PRE-RELEASE

Normal ignition timing

| Normal ignition timing |

This ignition function is the one normally used when driving.

The ignition timing is regulated depending on the engine speed and load. This is so that the right build-up of combustion pressure is attained.

The combustion pressure should normally reach its maximum value at around 16-17° ATDC. In order for this to be attained the fuel/air mixture must be ignited just before then.

The expansion rate of the flame varies with the conditions in the combustion chamber, heat, pressure and turbulence. The ignition timing must therefore vary over the engine's load/speed range.

| Principle, increasing engine speed |

The principle is that the degree of advanced ignition must increase at higher speeds, or the combustion pressure would build up to late. This in turn would mean that the engine efficiency was impaired, that is to say low torque and high fuel consumption. The exhaust temperature would also get too high and risk engine damage and damage to the catalytic converter.

Premature ignition of the fuel/air mixture would give a far too early pressure build-up resulting in less power, high emissions of NOx and also increased sensitivity to knocking.

| Principle, increasing load |

As the engine load increases so does the pressure, temperature and turbulence in the cylinders, which increases the rate of combustion.

The difference in ignition timing is reflected in the difference in combustion rate between high engine loads and low engine loads. Consequently, the ignition timing must be retarded at high engine loads.

| Optimisation |

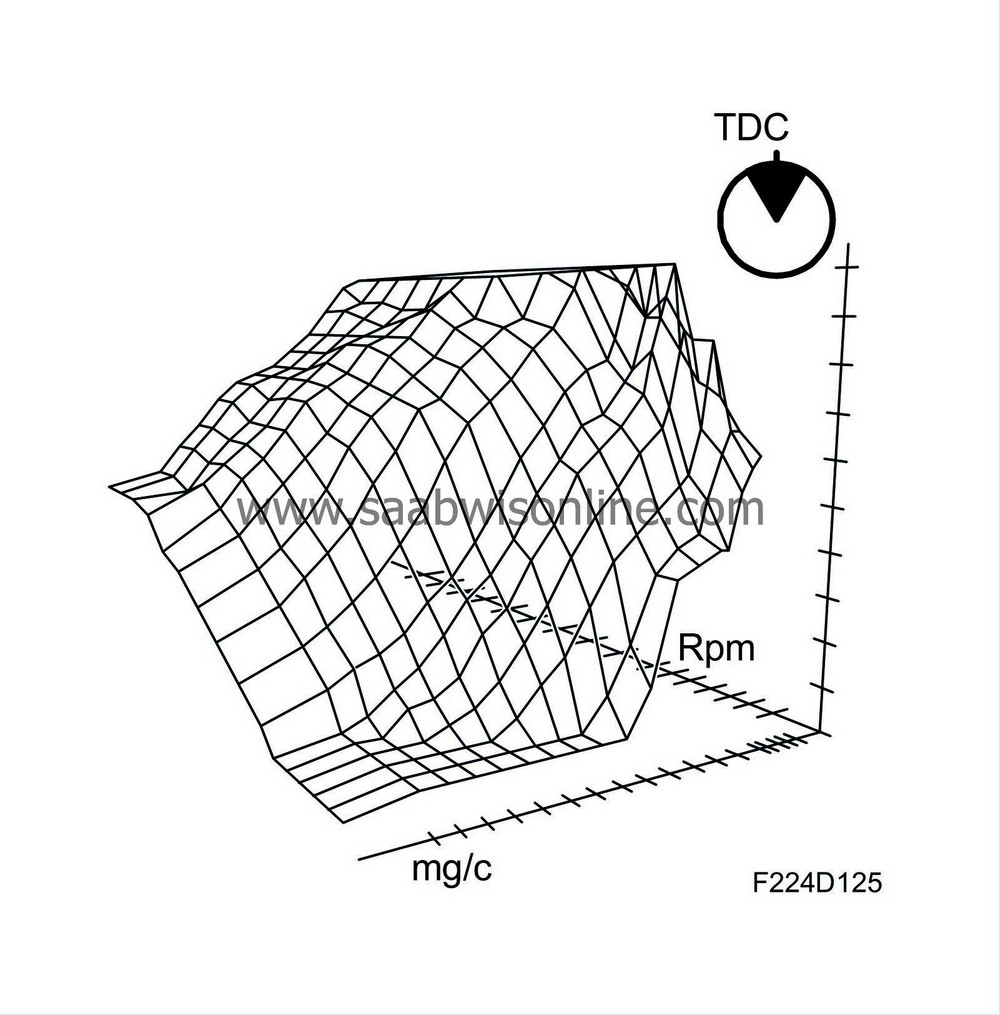

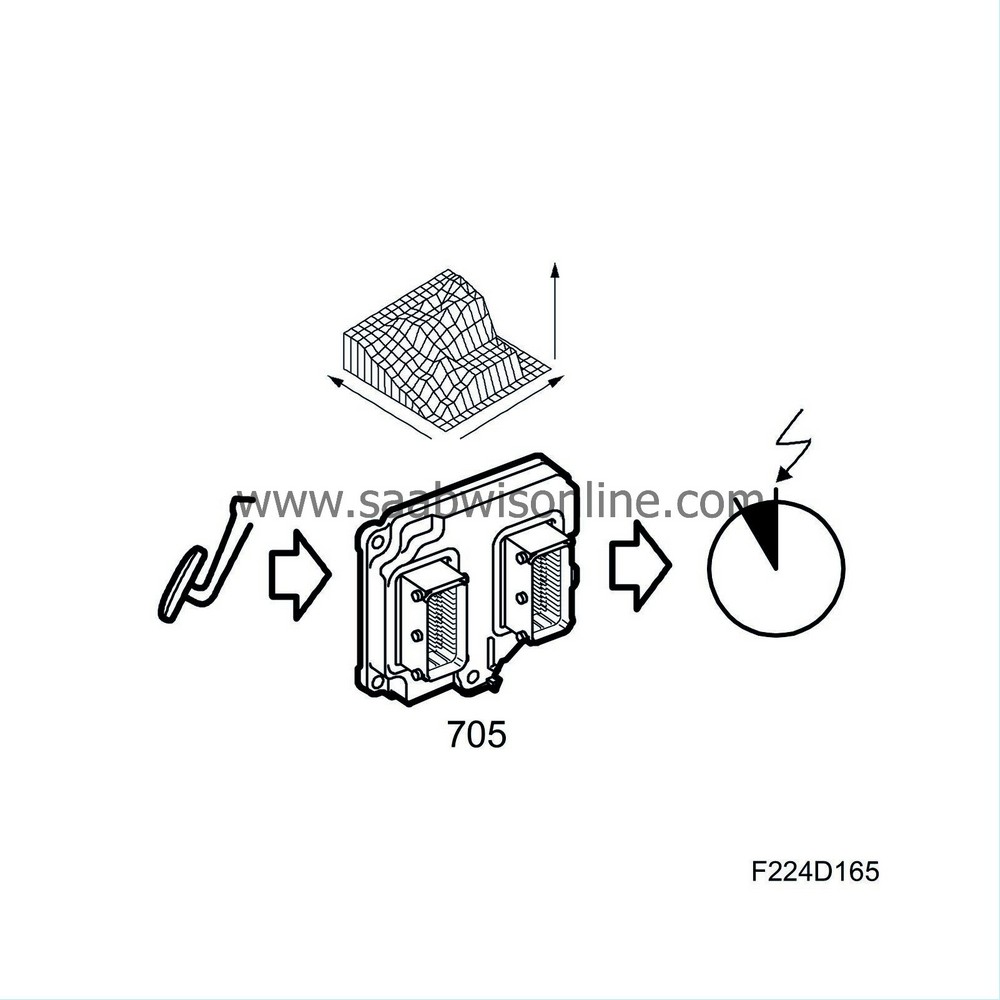

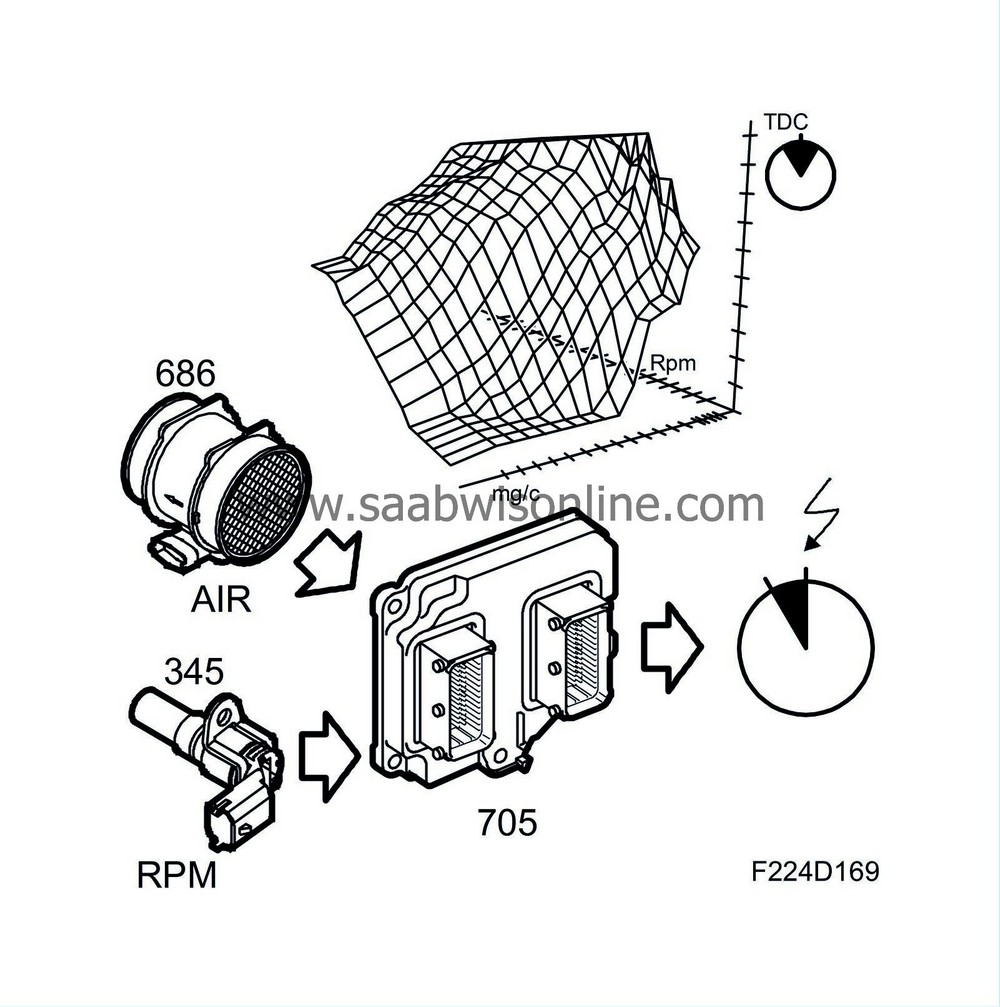

A matrix (map, kennfeldt) in the control module memory contains the ignition timing for each respective load and engine speed.

