(201-2446 ed. 2) Cylinder block as separate spare part

|

TECHNICAL SERVICE BULLETIN

|

|

Bulletin Nbr:

|

201-2446 ed. 2

|

|

Date:

...........

|

April 2004

|

|

Market:

|

all

|

|

|

Cylinder block as separate spare part

|

9-3 (9440) with engine variant B207

The cylinder block is now available as a separate spare part including pistons, connecting rods, crankshaft, and water pump with pinion and balancer. A new tool, 83 96 392 Lock pin, has been developed to lock the chain tensioner.

|

1.

|

Place the car on a lift.

CV

: Remove the chassis reinforcement, front subframe.

|

|

2.

|

Place a receptacle under the car. Use protective gloves. Remove the plug and drain the gearbox oil. Fit the plug.

Tightening torque, automatic transmission 45 Nm (33 lbf ft)

Tightening torque, manual gearbox 50 Nm (37 lbf ft)

|

|

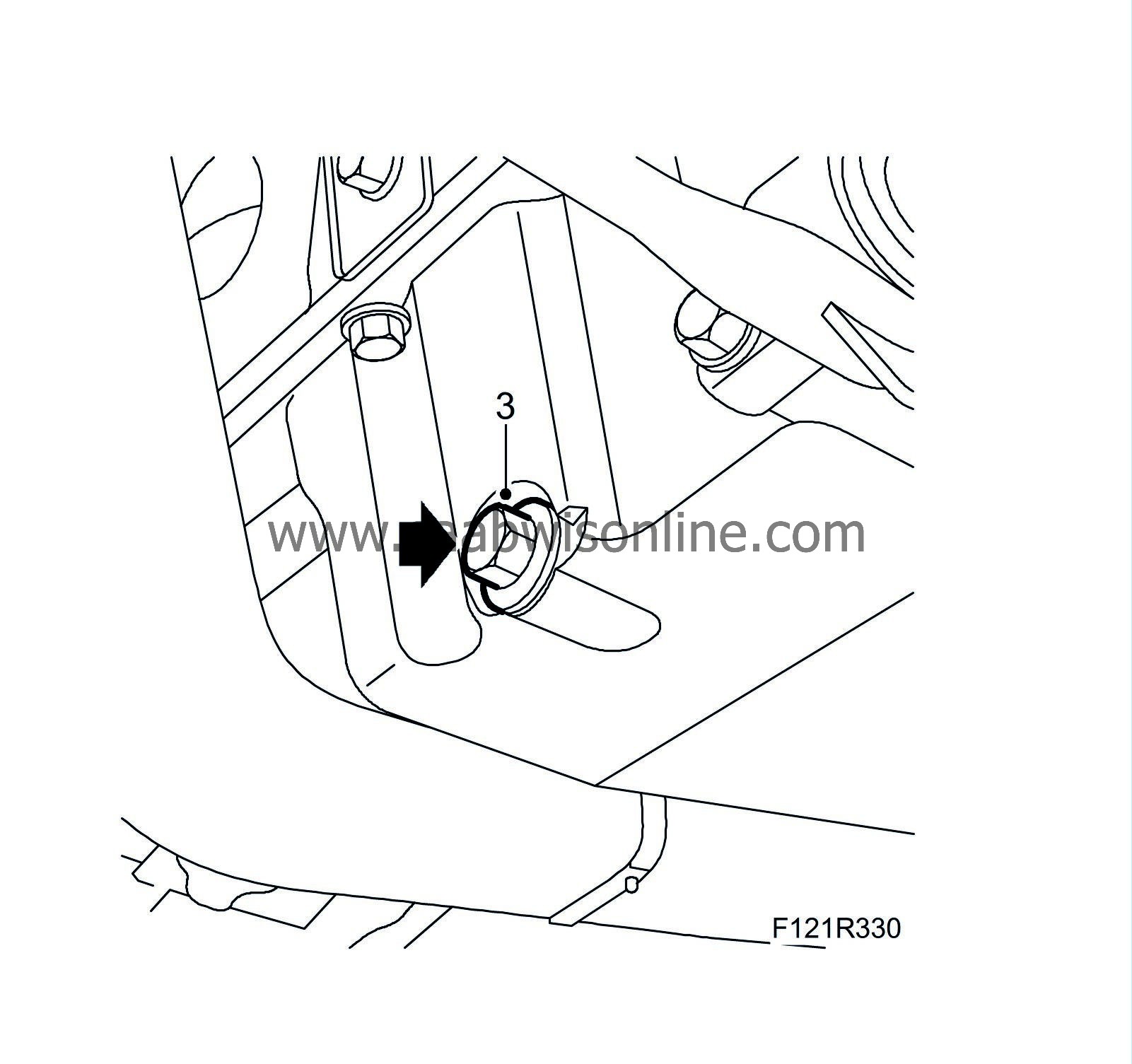

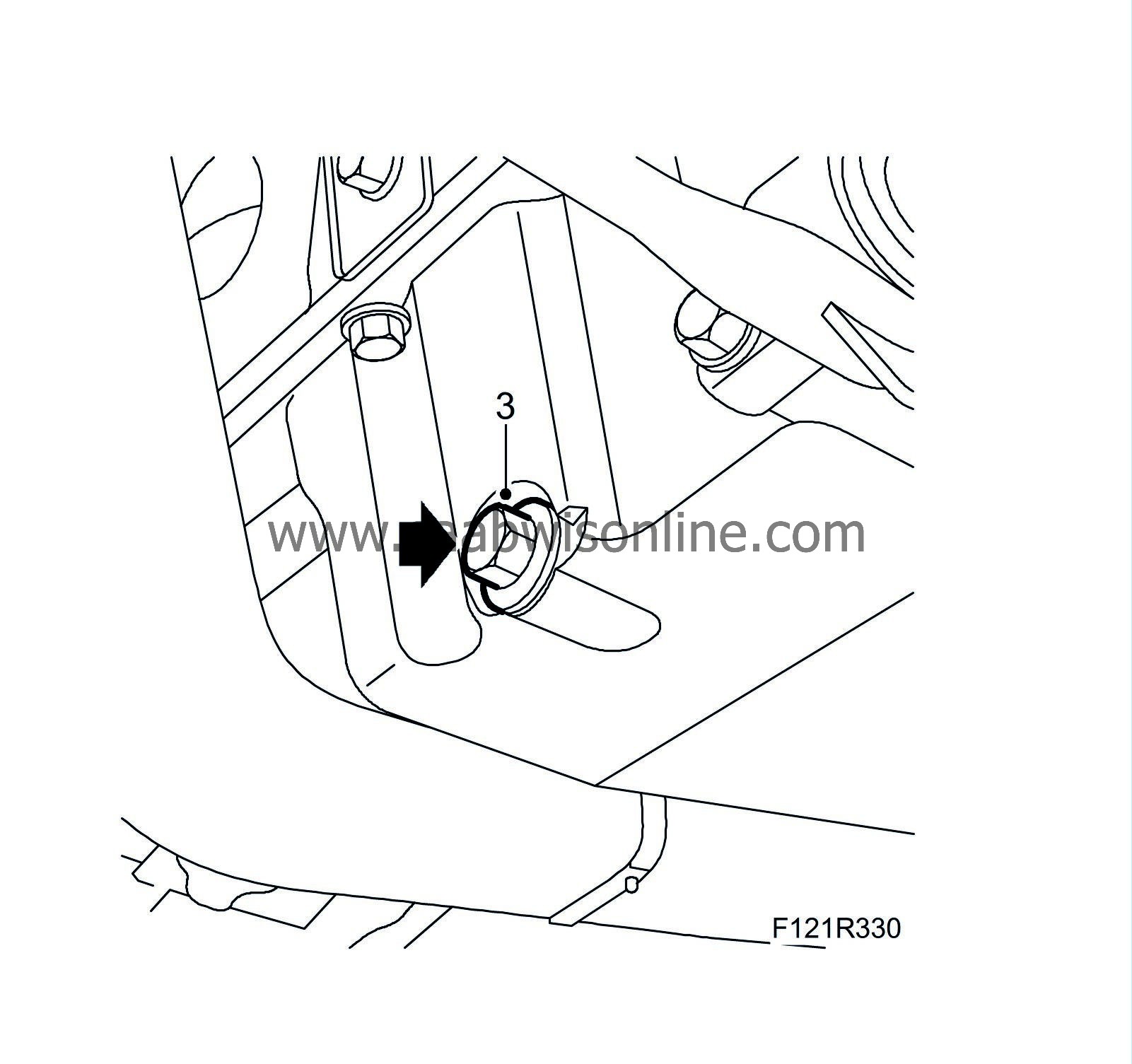

3.

|

Remove the drain plug and drain the engine oil. Fit the plug with a new O-ring.

Tightening torque 25 Nm (18 lbf ft)

|

|

4.

|

Remove the engine assembly, see WIS - 9-3 (9440) - Engine - 4 cylinder petrol - Basic engine - Adjustment/Replacement - Power train removal.

|

|

5.

|

Allow the power train to remain on the trolley lift.

|

|

6.

|

Remove the cover to the spark plugs.

|

|

7.

|

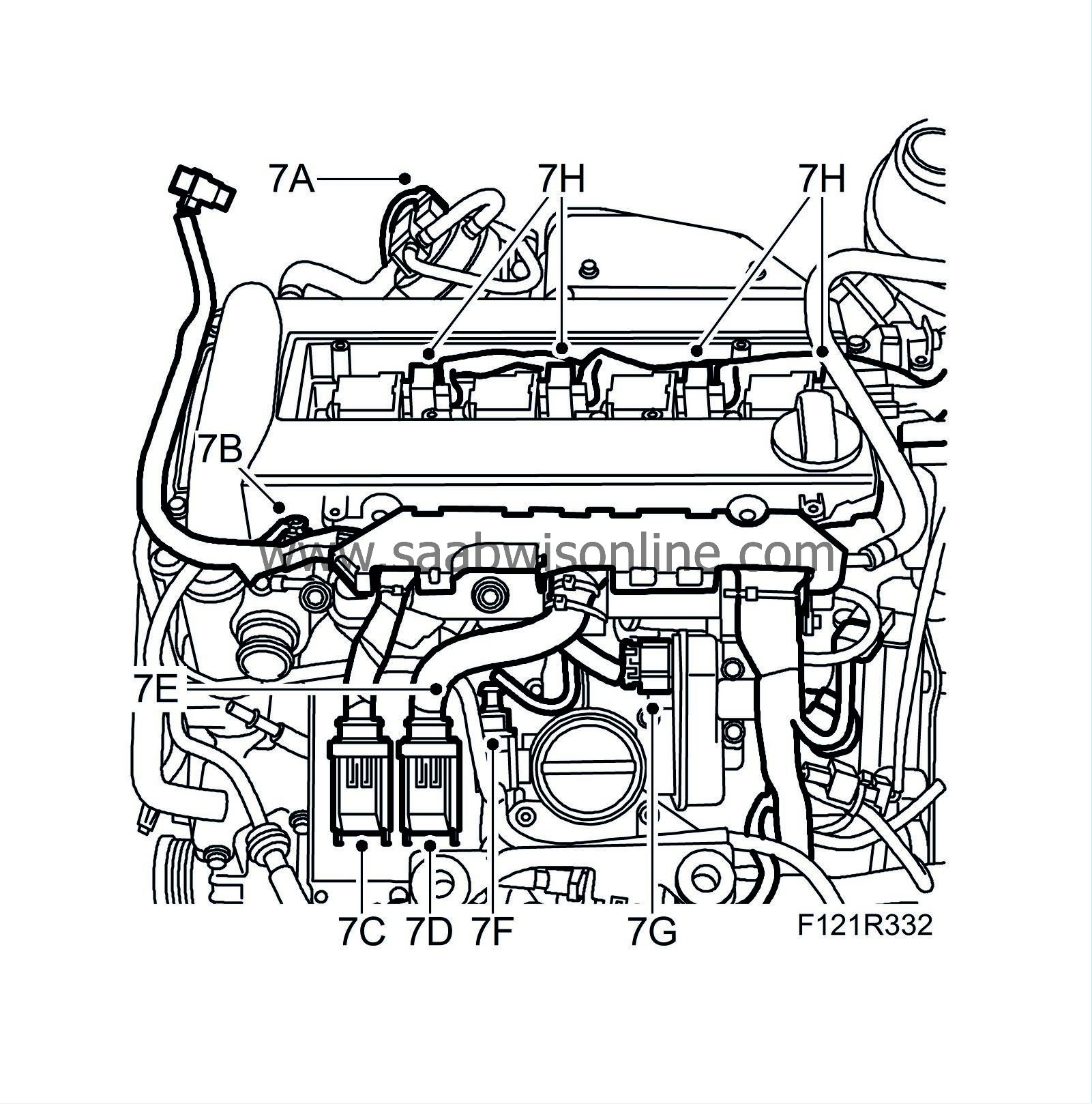

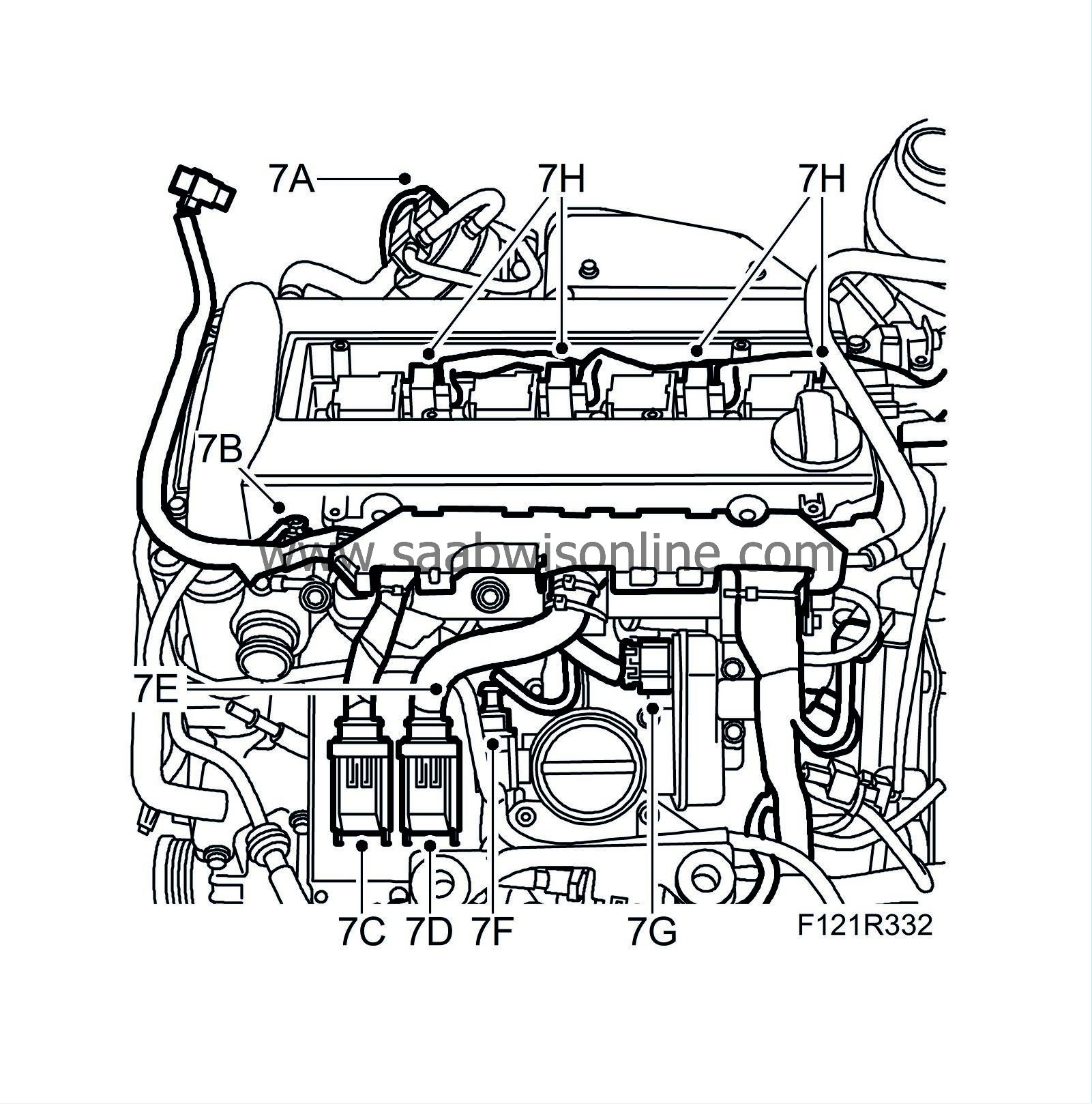

Remove the engine wiring harness using the following method:

|

|

|

7.A.

|

Unplug the connector from the charge air control valve.

|

|

|

7.B.

|

Unplug the connector from the coolant temperature sensor.

|

|

|

7.C.

|

Unplug the engine control module connector.

|

|

|

7.D.

|

Unplug the engine control module connector.

|

|

|

7.E.

|

Unplug the connector from grounding point G7.

|

|

|

7.F.

|

Unplug the bypass valve connector.

|

|

|

7.G.

|

Unplug the throttle body connector.

|

|

|

7.H.

|

Unplug the 4 ignition coil connectors.

|

|

|

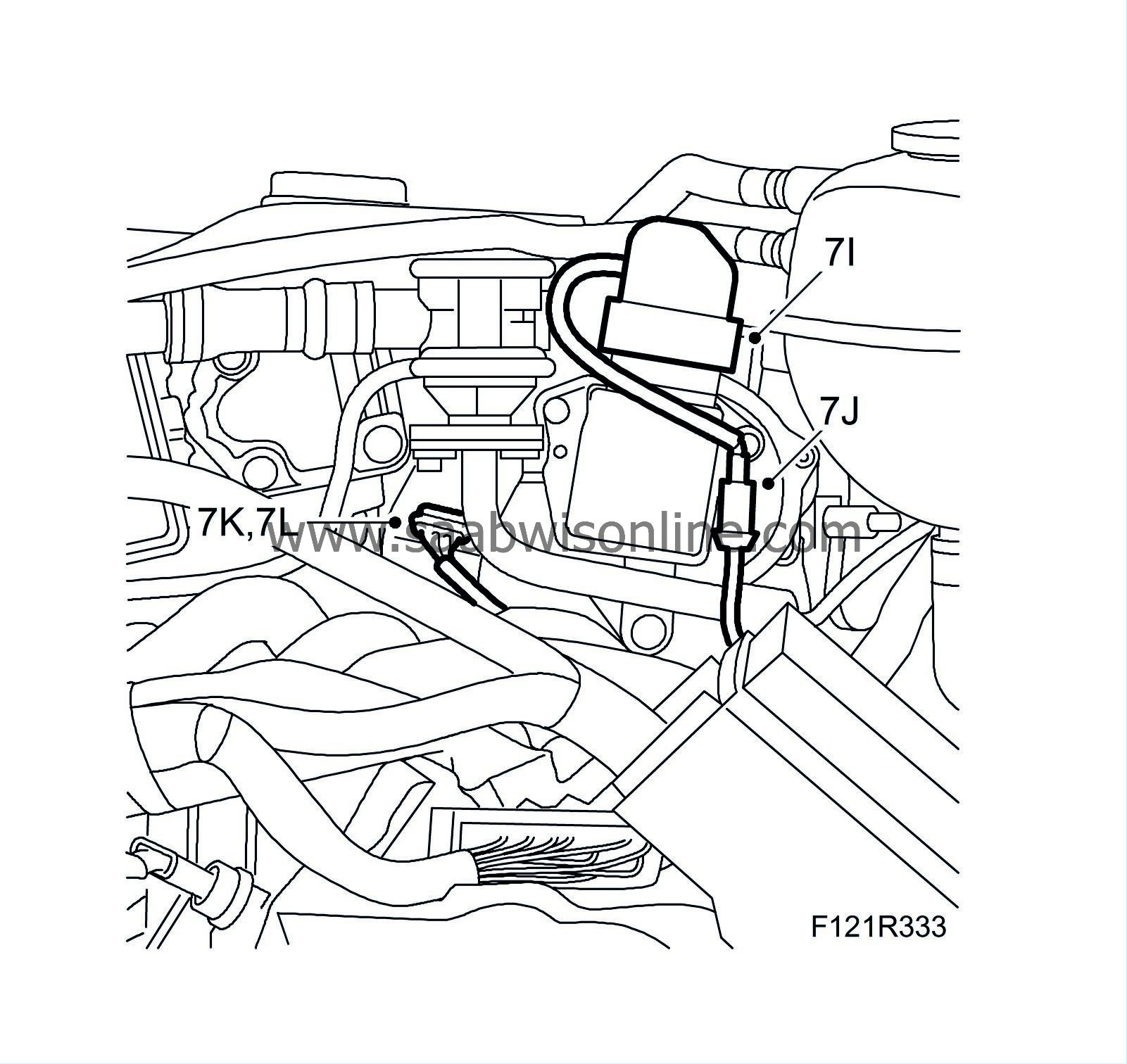

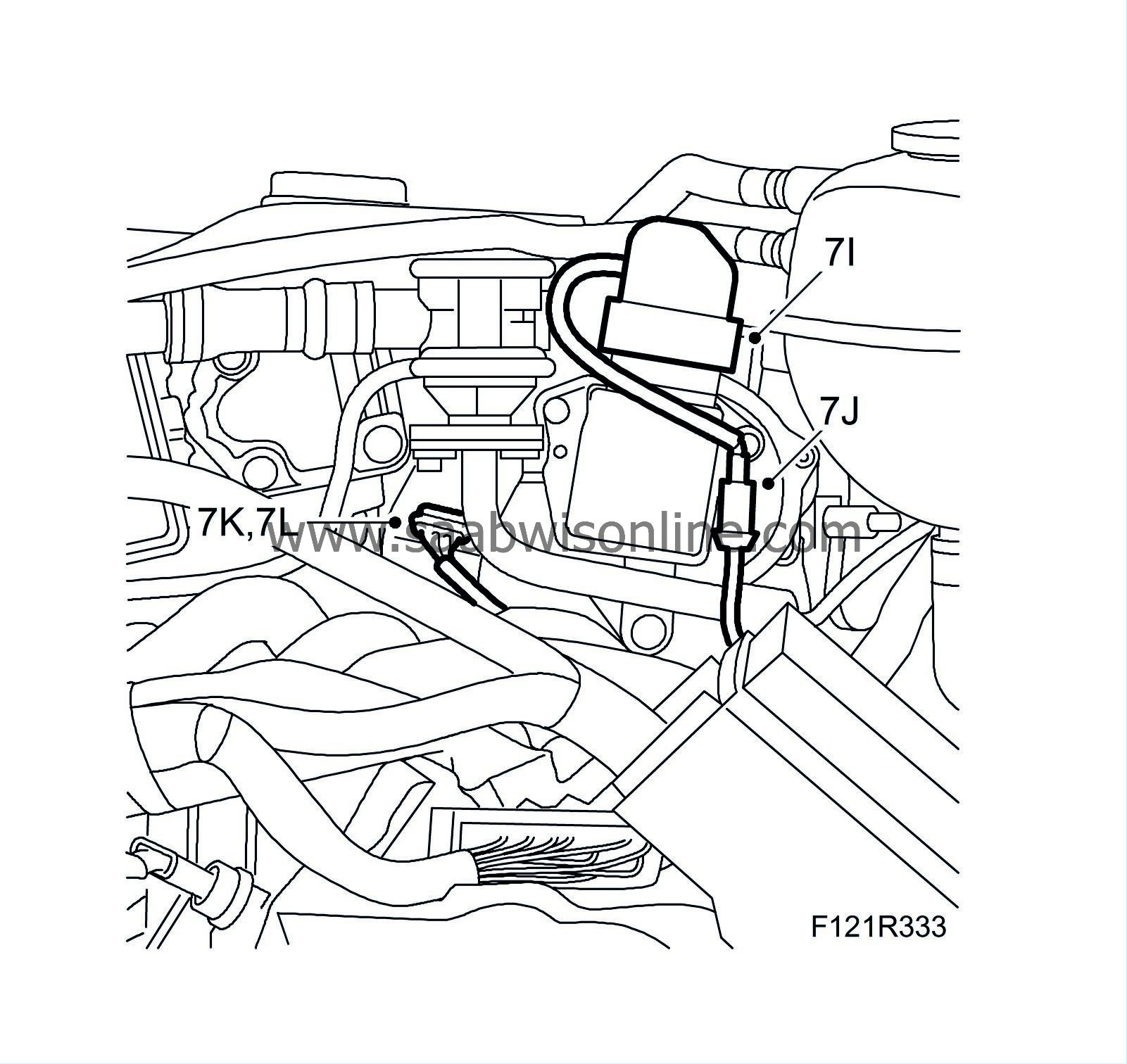

7.I.

|

Unplug the connector from the ionization detection module.

|

|

|

7.J.

|

M03

: Unplug the connector from the exhaust temperature sensor.

|

|

|

7.K.

|

Unplug the connector from the front heated oxygen sensor.

|

|

|

7.L.

|

Unplug the connector from the rear heated oxygen sensor.

|

|

|

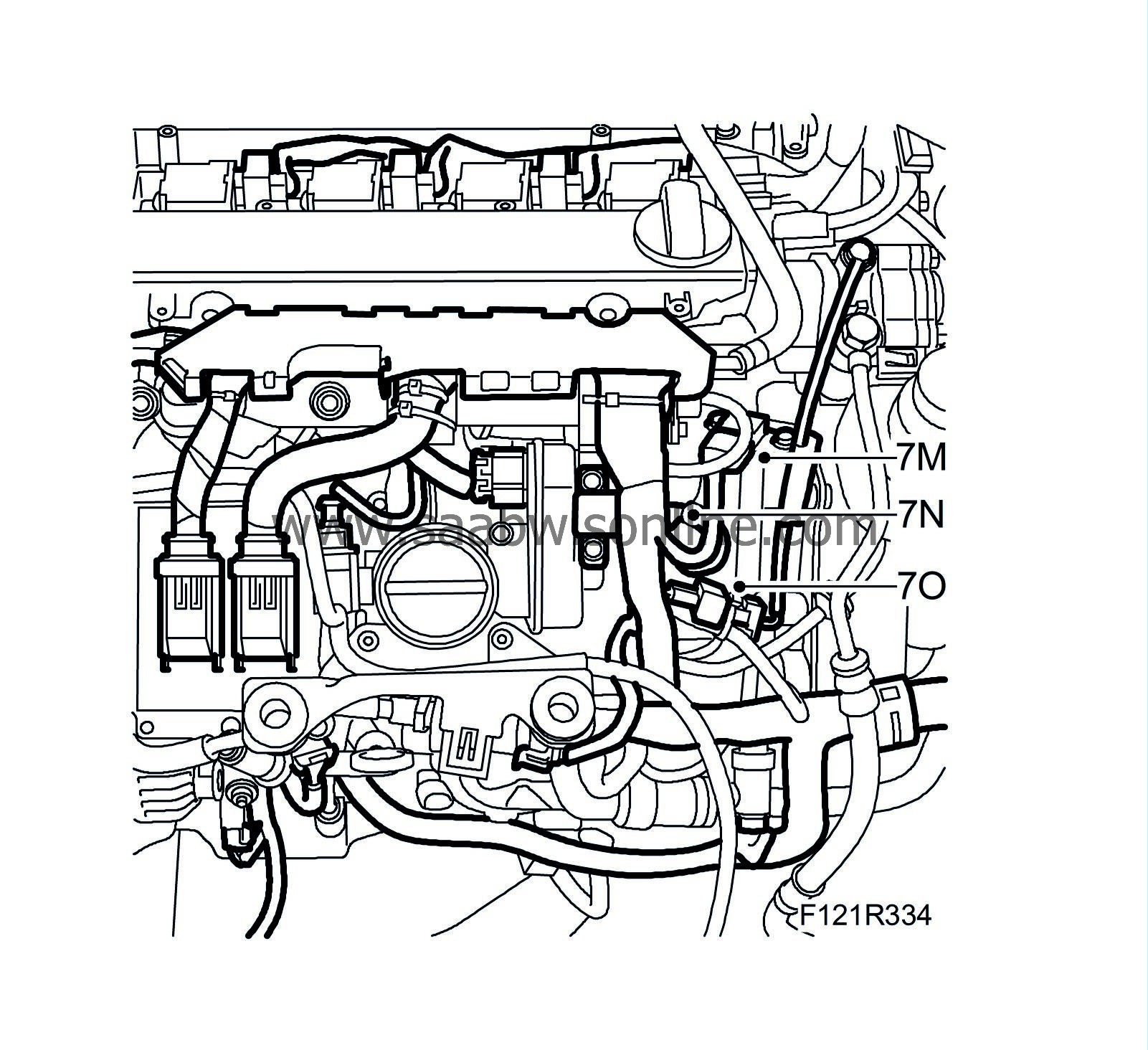

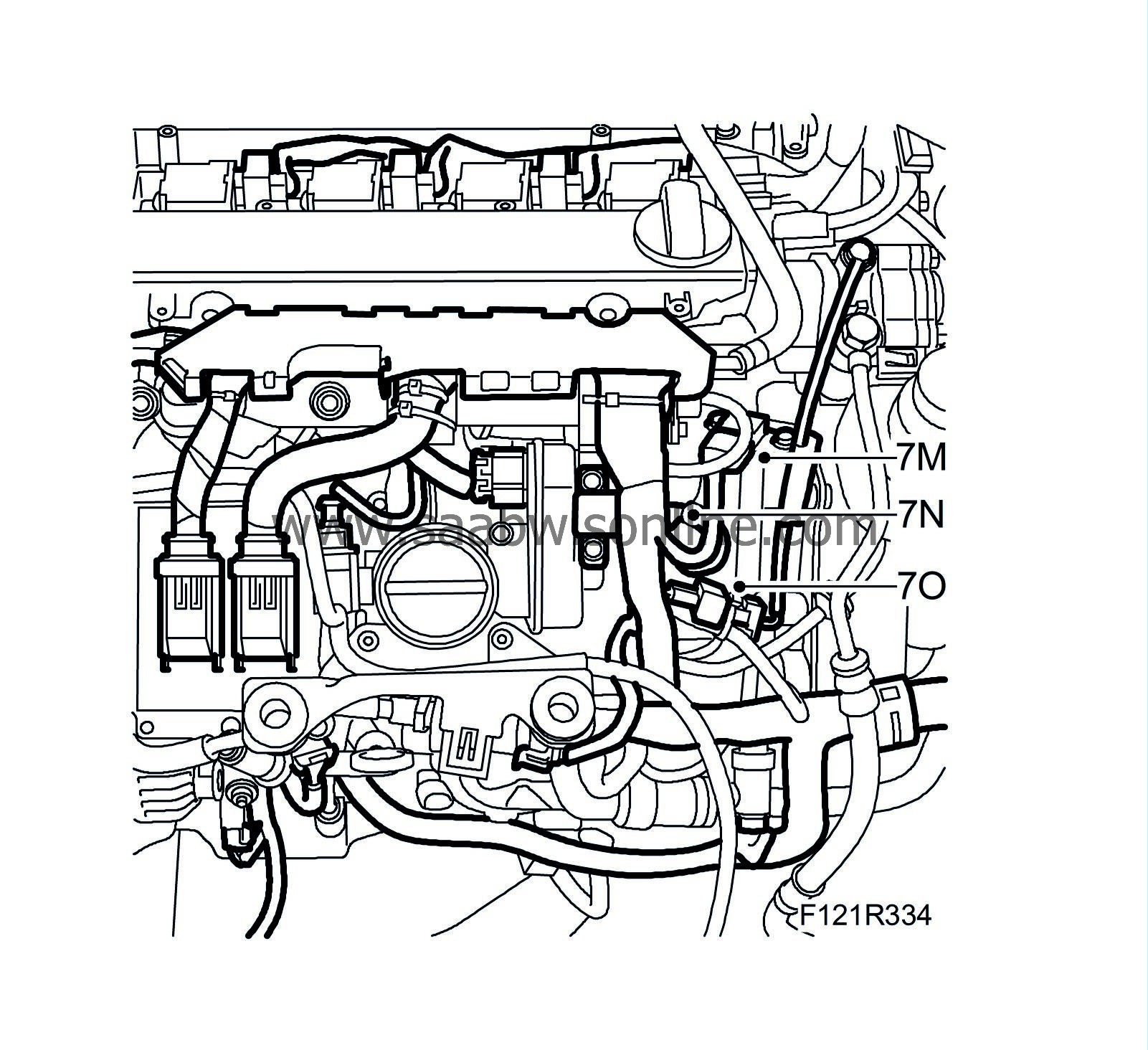

7.M.

|

Unplug the connector from the atmospheric pressure sensor.

|

|

|

7.N.

|

Unplug the connector from the intake manifold pressure sensor.

|

|

|

7.O.

|

Remove the power steering fluid pressure switch.

|

|

|

7.P.

|

Remove the starter motor contacts.

|

|

|

7.Q.

|

Cars with secondary air injection pump

: Unplug the secondary air injection pump connector.

|

|

|

7.R.

|

Remove the oil pressure switch.

|

|

|

7.S.

|

Unplug the connector from the crankshaft position sensor.

|

|

|

7.T.

|

Unplug the EVAP canister purge valve connector.

|

|

|

7.U.

|

Unplug the oil level sensor connector.

|

|

|

7.V.

|

Unplug the generator connector.

|

|

|

7.W.

|

Unplug connector H8-9.

|

|

|

7.X.

|

Cars with manual gearbox

: Unplug the reverse light contact.

|

|

|

7.Y.

|

Remove the wiring harness retaining bolts. Pull out the wiring harness and lift it aside.

|

|

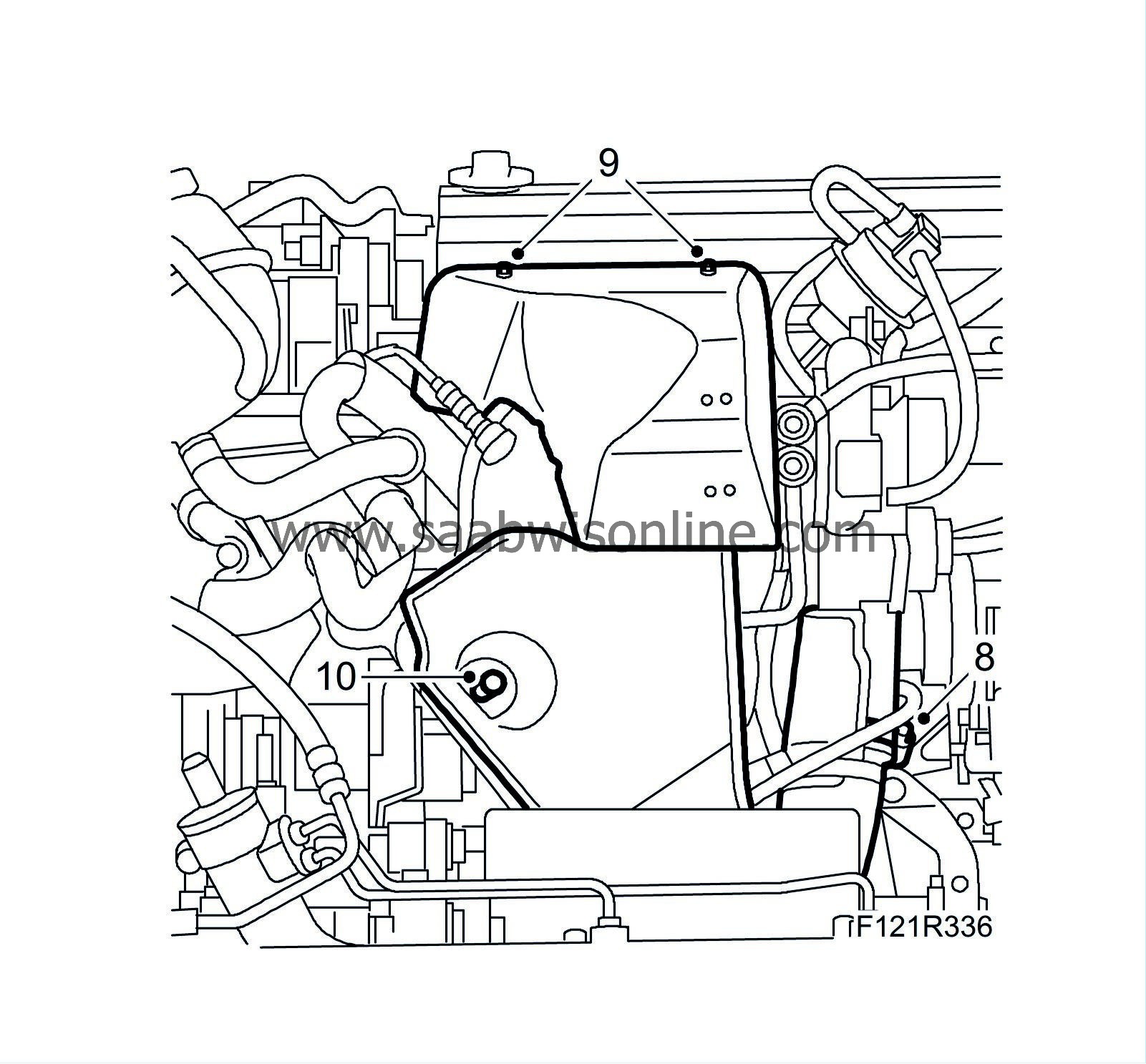

8.

|

Remove the lower charge air pipe.

|

|

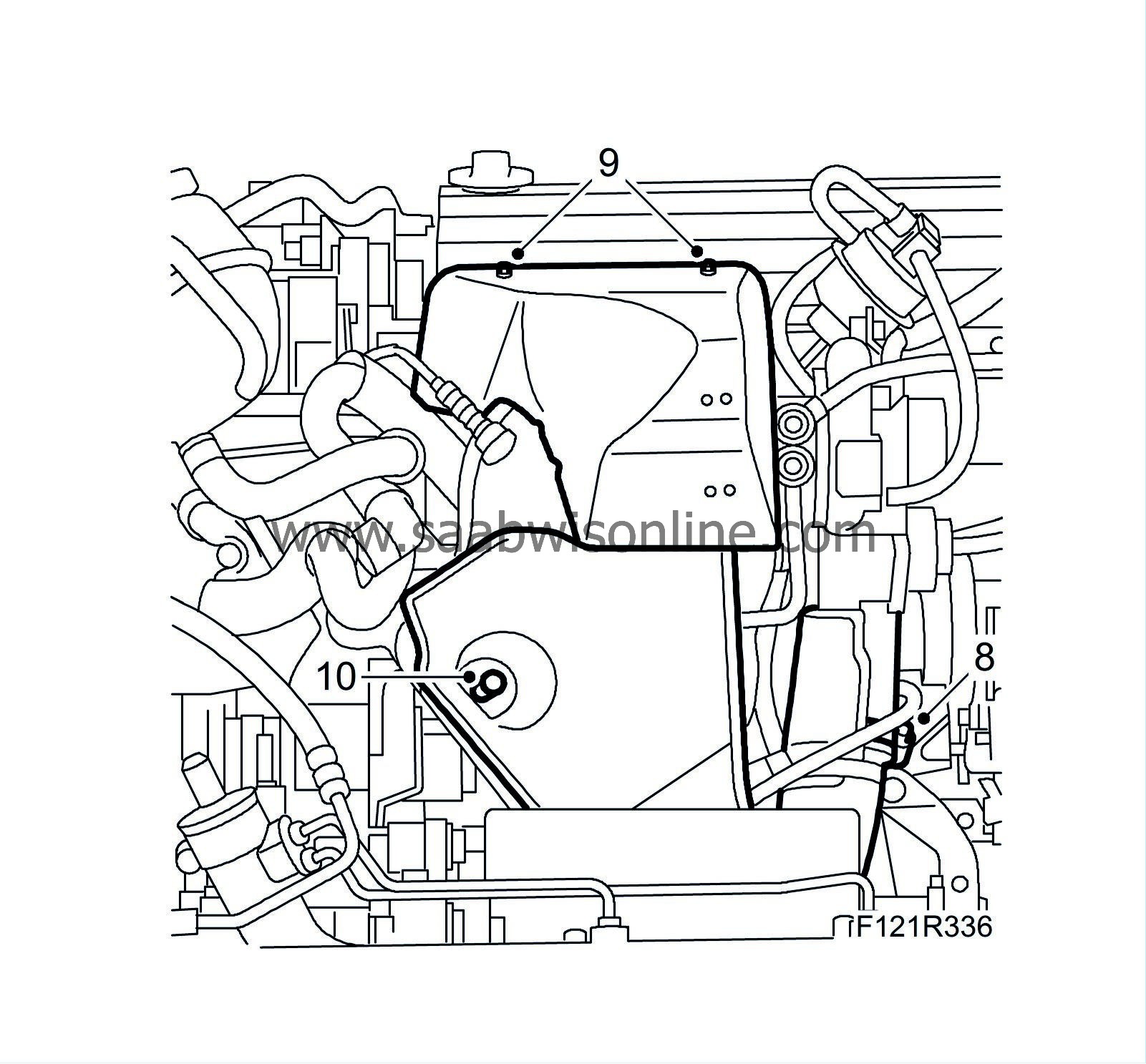

9.

|

Remove the turbocharger heat shield.

|

|

10.

|

Remove the catalytic converter heat shield.

|

|

11.

|

Unplug the heated oxygen sensor connectors and lower the cables carefully.

|

|

12.

|

Unplug the temperature sensor connector and lower it carefully.

|

|

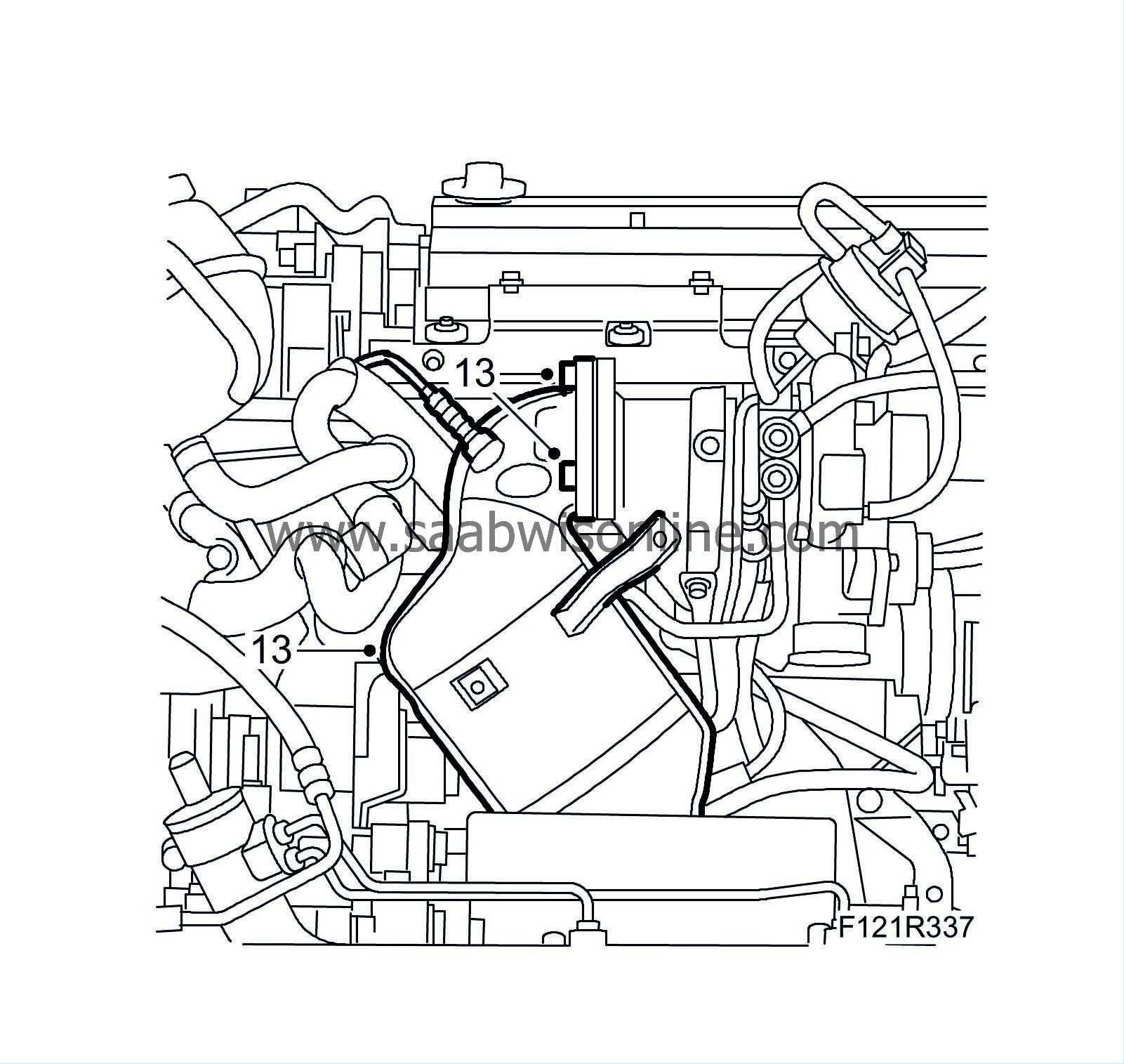

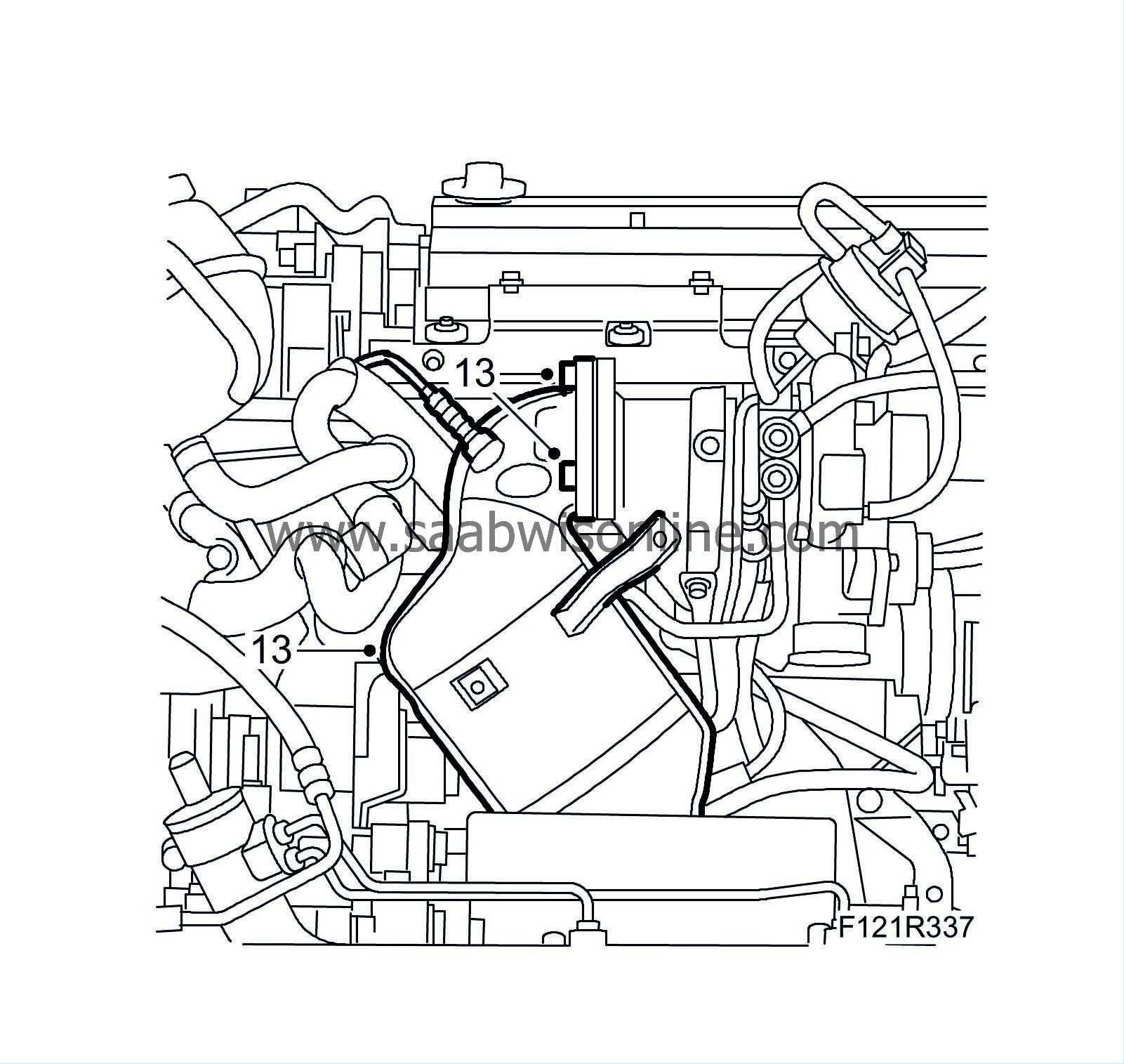

13.

