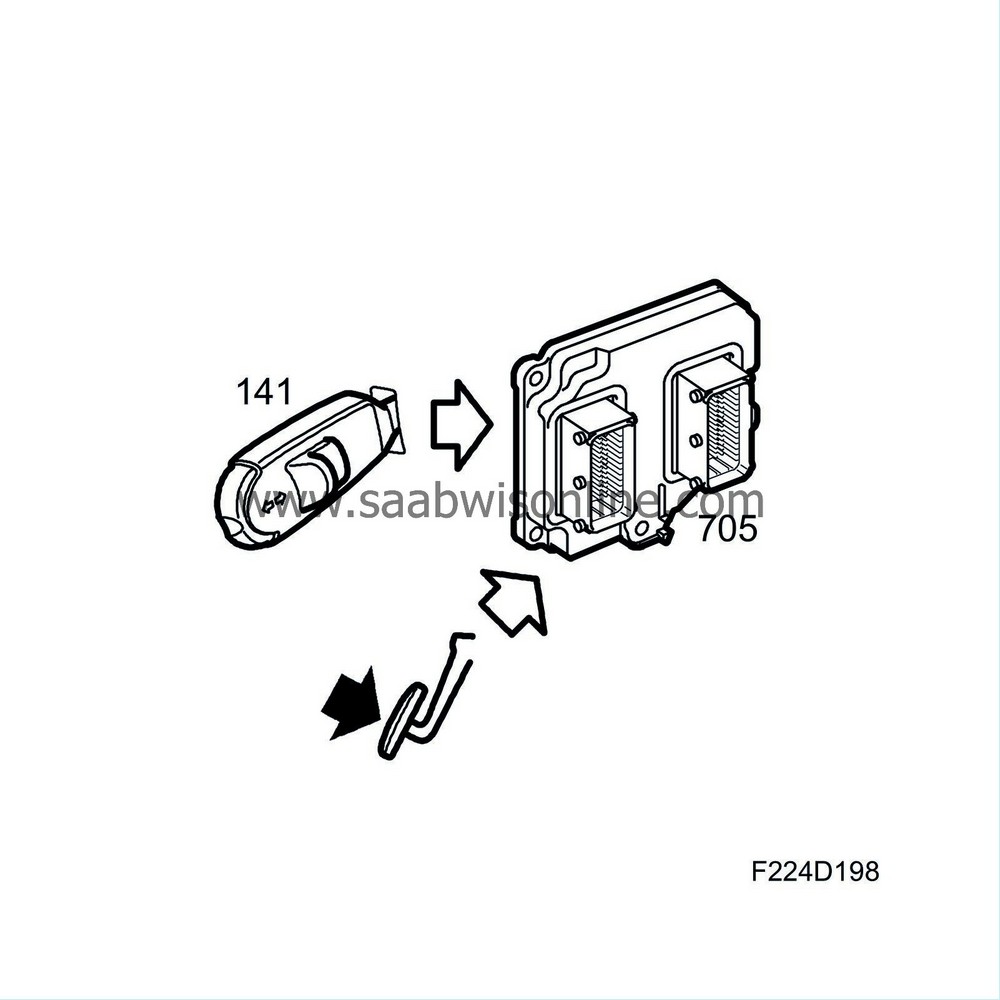

Torque request

Example of an "external" request:

|

•

|

Cruise control

Example of other engine torque requests:

|

|

•

|

Engine protection function

|

|

•

|

Safety critical fault in throttle control.

|

All torque requests, both positive and negative, are coordinated and result in ECM calculating how much air mass that must enter the engine for each combustion, i.e. requested air mass per combustion. The value from the mass air flow sensor is compared with "requested air mass per combustion" and any deviation results in the throttle area being adjusted to increase or decrease the air flow.