The ignition timing is optimised to obtain the best torque for the current operating point, which also coincides with the best efficiency and therefore the best fuel economy. Normal ignition timing, which is the basis of ignition timing control while driving, must be compensated occasionally towards a more retarded or advanced ignition timing due to other factors than just load and speed.

| Ignition Master |

Objective

To coordinate various requests for ignition timing depending on the engine's running conditions, such as idling, driving. The following are the different functions that can affect ignition timing.| Ignition Master, |

Objective

To coordinate various requests for ignition timing depending on the engine's running conditions, such as idling, driving. The following are the different functions that can affect ignition timing.| Start-up ignition timing |

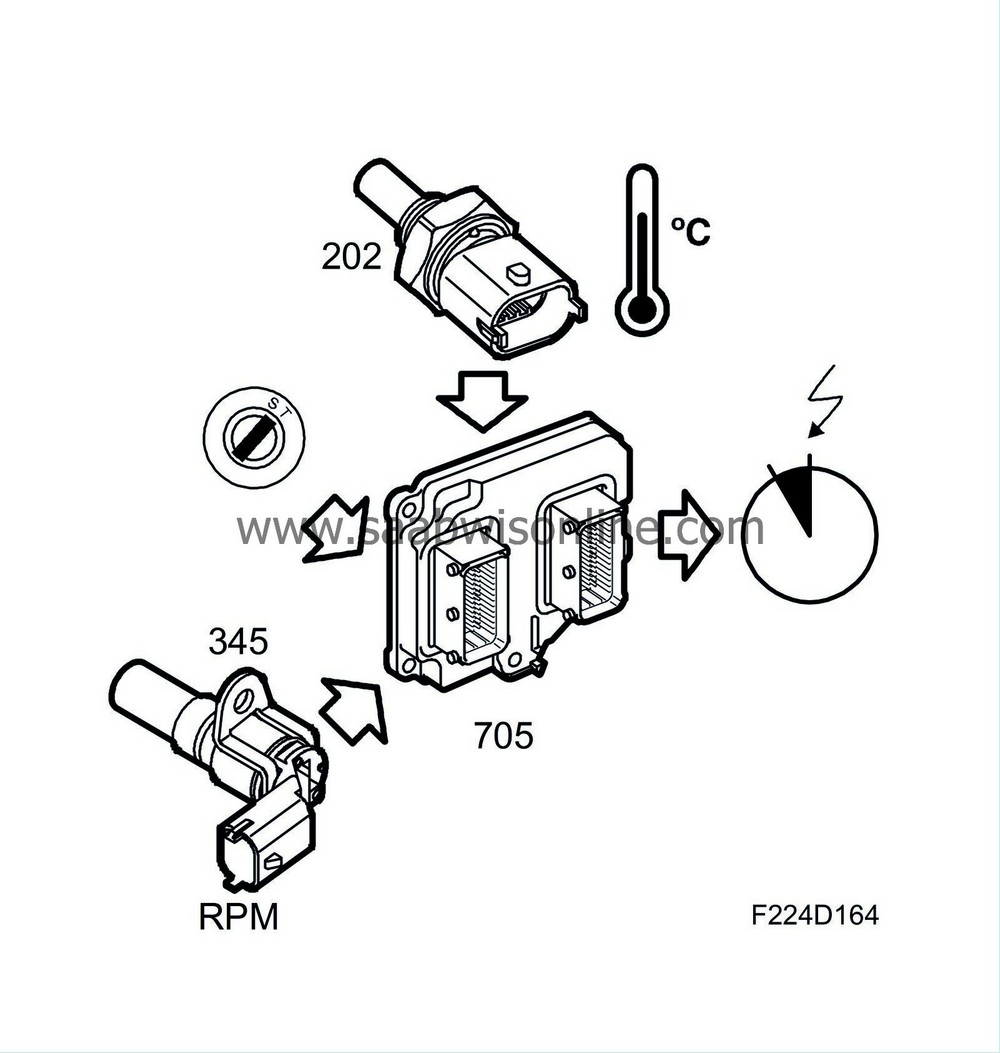

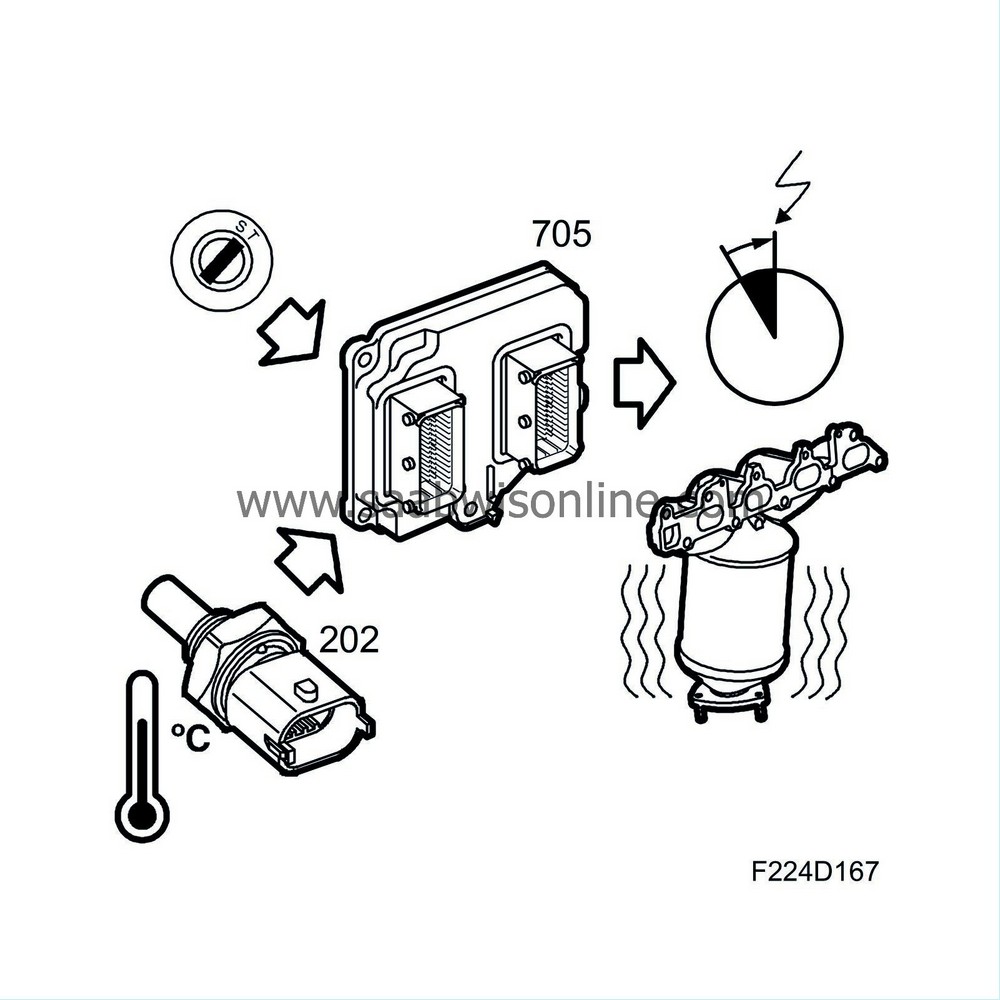

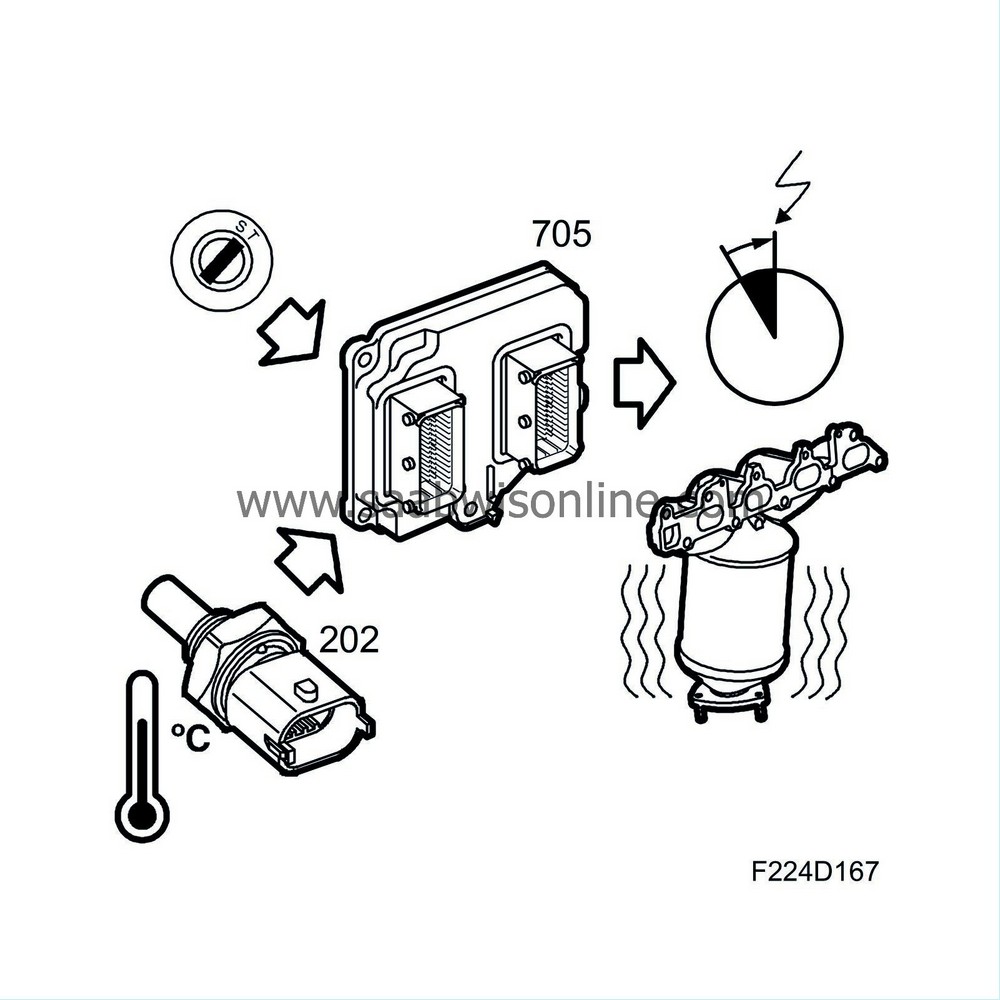

General

The ignition timing applicable when starting the engine depends on the coolant temperature and engine speed. The function is active when starting the engine.

Principle

To compensate the differences in the expansion rate of the flame the ignition timing when starting must vary depending on the engine coolant temperature. At low temperatures, the flame will expand slowly in the combustion chamber. In order for the pressure in the cylinder to reach its maximum value at the correct crankshaft position, the ignition timing must consequently be relatively advanced when the coolant temperature is low.The reverse applies at high temperatures when the flame expands rapidly. The ignition timing must then be retarded slightly. If this does not happen the pressure in the cylinder will attain high values before TDC. This could result in the engine starting roughly with spiking noises.

During slow starter motor cranking, ignition timing is retarded slightly. When the engine speed during starter motor cranking is high, the ignition timing must be set to a more advanced position. This is to compensate for the flame expansion rate.

Once the engine has started, the ignition timing from the start function will be increased to the value from the idling speed ignition timing.

| Idle speed ignition timing |

General

The ignition timing applicable at idling speed is determined mainly by the engine load/speed. But this can be compensated by the effect of various parameters. The idling speed ignition timing function is active during idling. (Accelerator pedal released).