|

Remove the catalytic converter from the cylinder block and the turbocharger. Lubricate the turbocharger studs with rust solvent oil. Lift out the catalytic converter.

|

|

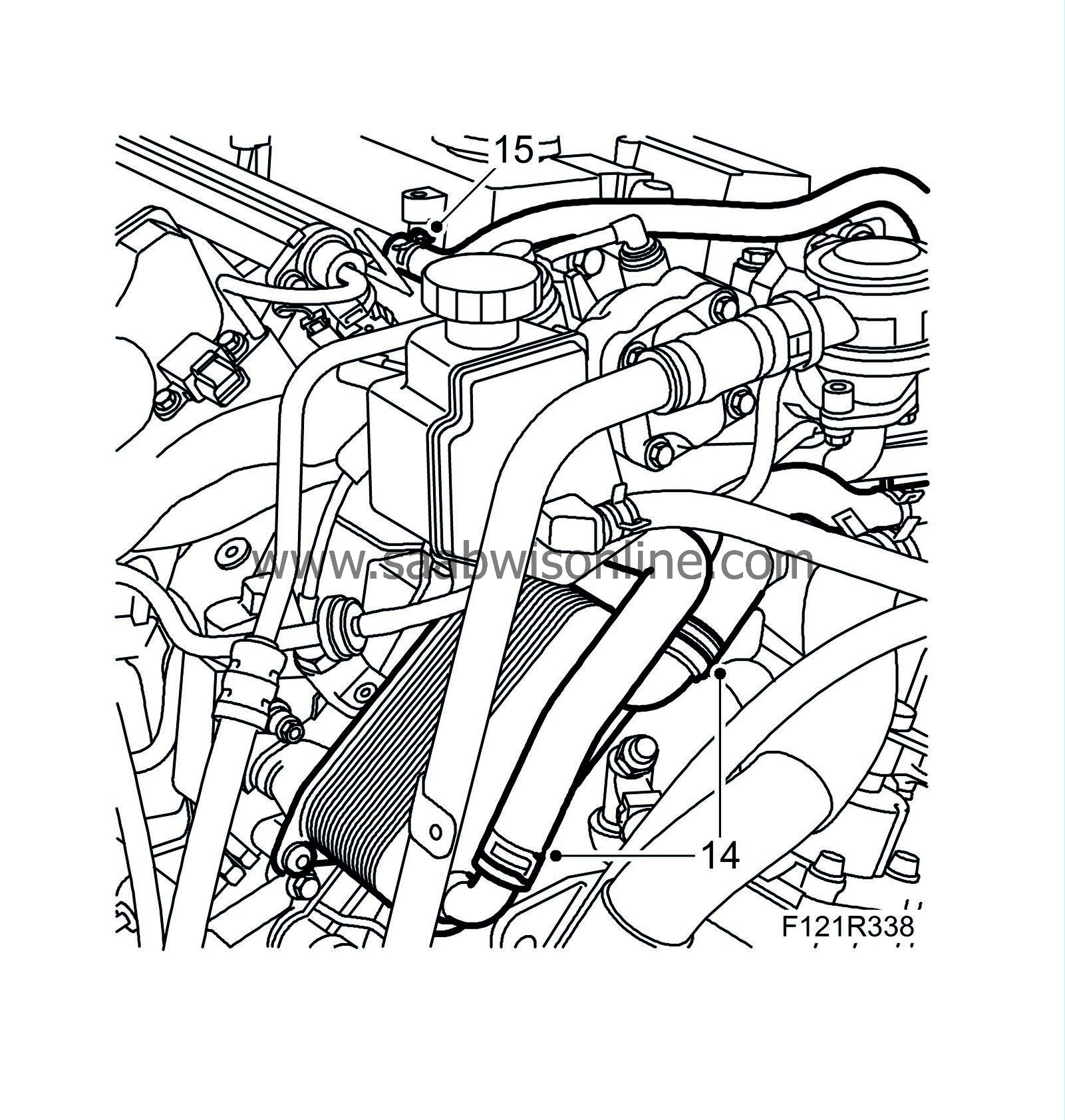

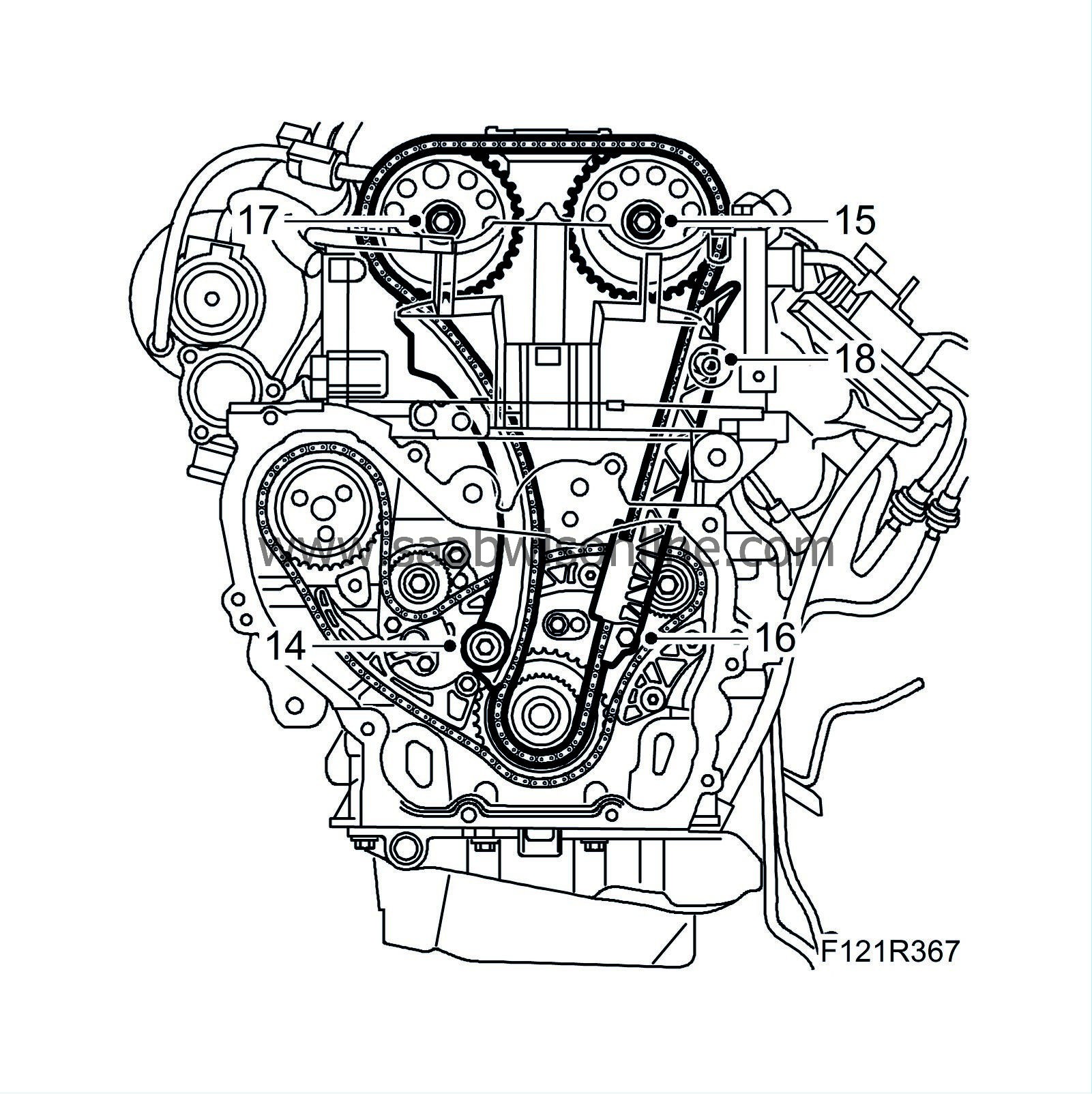

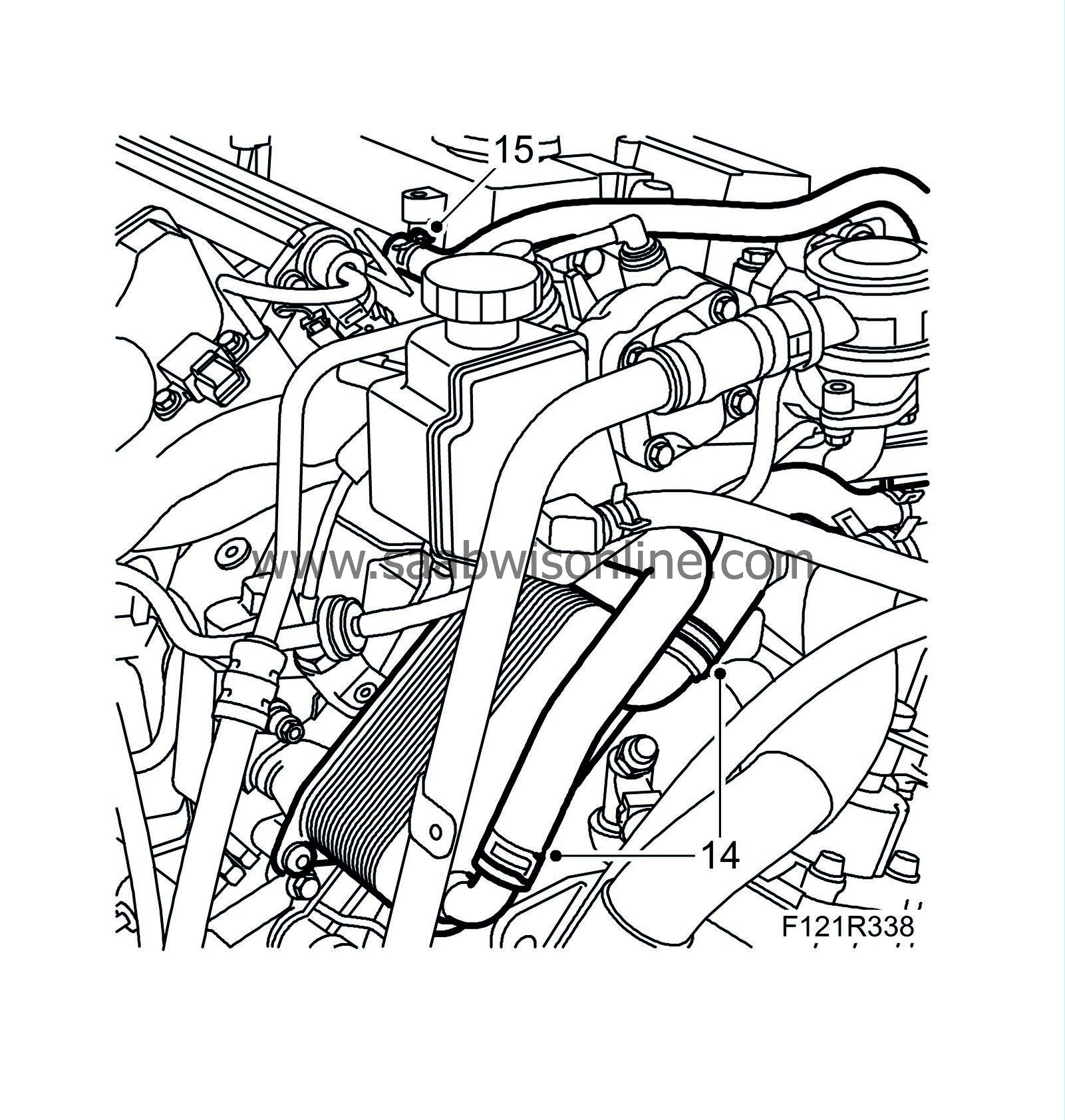

14.

|

Remove the hoses from the coolant-cooled oil cooler.

|

|

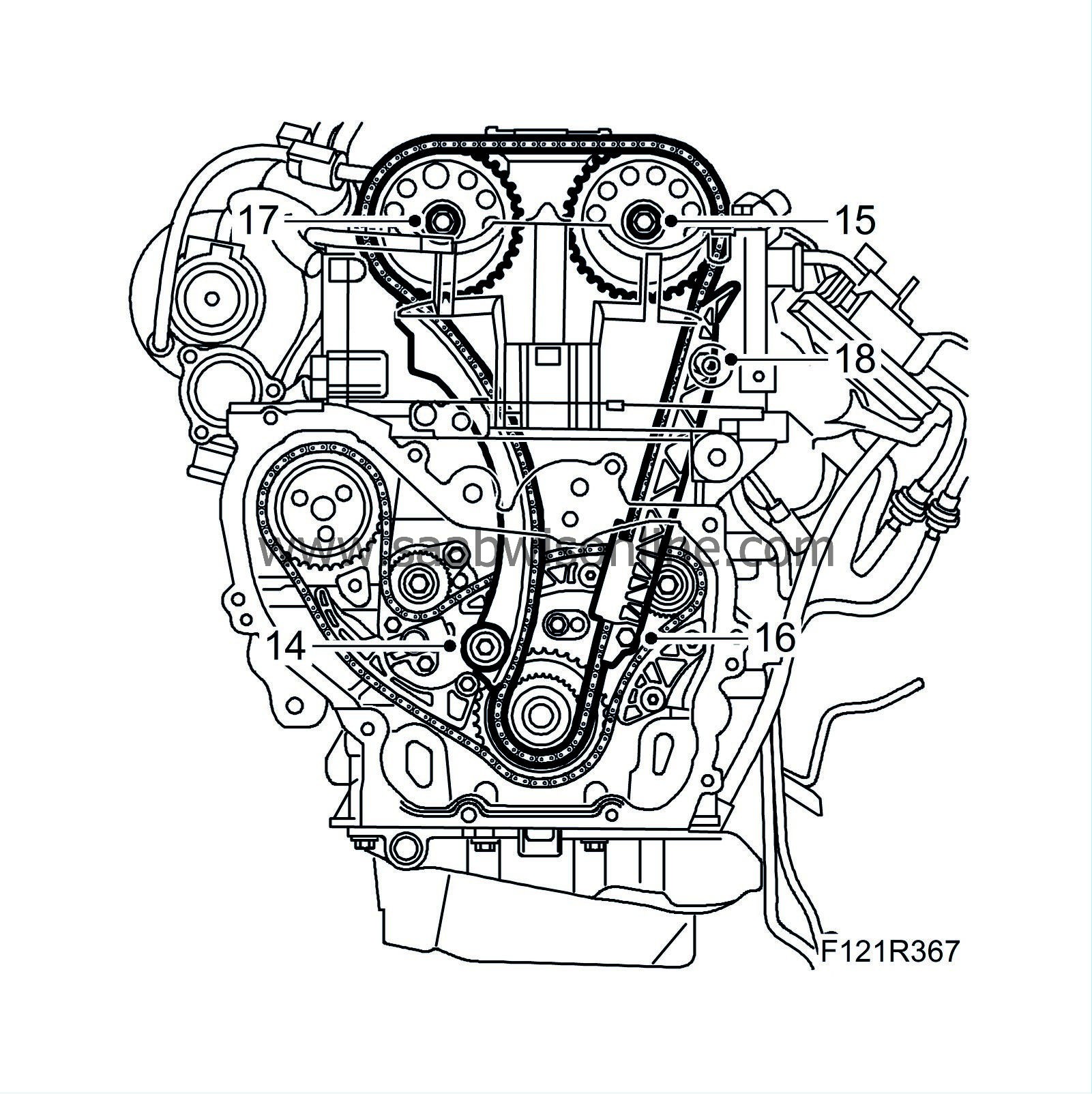

15.

|

Remove the breather hose on the cylinder head.

|

|

16.

|

Remove the turbocharger coolant pipe.

|

|

17.

|

Remove the thermostat housing and pipe. Allow the hoses to remain on the thermostat housing.

|

|

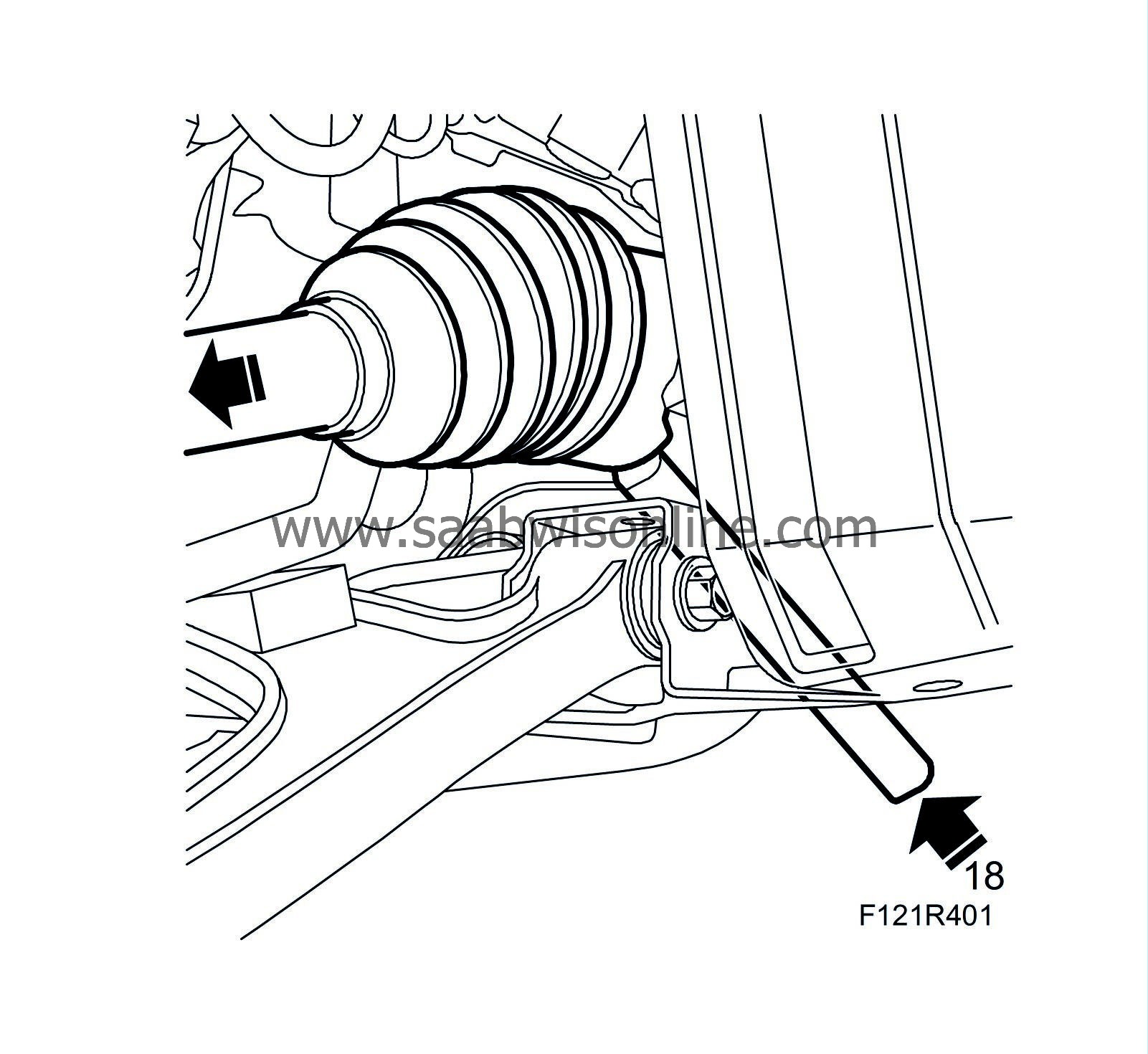

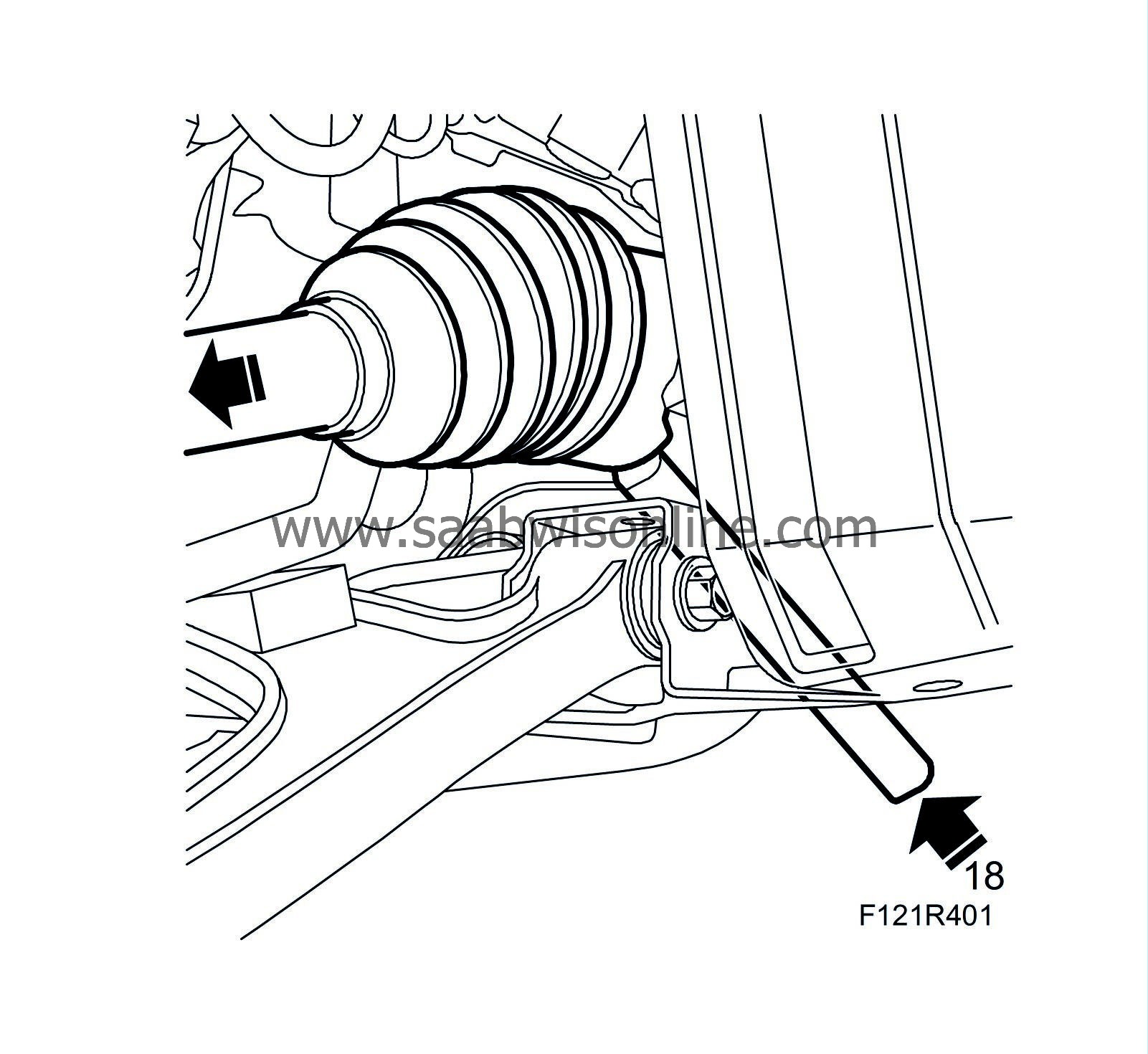

18.

|

RH side

: Tap out the drive shaft from the intermediate shaft with a brass drift and mallet. Lift out the drive shaft.

|

|

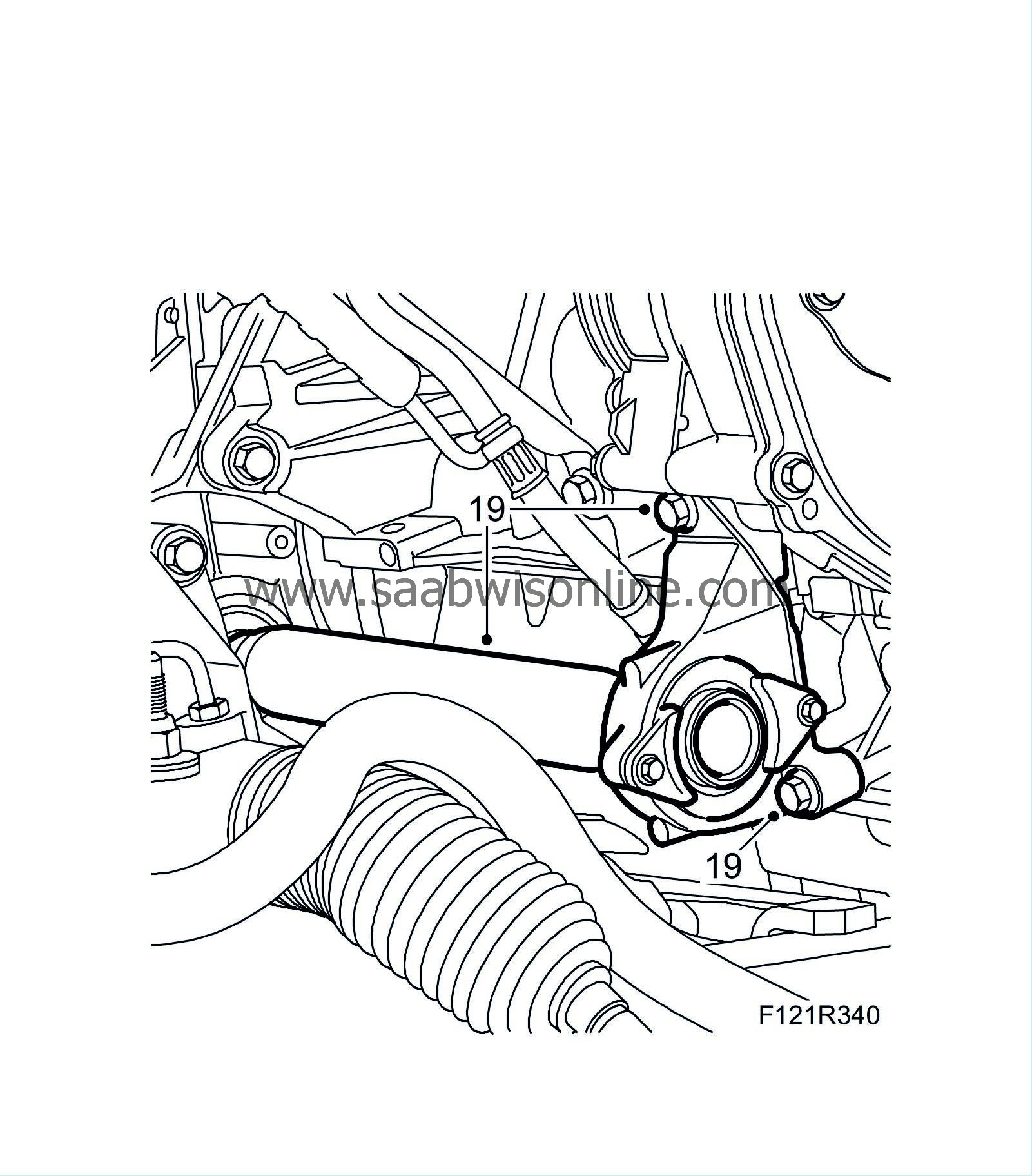

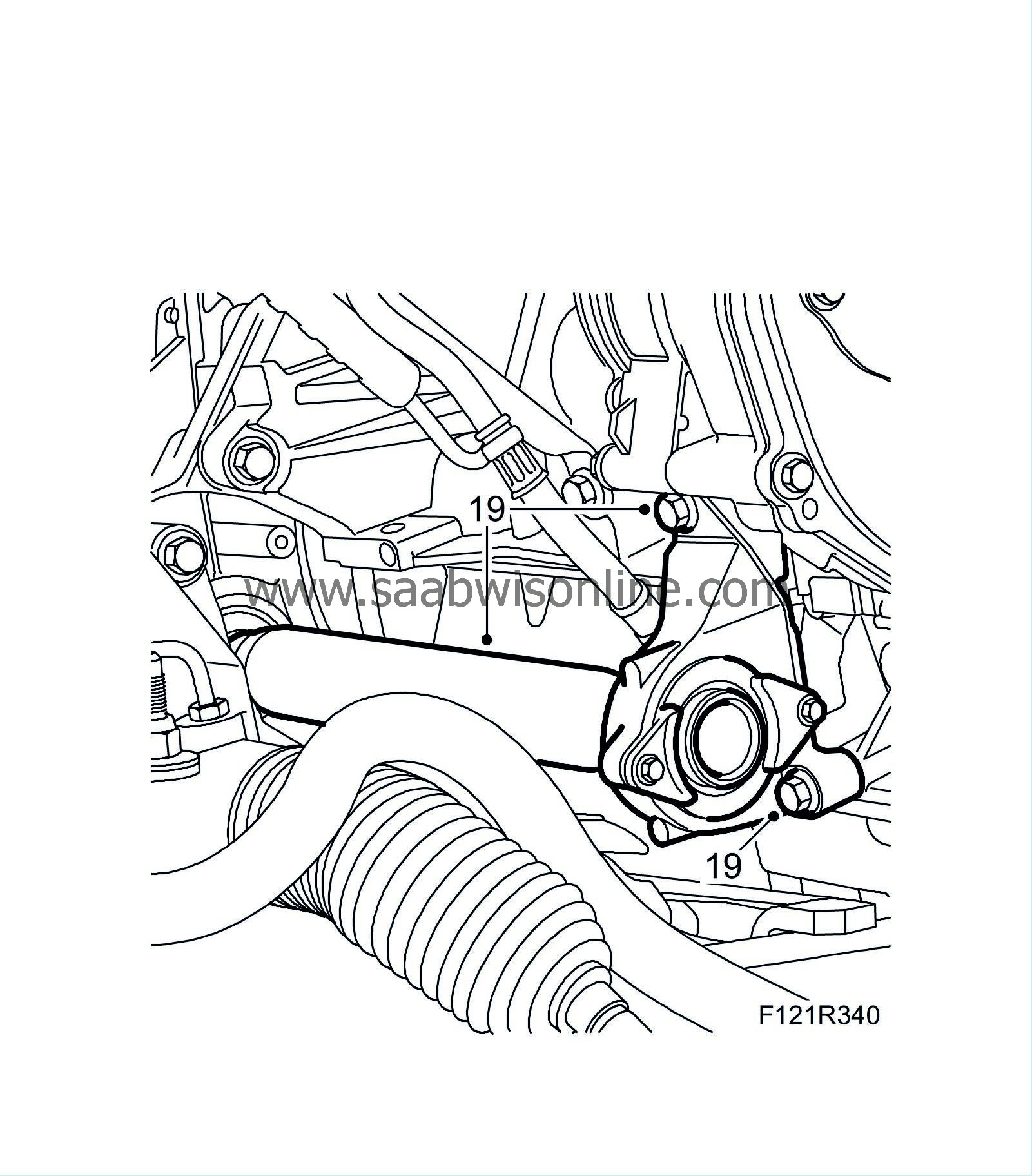

19.

|

Remove the intermediate shaft from the engine.

|

|

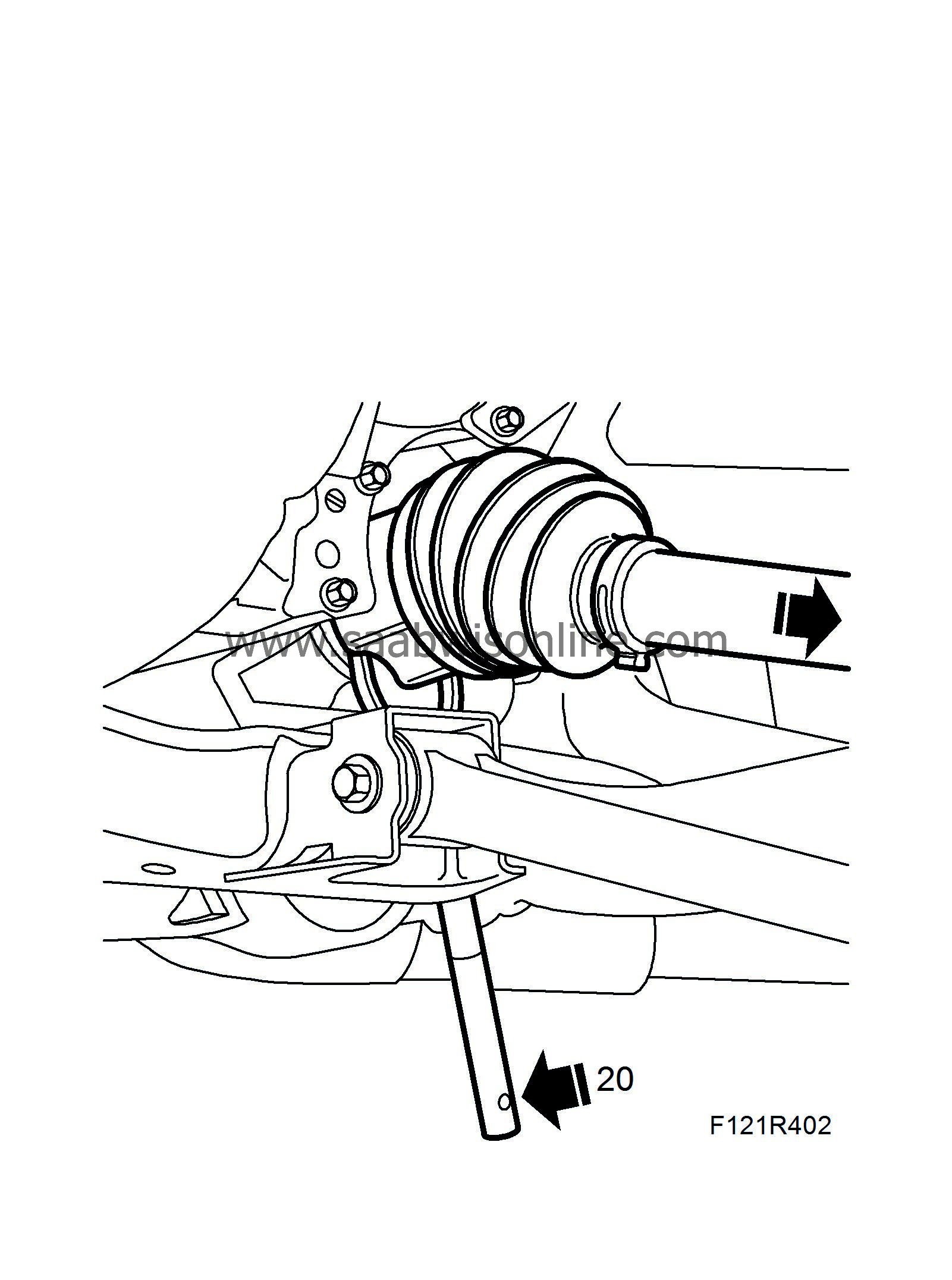

20.

|

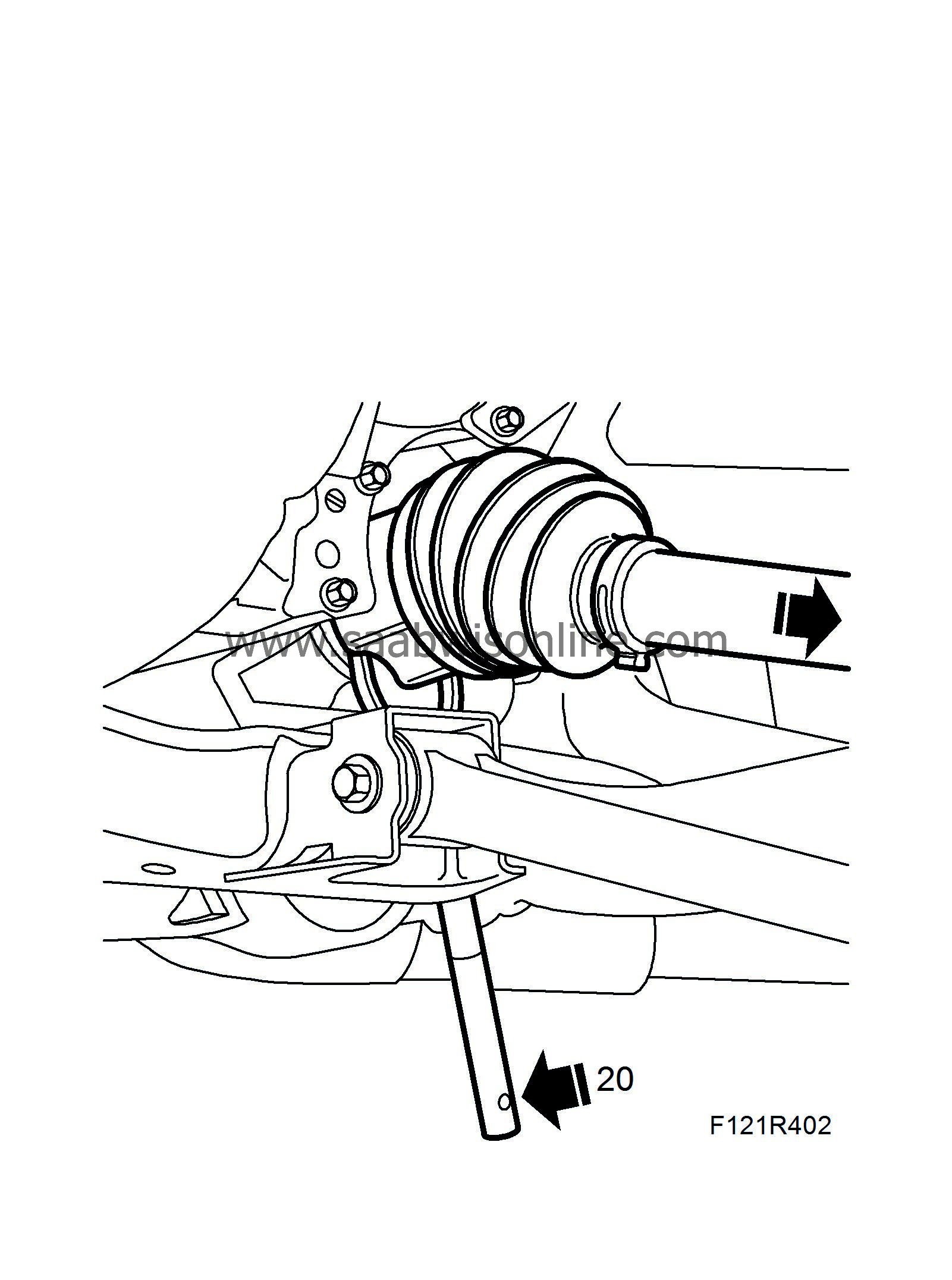

LH side

: Pull out the drive shaft from the gearbox. Prise with 87 92 616 Removal tool, drive shafts. Lift out the drive shaft.

|

|

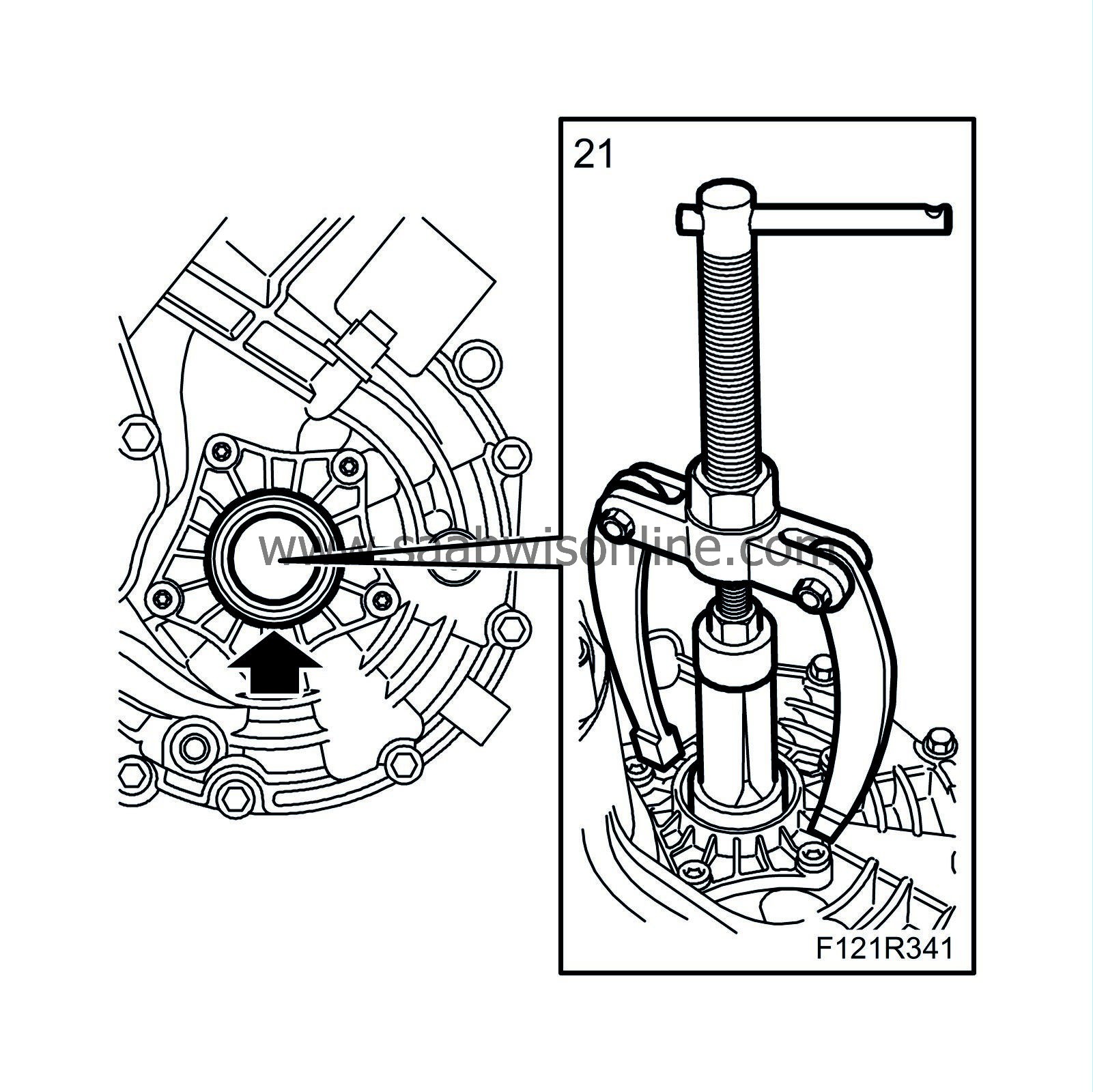

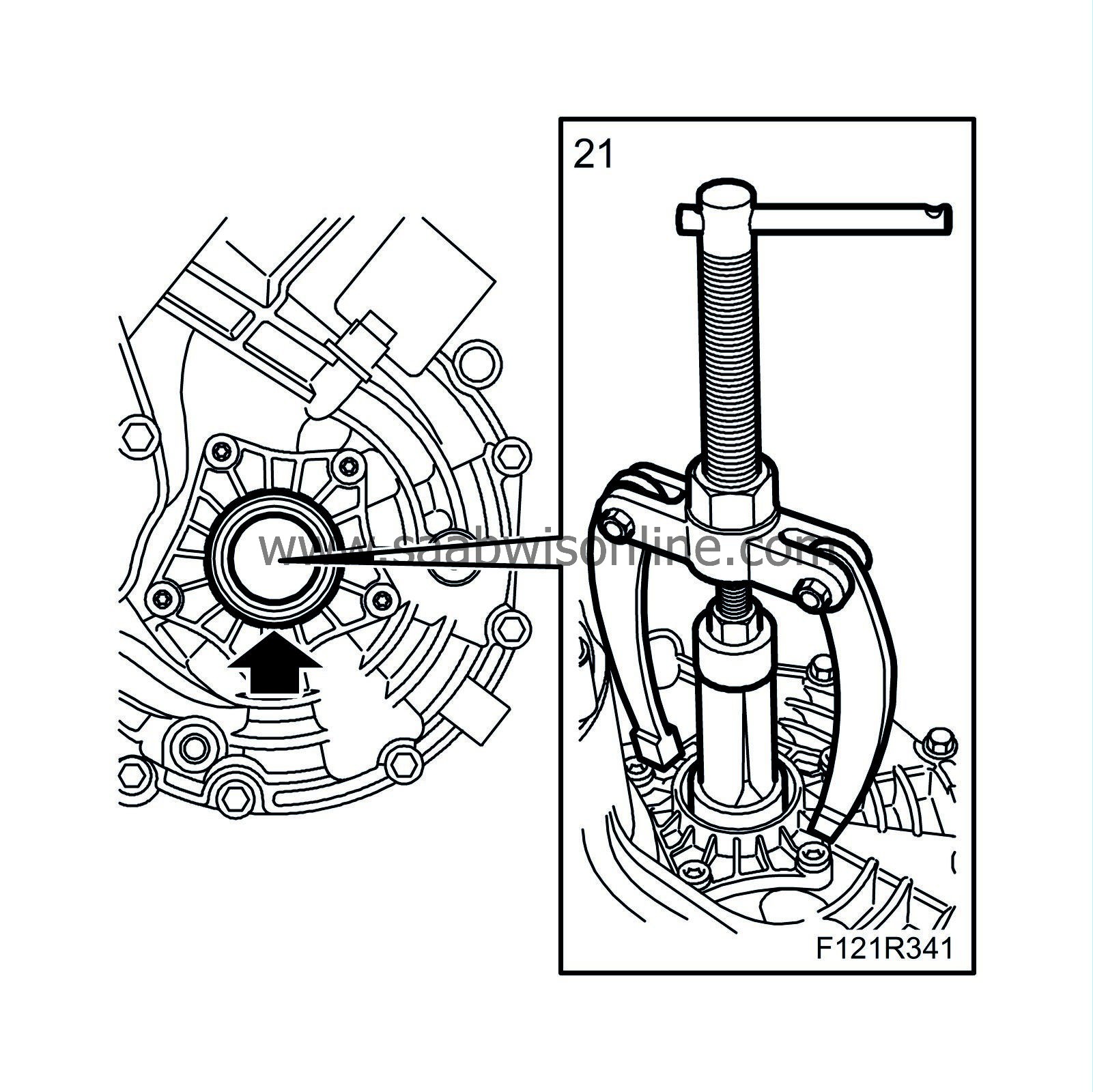

21.

|

Remove the LH drive shaft seal with 87 92 350 Puller, drive shaft seal and 87 91 683 Puller.

|

|

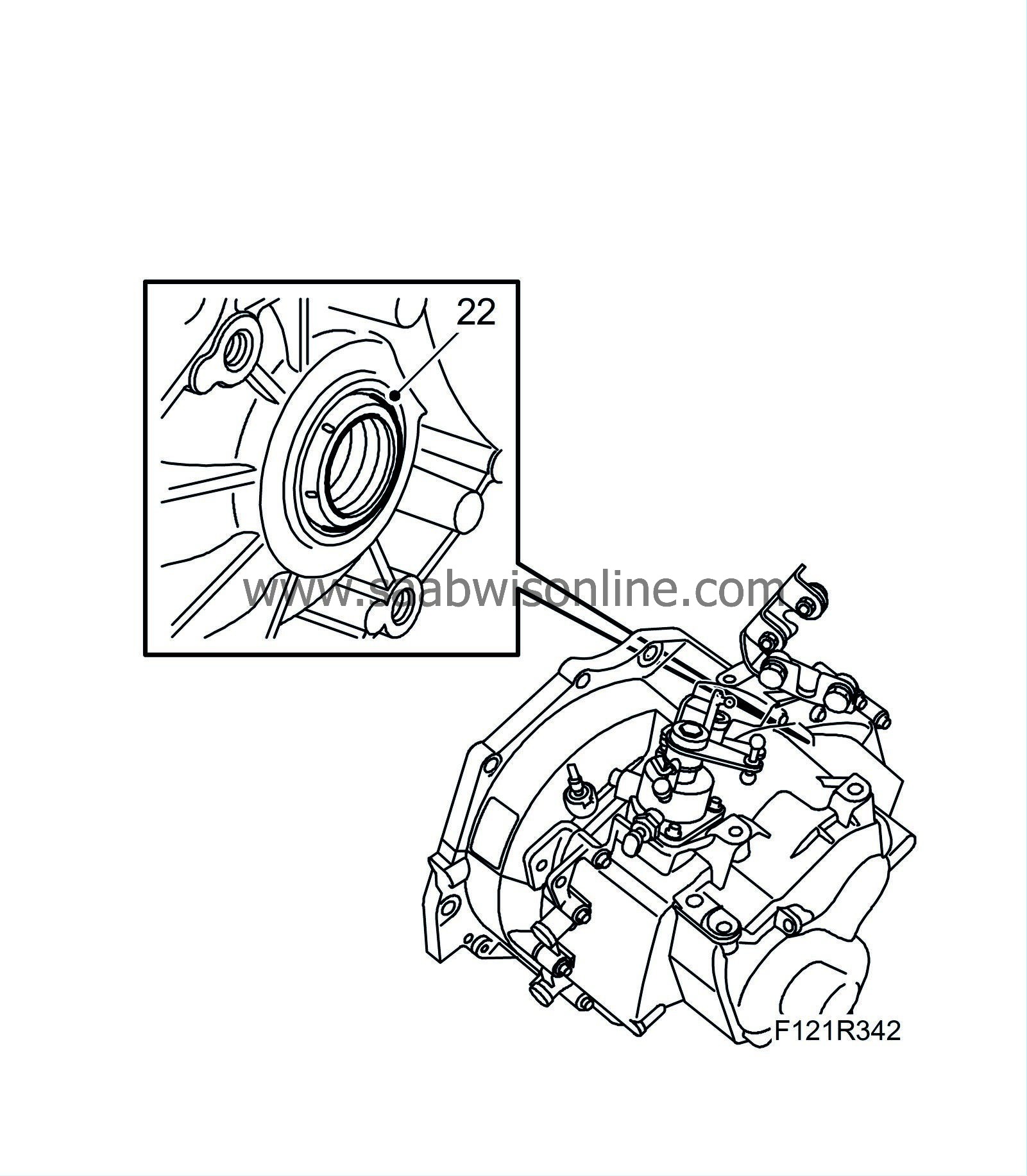

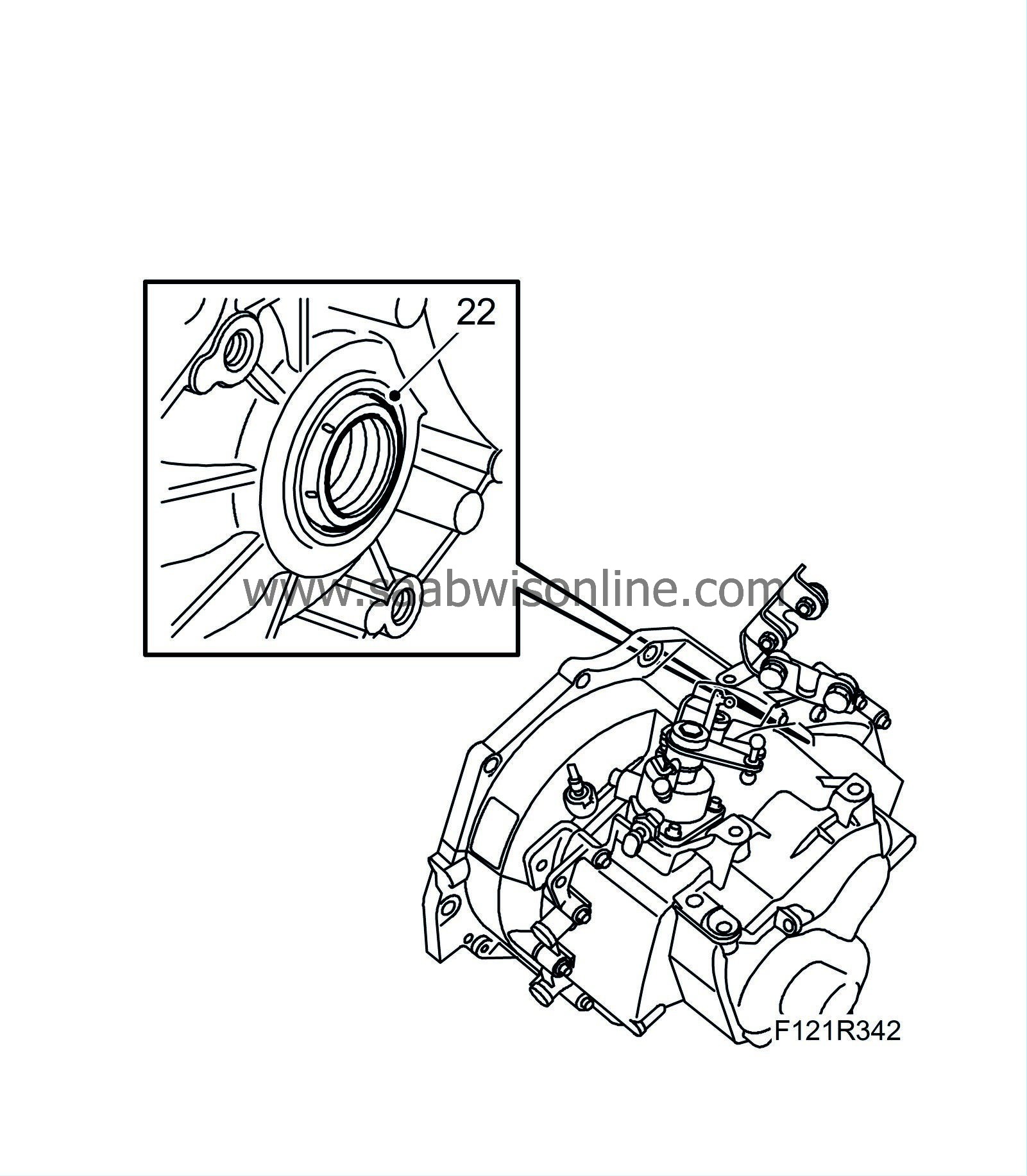

22.

|

Remove the RH drive shaft seal with 87 92 350 Puller, drive shaft seal and 87 91 683 Puller.

|

|

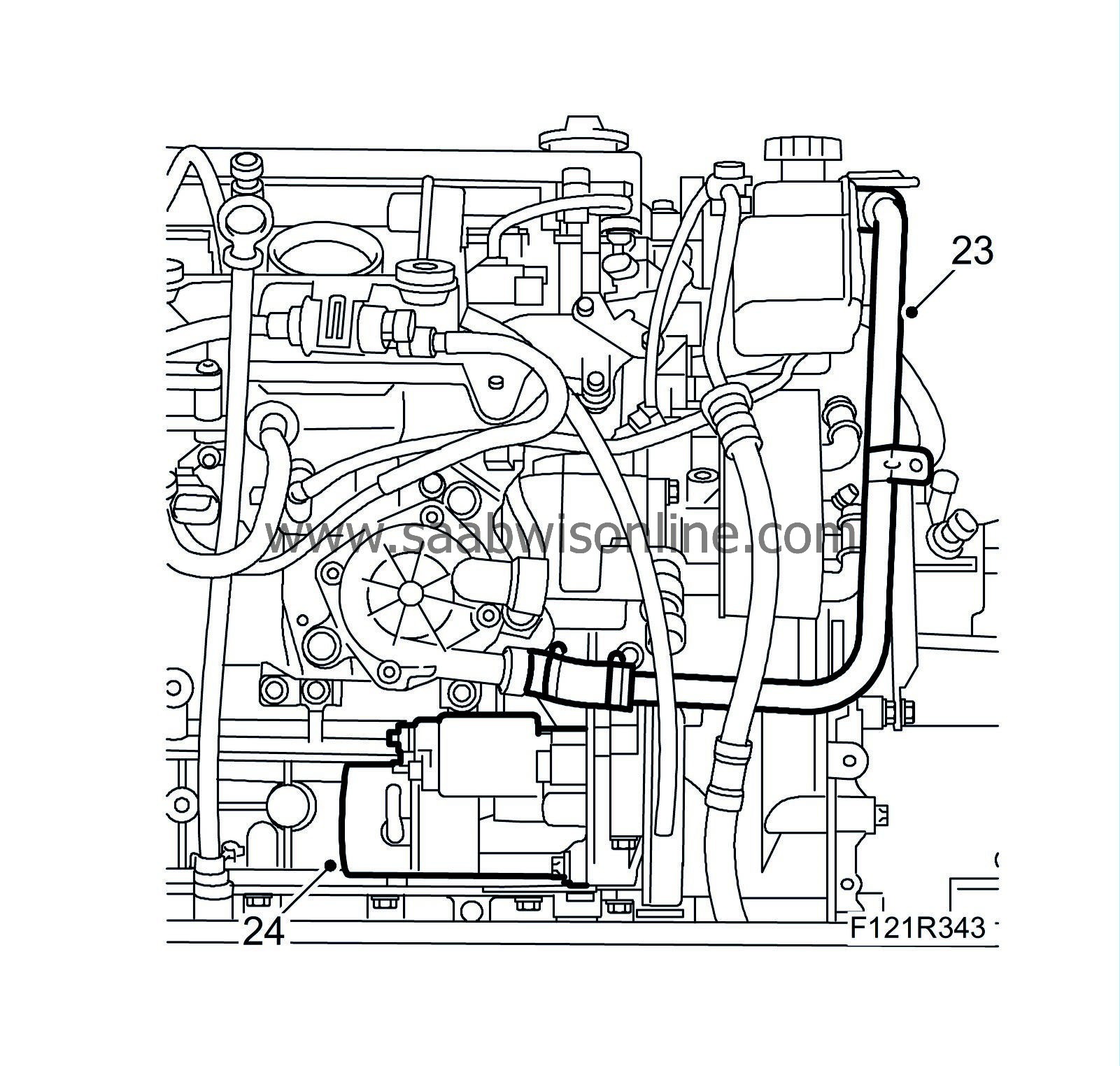

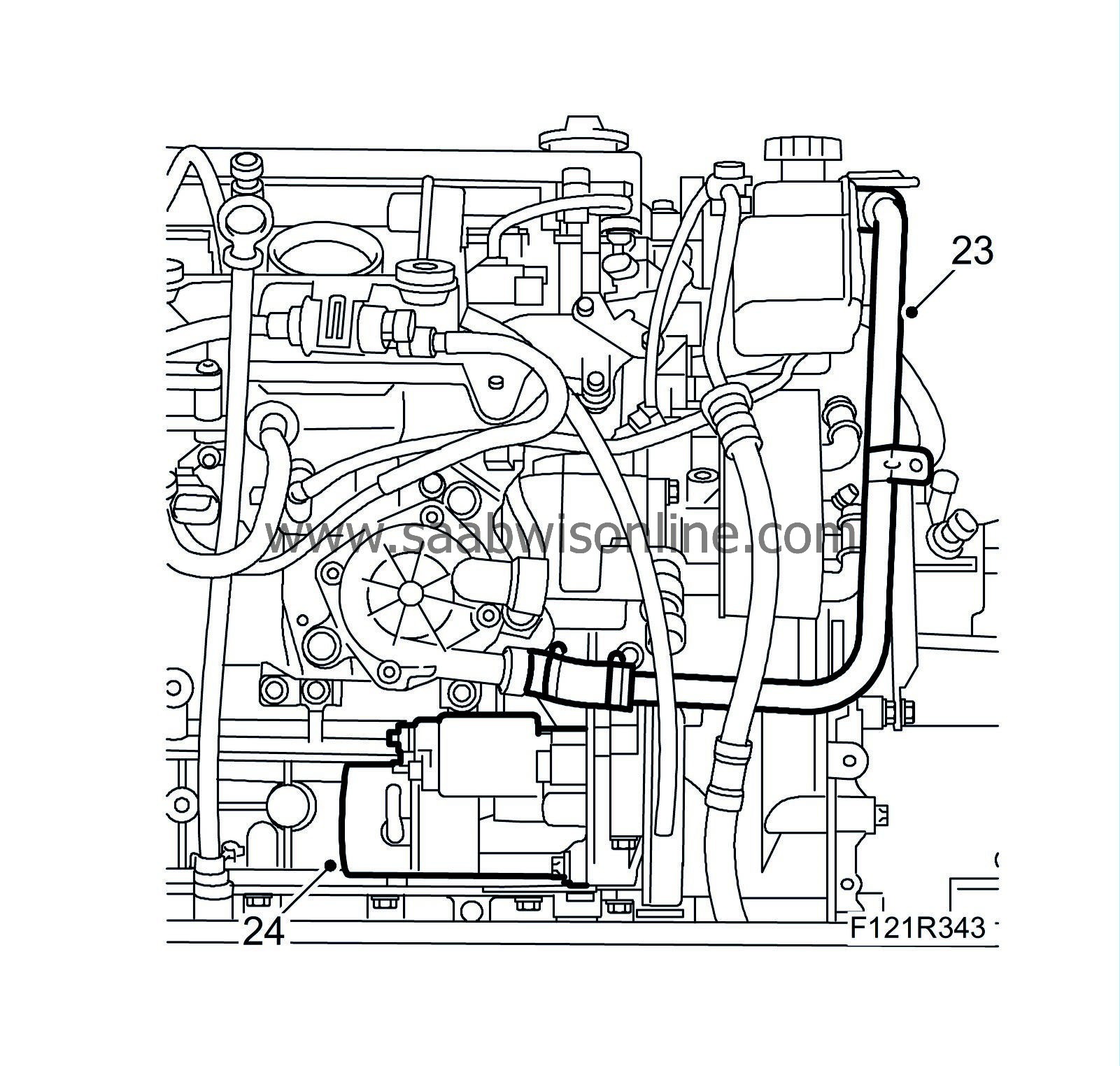

23.

|

Cars with secondary air injection pump

: Remove the pipe between the pump and the valve.

|

|

24.

|

Remove the starter motor.

|

|

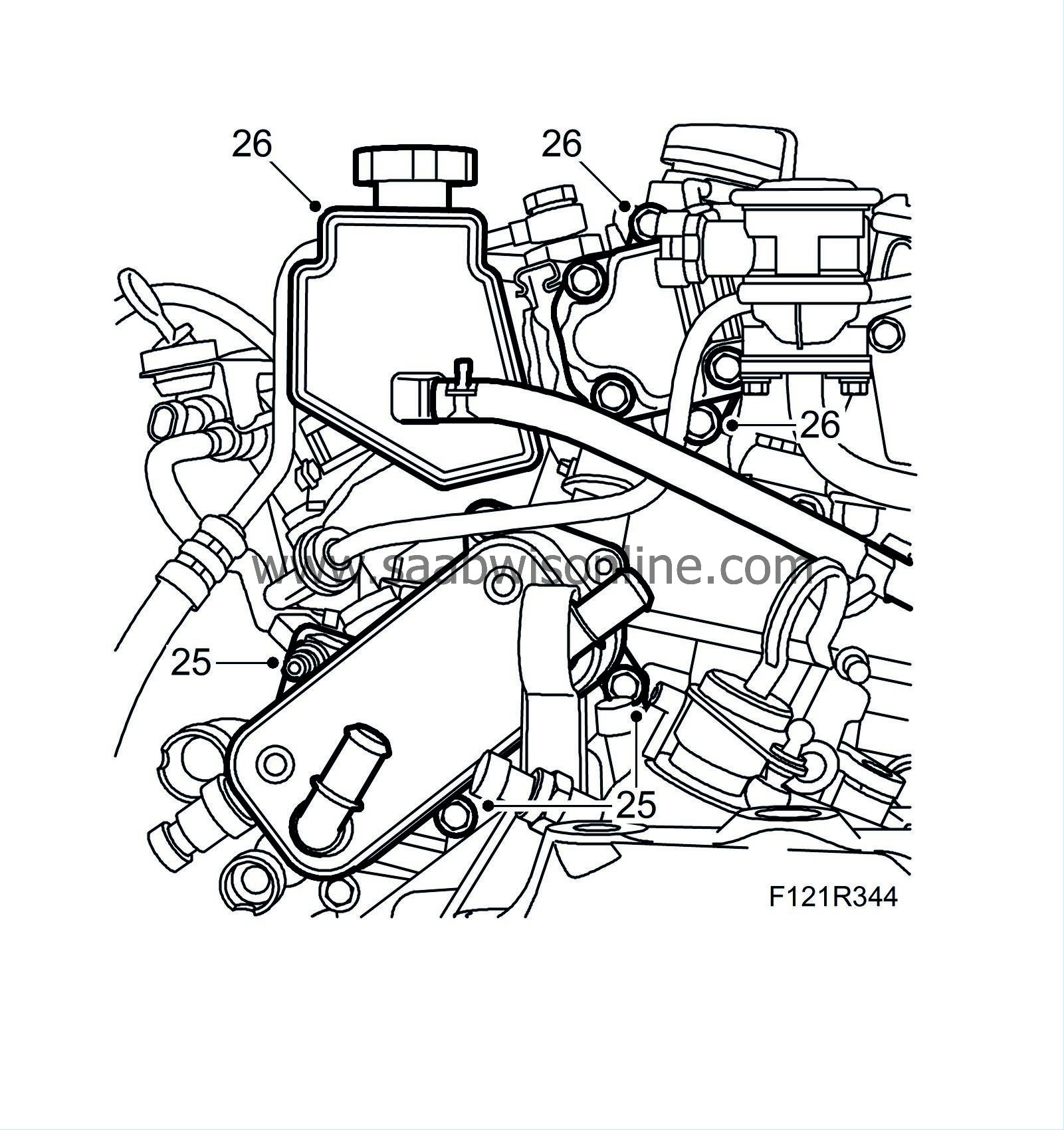

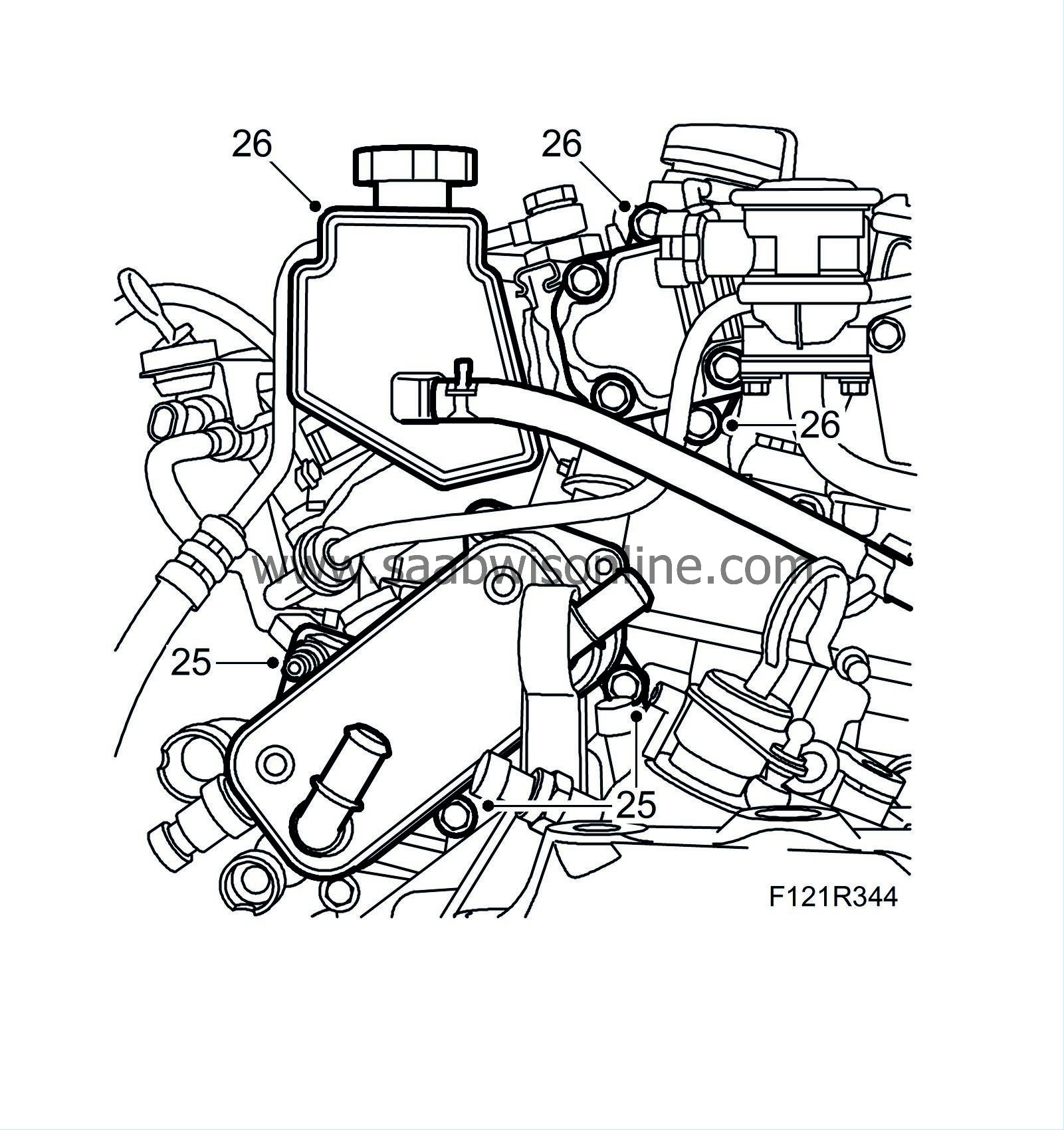

25.

|

Remove the coolant-cooled oil cooler.

|

|

26.

|

Remove the power steering pump from the cylinder head and move it aside.

|

|

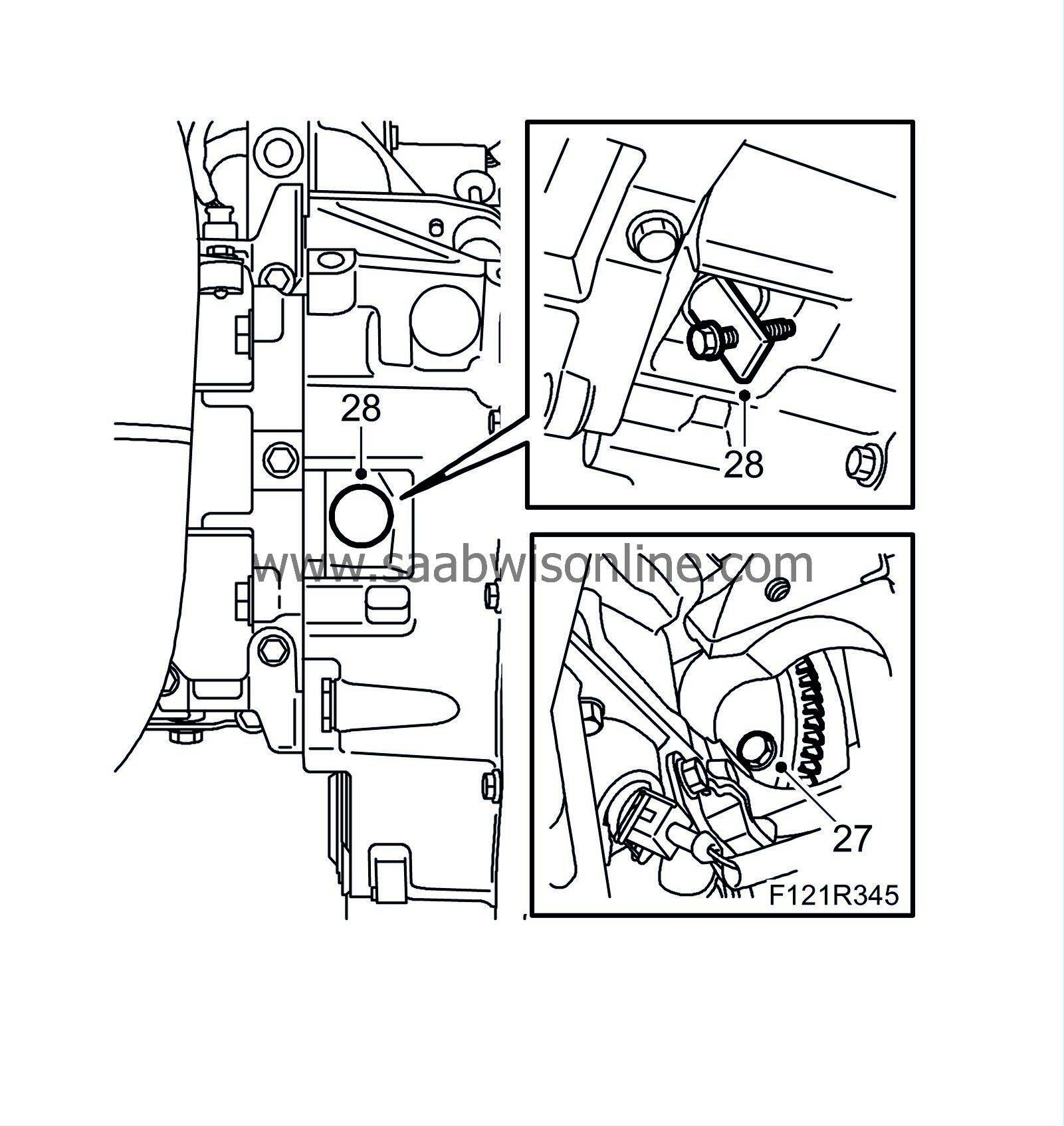

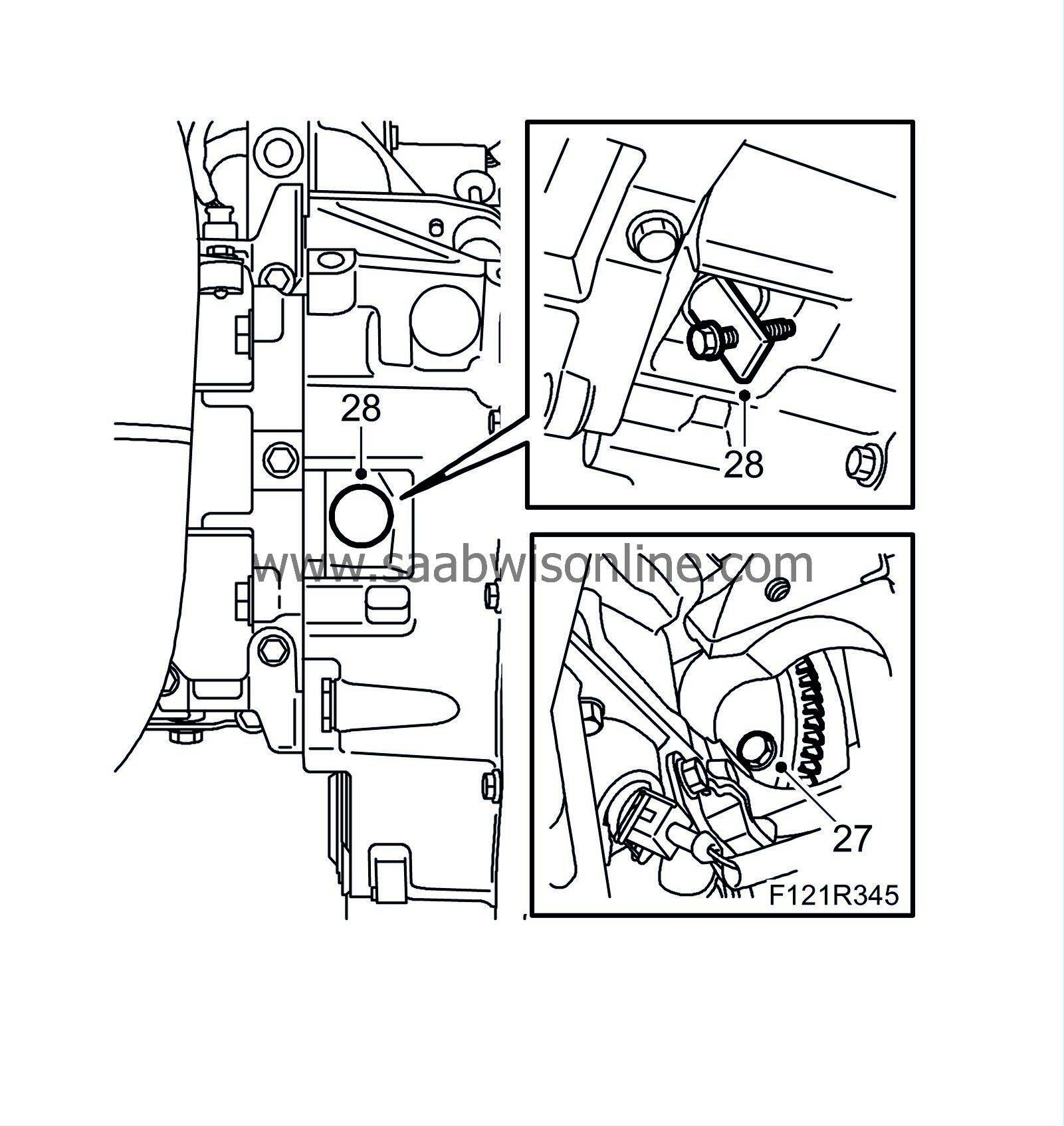

27.

|

Cars with automatic transmission

: Loosen the 6 bolts holding the torque converter to the driver plate. Turn the engine clockwise with the pulley.

|

|

28.

|

Cars with automatic transmission

: Detach the plug, press the torque converter toward the transmission and fit holder 87 92 574 to hold the torque converter in place when removing the transmission.

|

|

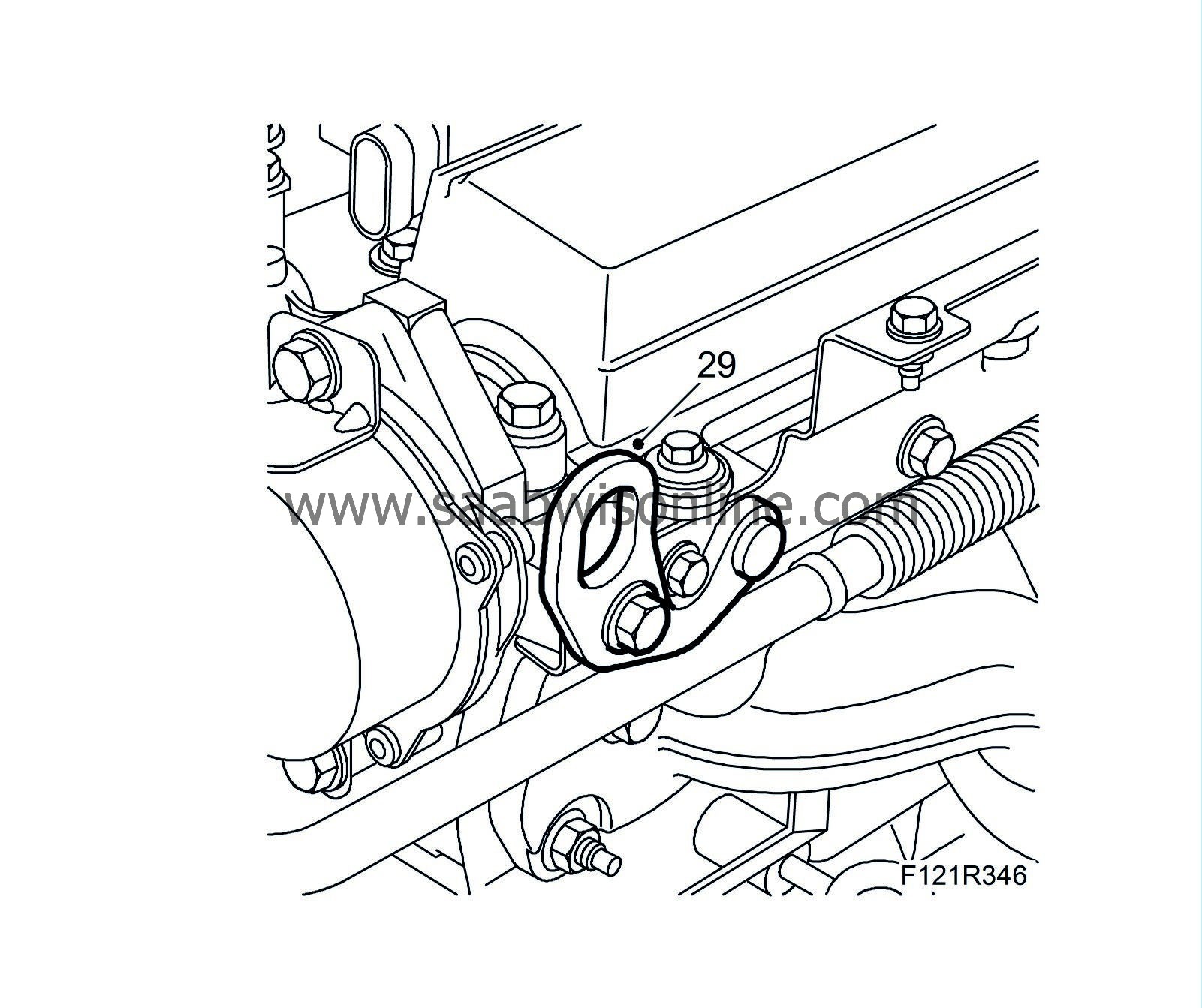

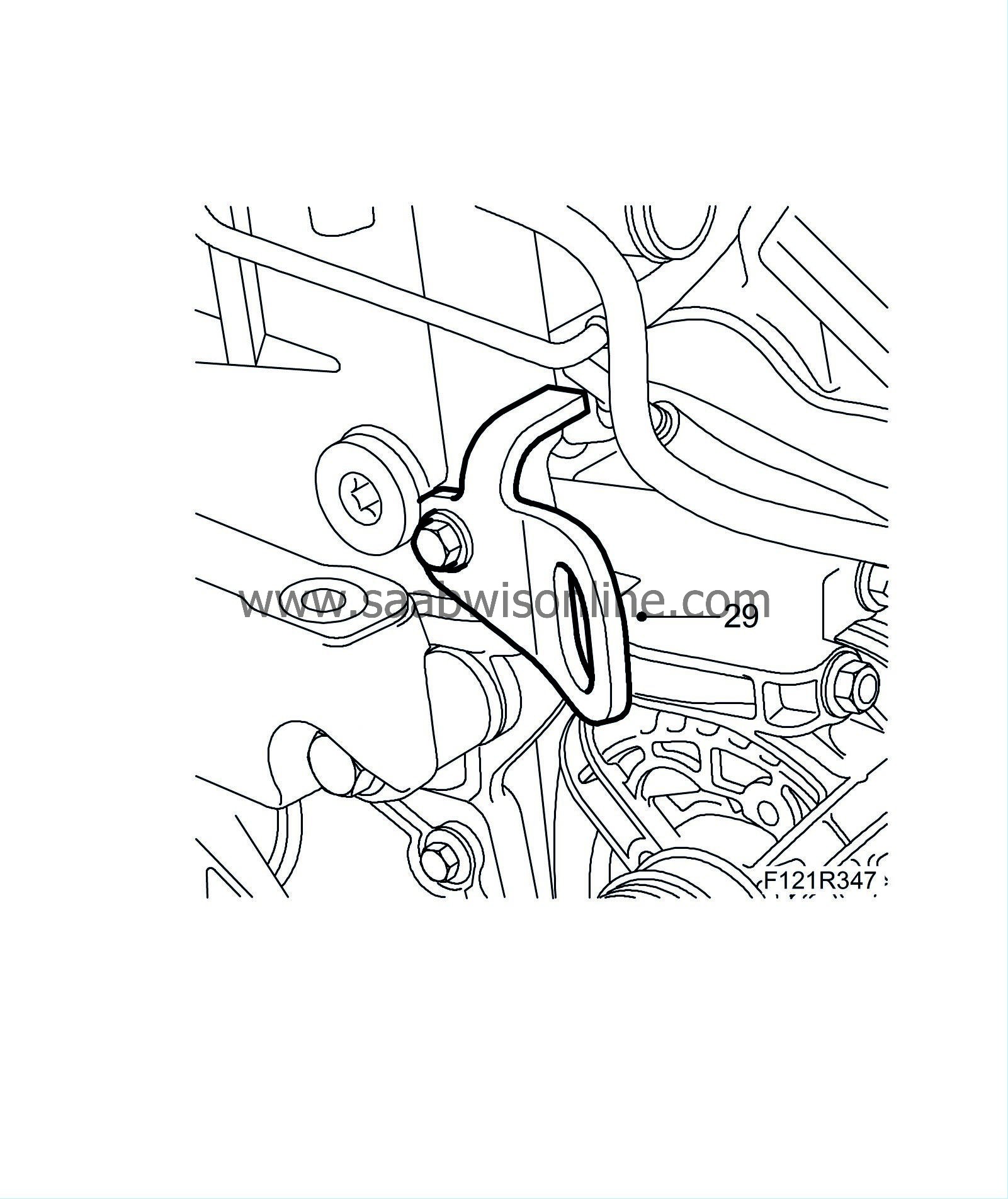

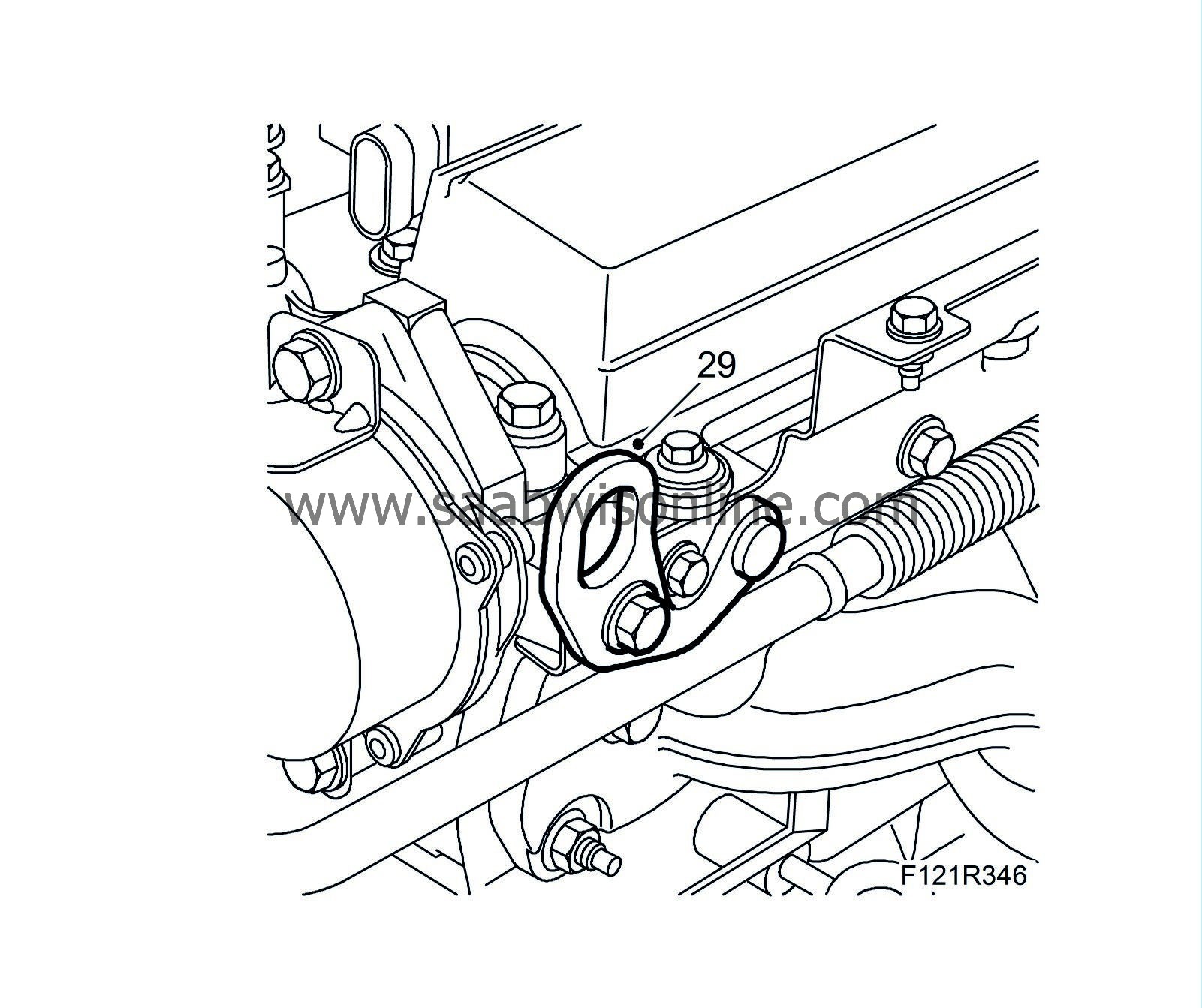

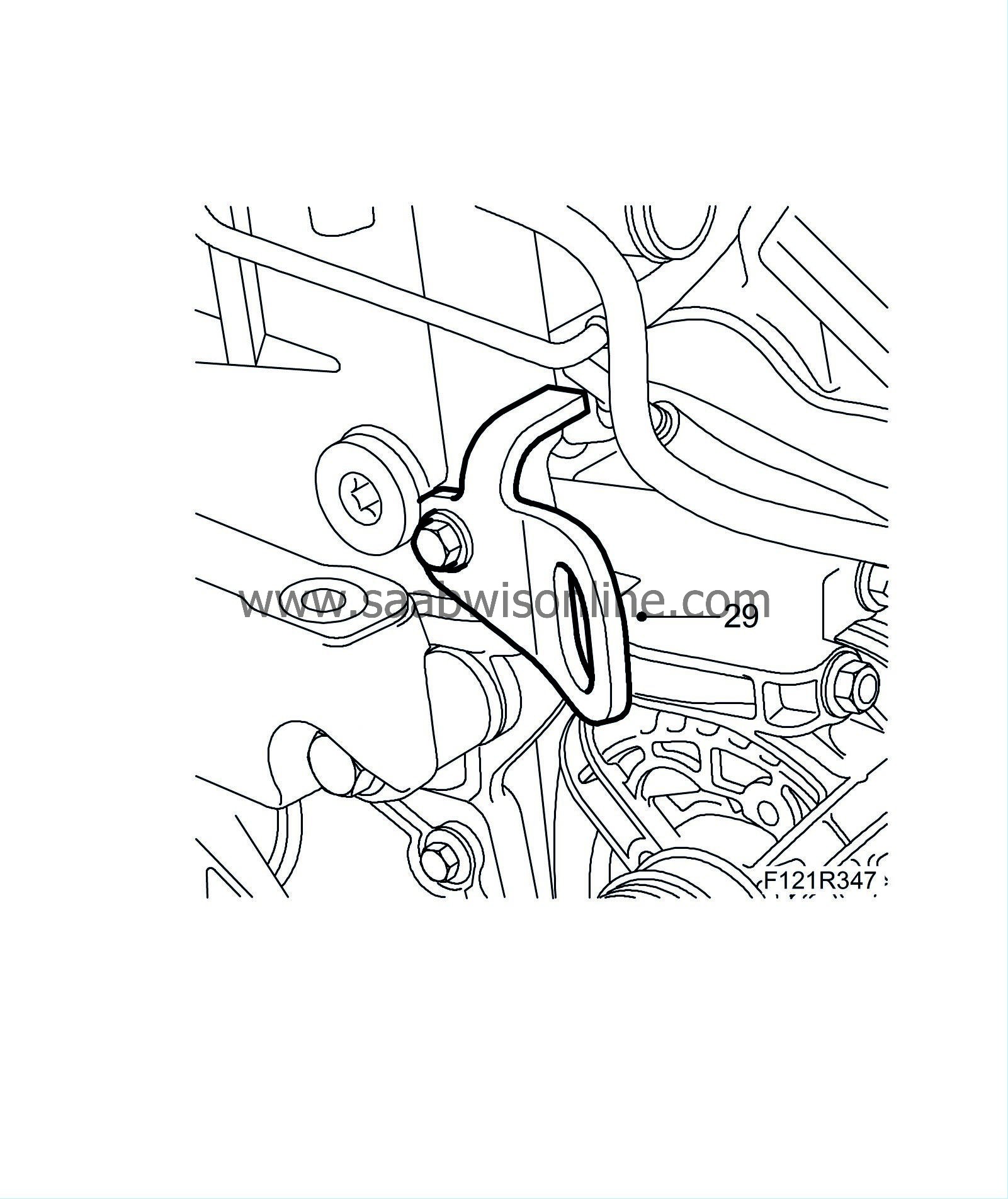

29.