Principle, basic matrix idling speed ignition timing

The basic idling speed ignition timing is determined by the engine load and speed. This is called the basic idling speed ignition timing.

Principle, temperature correction of idling speed ignition timing

The value from the "basic idling speed ignition timing" is corrected with the prevailing coolant and intake air temperature sensor.Low coolant temperature gives a positive compensation, i.e. the ignition timing is displaced to a somewhat more advanced value.

High intake air temperature gives a negative compensation, which means the ignition timing is displaced to a more retarded value.

Principle, catalytic converter heating "light off"

Under certain cold starting conditions, the "catalytic converter heating" function will be activated. This means that the ignition timing is displaced to a more retarded value, usually ATDC. As a result, the exhaust temperature will rise considerably and the catalytic converter will heat up rapidly. This function is combined with opening the throttle slightly to give a higher idling speed. This increases the air mass flow through the catalytic converter.

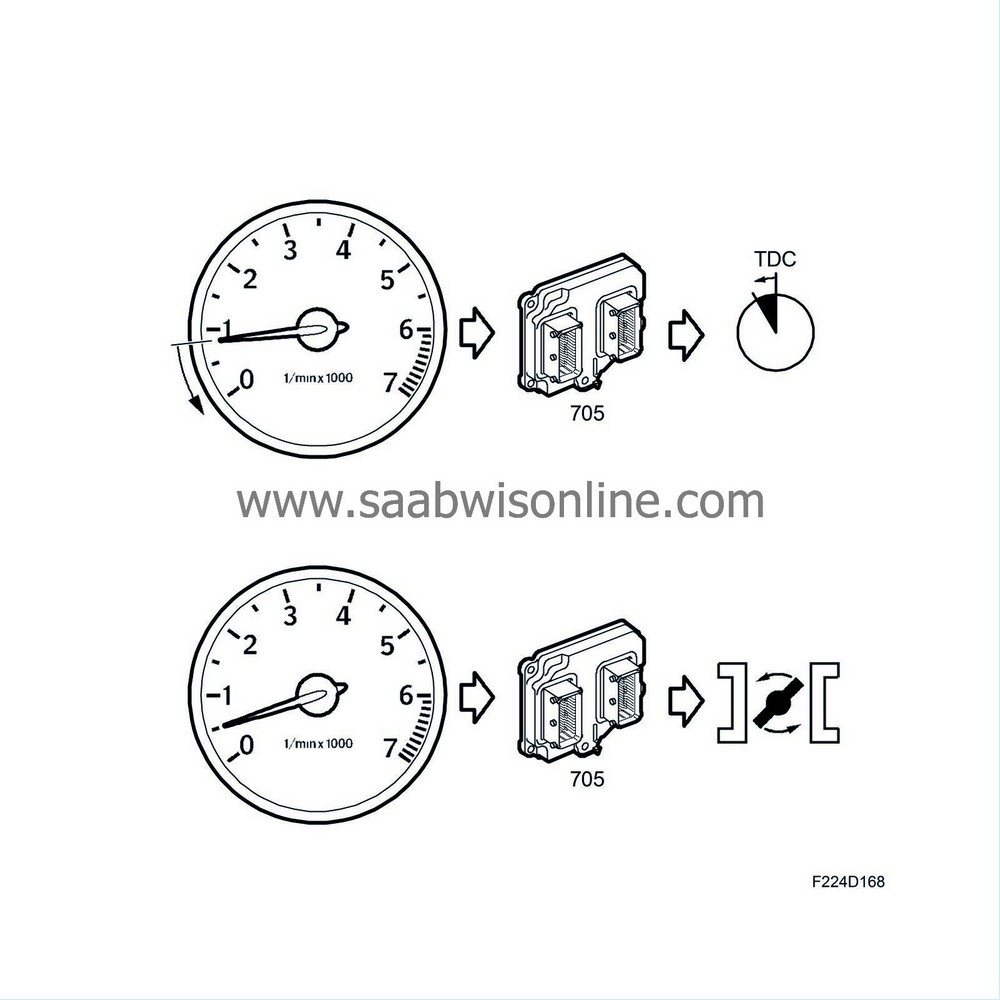

Principle, idling speed stabilisation

Together with the engine's mass air flow control, this function will ensure the engine develops the correct idling speed/torque for driving the generator, A/C compressor, etc. Rapid deviations from the nominal idling speed are adjusted by changing the ignition timing. As the idling speed is lower than the nominal, the ignition timing will be displaced toward a more advanced value so that the engine will generate more torque. A rapid rise in idling speed on the other hand will be compensated with an ignition timing that is somewhat retarded to give a lower engine torque. Slow deviations in engine speed are taken care of through the throttle control.

| Normal ignition timing |

General

The ignition timing applicable at idling speed is determined mainly by the engine load/speed but is compensated by a number of influences. The function is active while the accelerator pedal is depressed.