|

Fit lifting eyes, B207, 83 96 178.

|

|

30.

|

Secure the engine with an engine lift.

|

|

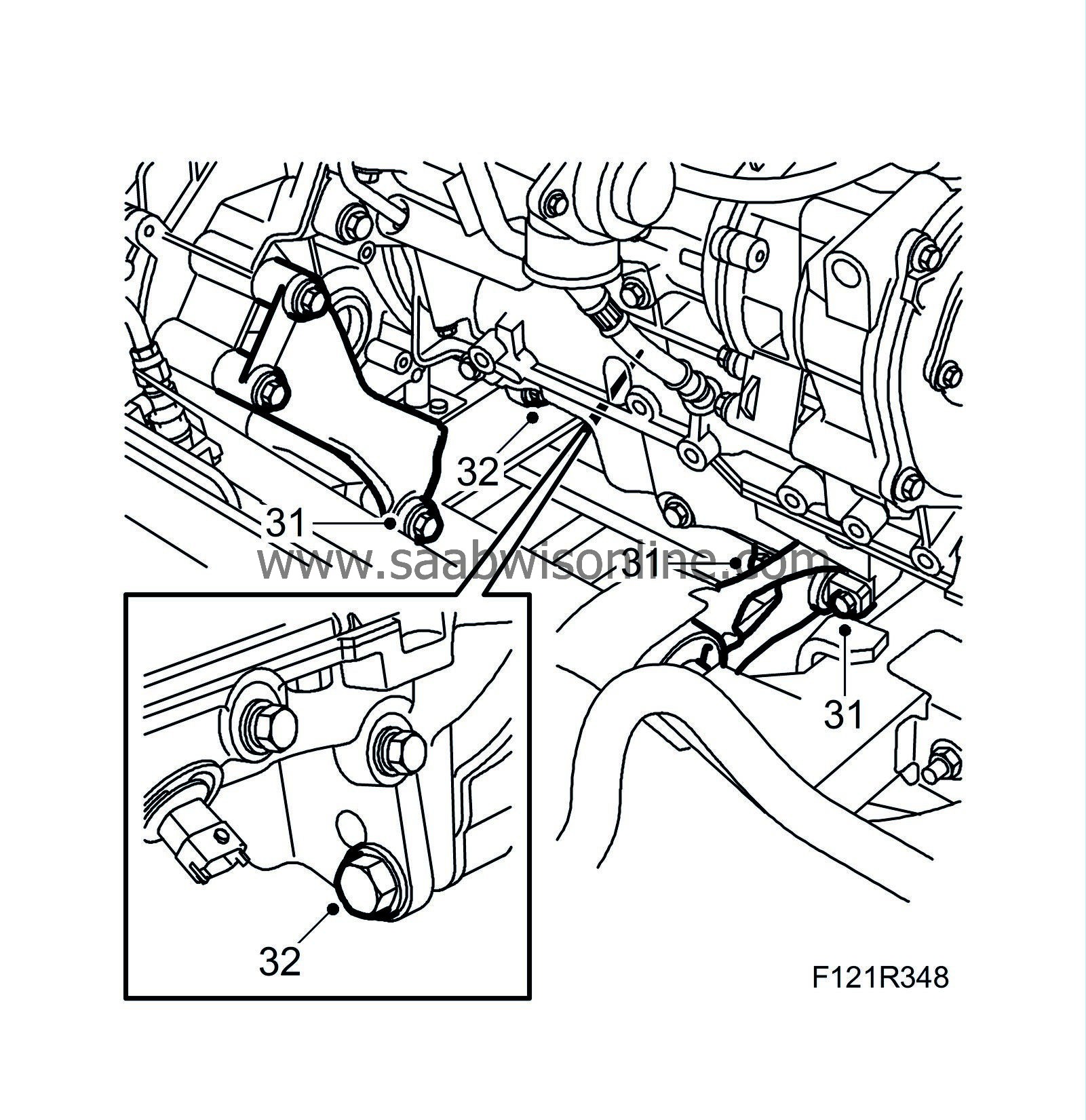

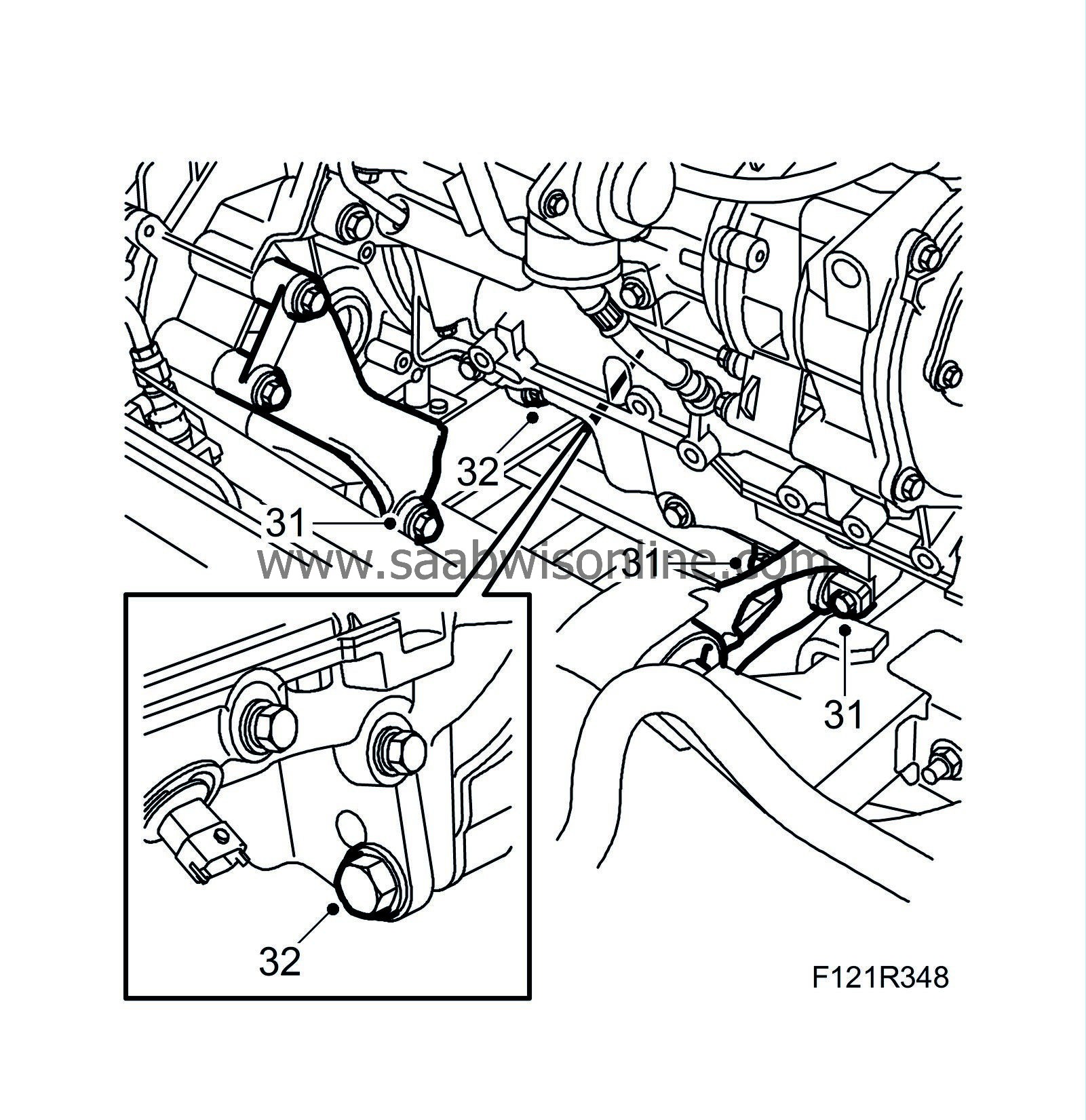

31.

|

Remove the torque arms from the oil sump and gearbox.

|

|

32.

|

Raise the engine and remove the lower gearbox retaining bolts.

|

|

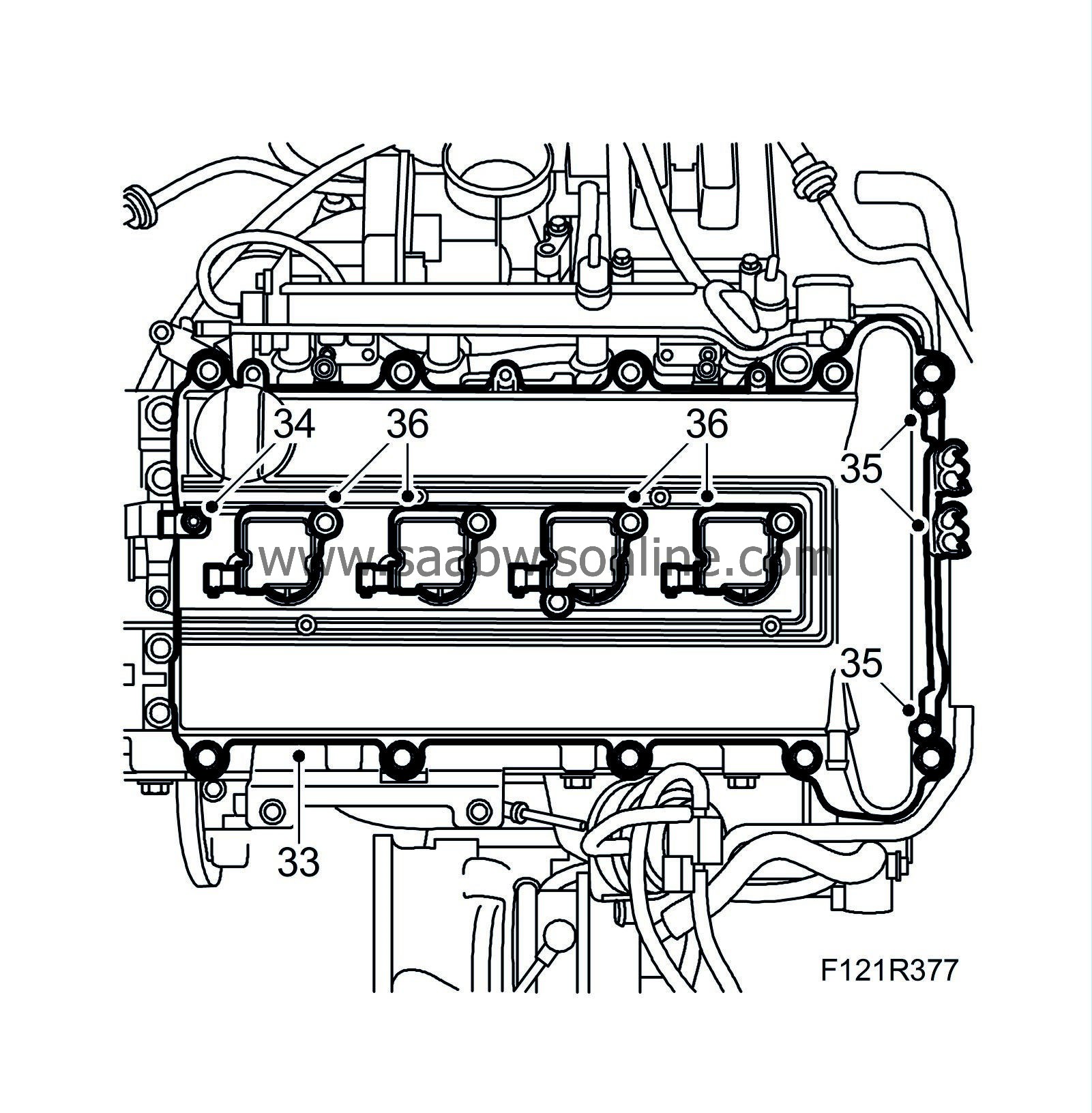

33.

|

Carefully lower the engine onto a pallet, for example.

|

|

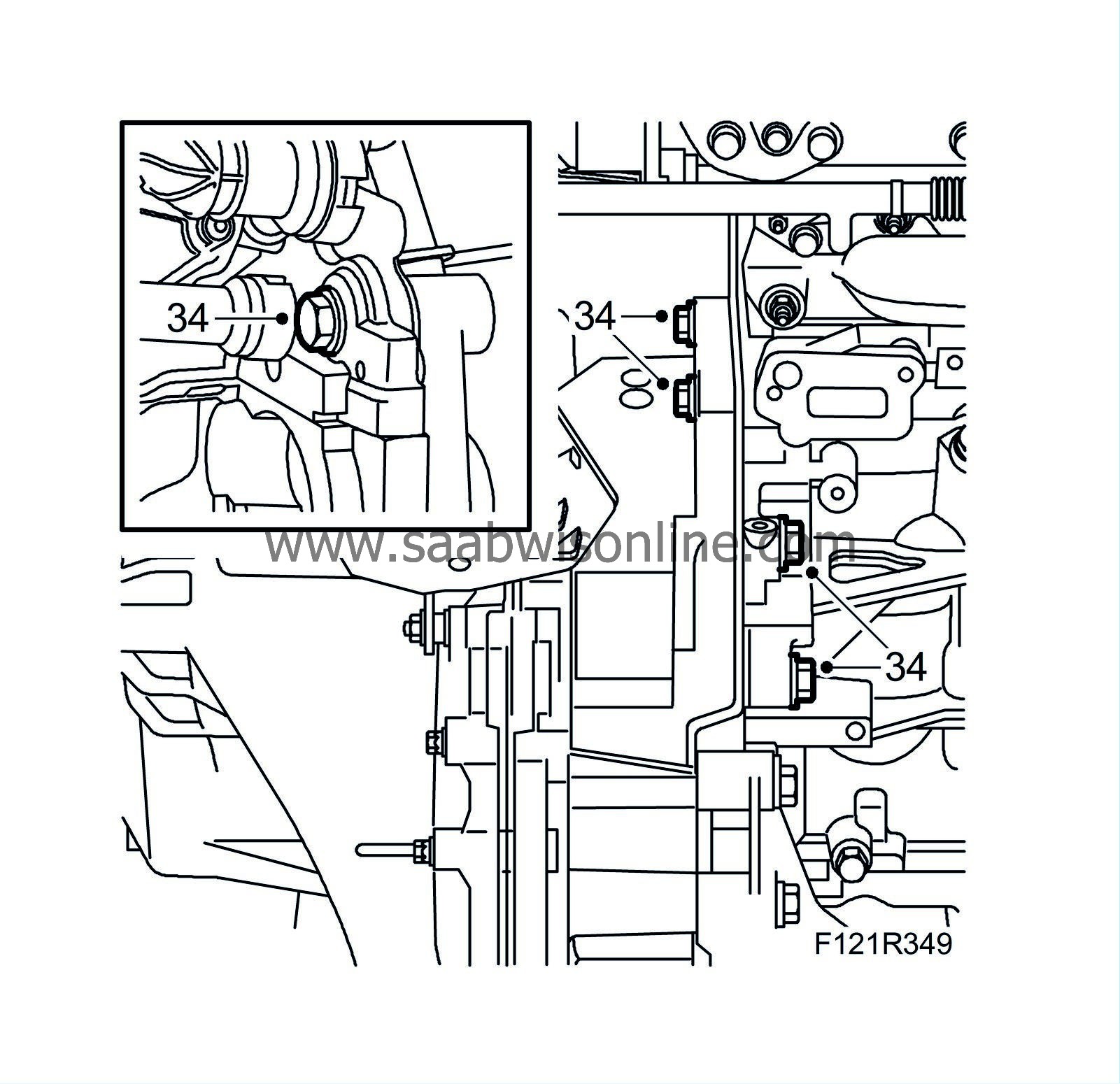

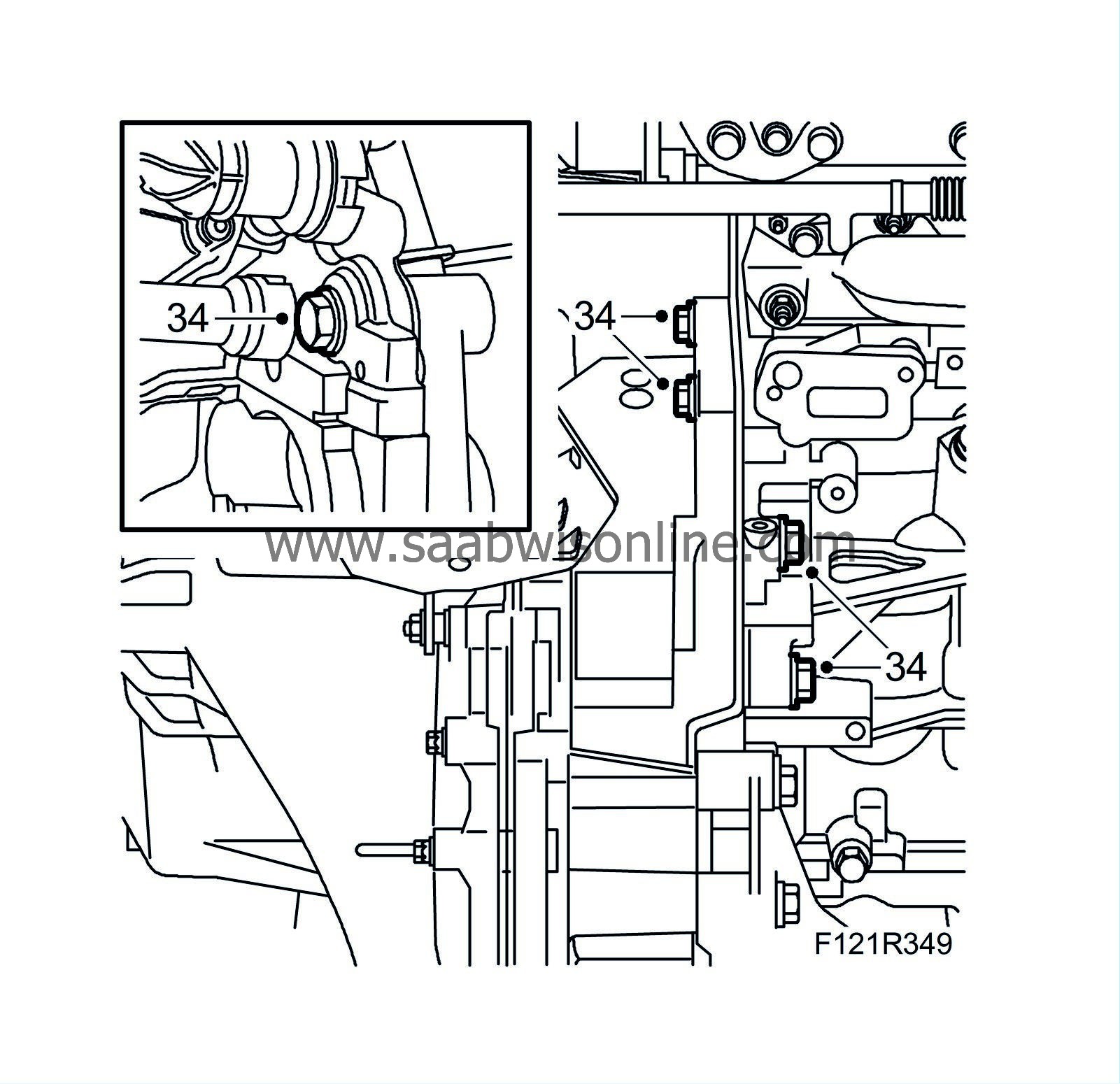

34.

|

Remove the upper gearbox retaining bolts.

|

|

35.

|

Fit 87 92 442 Lifting cable to the gearbox and raise the gearbox slightly. Remove the gearbox from the engine.

|

|

36.

|

Raise the engine and fit 83 94 751 Holder. Fit the engine to the floor stand 78 74 878.

|

|

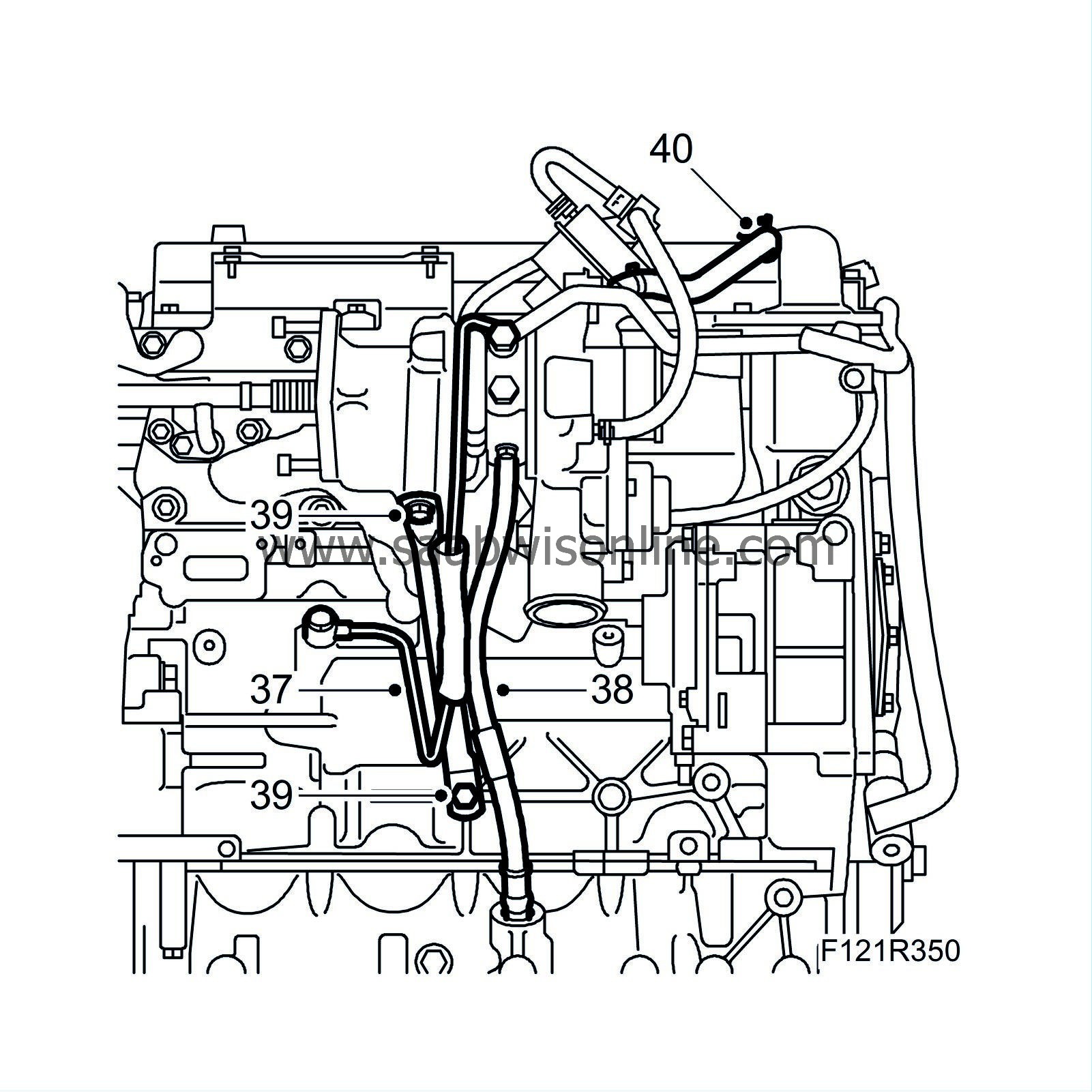

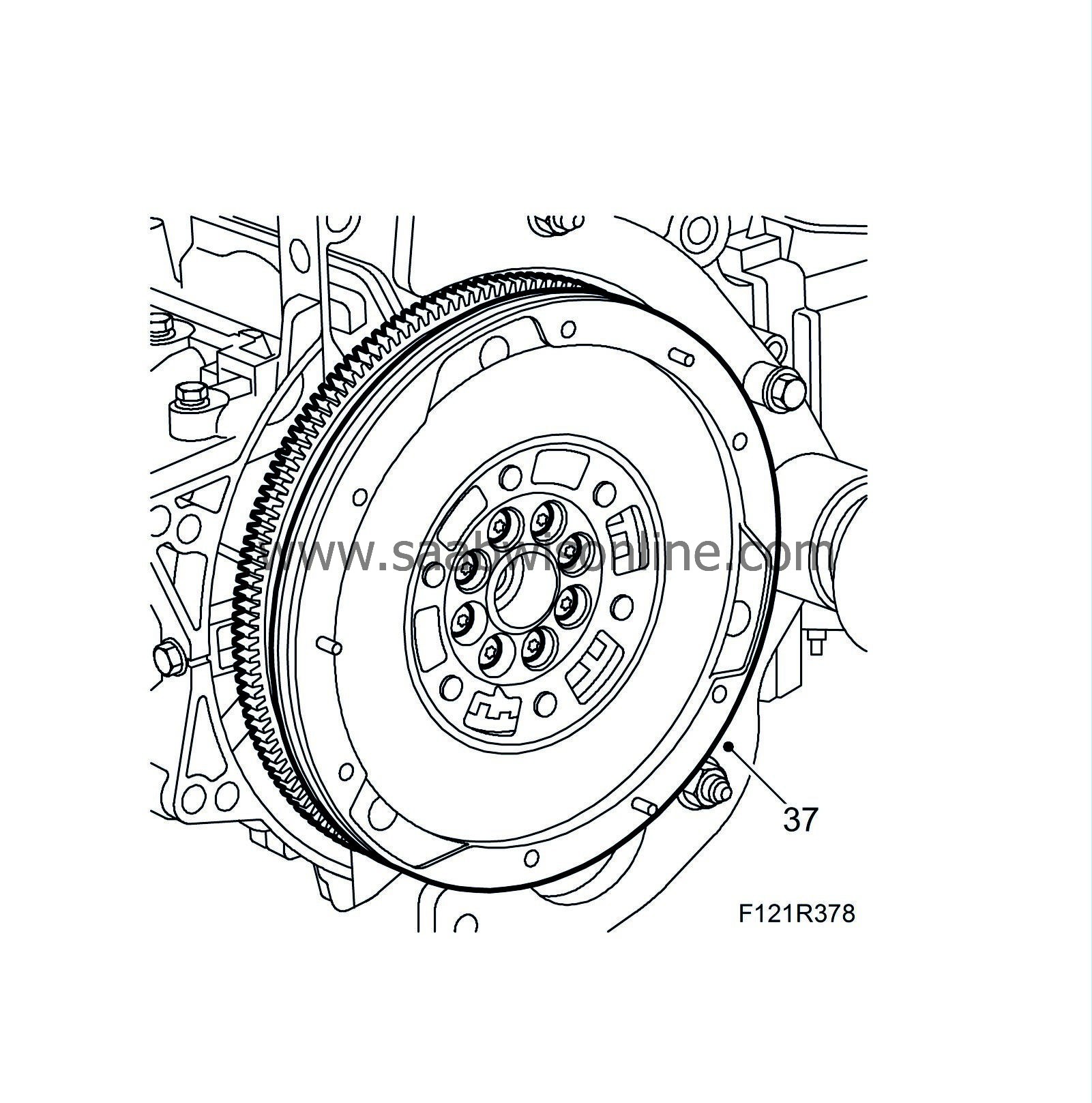

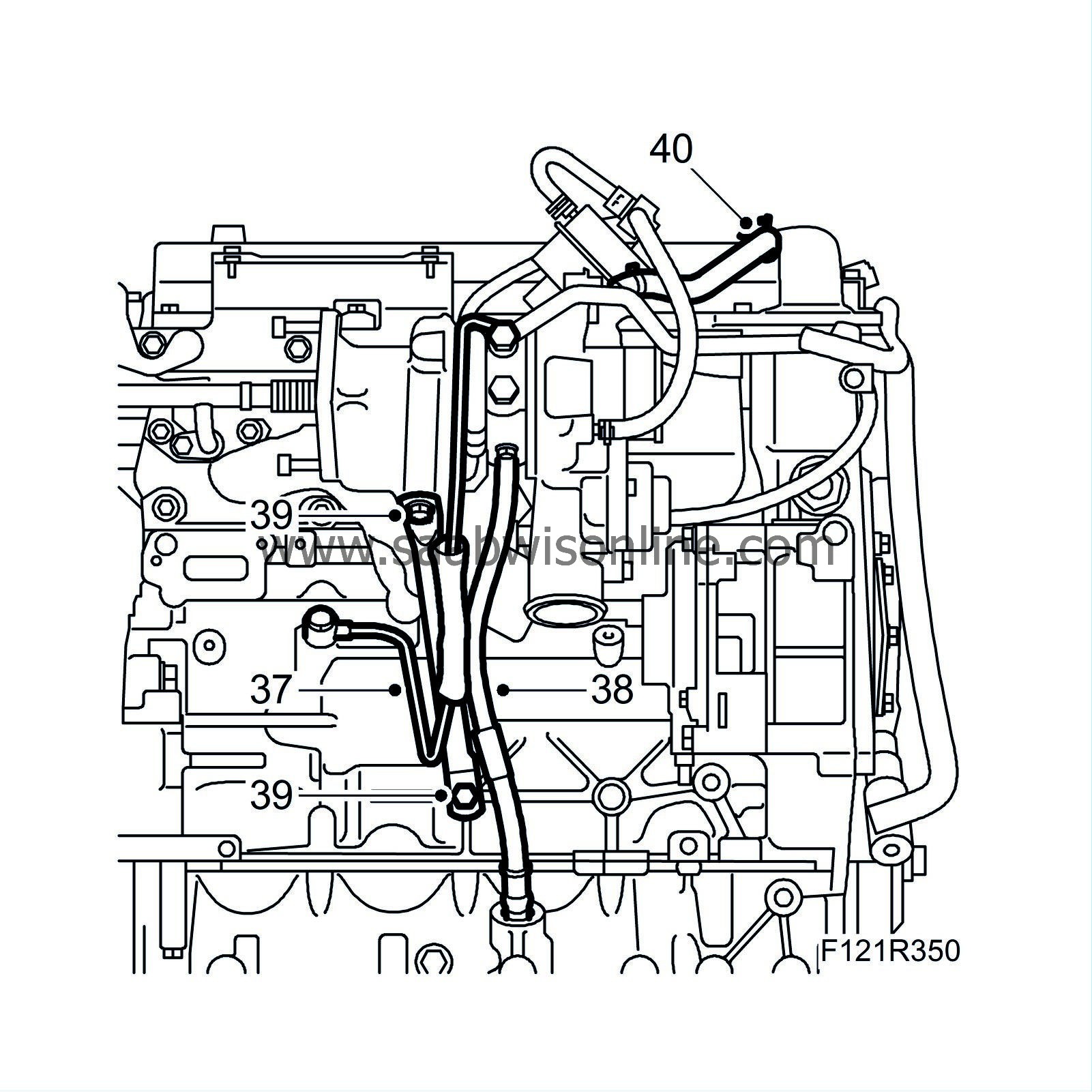

37.

|

Remove the turbocharger oil delivery pipe.

|

|

38.

|

Remove the turbocharger oil return pipe.

|

|

39.

|

Remove the lower turbocharger attachment bracket.

|

|

40.

|

Remove the crankcase ventilation hose from the camshaft cover.

|

|

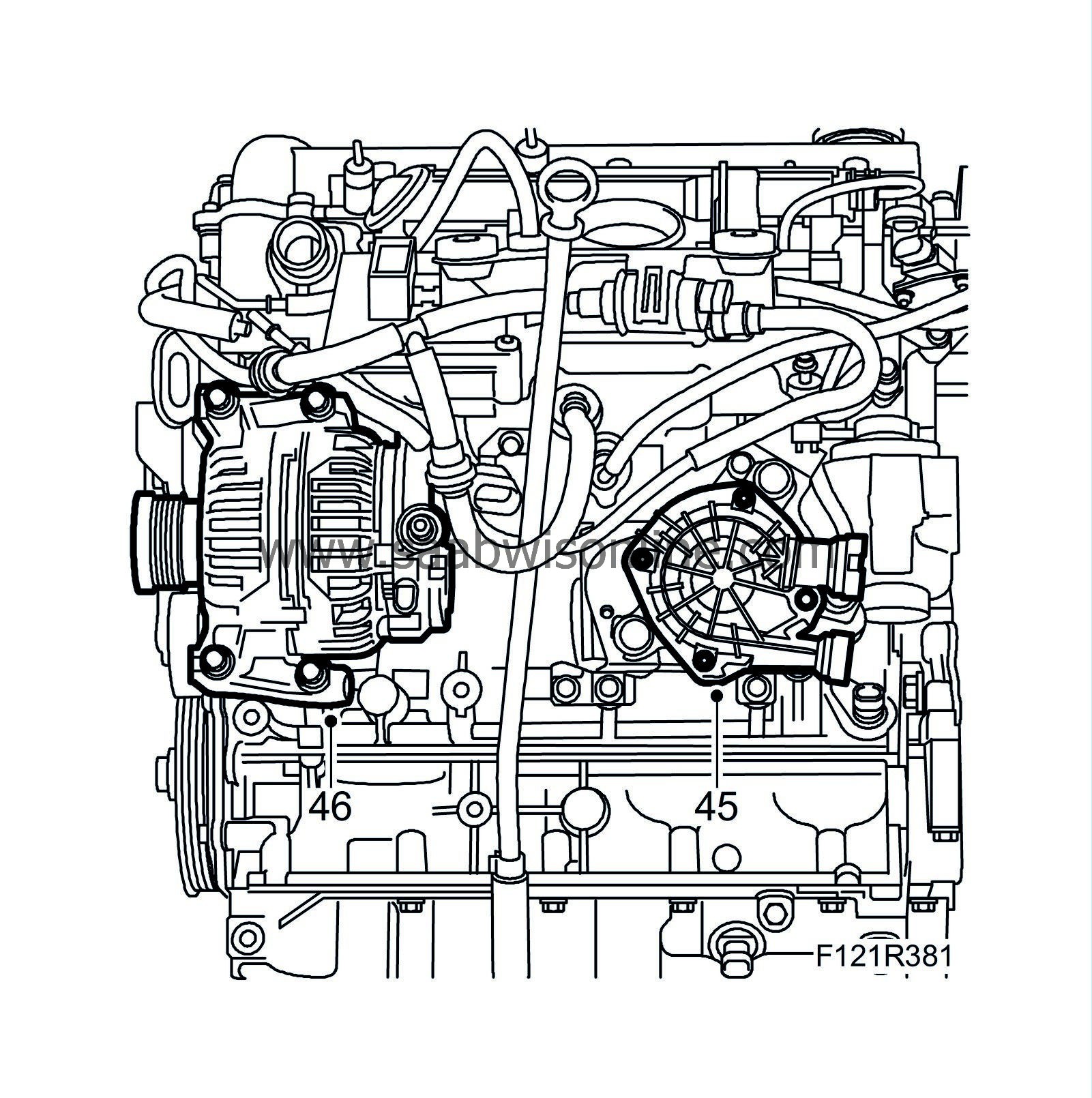

41.

|

Remove the generator.

|

|

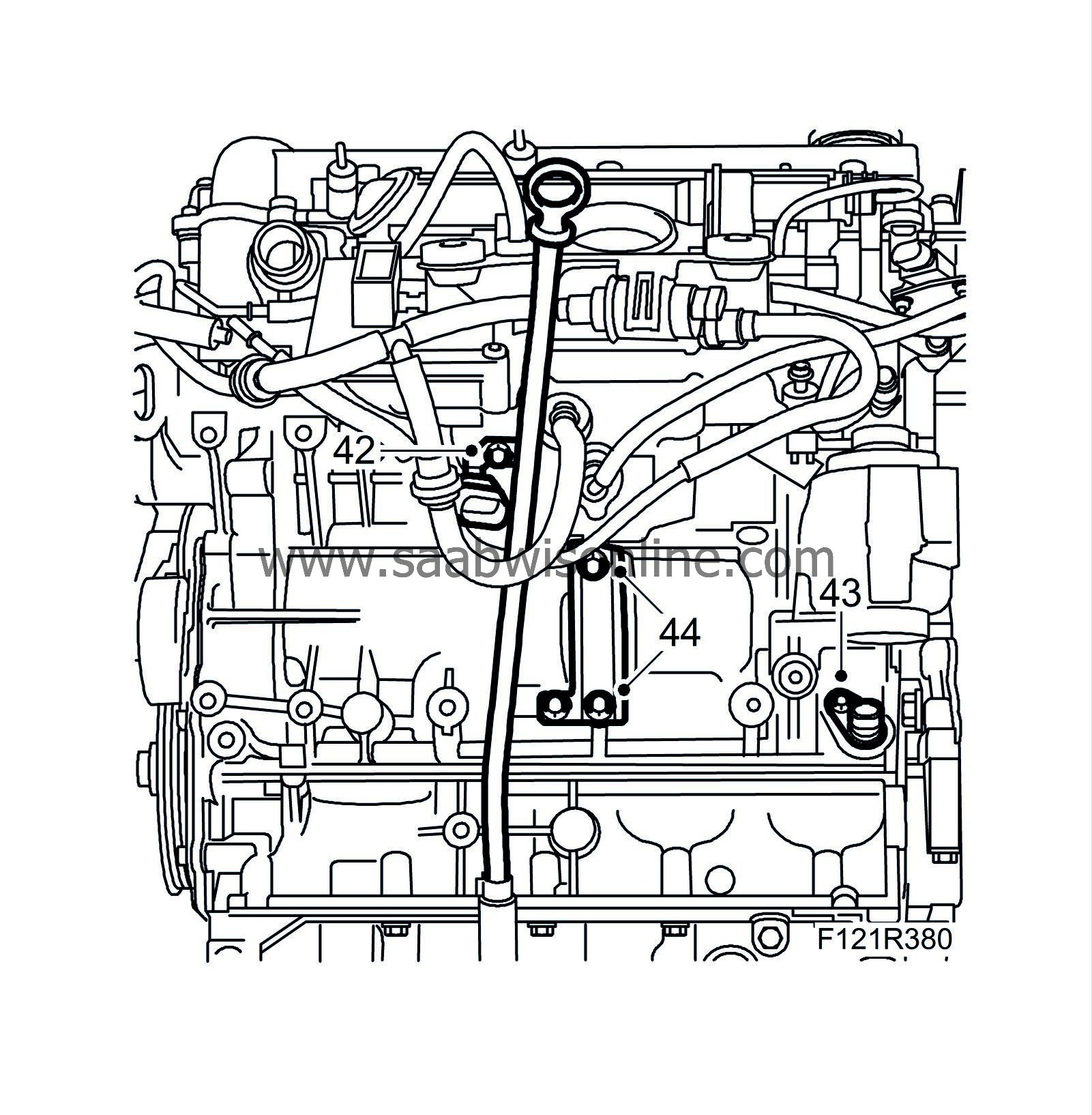

42.

|

Cars with secondary air injection pump

: Remove the pump with bracket.

|

|

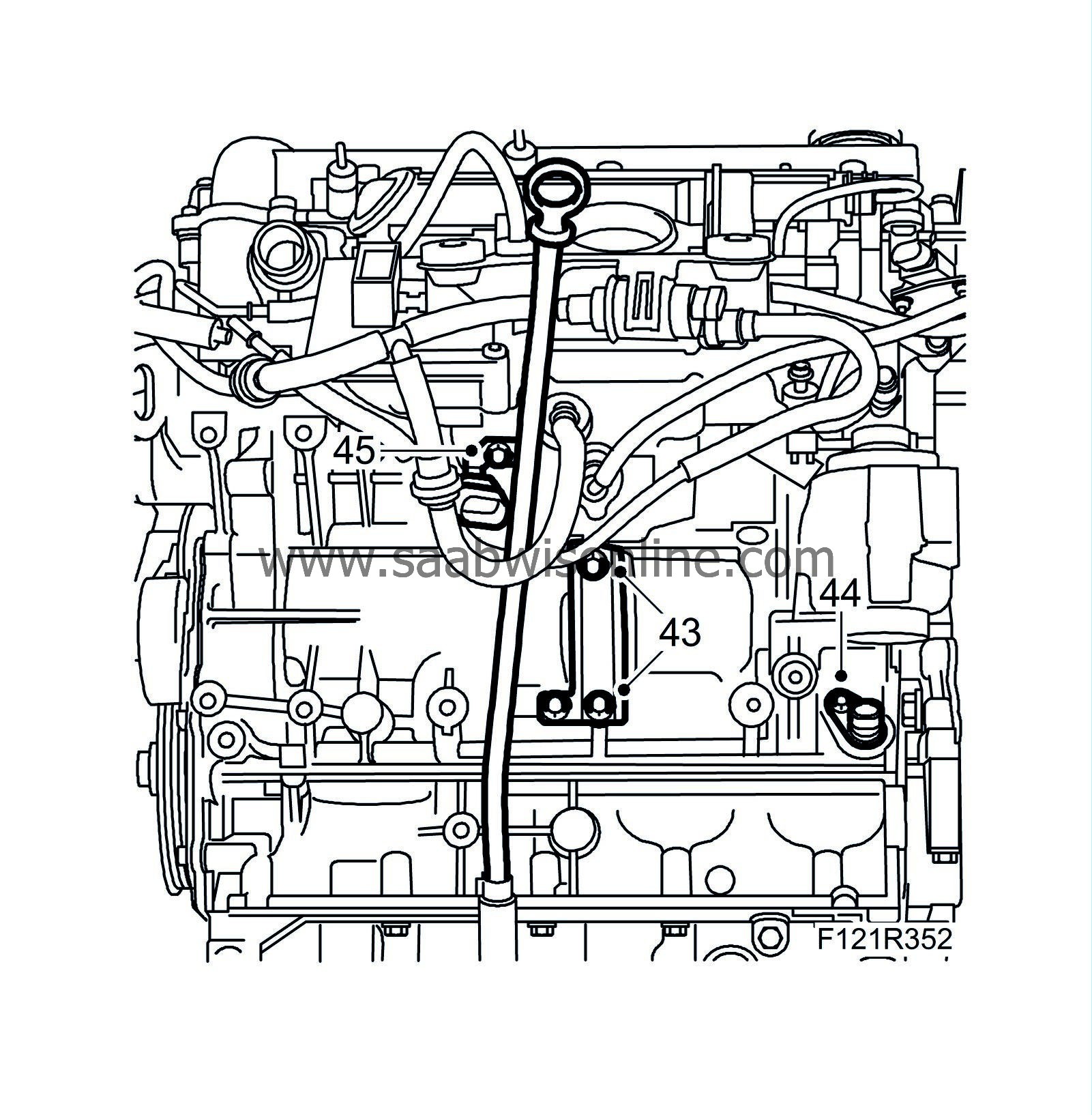

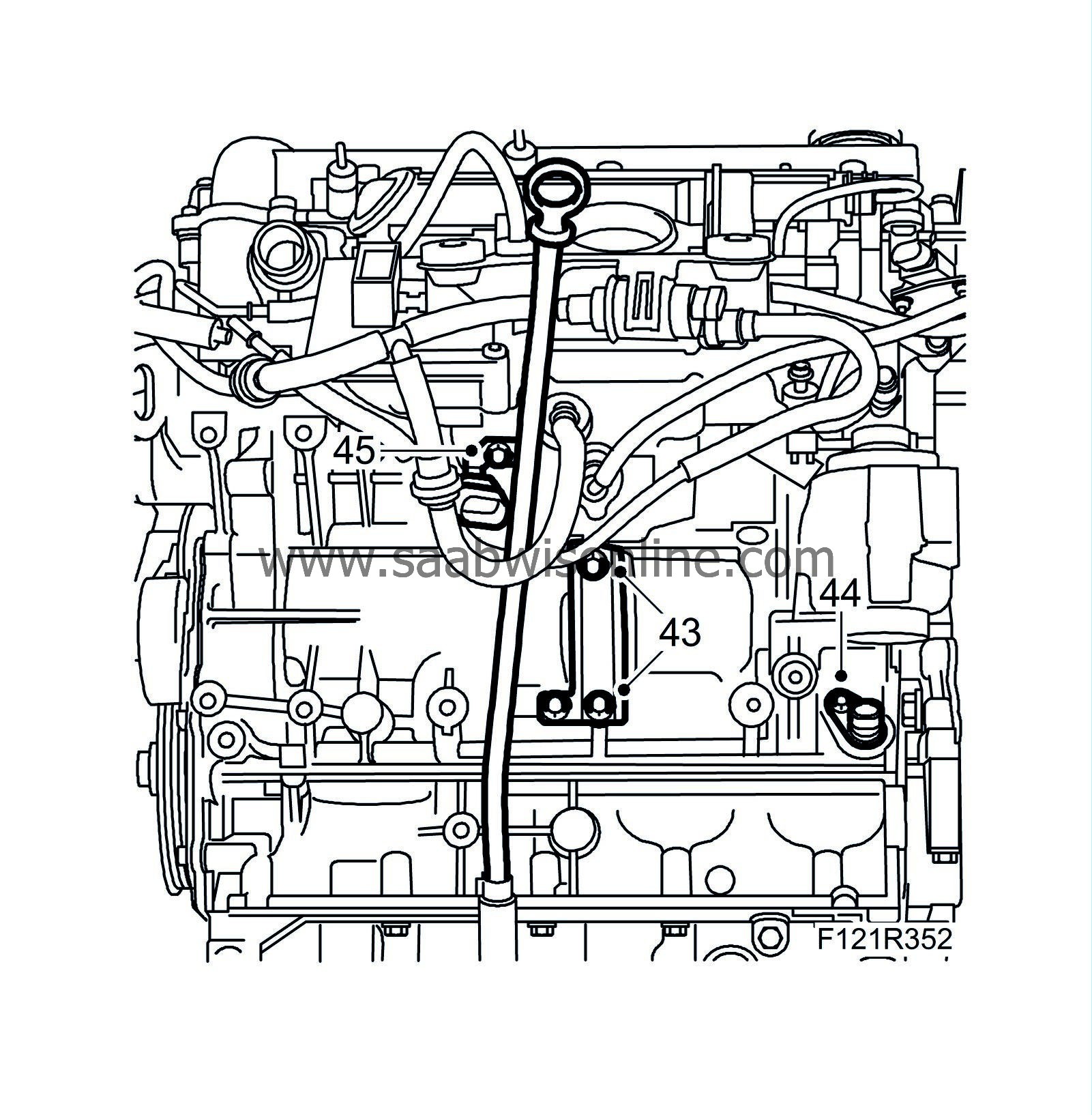

43.

|

Remove the lower intake manifold attachment bracket.

|

|

44.

|

Remove the crankshaft position sensor.

|

|

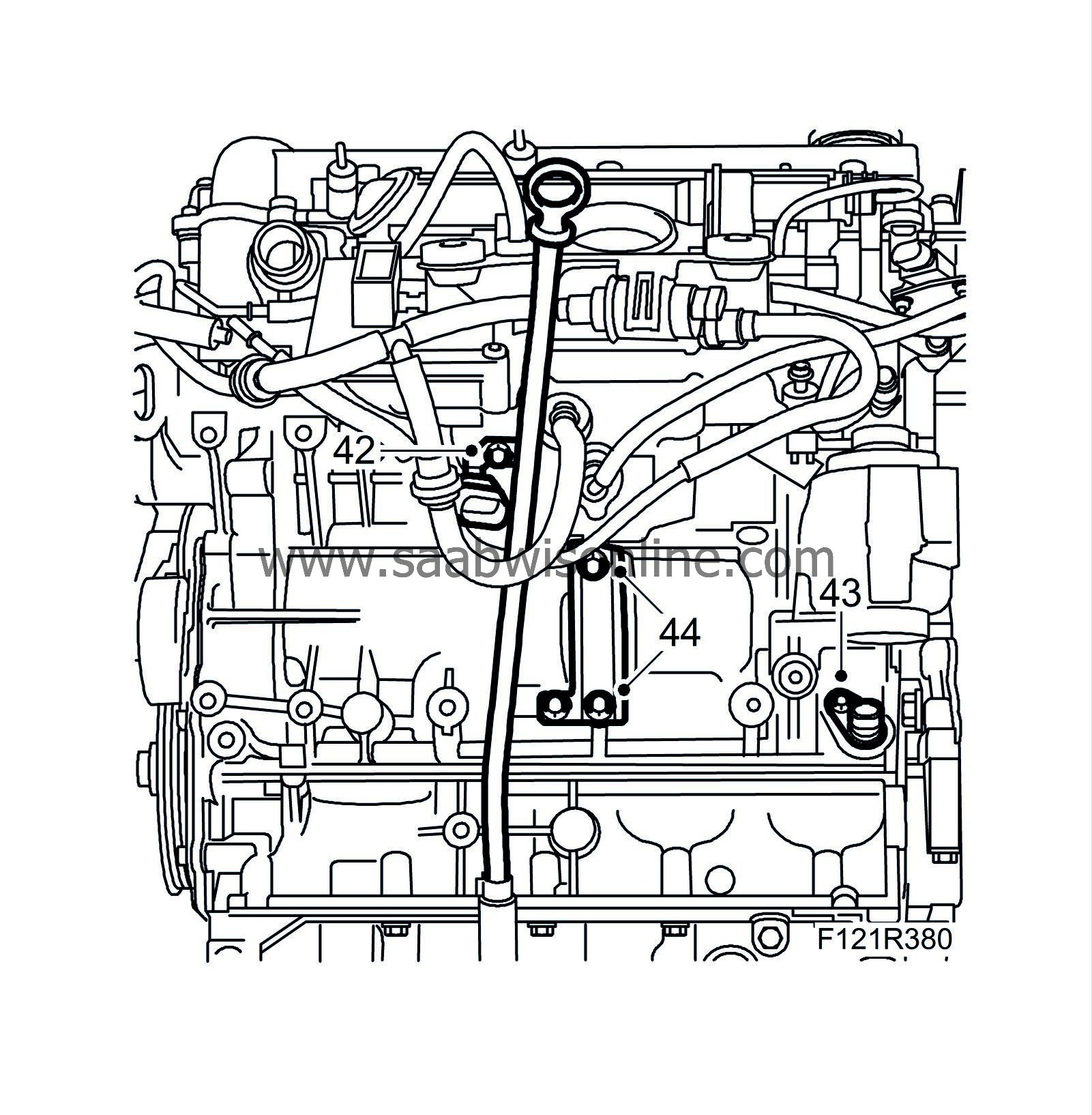

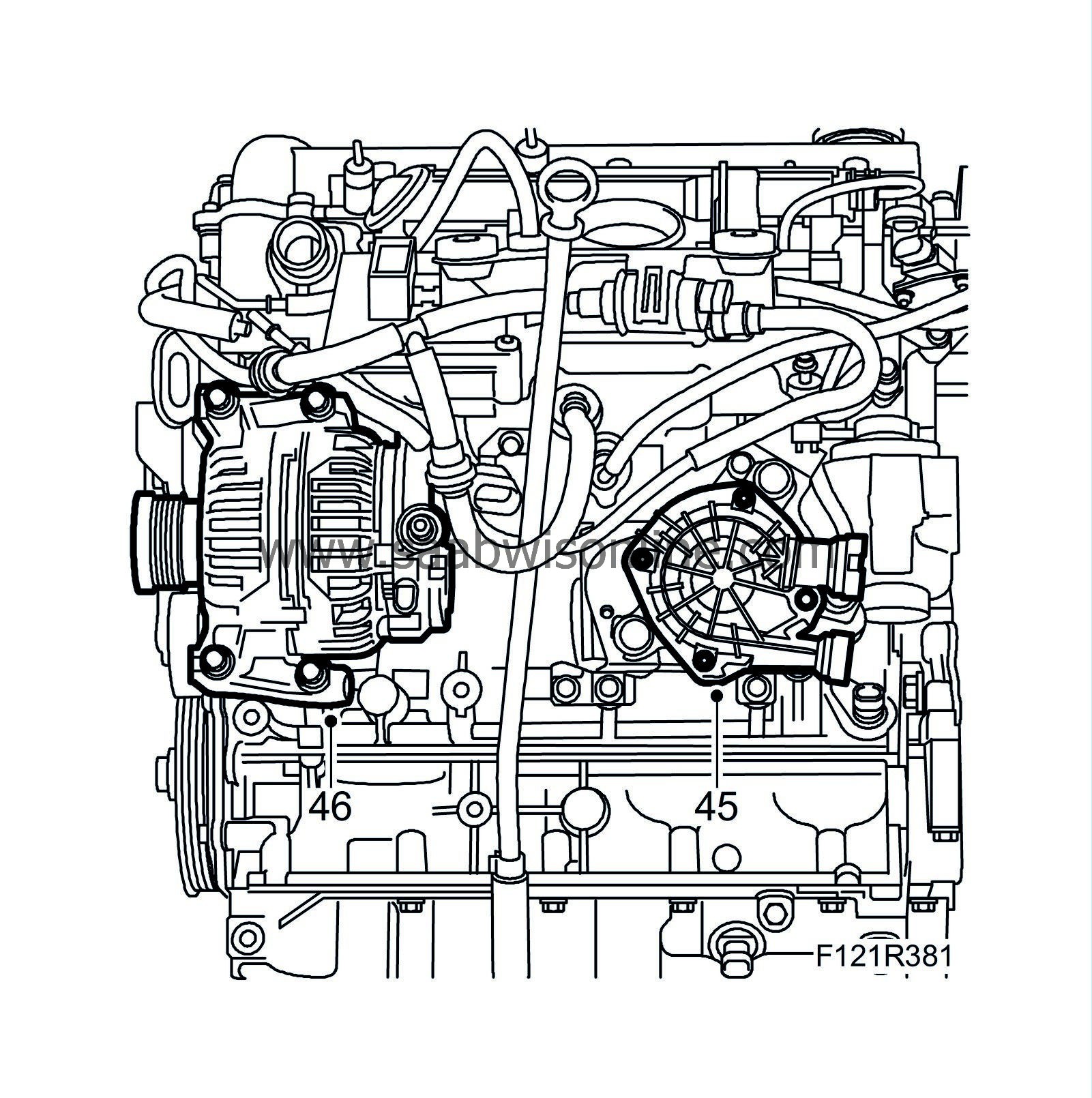

45.

|

Remove the bolt from the dipstick pipe.

|

|

46.

|

Fit the flywheel locking attachment 83 94 868 so that the flywheel/driver plate are locked.

|

|

47.

|

Cars with manual gearbox

: Remove the bolts holding the pressure plate and remove the clutch and driven plate hub.

|

|

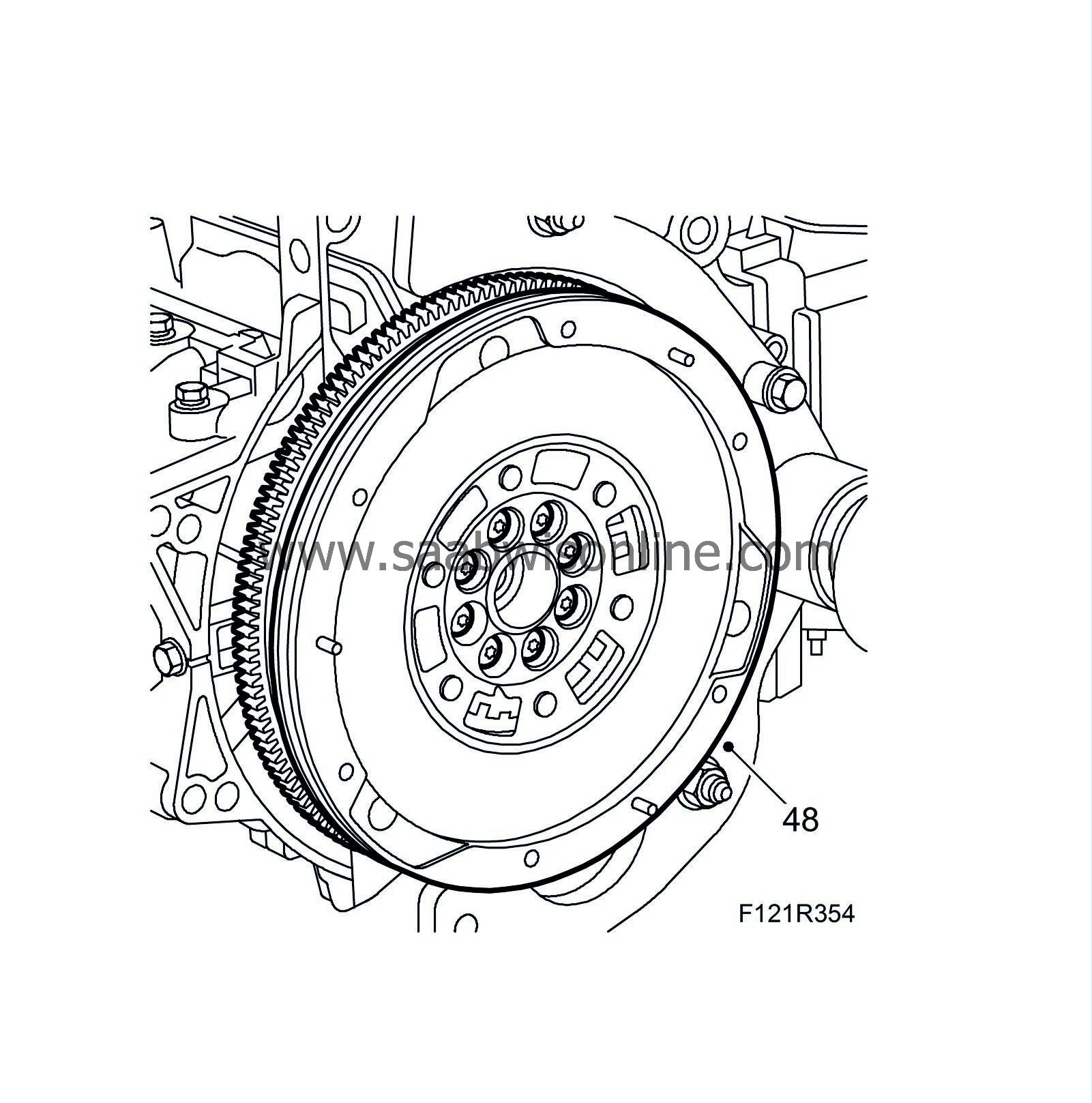

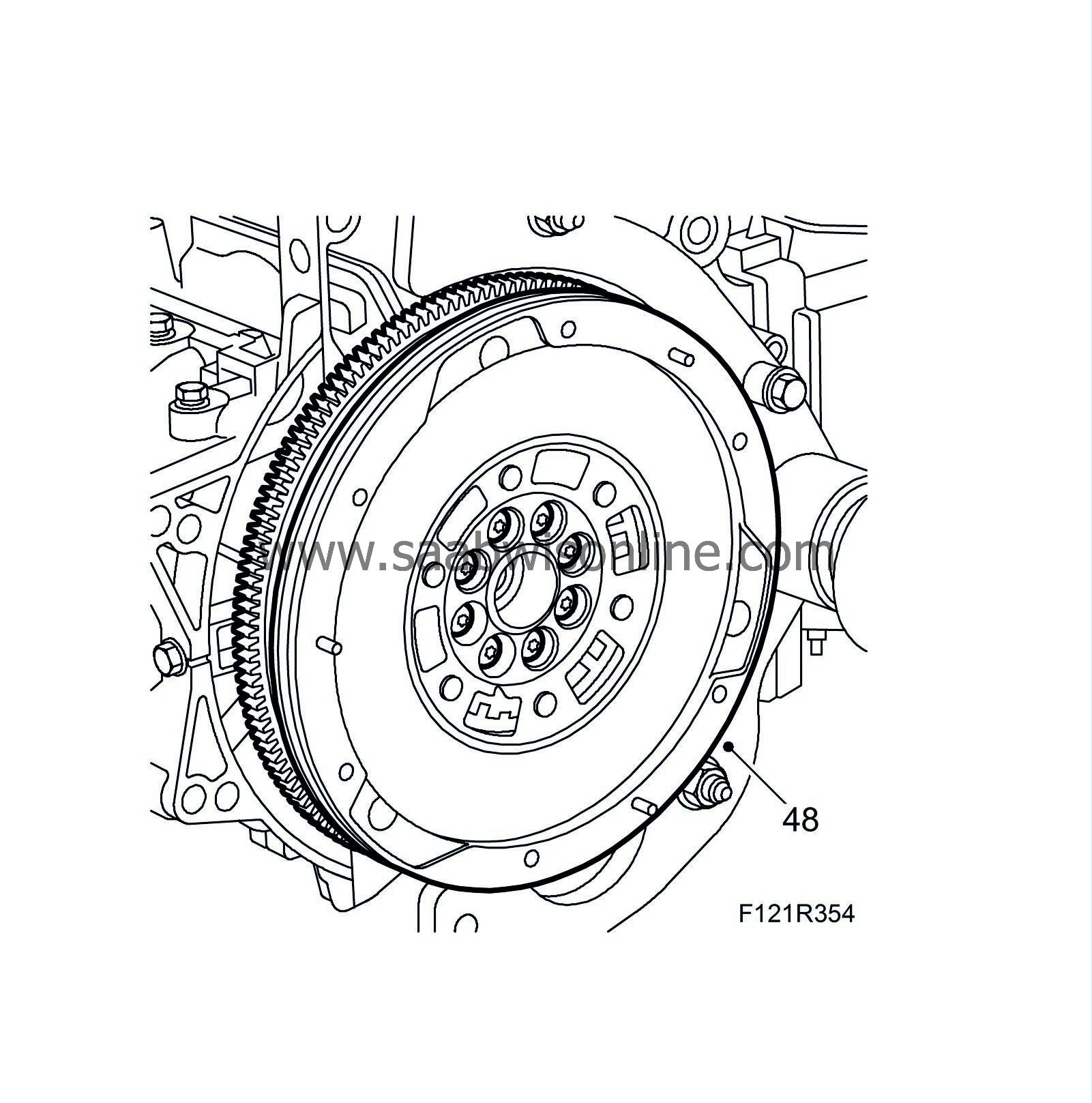

48.

|

Cars with manual gearbox

: Remove the flywheel.

Cars with automatic transmission

: Remove the driver plate.

|

|

49.

|

Remove the flywheel locking attachment 83 94 868.

|

|

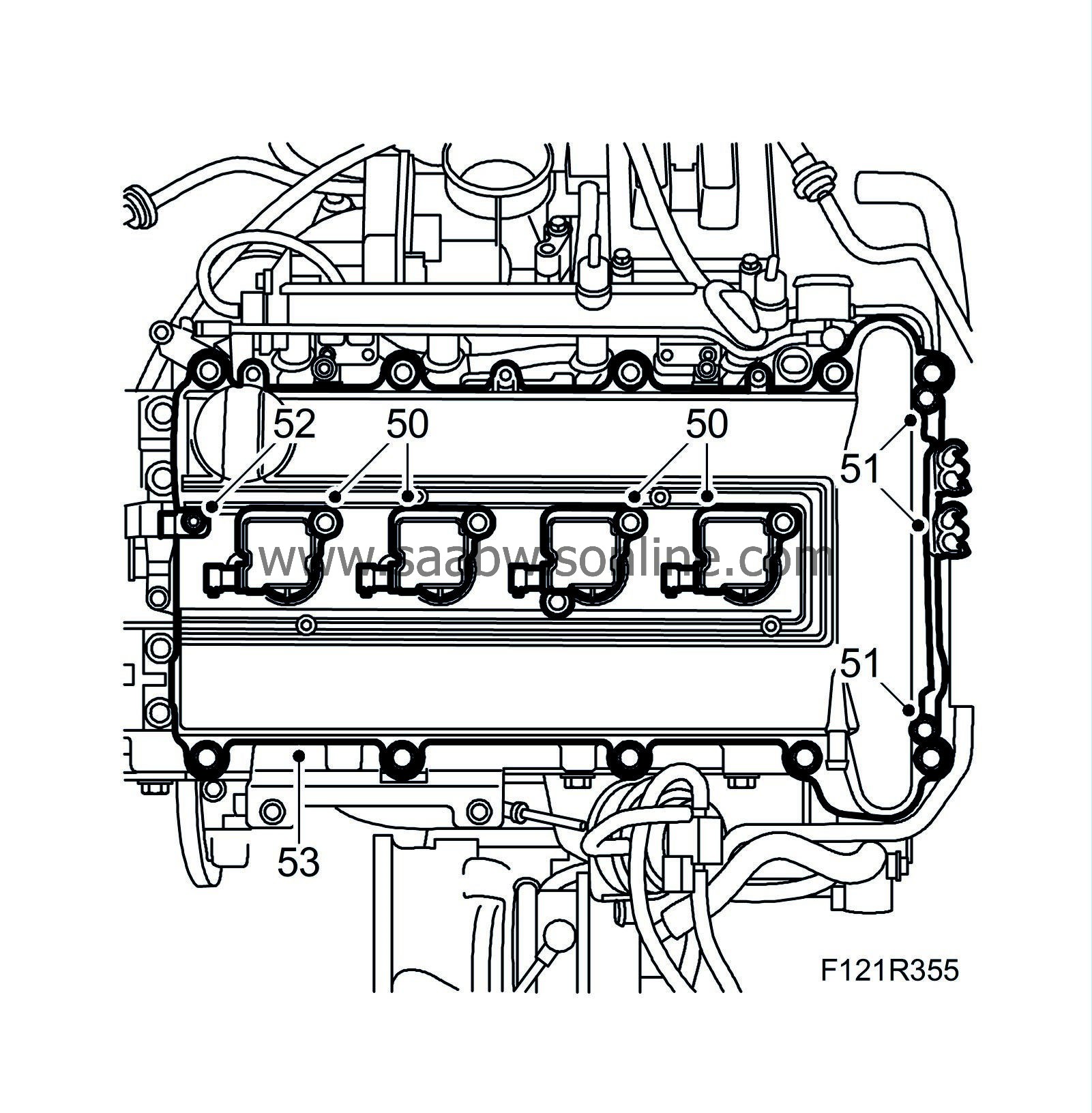

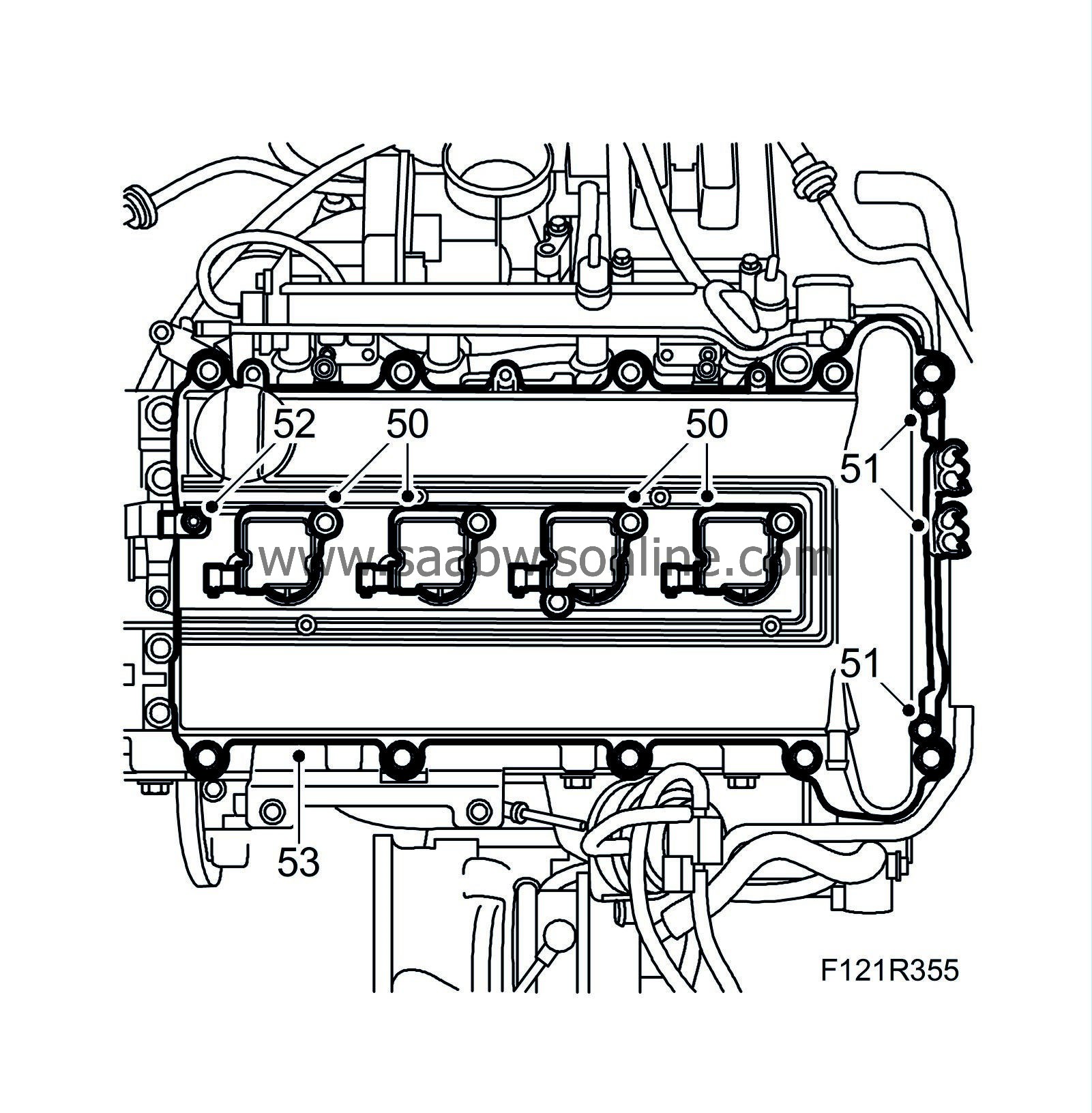

50.

|

Remove the ignition coils.

|

|

52.

|

Remove the ground cable from the camshaft cover.

|

|

53.

|

Remove the camshaft cover.

|

|

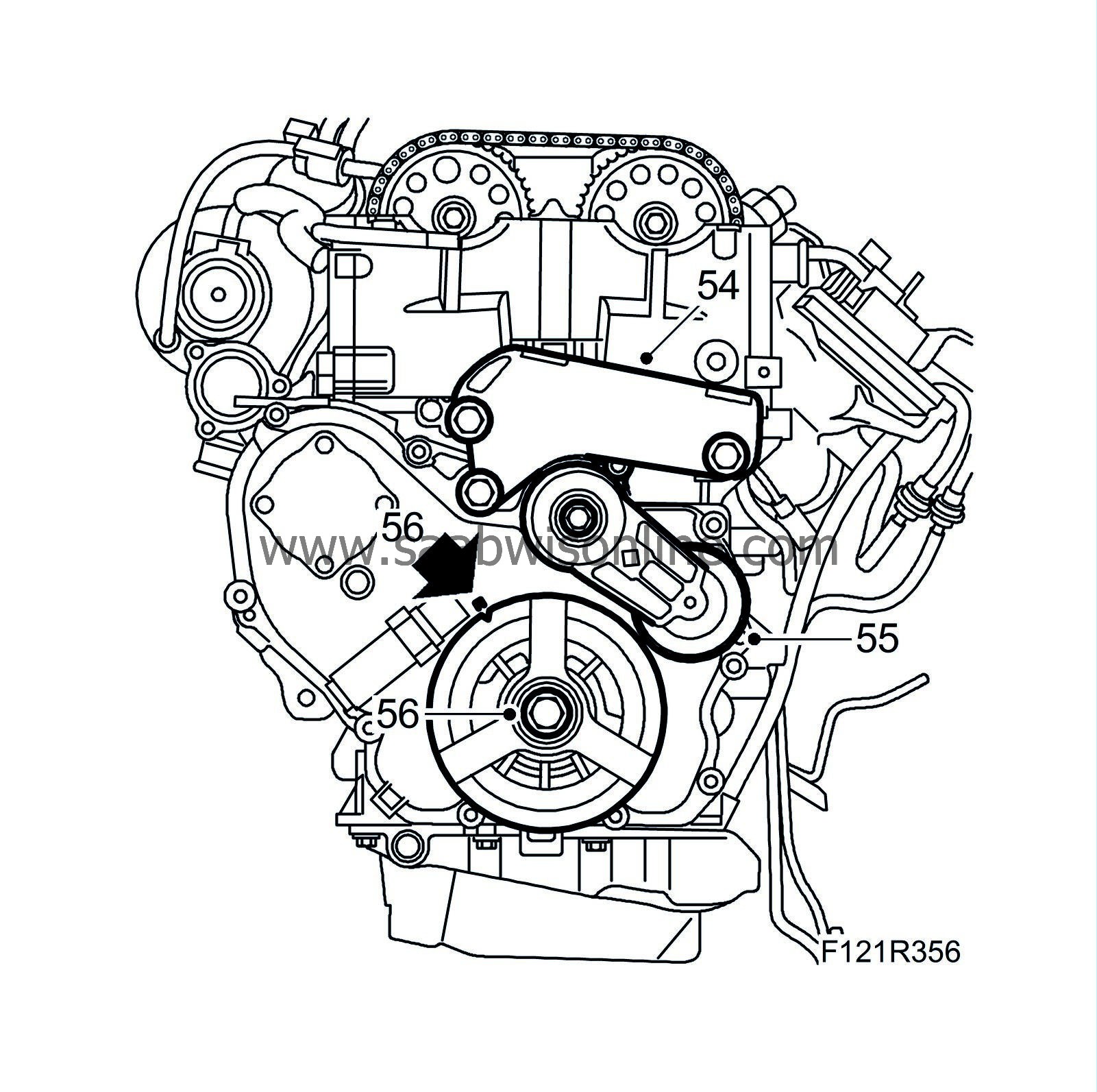

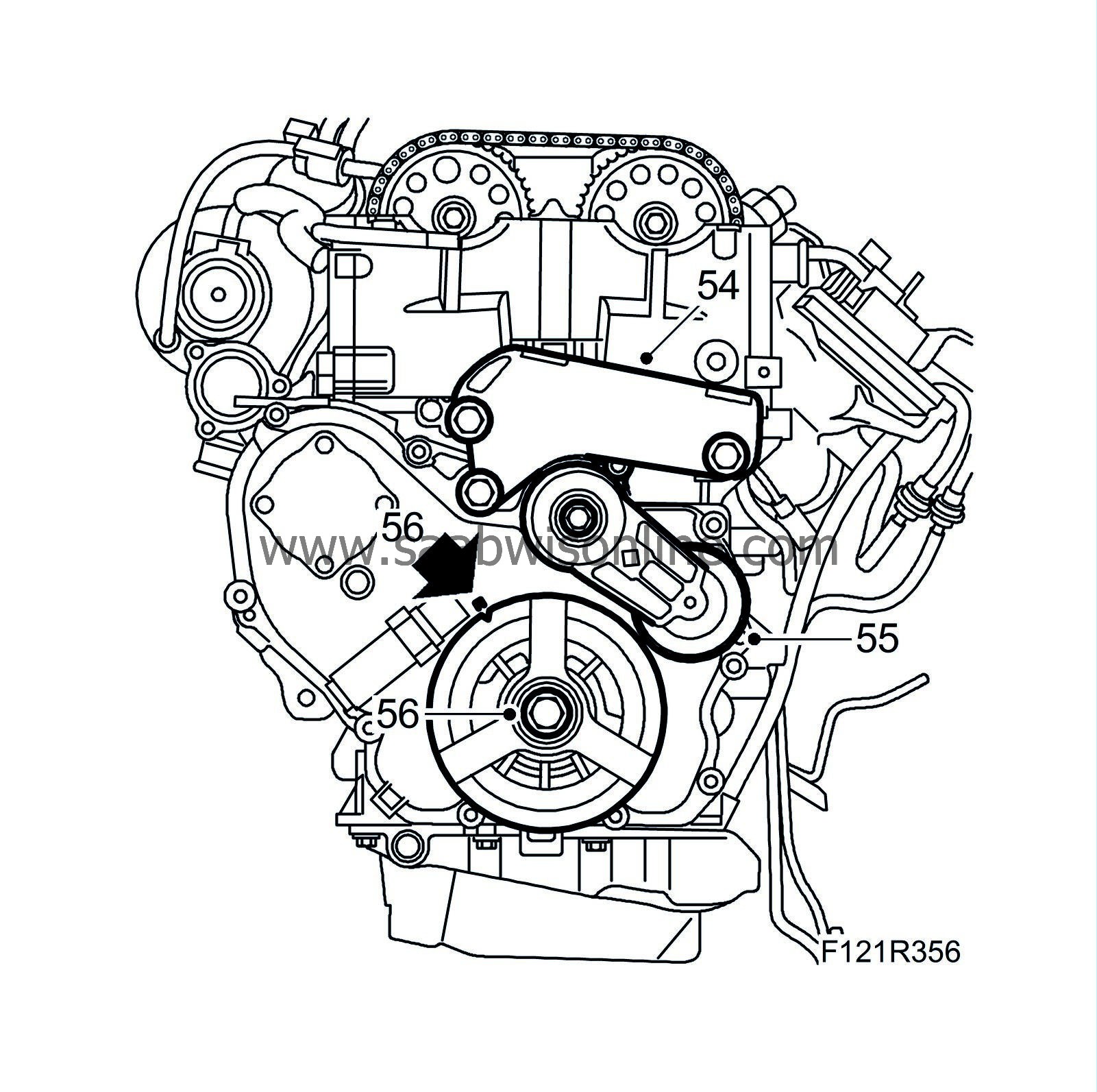

54.

|

Remove the engine mounting bracket.

|

|

55.

|

Remove the belt tensioner.

|

|

56.

|

Reset the crankshaft. Remove the crankshaft pulley with 83 95 360 Holding tool, crankshaft pulley (shaft only) and 83 96 210 Holding tool, crankshaft pulley, B207.

|

|

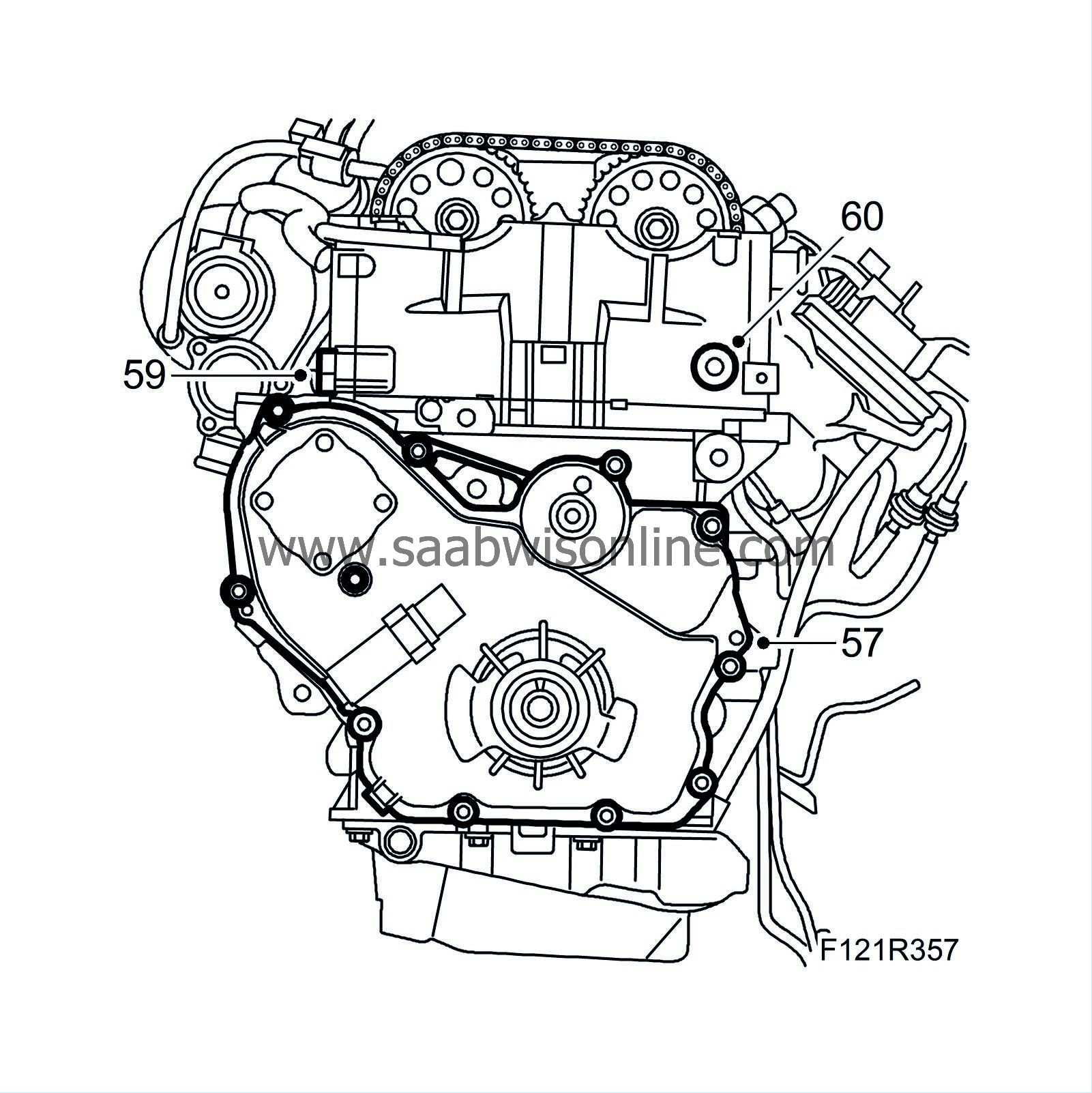

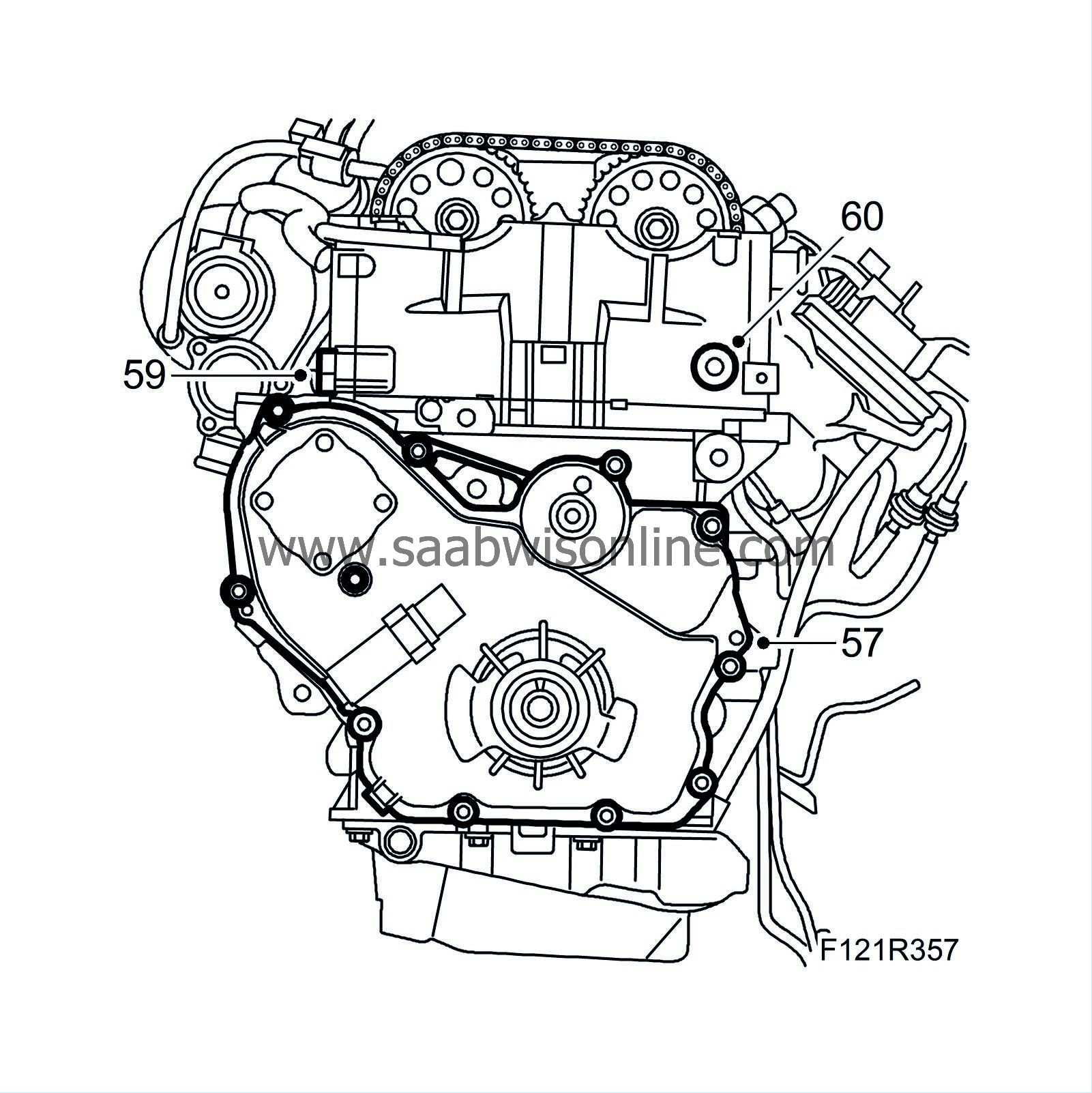

57.

|

Remove the timing cover and gasket.

|

|

58.

|

Remove the crankshaft seal.

|

|

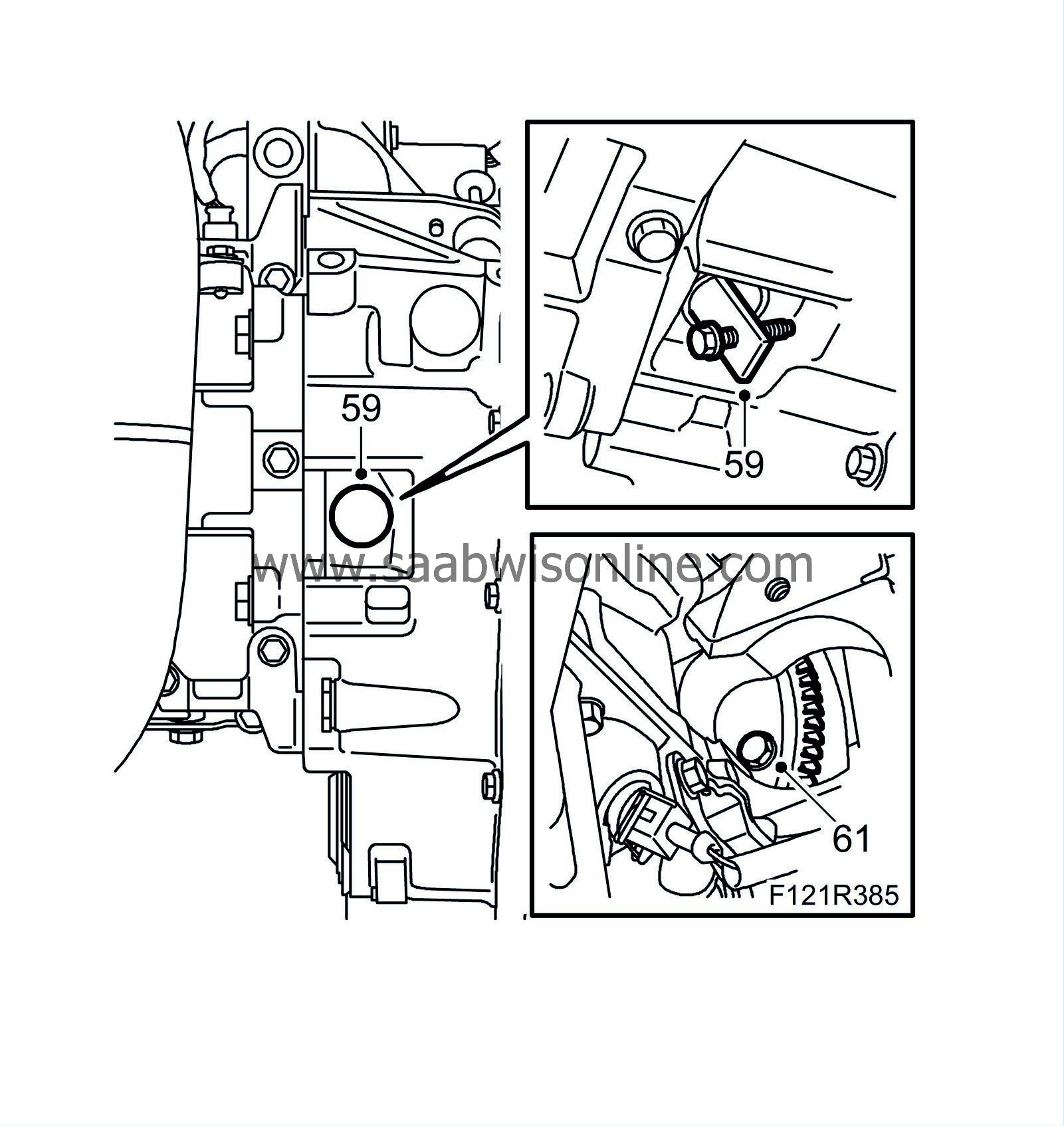

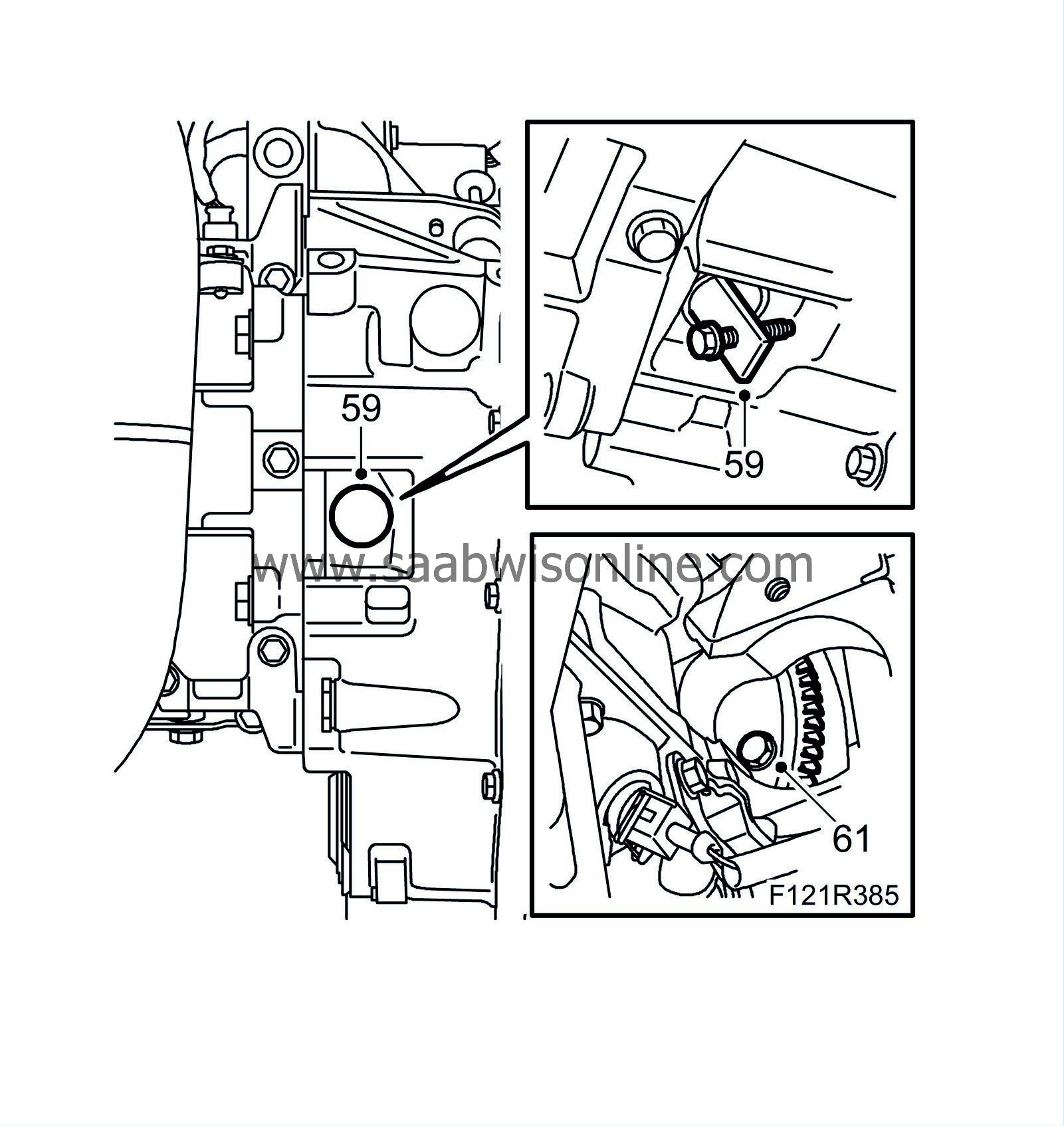

59.