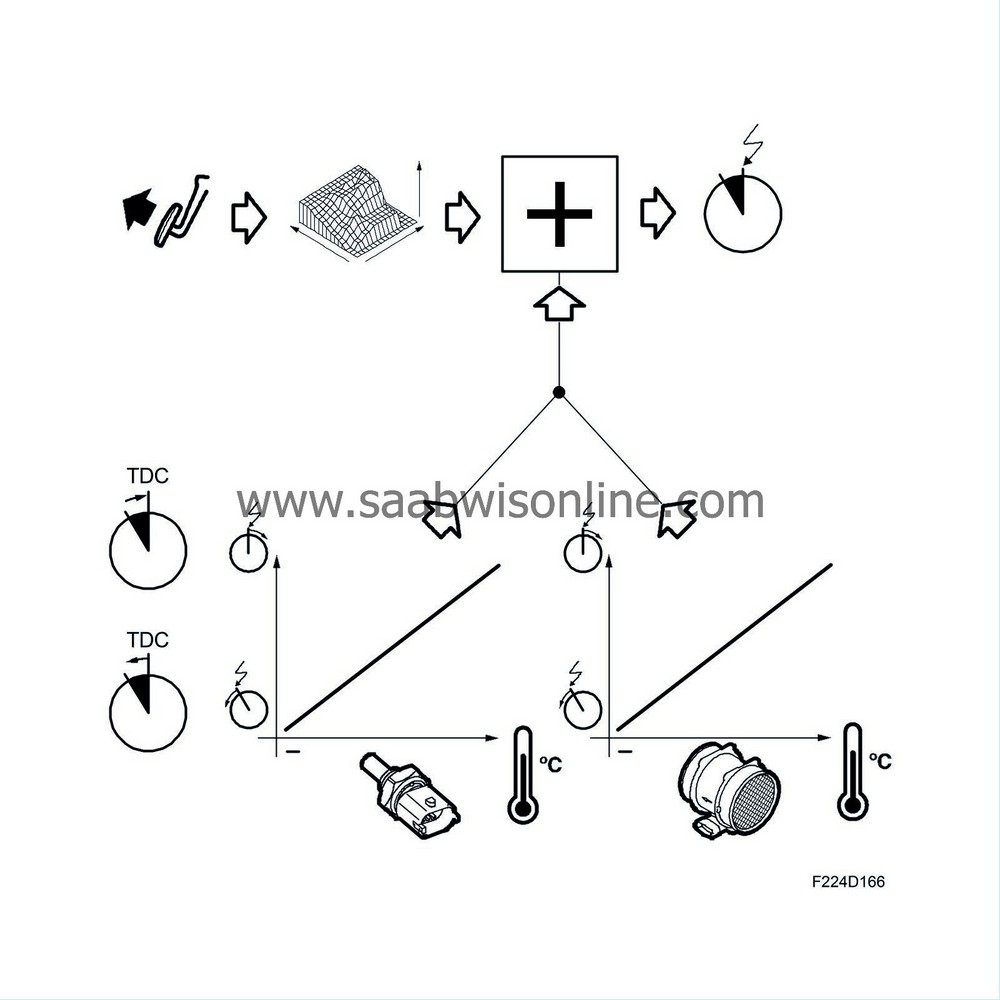

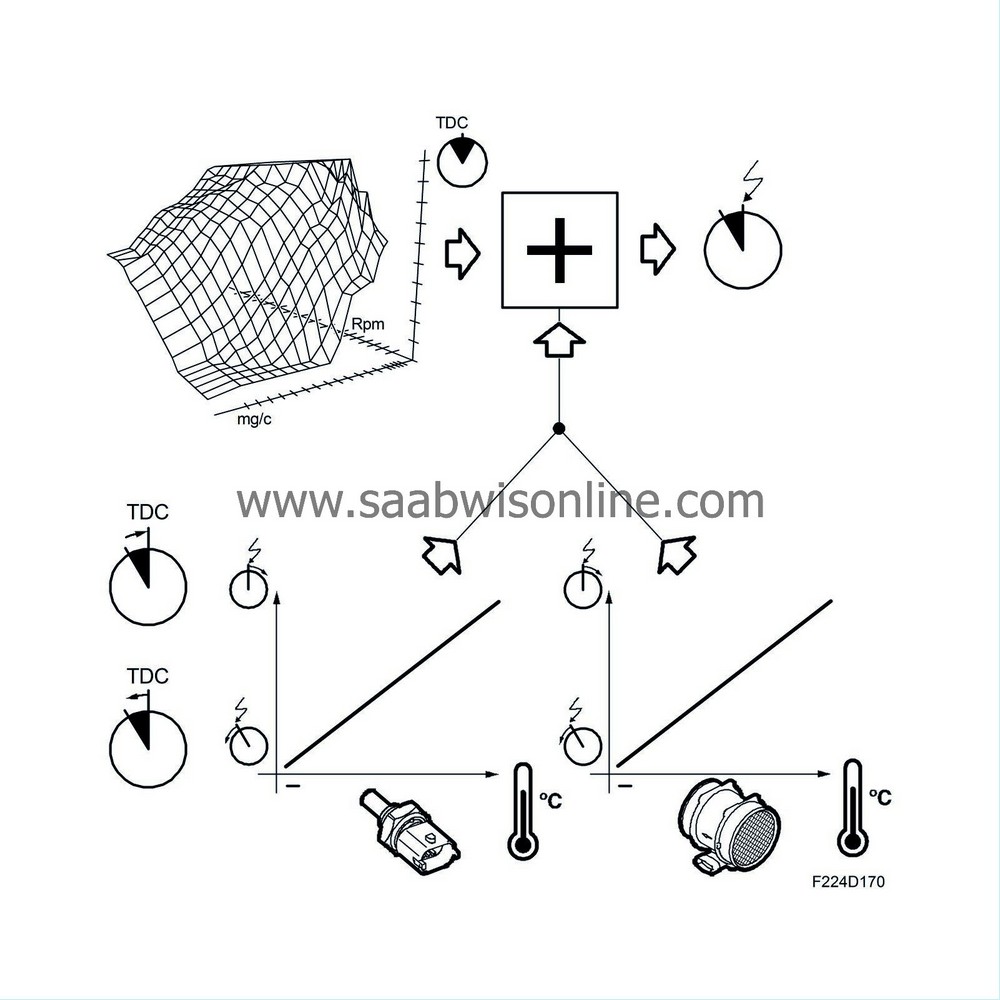

Principle, basic matrix normal ignition timing

The basic value for normal ignition timing is determined depending on the engine load and speed. This is called "normal ignition timing". The value is compensated through the influence of a number of factors.Principle, temperature correction of normal ignition

The value from "basic normal ignition timing" is corrected with the prevailing coolant and intake air temperatures.Low coolant temperature gives a positive compensation, which means that the ignition timing is displaced to a somewhat more advanced value.