|

Remove the timing chain tensioner.

|

|

60.

|

Remove the plug from the cylinder head.

|

|

61.

|

Remove the upper bolt from the chain guide near the intake side.

|

|

62.

|

Remove the upper timing chain guide rail.

|

|

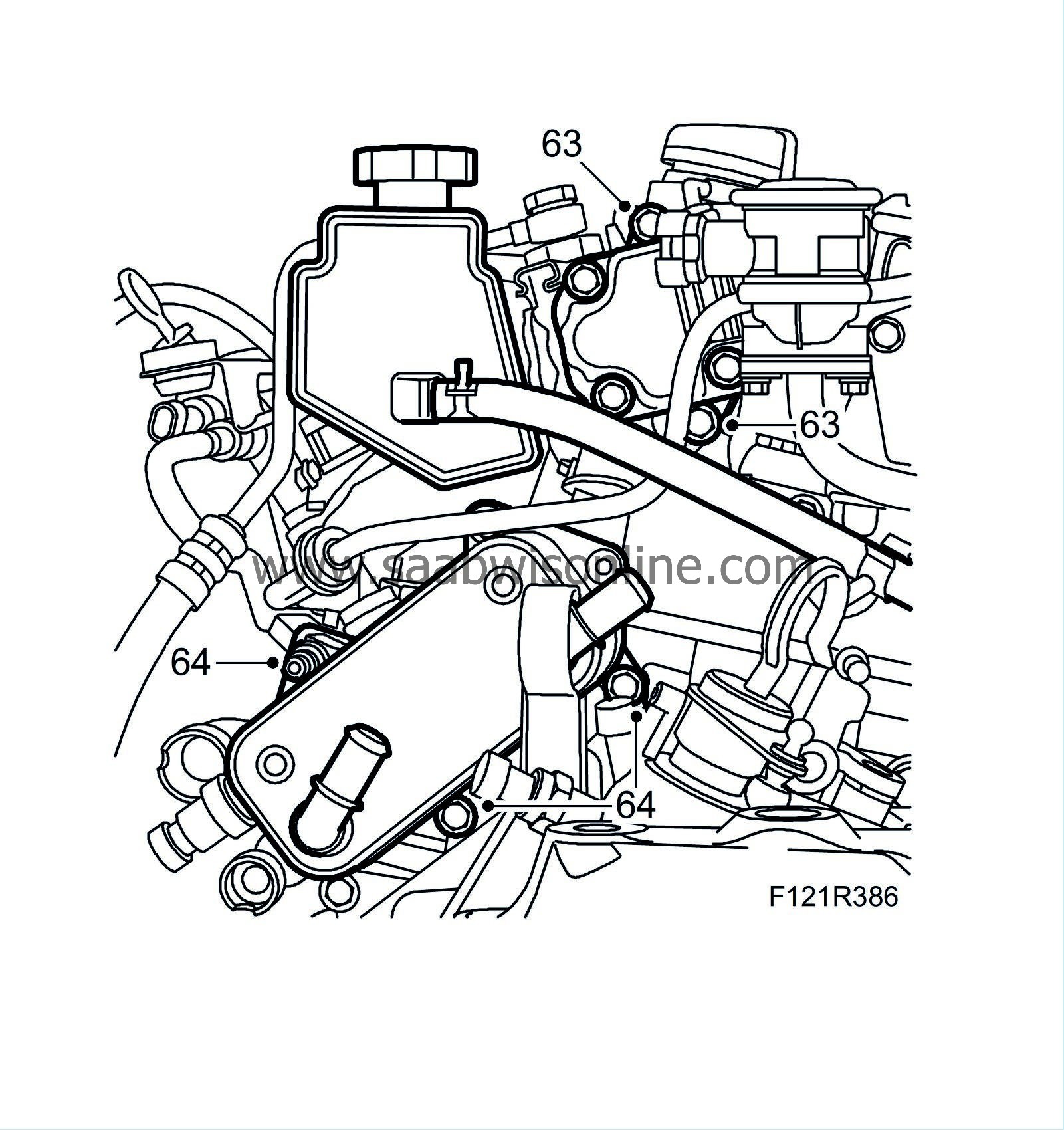

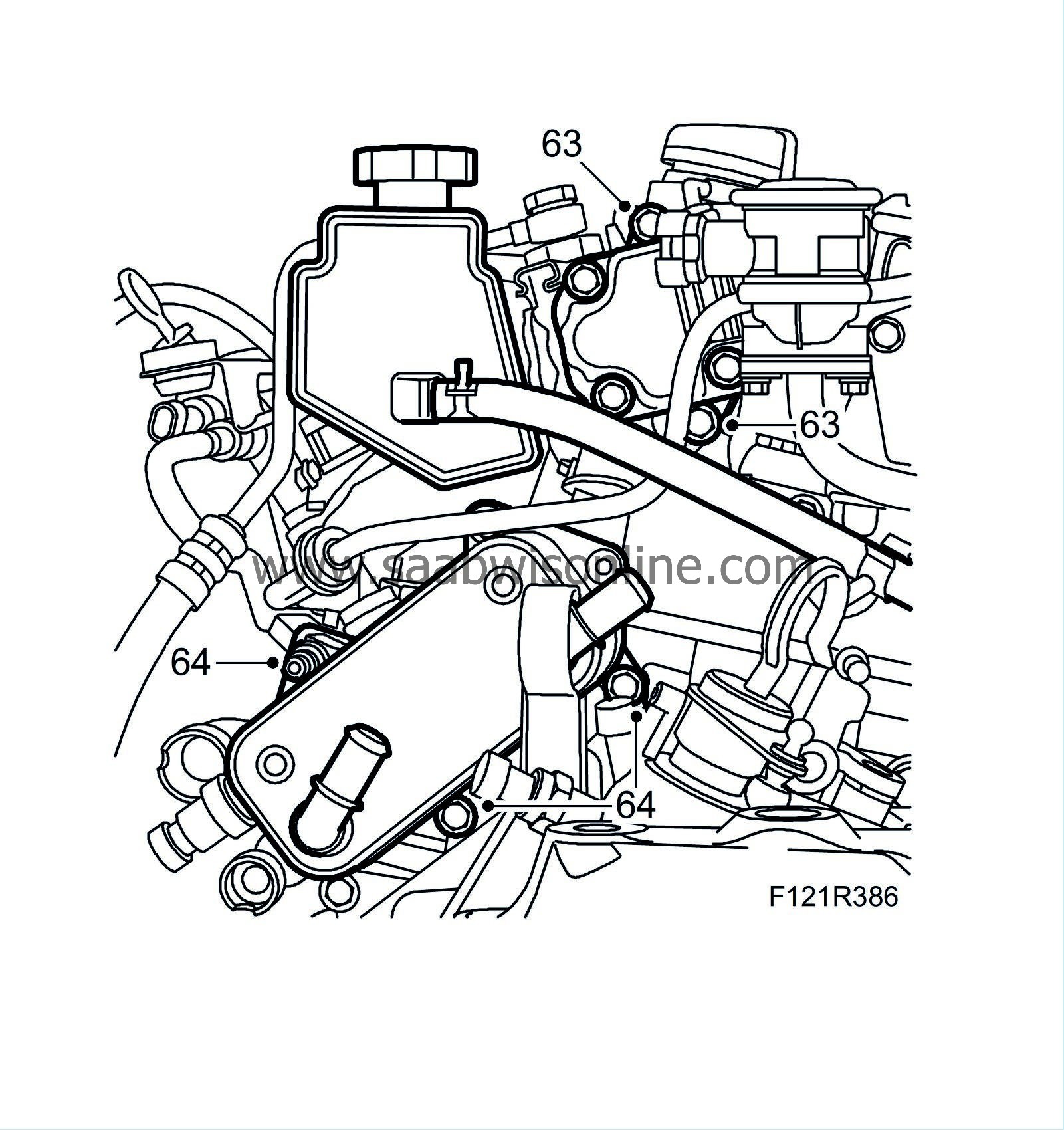

63.

|

Remove the lower chain guide bolt. Pull the chain guide down. Detach the lower section of the chain. Remove the sprocket.

|

|

64.

|

Remove the camshaft sprockets. Use a wrench to grip the camshaft flats when the bolts are loosened. Lift up the chain.

|

|

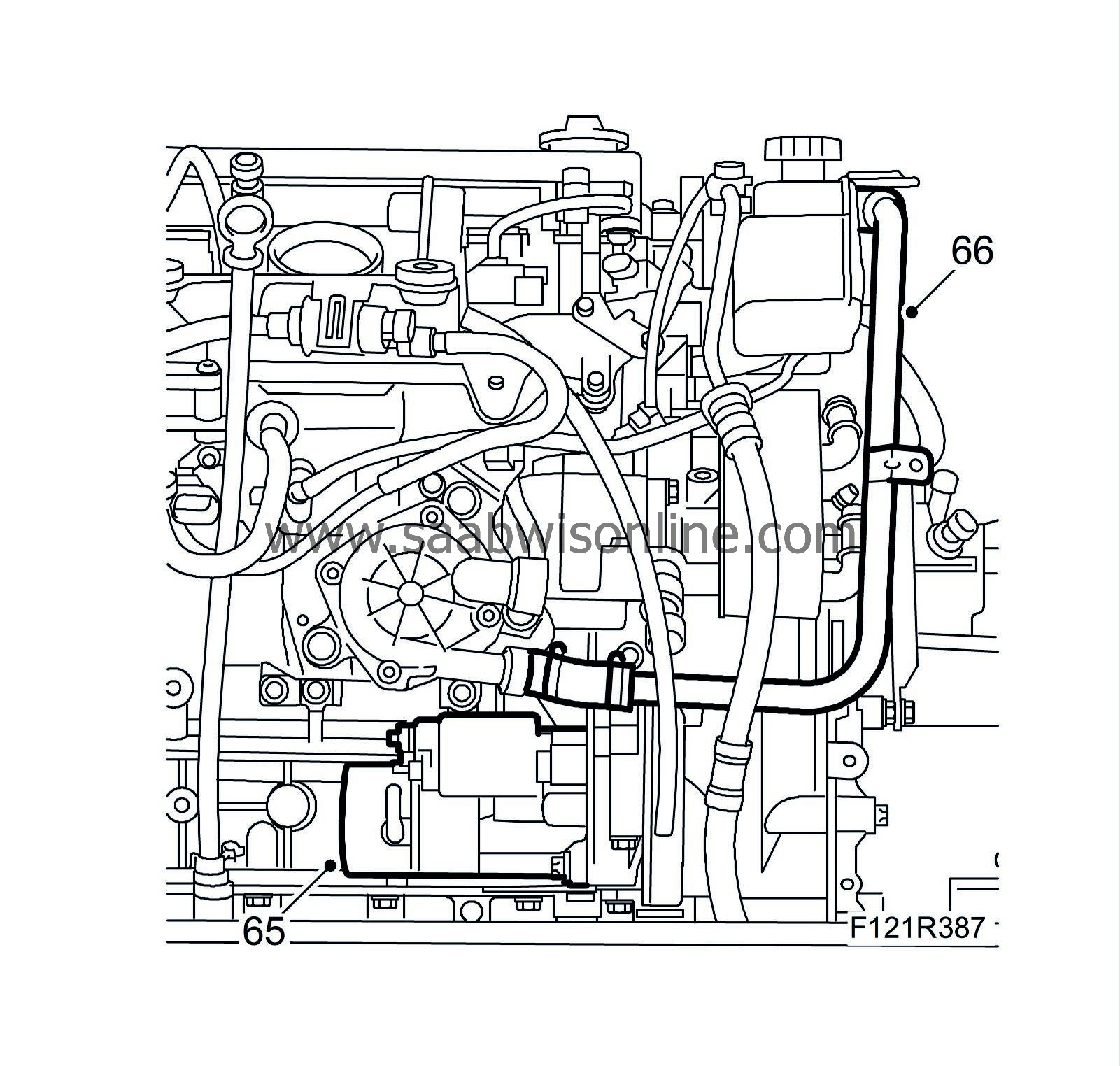

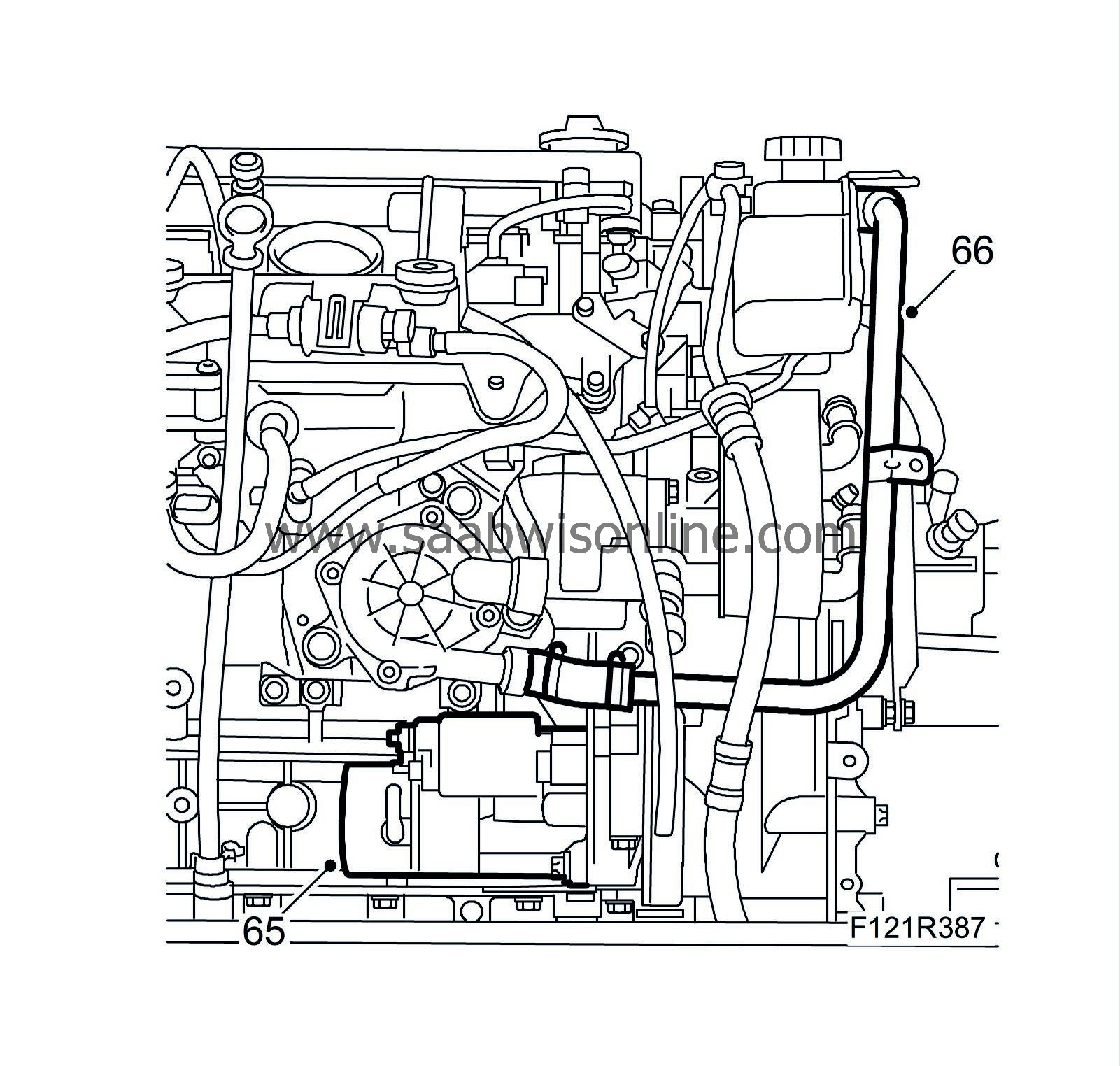

65.

|

Remove the tensioner guide by lifting it up. Inspect the condition of the guide. Replace if necessary.

|

|

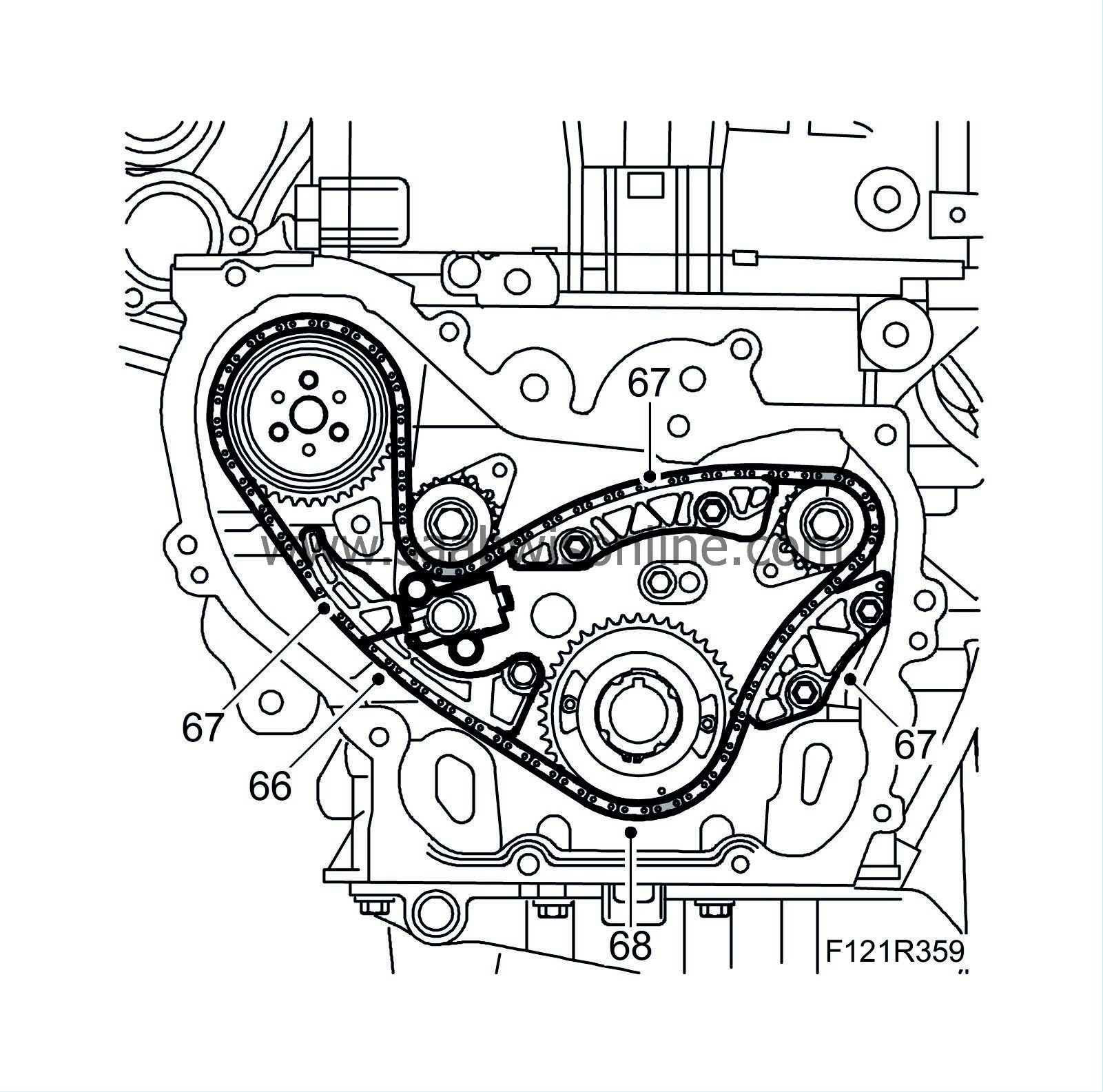

66.

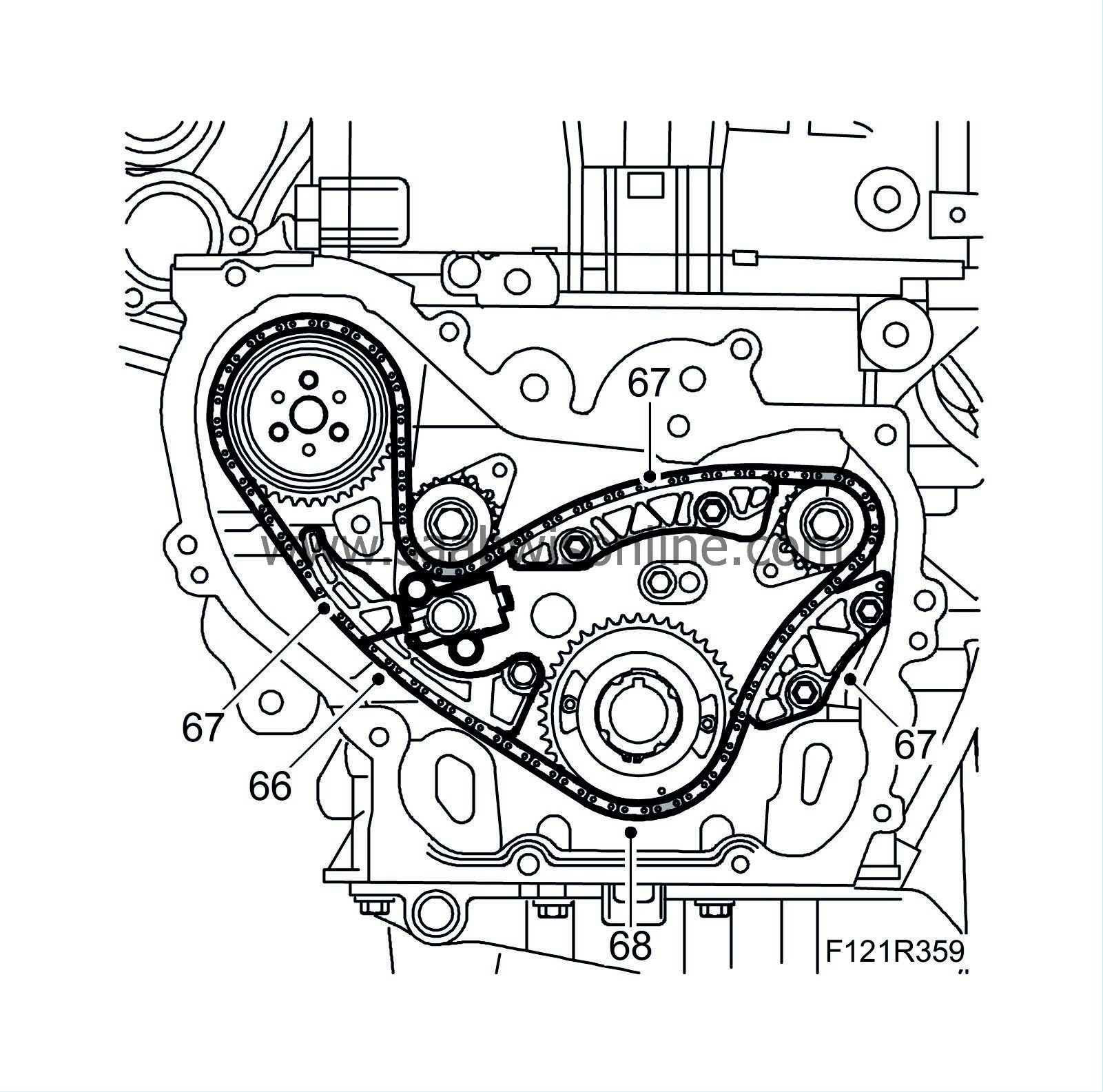

|

Remove the balancer shaft chain tensioner.

|

|

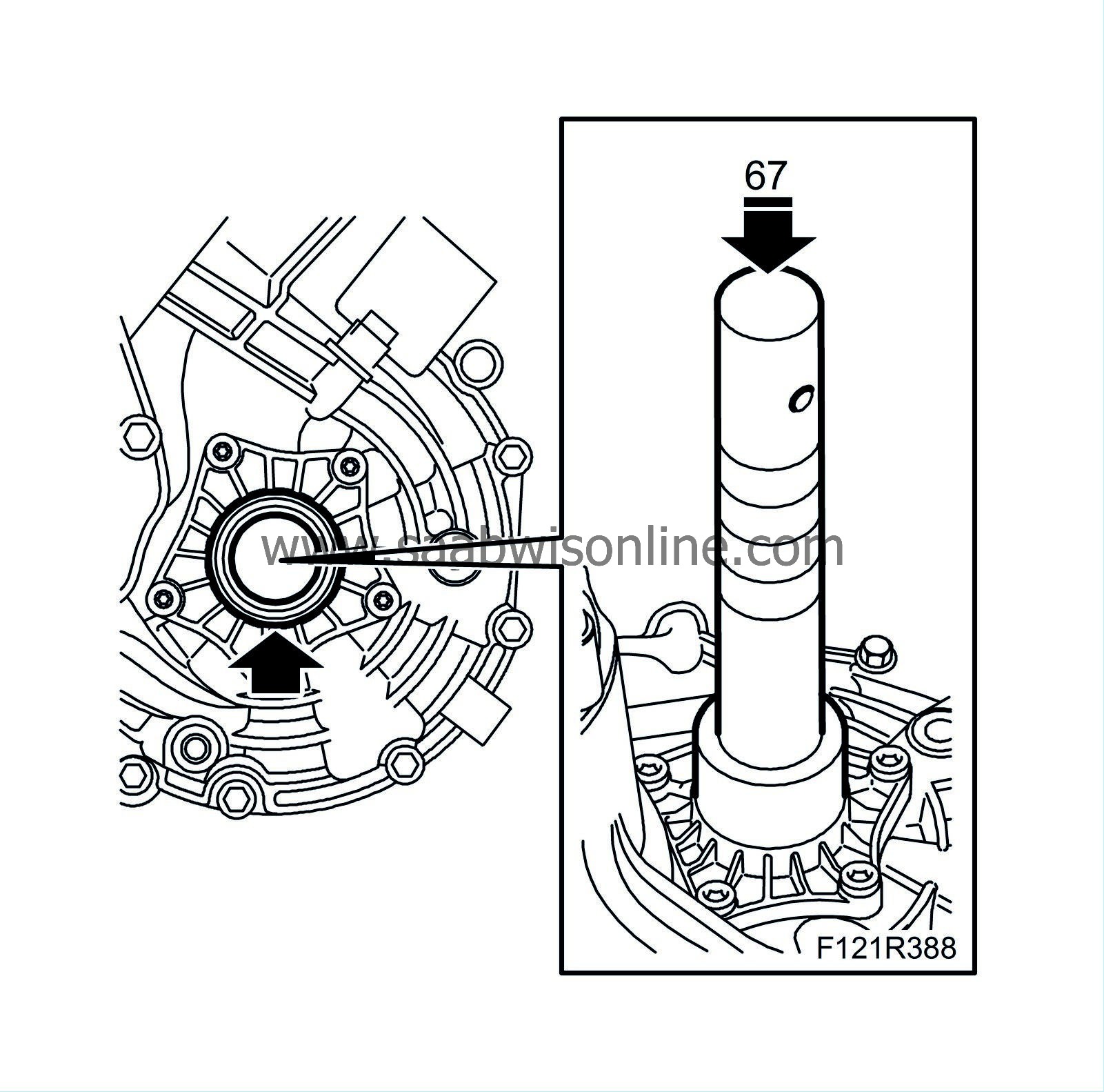

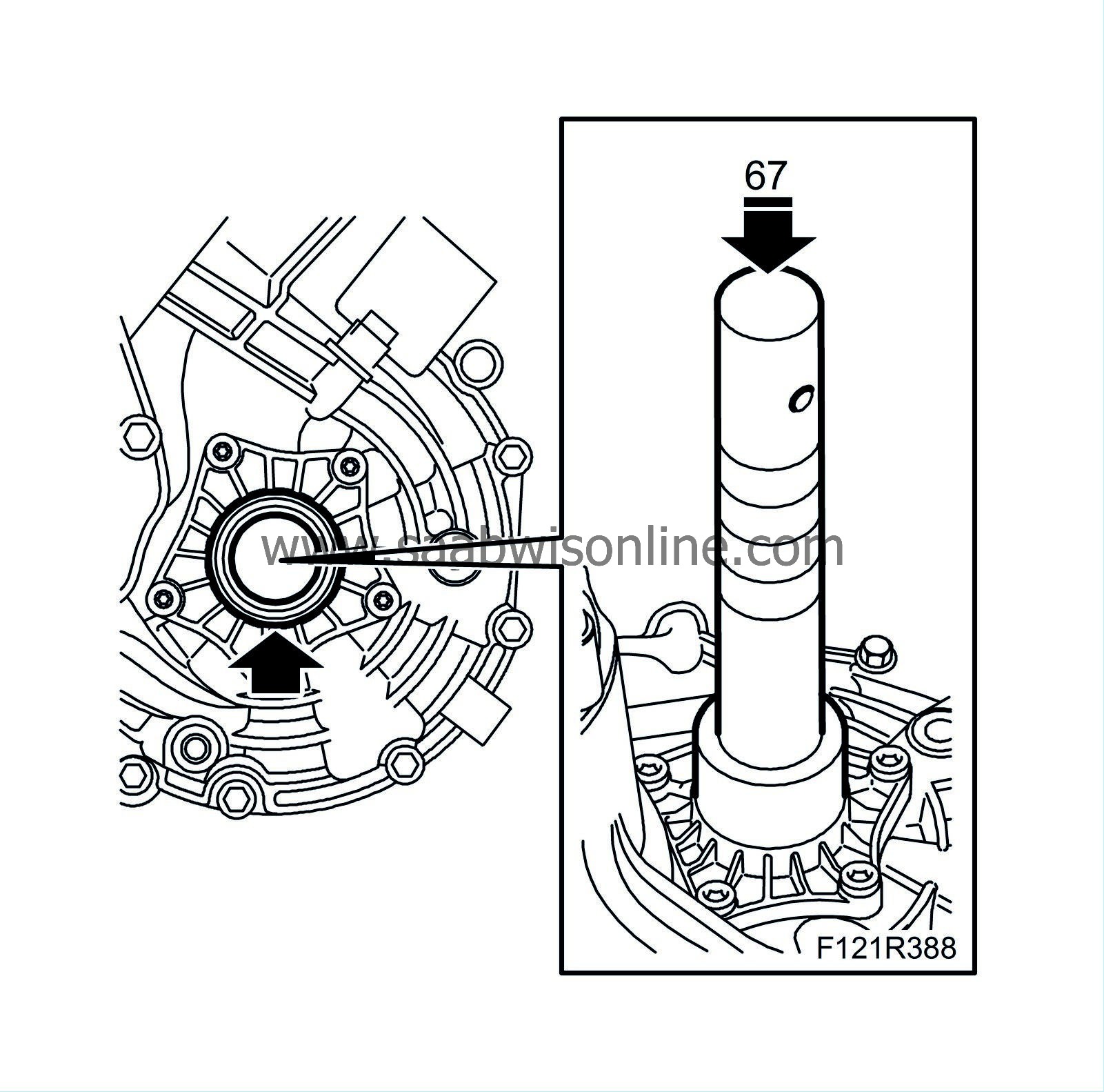

67.

|

Remove the balancer shaft chain guide bars.

|

|

68.

|

Remove the balancer shaft chain, sprocket and wedge.

|

|

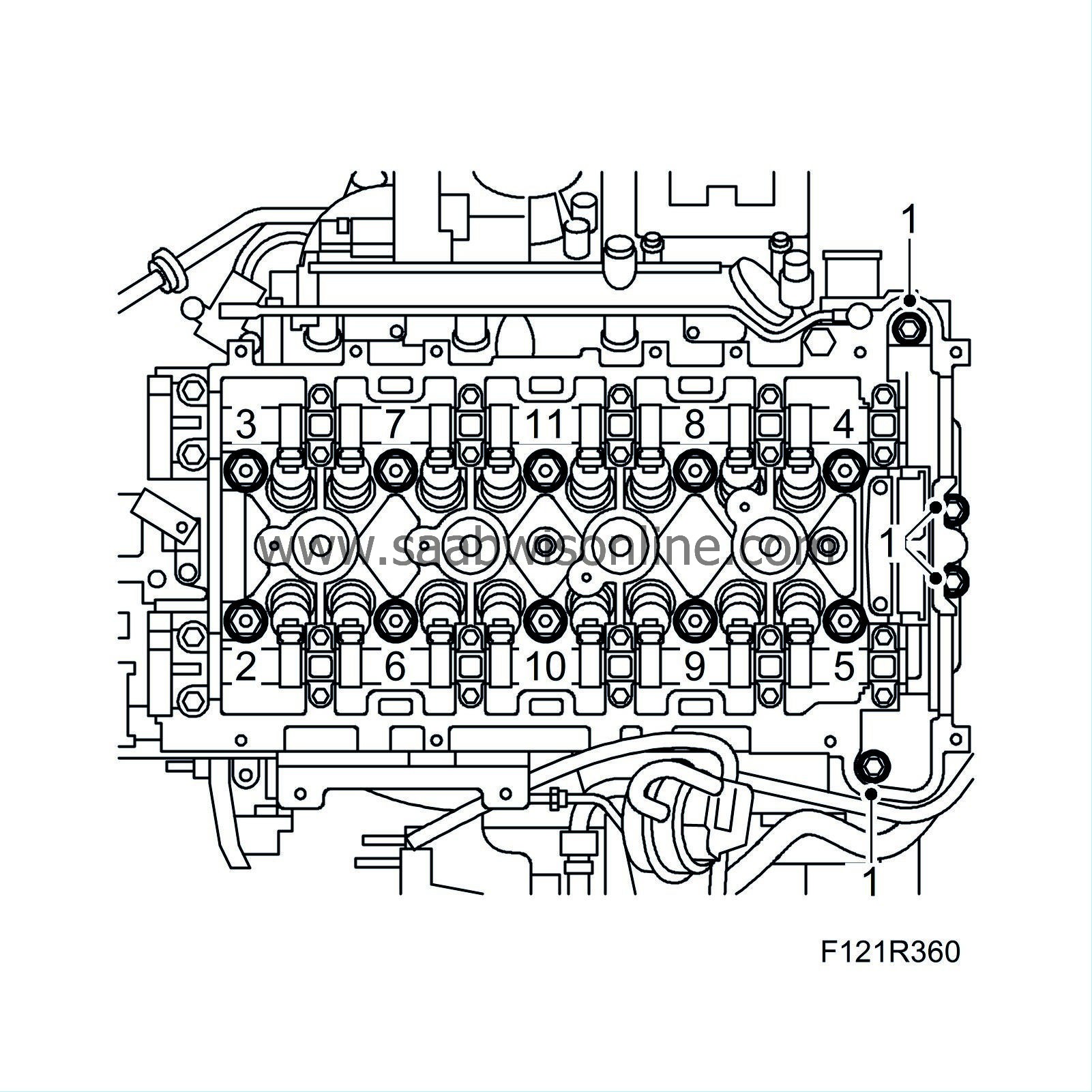

69.

|

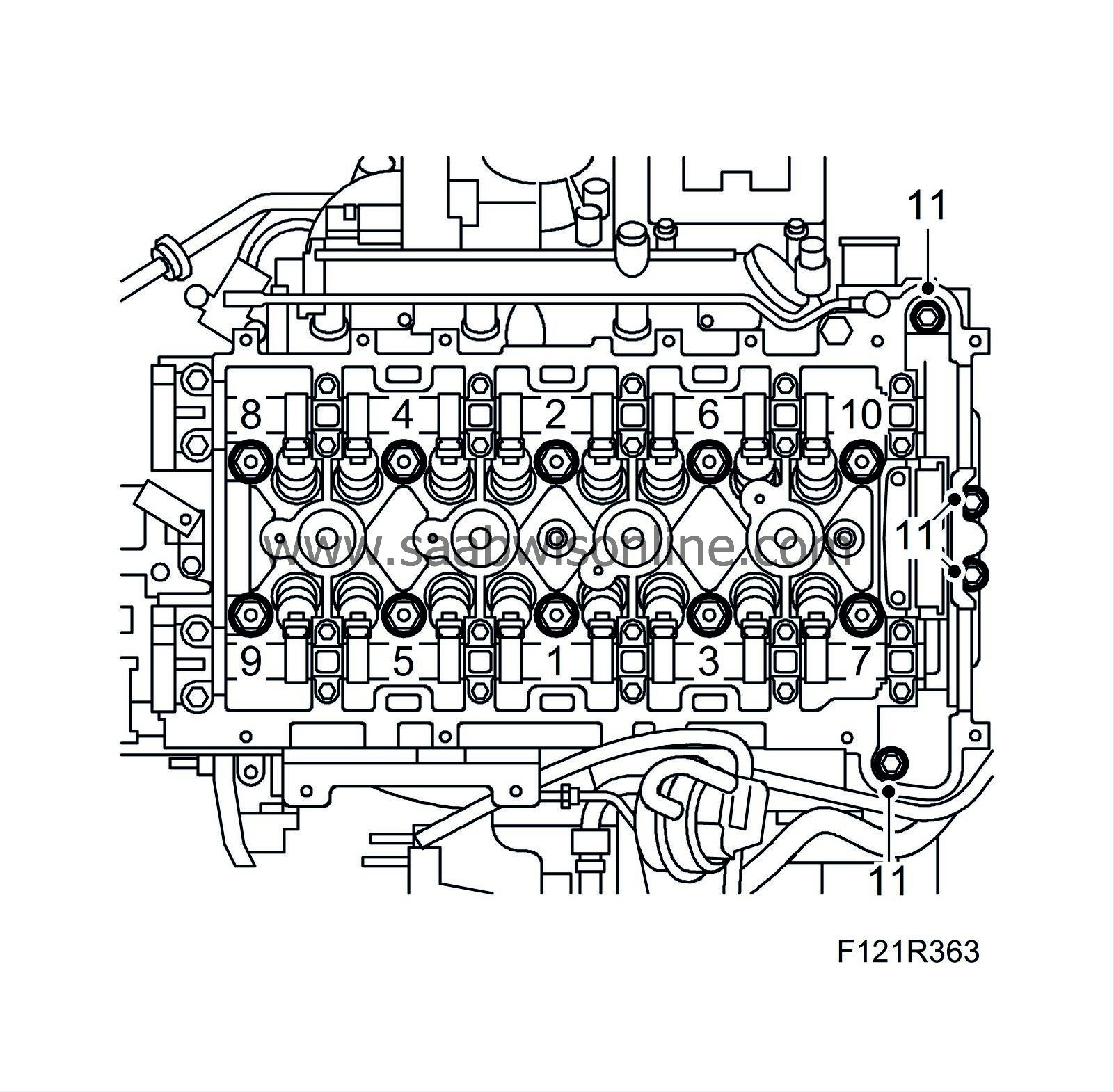

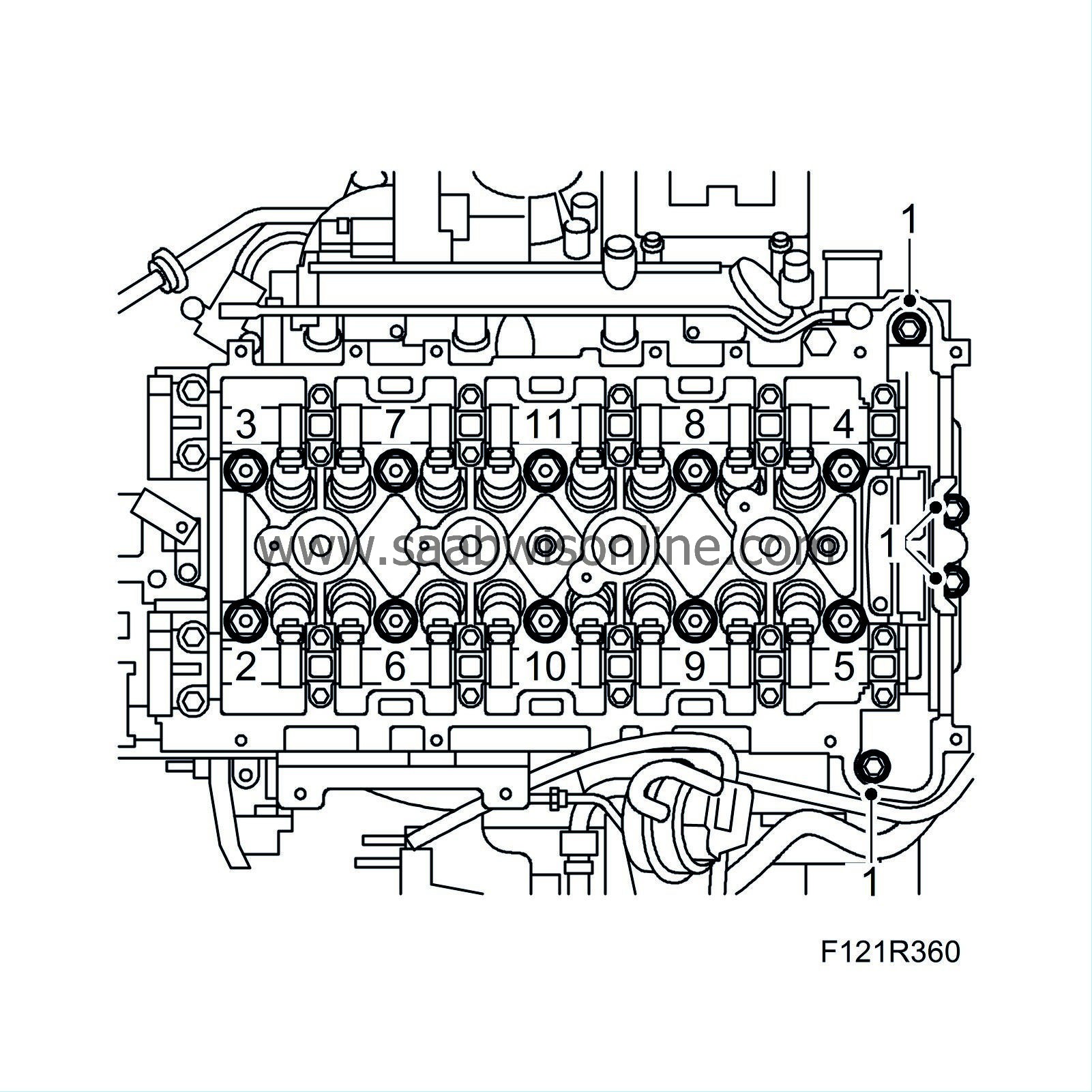

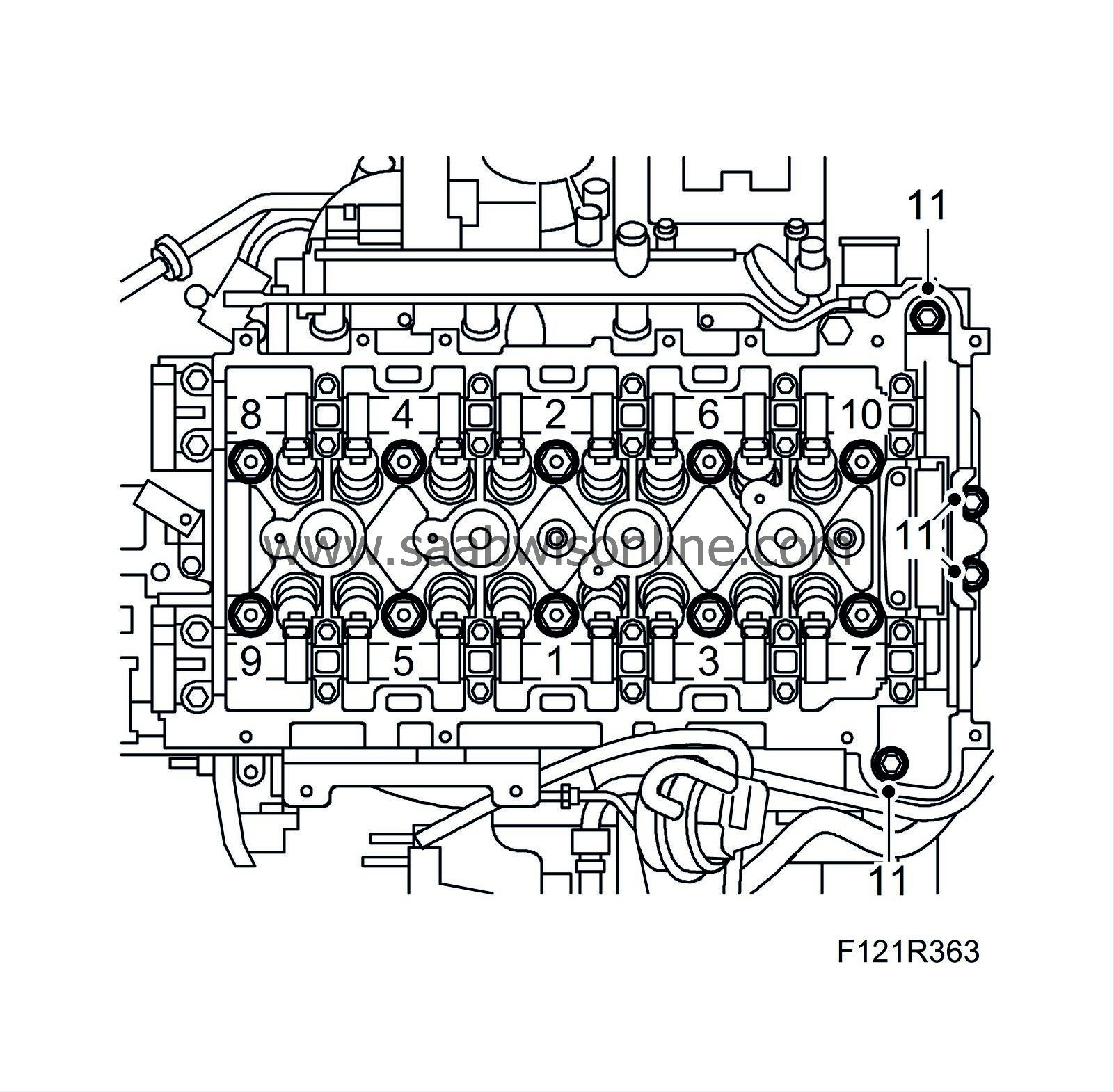

Remove the cylinder head in the order shown in the illustration.

|

|

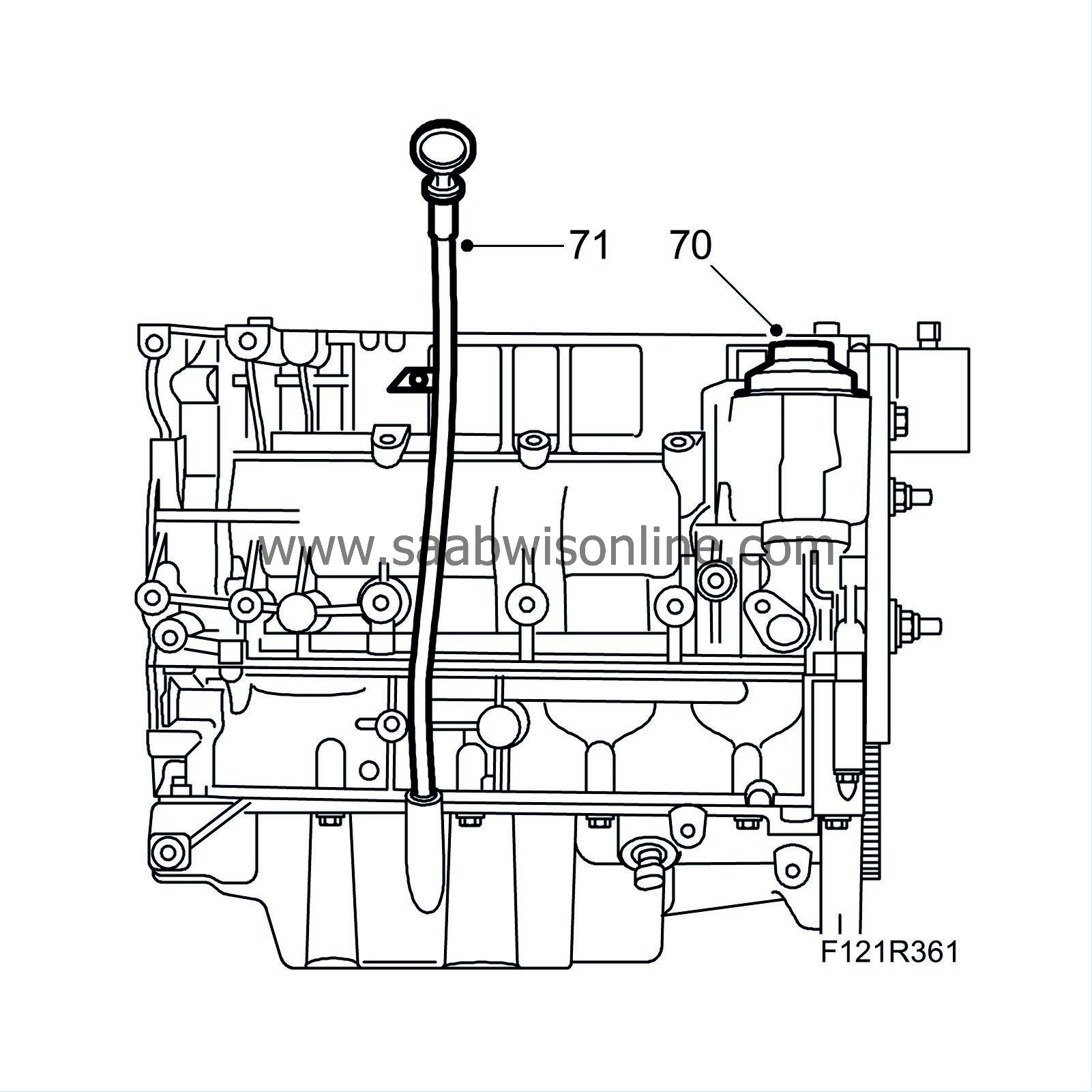

70.

|

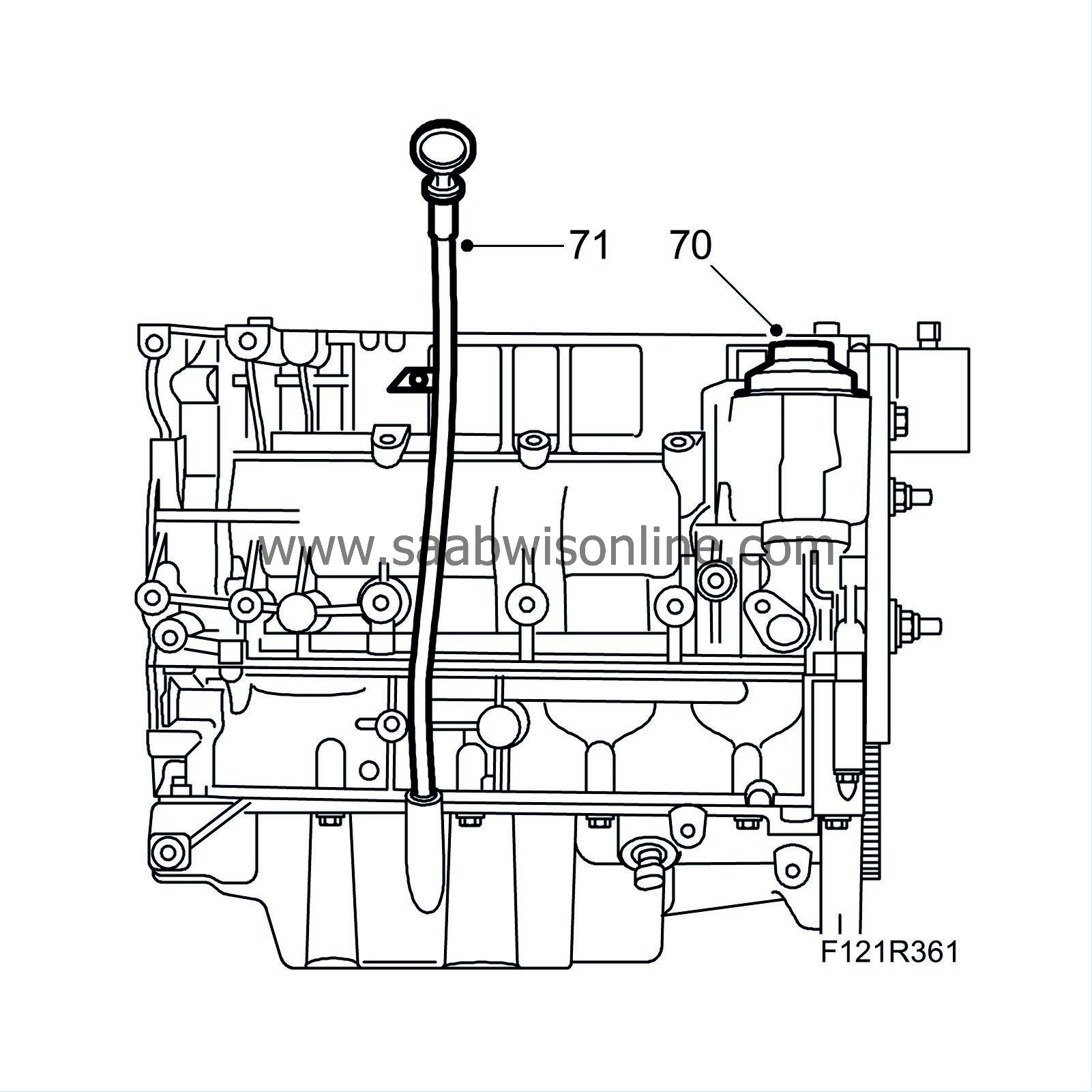

Remove the oil filter cover and oil filter.

|

|

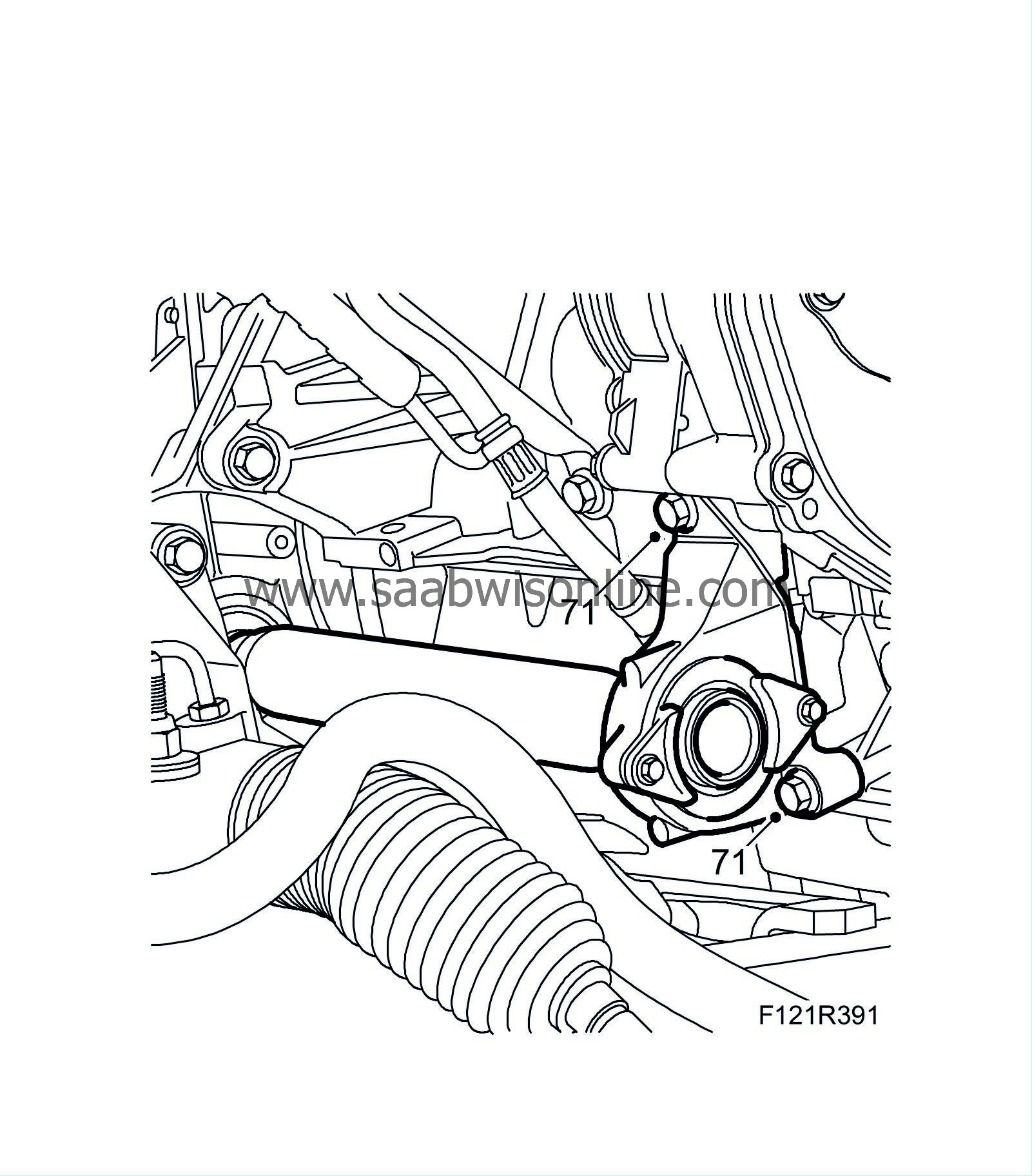

71.

|

Remove the dipstick pipe.

|

|

72.

|

Lower the cylinder block from 78 74 878 floor stand and remove 83 94 751 holder.

|

|

Fitting the spare part cylinder block

|

|

1.

|

Fit 83 94 751 holder and lift the cylinder block into the 78 74 878 floor stand.

|

|

2.

|

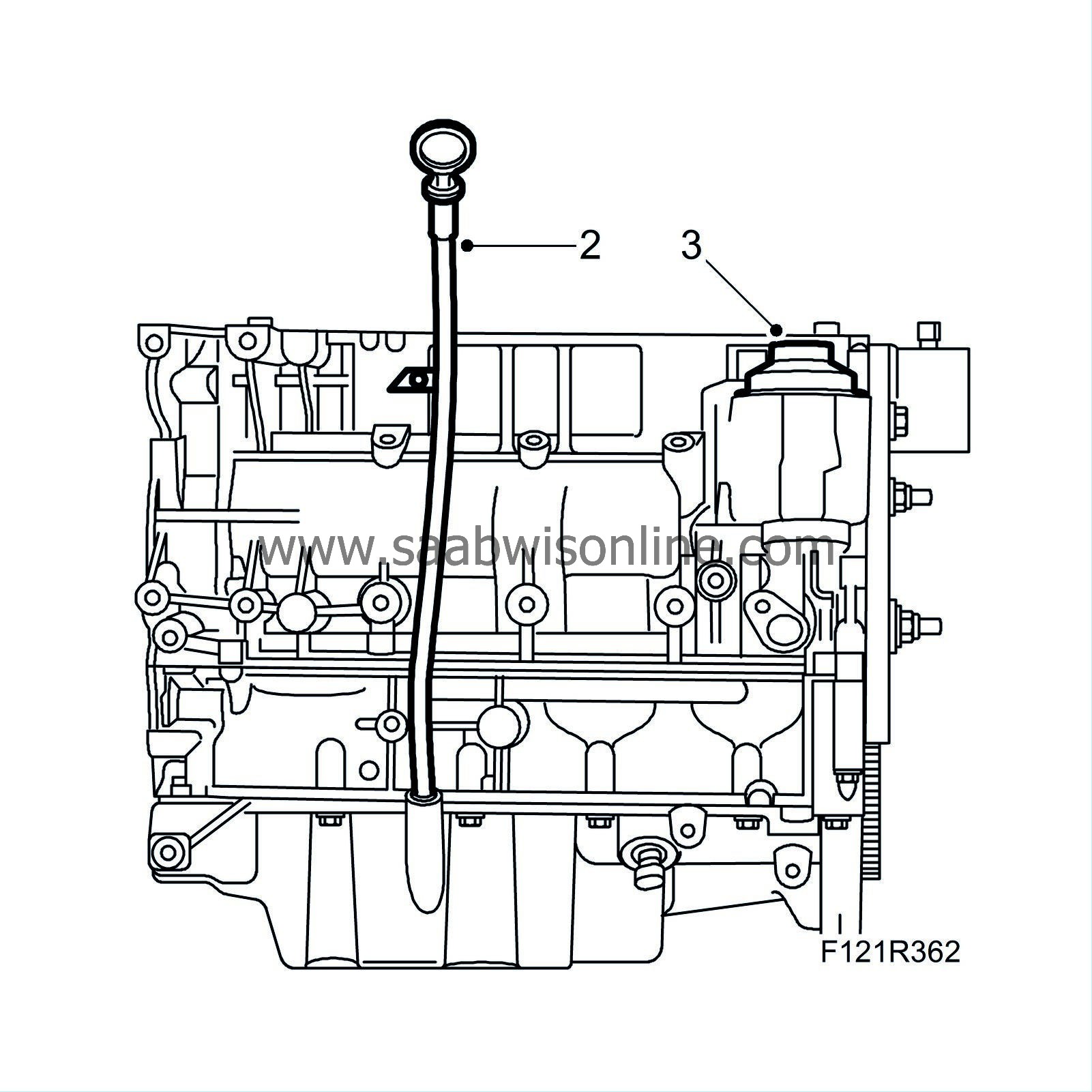

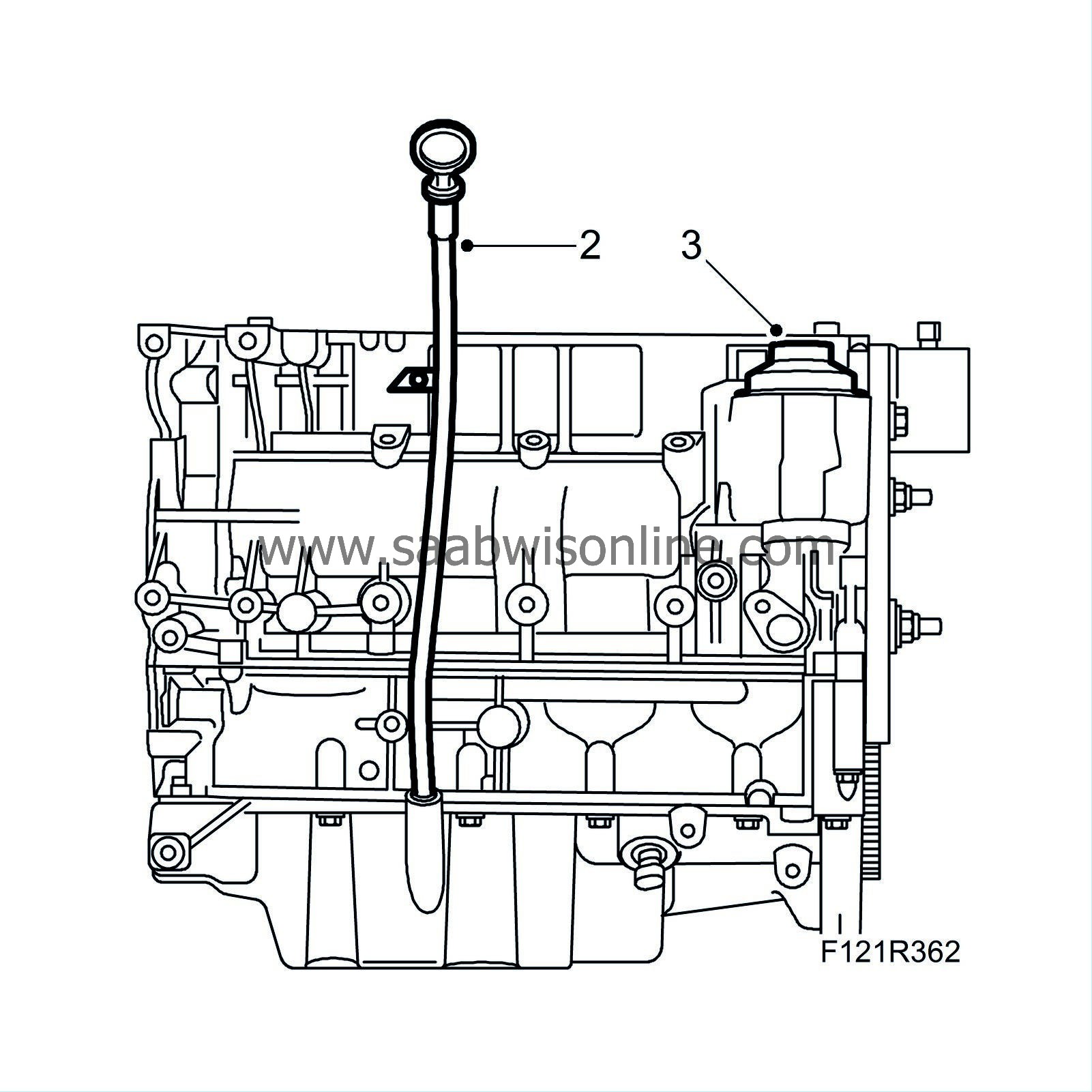

Fit the dipstick pipe with new O-rings.

|

|

3.

|

Fit a new oil filter and replace the O-ring on the oil filter cover. Use 83 96 121.

Tightening torque 25 Nm (18 lbf ft)

|

|

4.

|

Check that the crankshaft has been reset using the markings on the pulley and timing cover.

|

|

5.

|

Place a new gasket on the cylinder block.

|

|

6.

|

Fit the cylinder head in the order shown in the illustration. Insert the bolts carefully. The threads in the cylinder block can become damaged if they are lowered too rapidly. Check that the guide sleeves function properly.

Tightening torque step 1, 30 Nm (22 lbf ft)

Tightening torque step 2, 75°

Tightening torque step 3, 80°

Tightening torque, bolts for shaft drive, 25 Nm (18 lbf ft)

|

|

7.

|

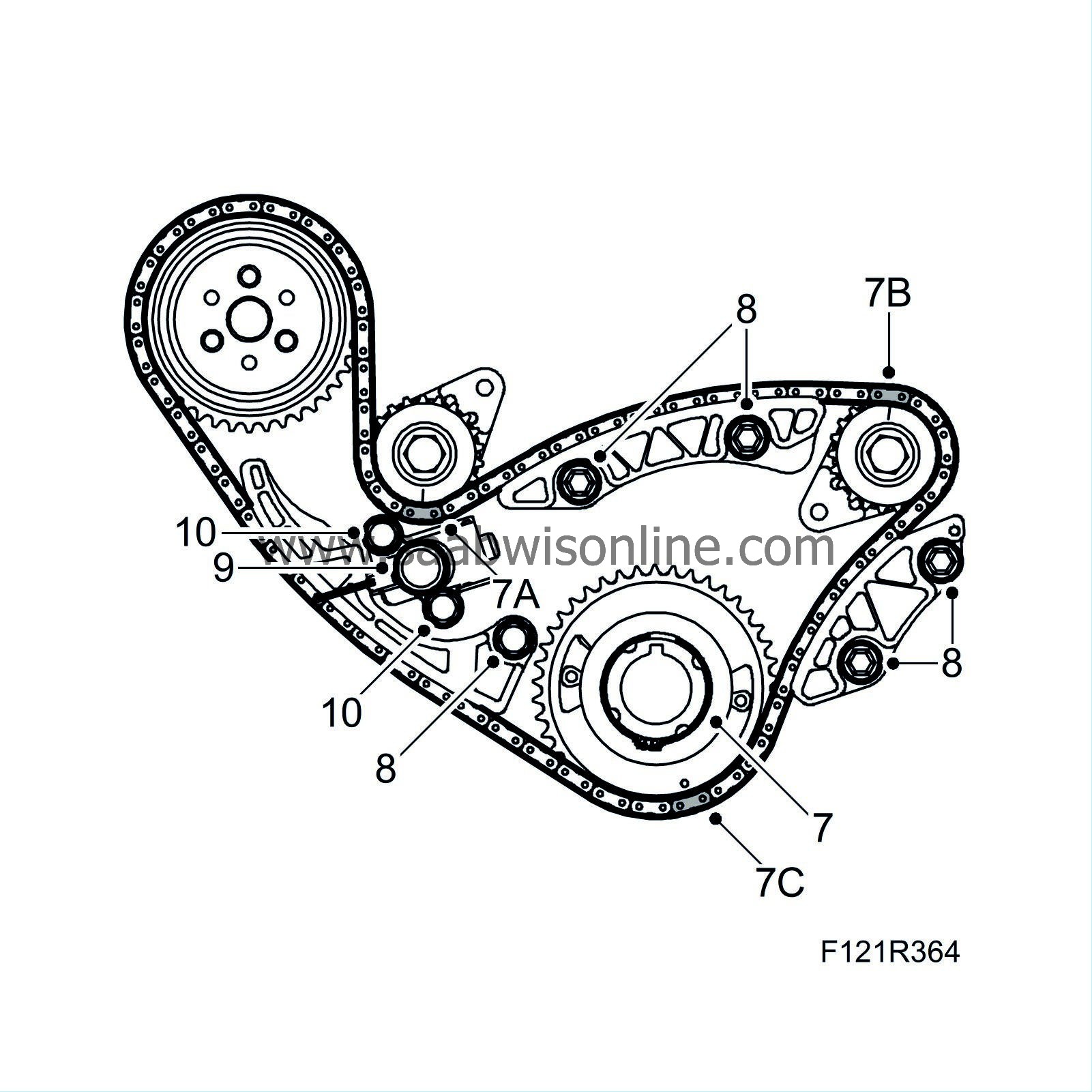

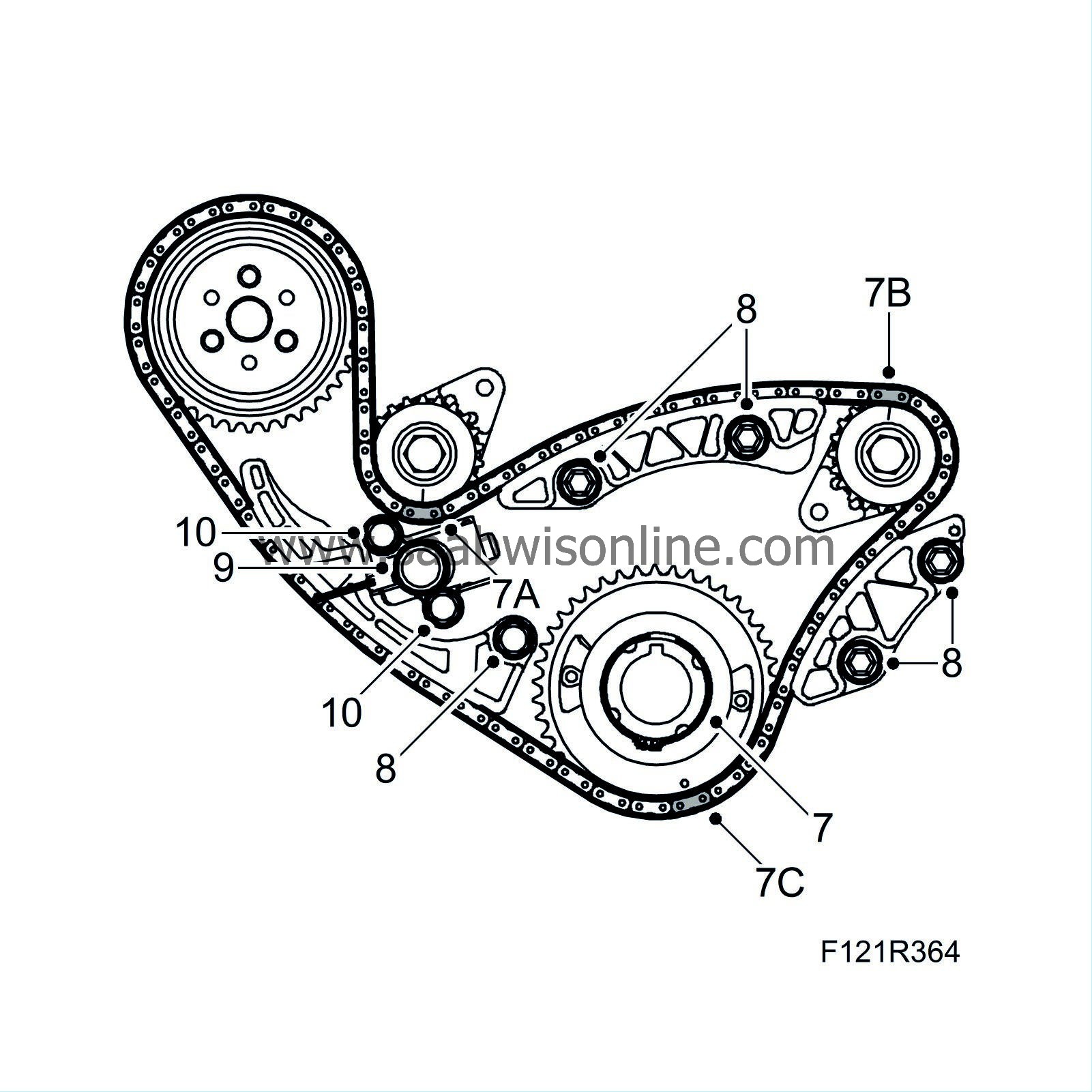

Fit the balancer shaft chain sprocket and wedge. Fit the balancer shaft chain. Start fitting of the water pump pinion. Continue as follows:

|

|

|

7.A.

|

The silver-coloured link must be fitted to the exhaust side balancer shaft sprocket.

|

|

|

7.B.

|

The copper-coloured link must be fitted to the intake side balancer shaft sprocket.

|

|

|

7.C.

|

The silver-coloured link must be fitted to crankshaft sprocket.

|

|

8.

|

Fit the balancer shaft chain guide rails. Use 74 96 268 Thread locking adhesive.

Tightening torque 10 Nm (7 lbf ft)

|

|

9.

|

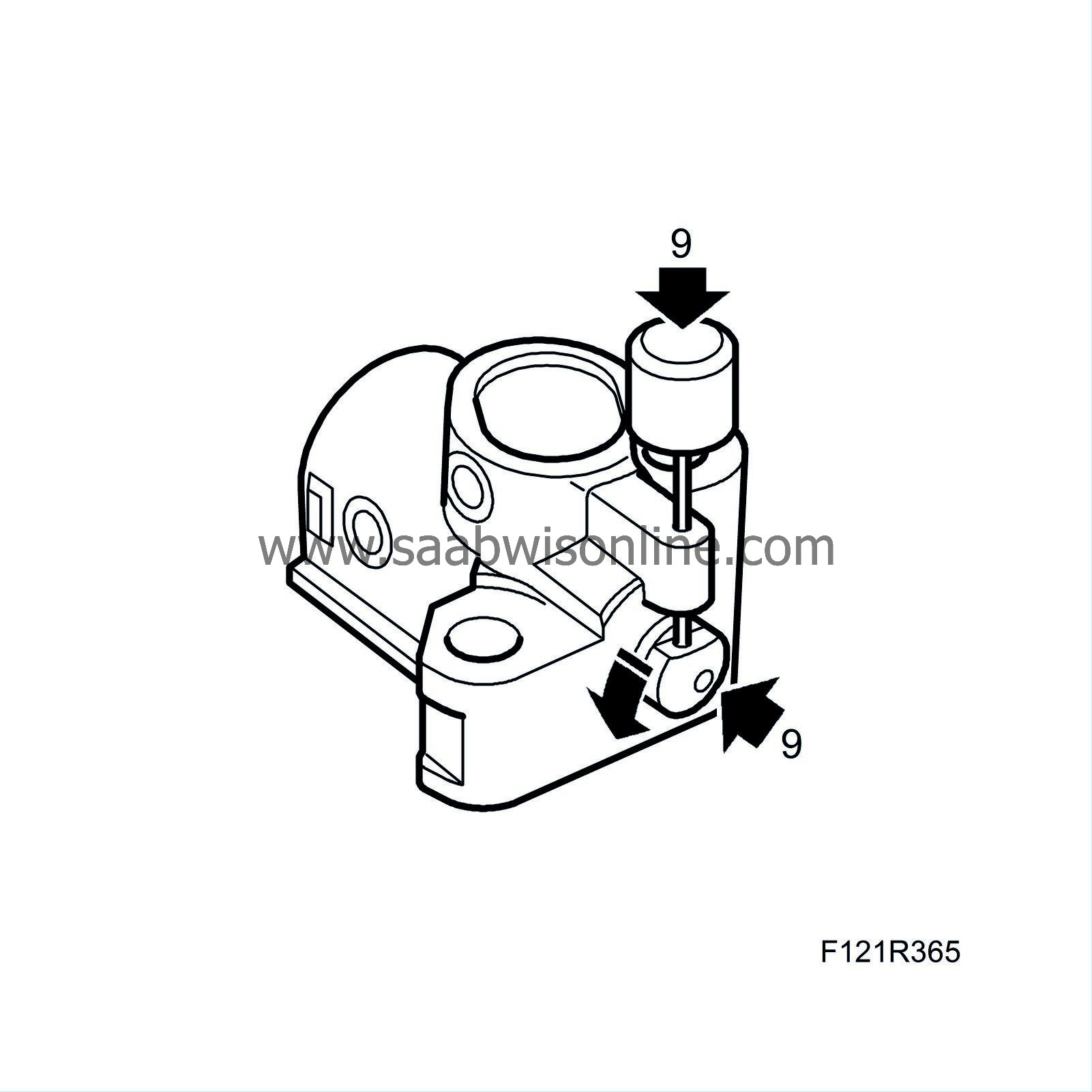

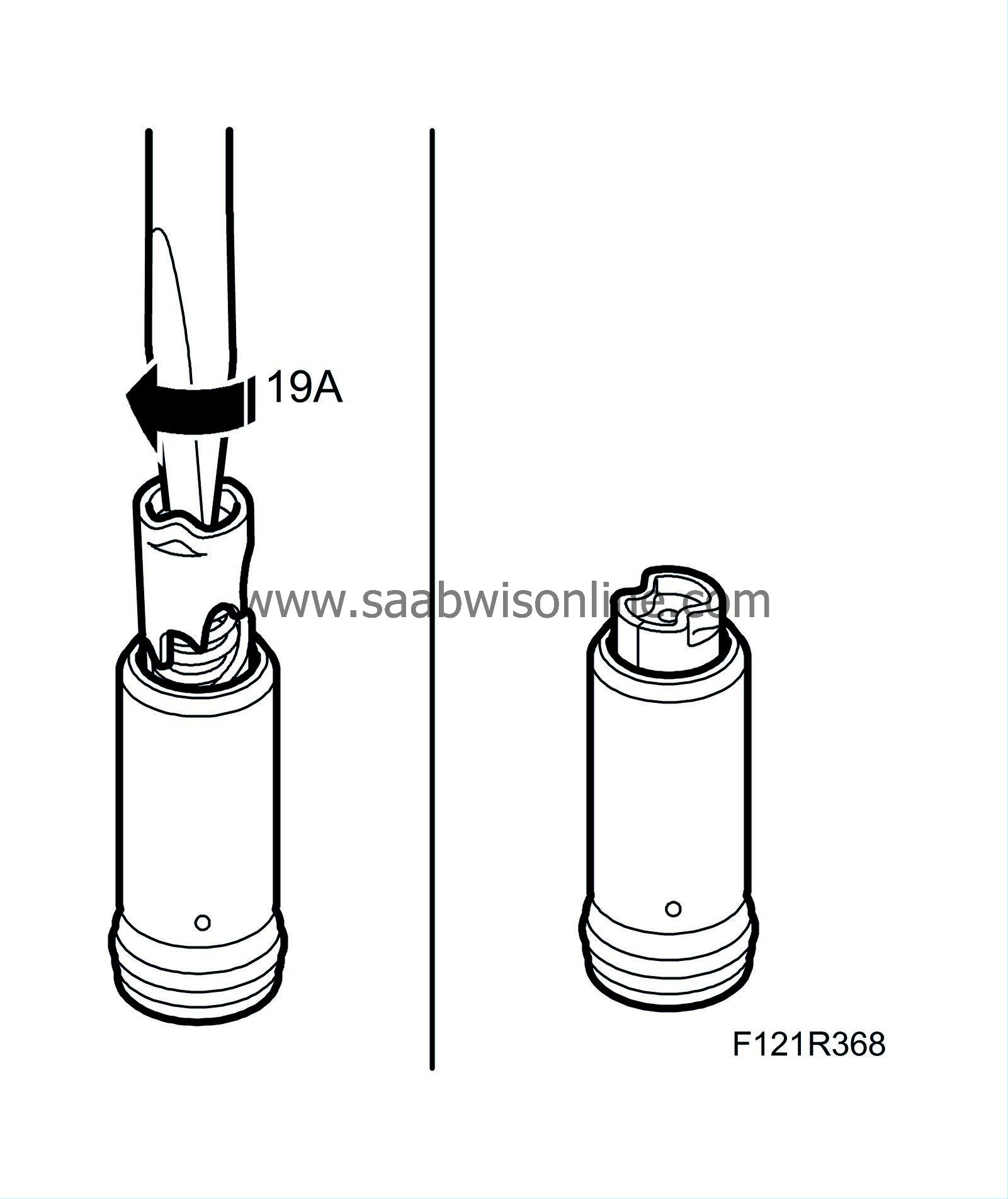

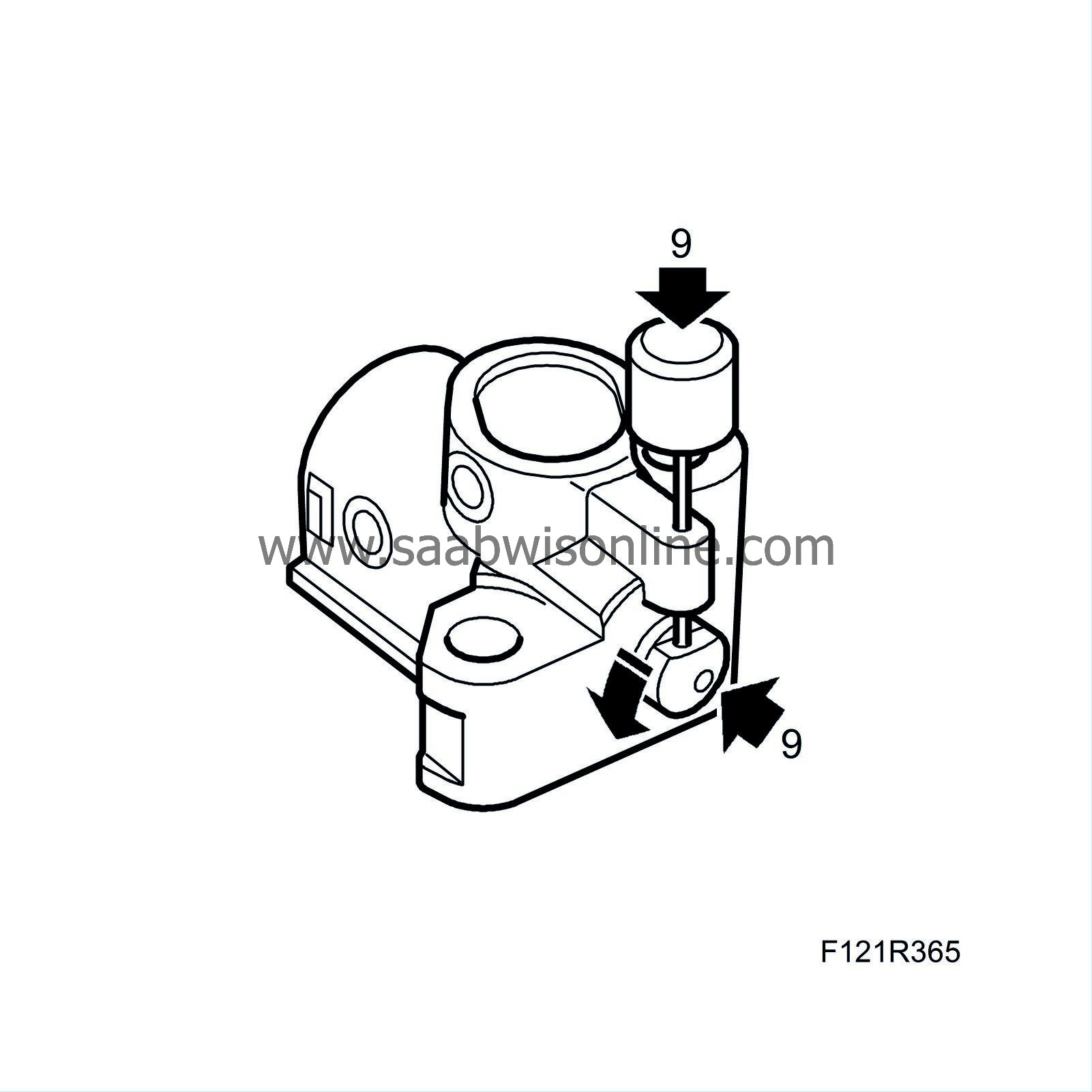

Fit the chain tensioner. Tighten the tensioner by pressing in the plunger and turning it to the right. Secure with tool 83 96 392 Lock pin.

|

|

10.

|

Fit the chain tensioner screws. Use 74 96 268 Thread locking adhesive.

Tightening torque 10 Nm (7 lbf ft)

|

|

11.

|

Remove the tool from the tensioner. Press the tensioner guide rail to check that backward movement of the plunger is prevented.

|

|

12.

|

Fit the crankshaft sprocket.

|

|

13.

|

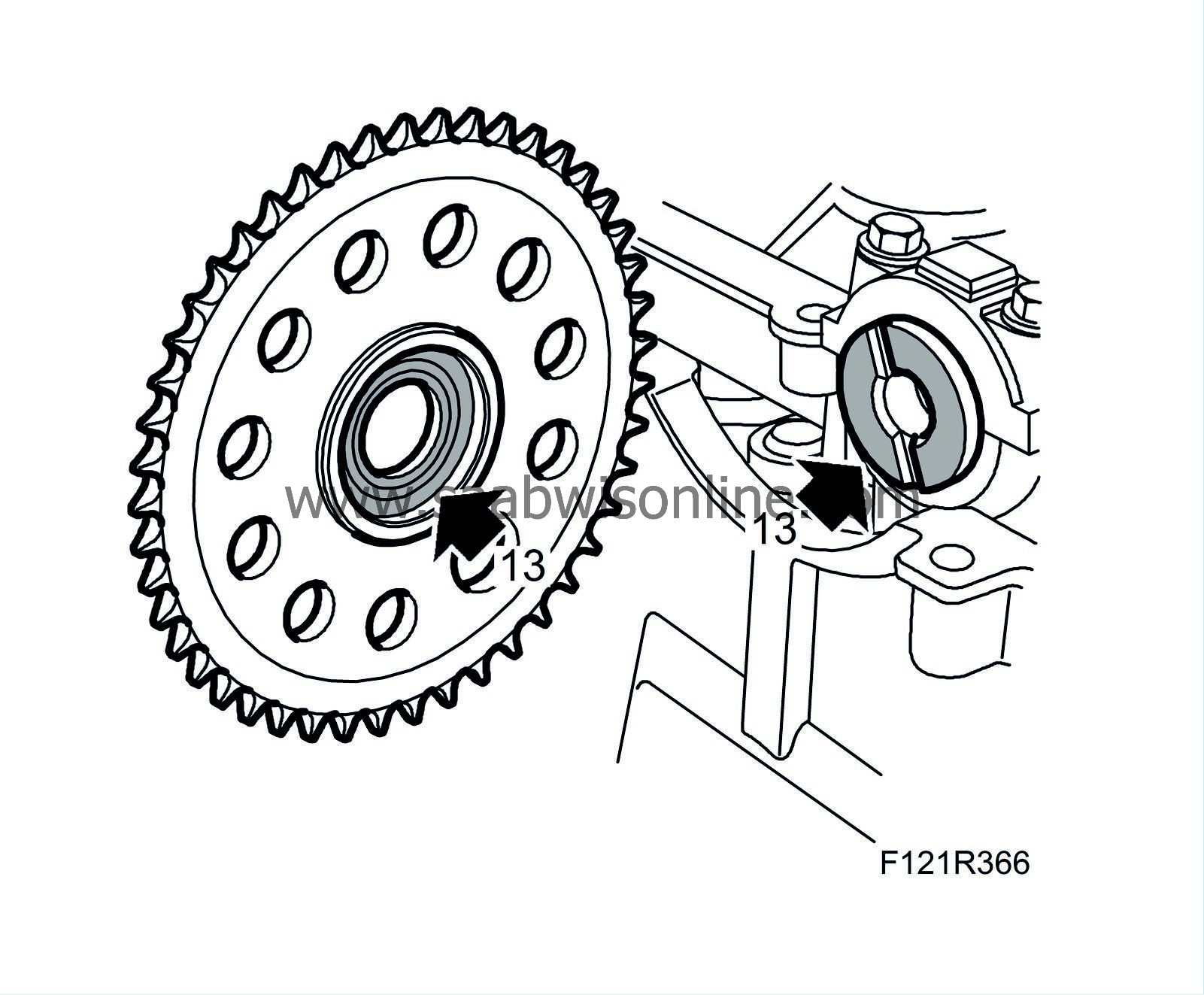

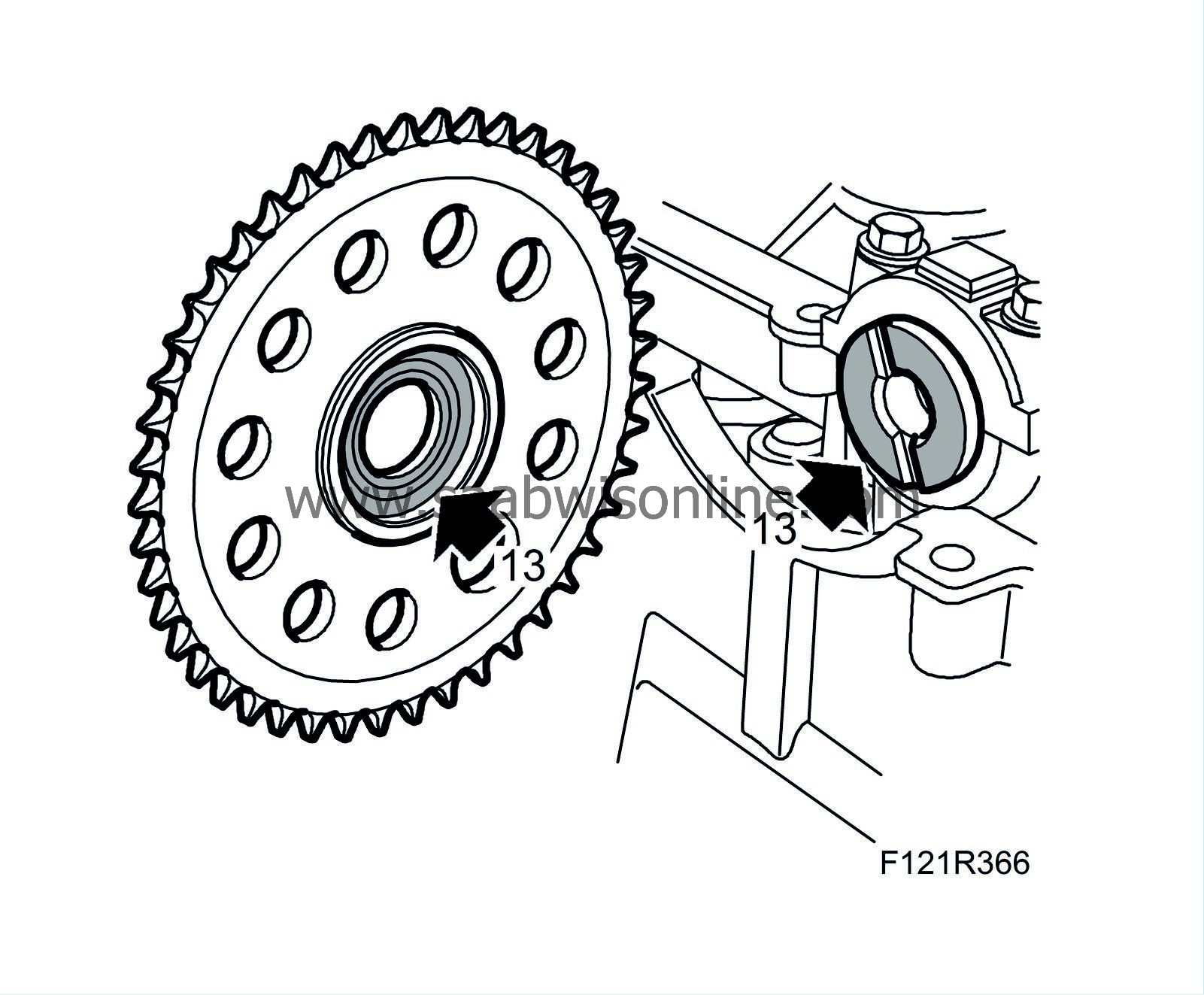

Clean the camshaft and sprocket contact surfaces from oil and grease.

|

|

14.

|

Fit the tensioner guide.