High intake air temperature gives a negative compensation, which means the ignition timing is displaced to a more retarded value.

Principle, catalytic converter heating "light off"

Under certain cold starting conditions, the "catalytic converter heating" function will be activated. This means that the ignition timing is displaced to a more retarded value, usually ATDC. As a result, the exhaust temperature will rise considerably and the catalytic converter will heat up rapidly. This function is combined with opening the throttle slightly to give a higher idling speed. This increases the air mass flow through the catalytic converter. At high loads there is no displacement of the ignition angle or the exhaust temperature would become too high and risk damaging the engine and catalytic converter.

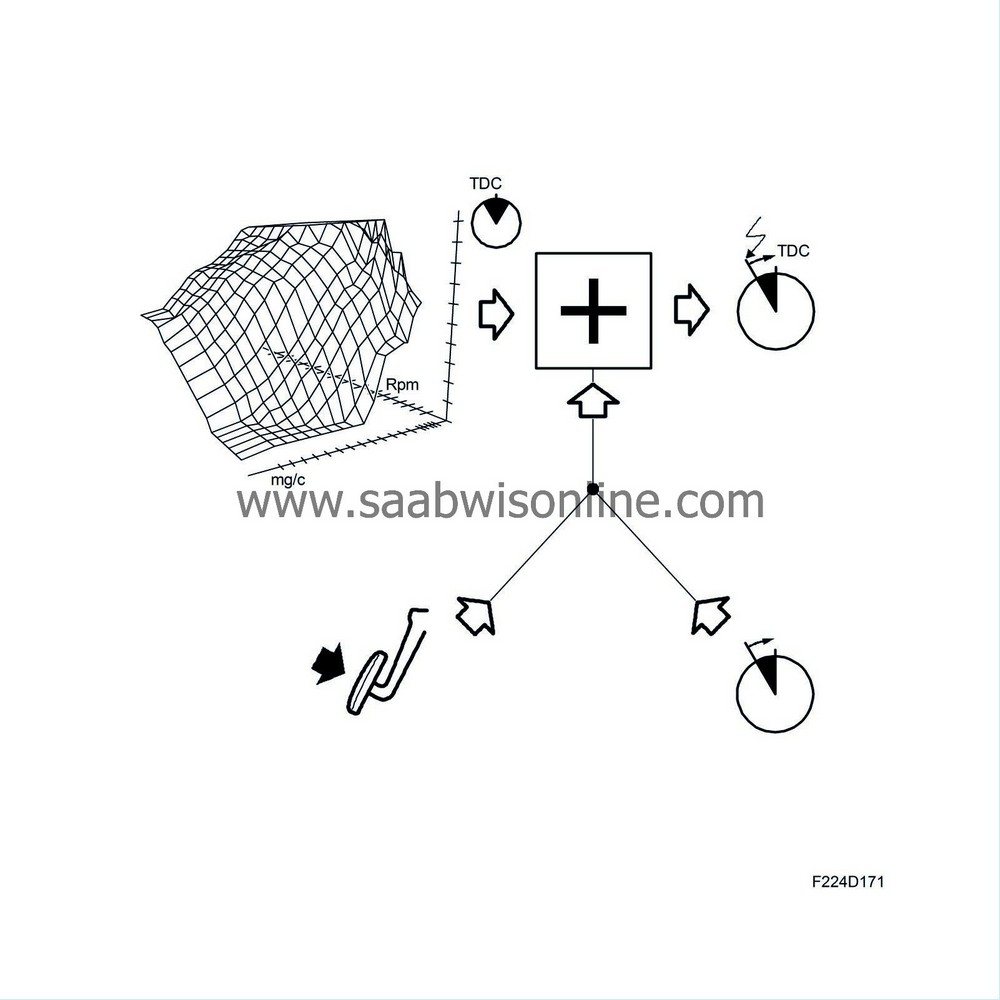

Principle, ignition timing retardation during rapid throttle openings

During rapid opening, the ignition timing will be retarded temporarily to avoid knocking.

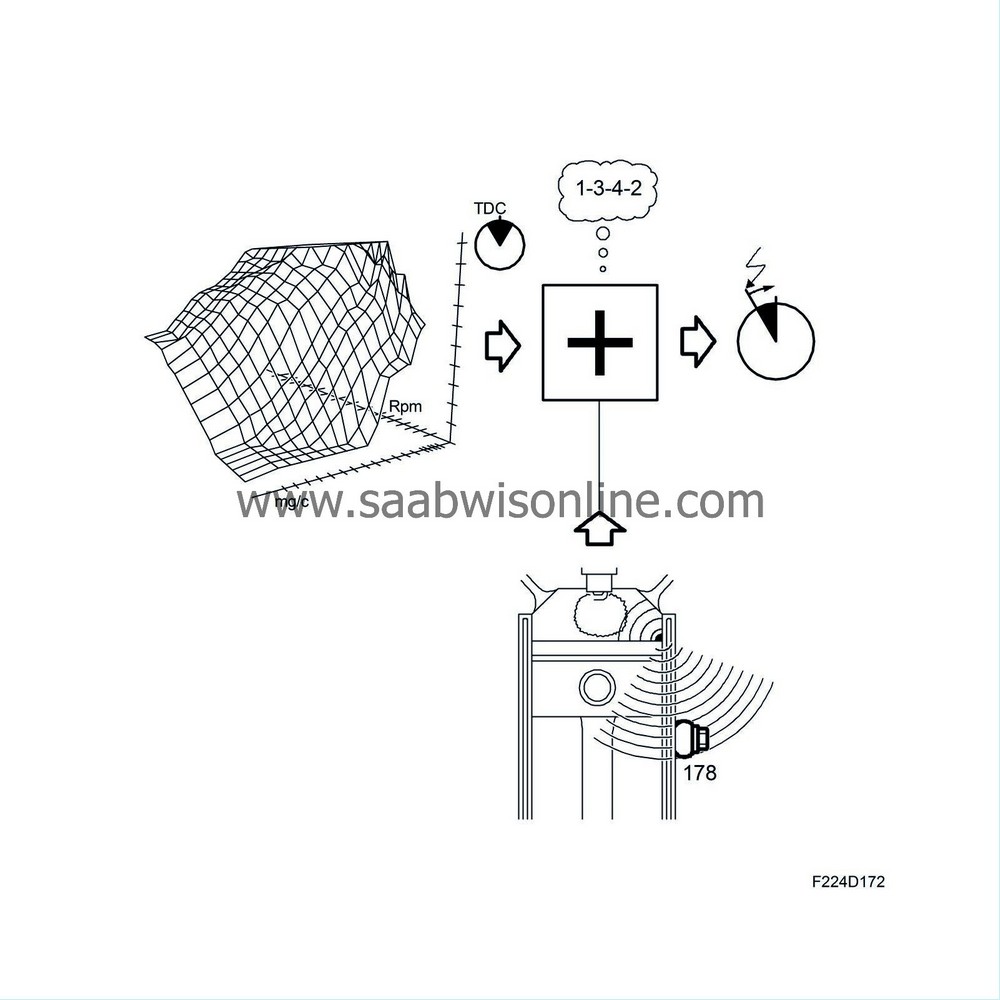

Principle, ignition timing when knocking

The engine has a piezoelectric knock sensor fitted on the cylinder block between cylinders 2 and 3. Its signal is assessed by ECM. When ECM determines the engine is knocking, the timing will be retarded. This takes place in each individual cylinder. The value from knock control, which is negative, is subtracted from the current value of the ignition timing.

Principle, anti-surge compensation

The engine may surge during acceleration. This is caused by sudden increases in engine torque in combination with certain elasticity in the drive line and engine mountings.The anti-surge function detects variations in engine speed and dampens them by influencing the ignition timing, normally to a somewhat more retarded value.

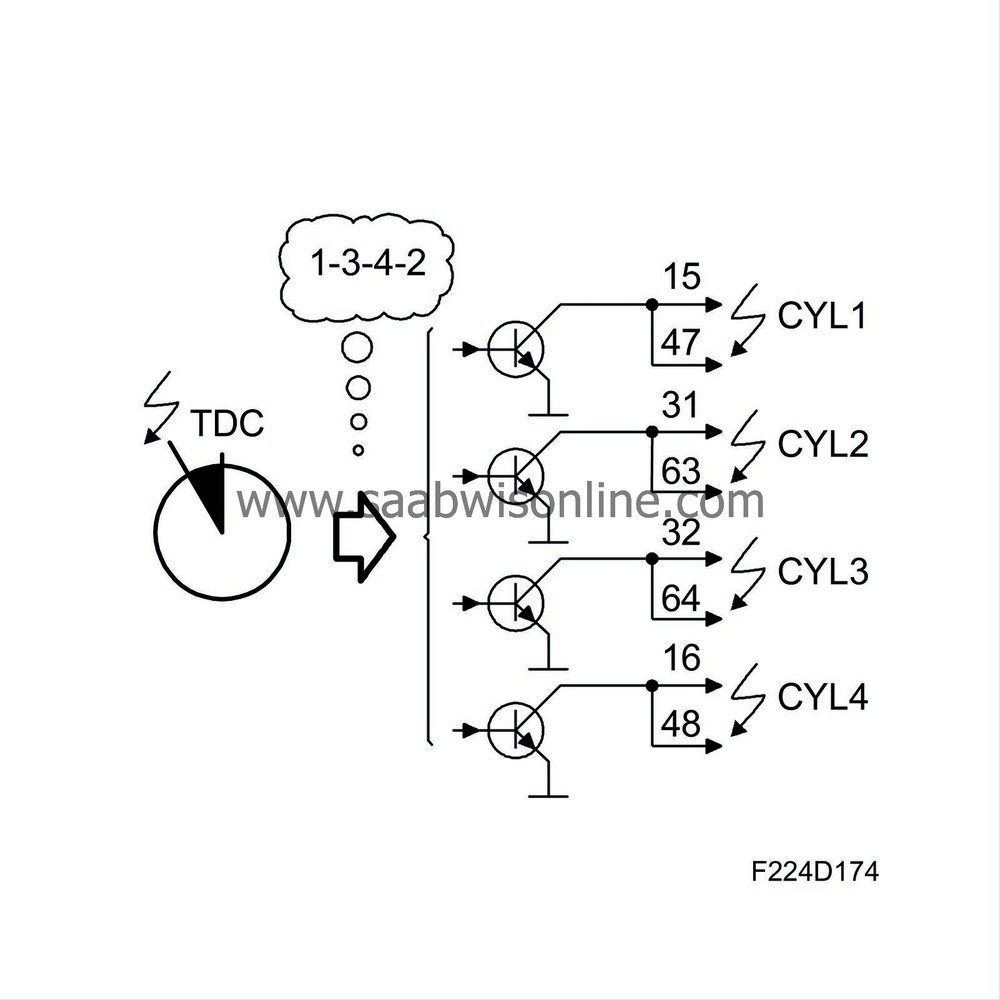

Final ignition timing

The "basic normal ignition timing" after all the compensations will be converted to a signal that controls the output stages for the ignition coils for the four cylinders.