Tightening torque 10 Nm (7 lbf ft)

|

|

15.

|

Lay the chain on the intake sprocket and lower the chain. Fit the sprocket on the camshaft and tighten the bolt.

|

|

16.

|

Fit the chain on the crankshaft sprocket and fit the chain guide. Fit the lower bolt.

Tightening torque 10 Nm (7 lbf ft)

|

|

17.

|

Fit the exhaust sprocket and tighten the bolt.

|

|

18.

|

Fit the upper bolt. Fit the plug on the cylinder head.

|

|

19.

|

Fit the timing chain tensioner using the following method:

|

|

|

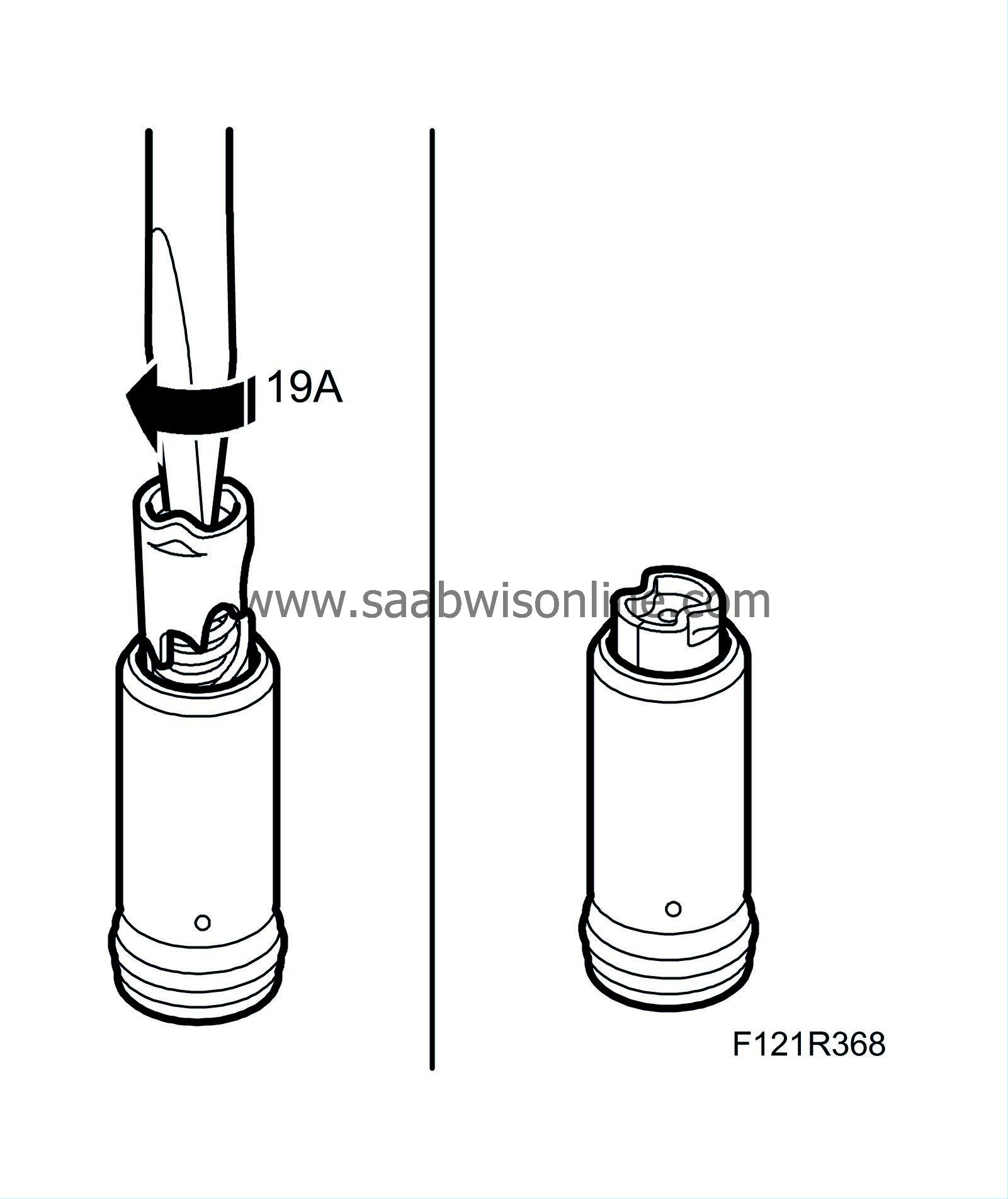

19.A.

|

Turn the camshaft drive tensioner clockwise with a screwdriver until it engages in the tensioned position.

|

|

|

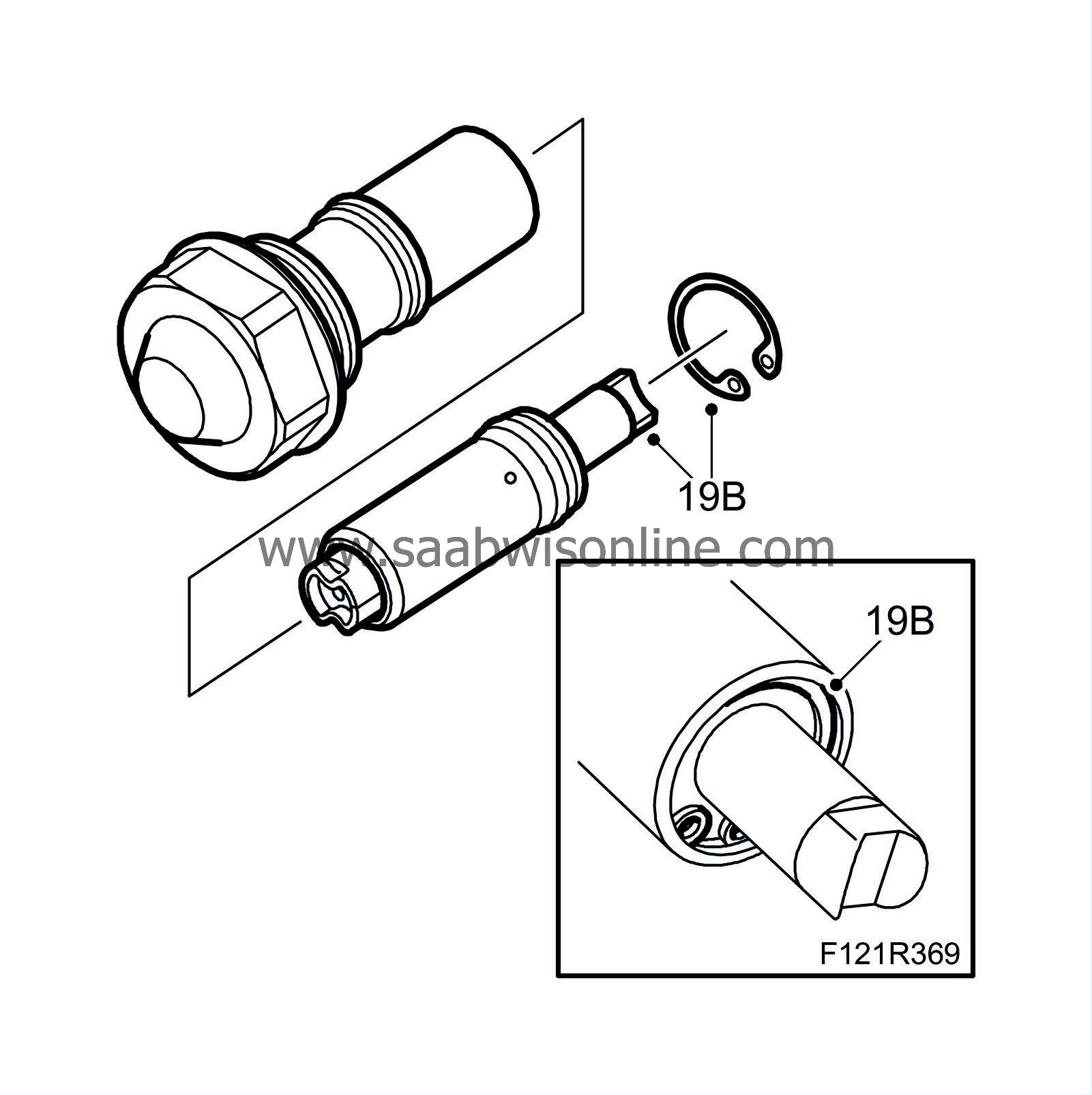

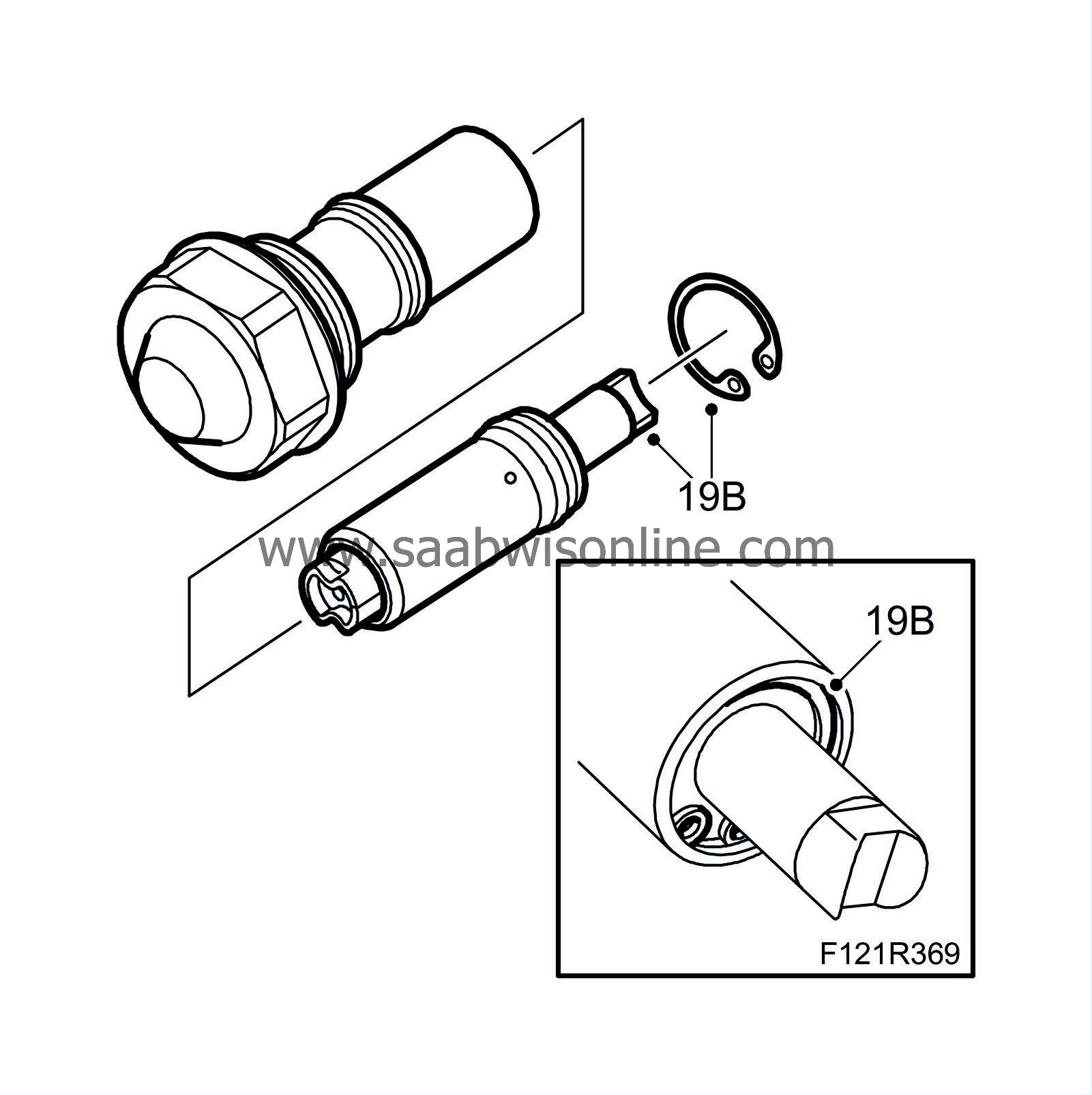

19.B.

|

Place the plunger in the chain tensioner sleeve. Fit the circlip and check that it is fitted correctly in the groove.

|

Note

|

|

Check that the O-ring and gasket are intact. If damaged, replace the chain tensioner assembly.

|

|

|

|

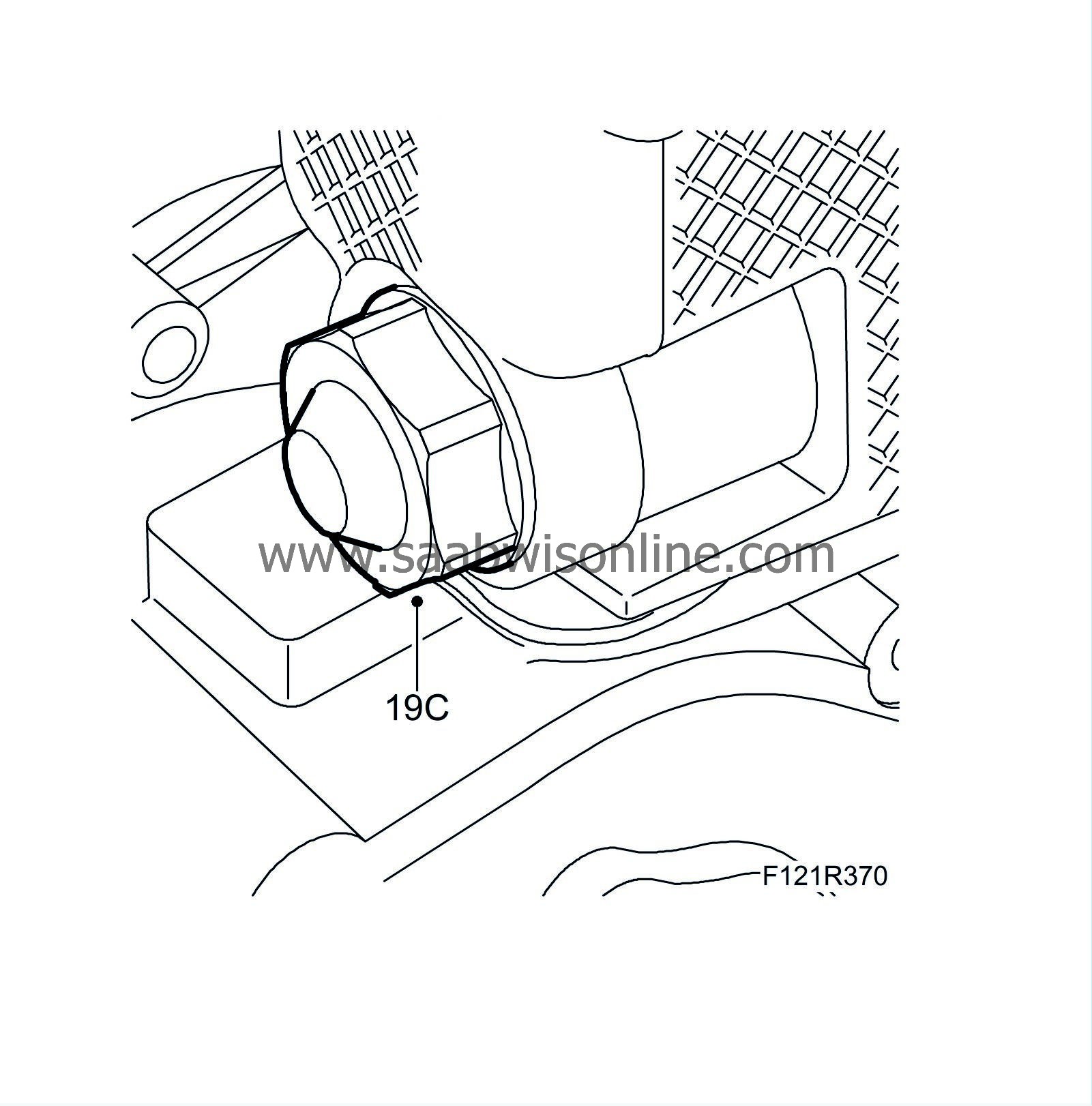

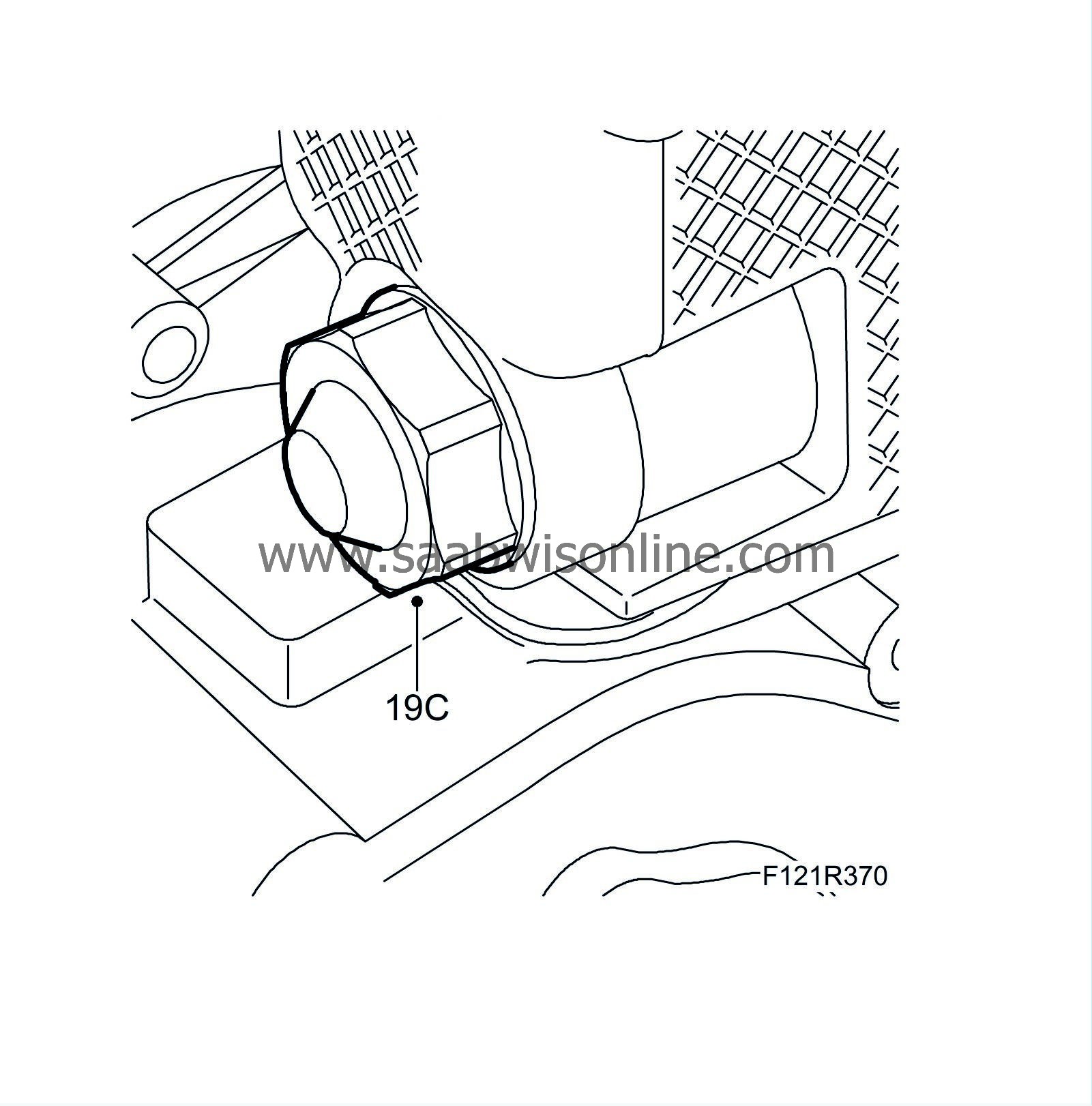

19.C.

|

Fit the chain tensioner.

Tightening torque 75 Nm (55 lbf ft)

|

|

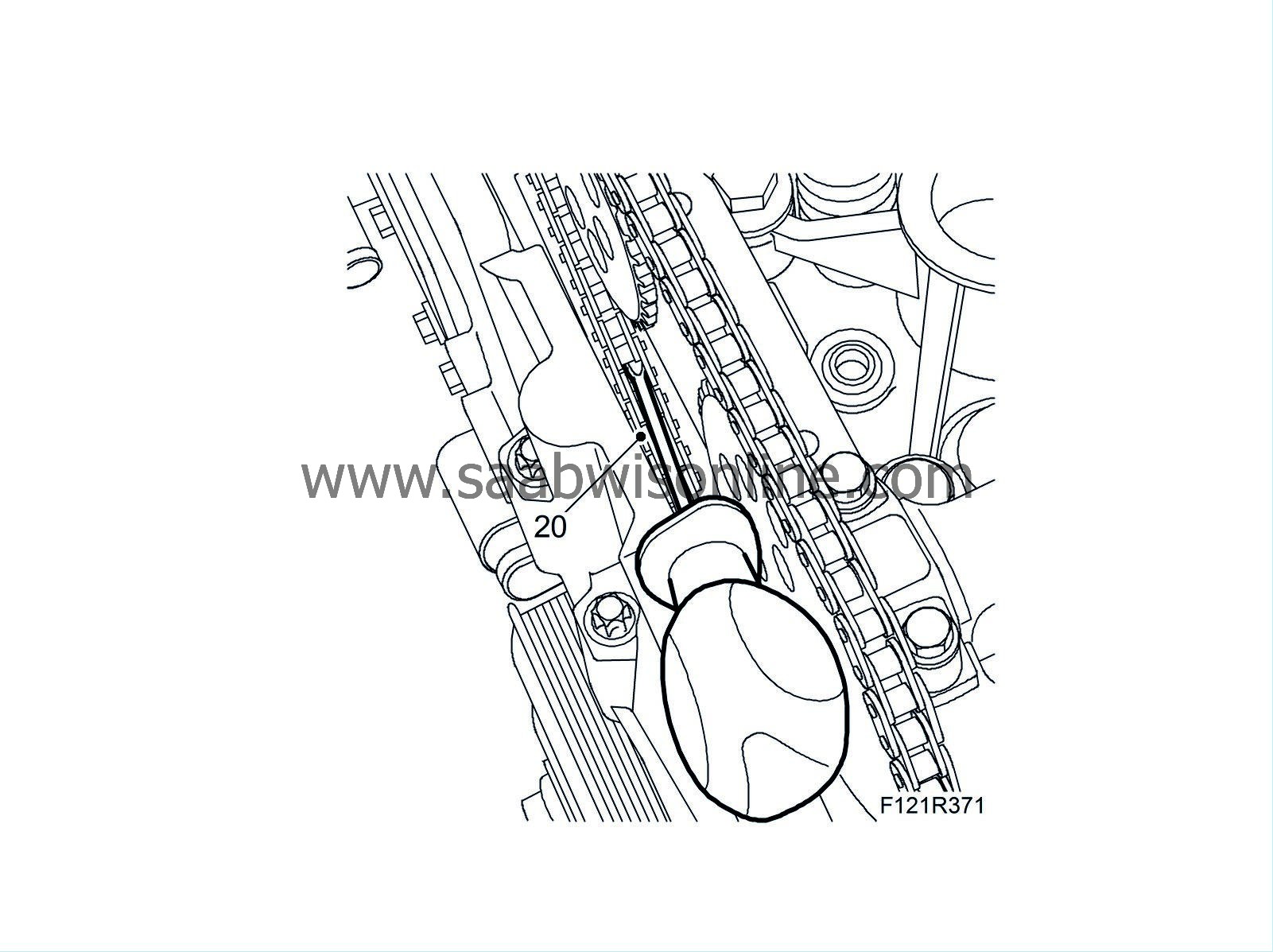

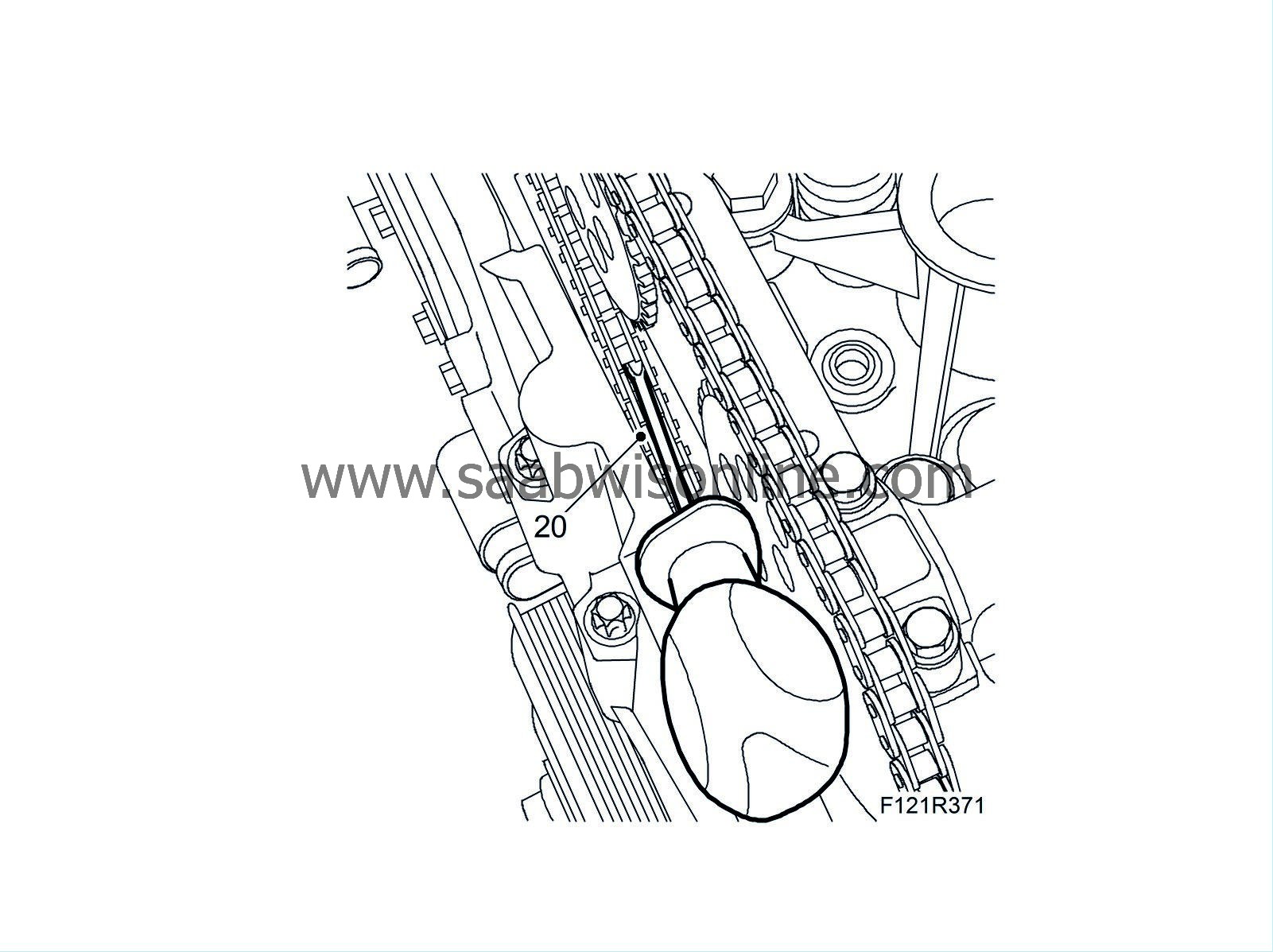

20.

|

Release/activate the chain tensioner by carefully pressing on the timing chain or chain guide (as shown in the illustration). Use a screwdriver. Check that the tensioner releases

|

|

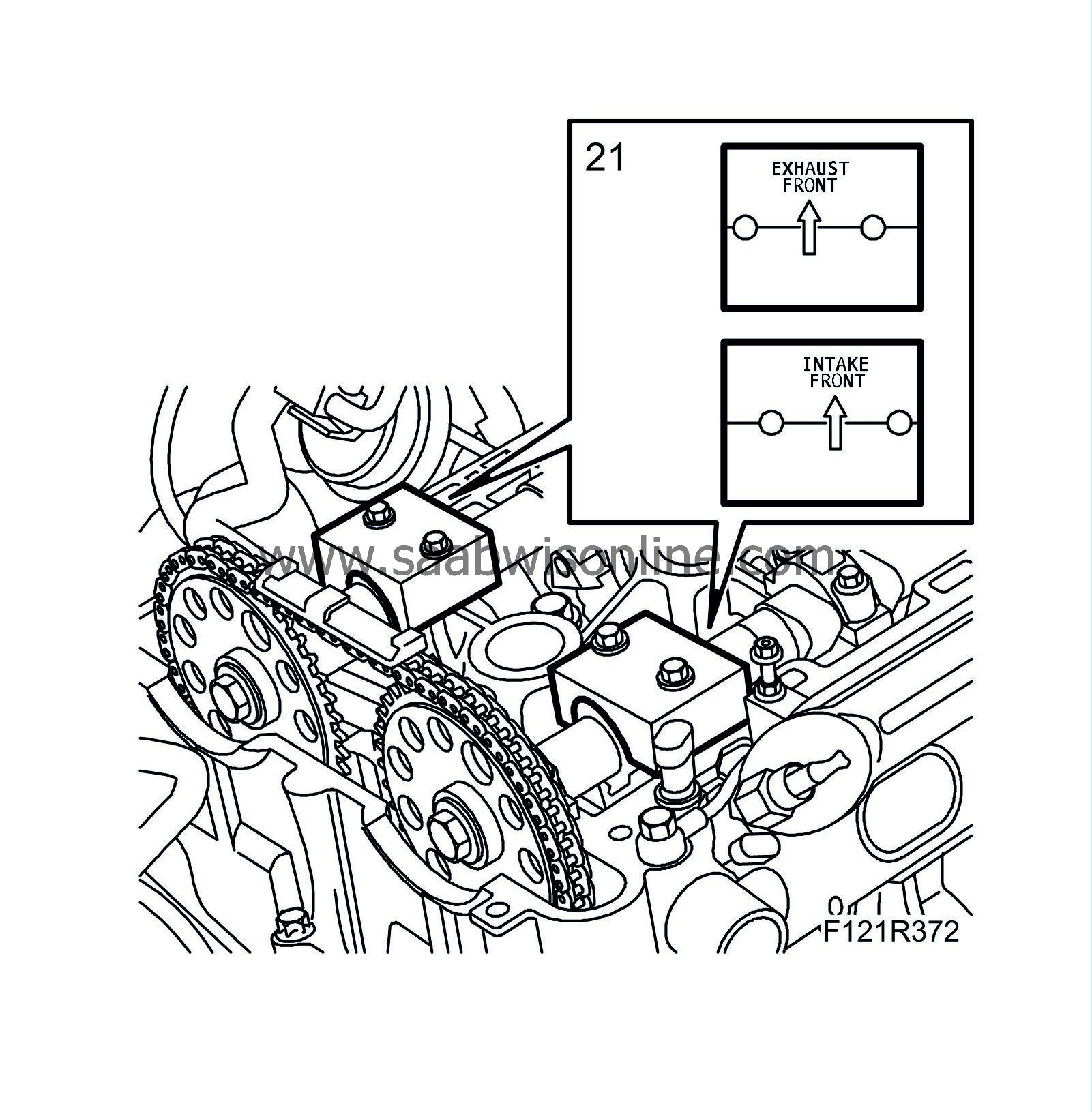

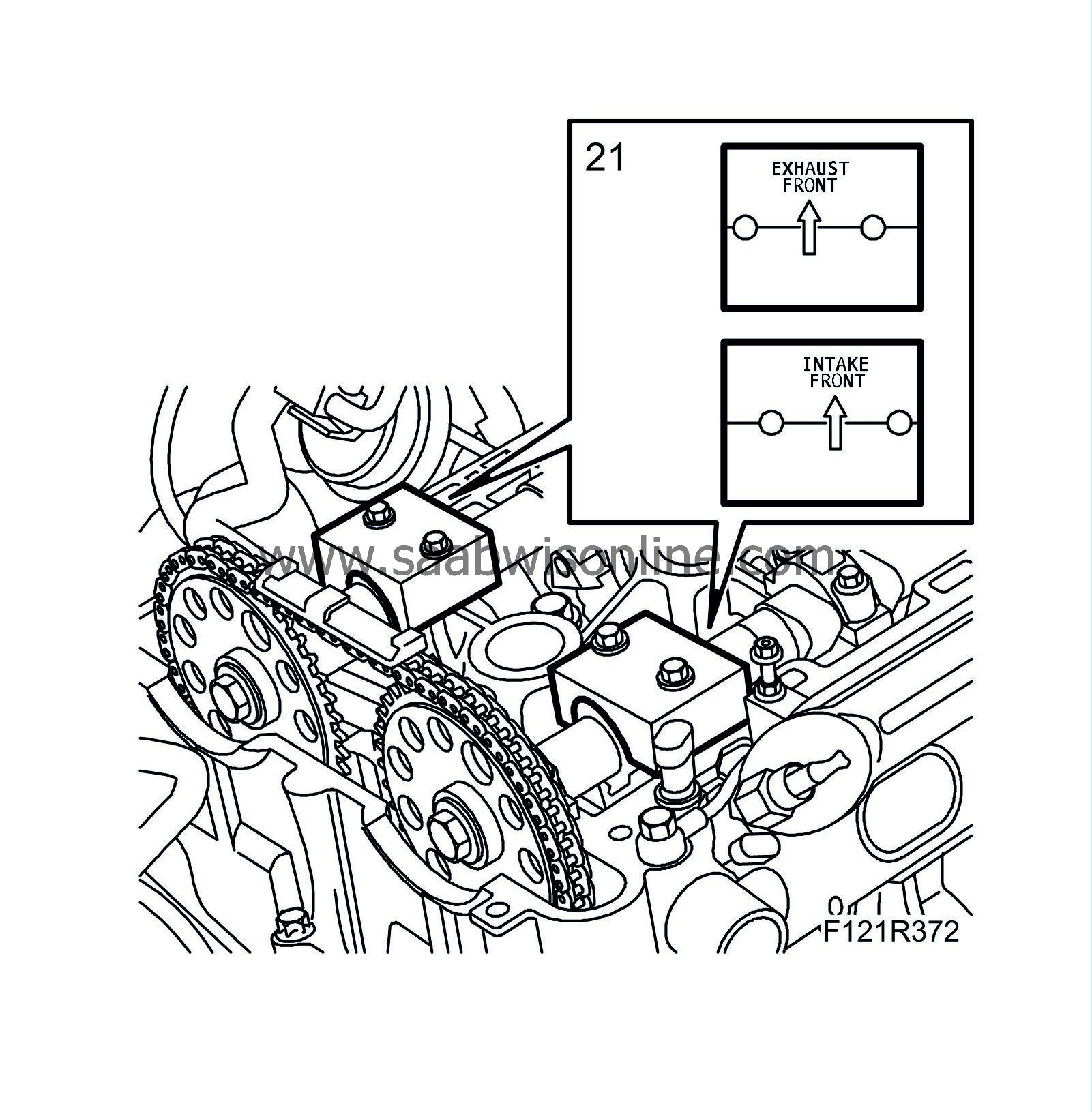

21.

|

Remove the exhaust camshaft and intake camshaft bearing caps no. 2 and no. 7. Position 83 96 046 Adjustment tool, camshaft (B207 150-175 hp) and 83 96 079 Adjustment tool, camshaft (B207 200 hp) by pressing down the tool by hand onto the camshafts without tightening the bolts. Rotate the camshaft with a wrench on the camshaft flats until the tool fits. Tighten the adjustment tool bolts.

Tightening torque 10 Nm (7 lbf ft)

|

|

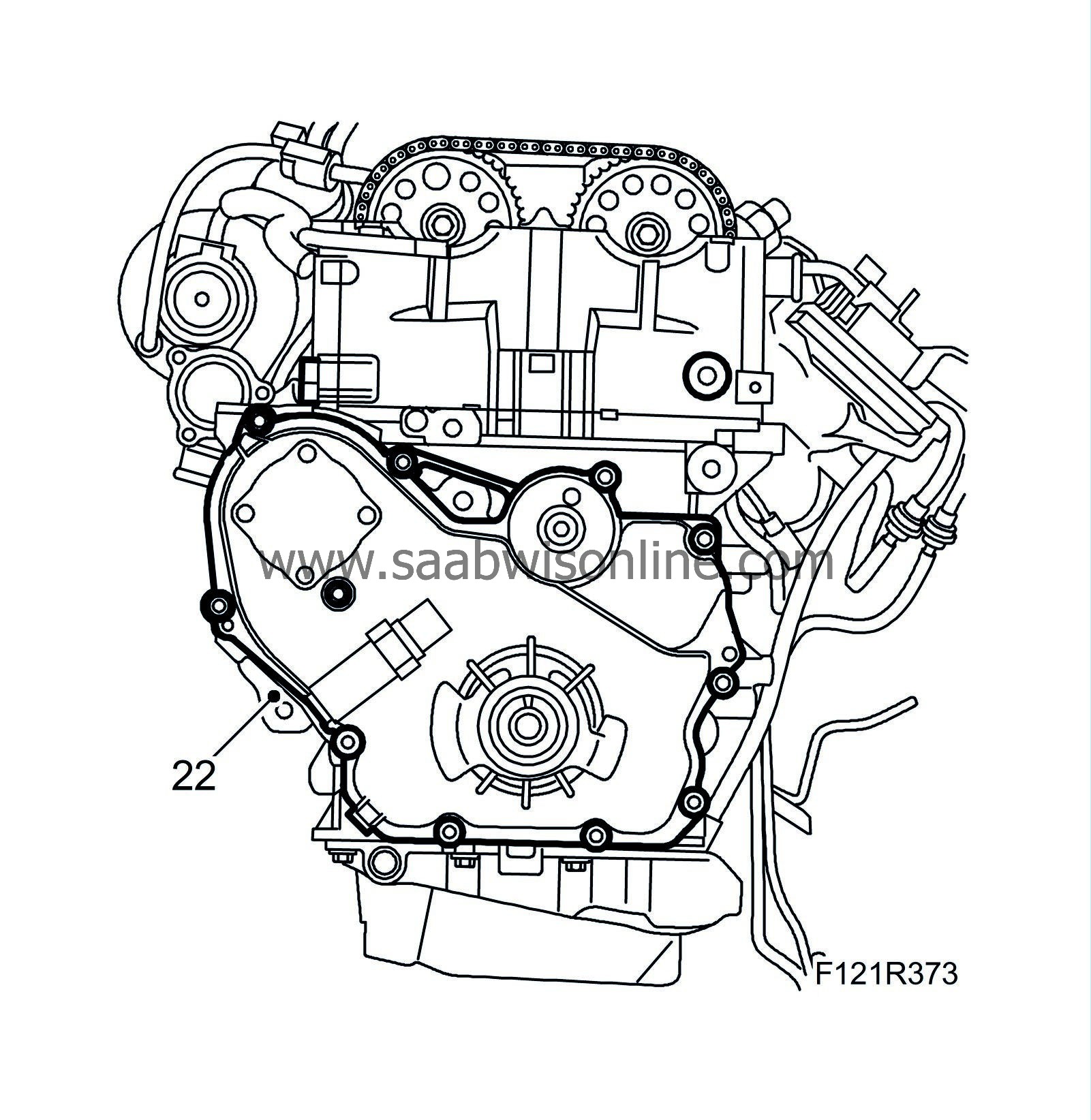

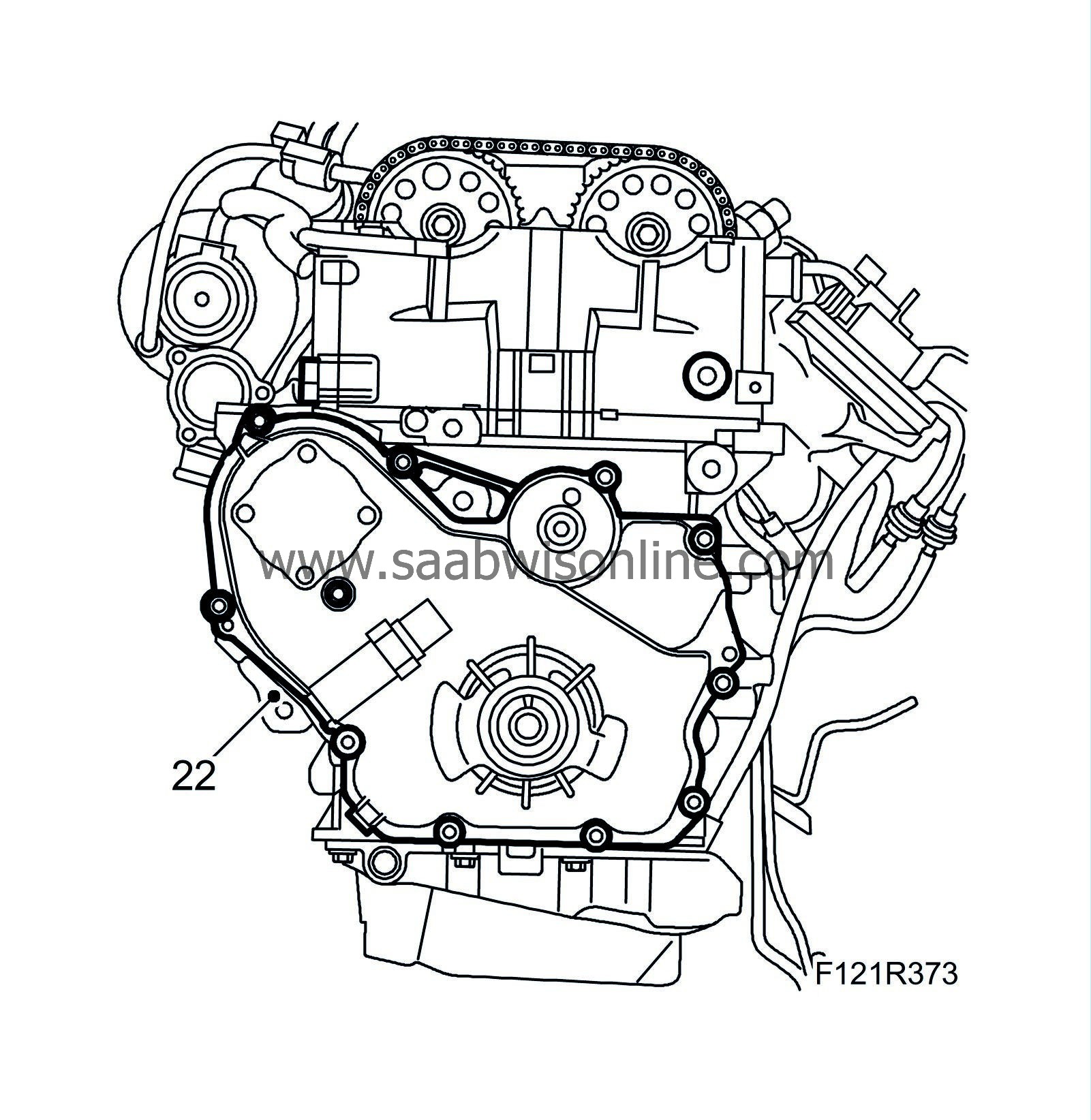

22.

|

Fit the timing cover with a new gasket.

Tightening torque 20 Nm (15 lbf ft)

|

|

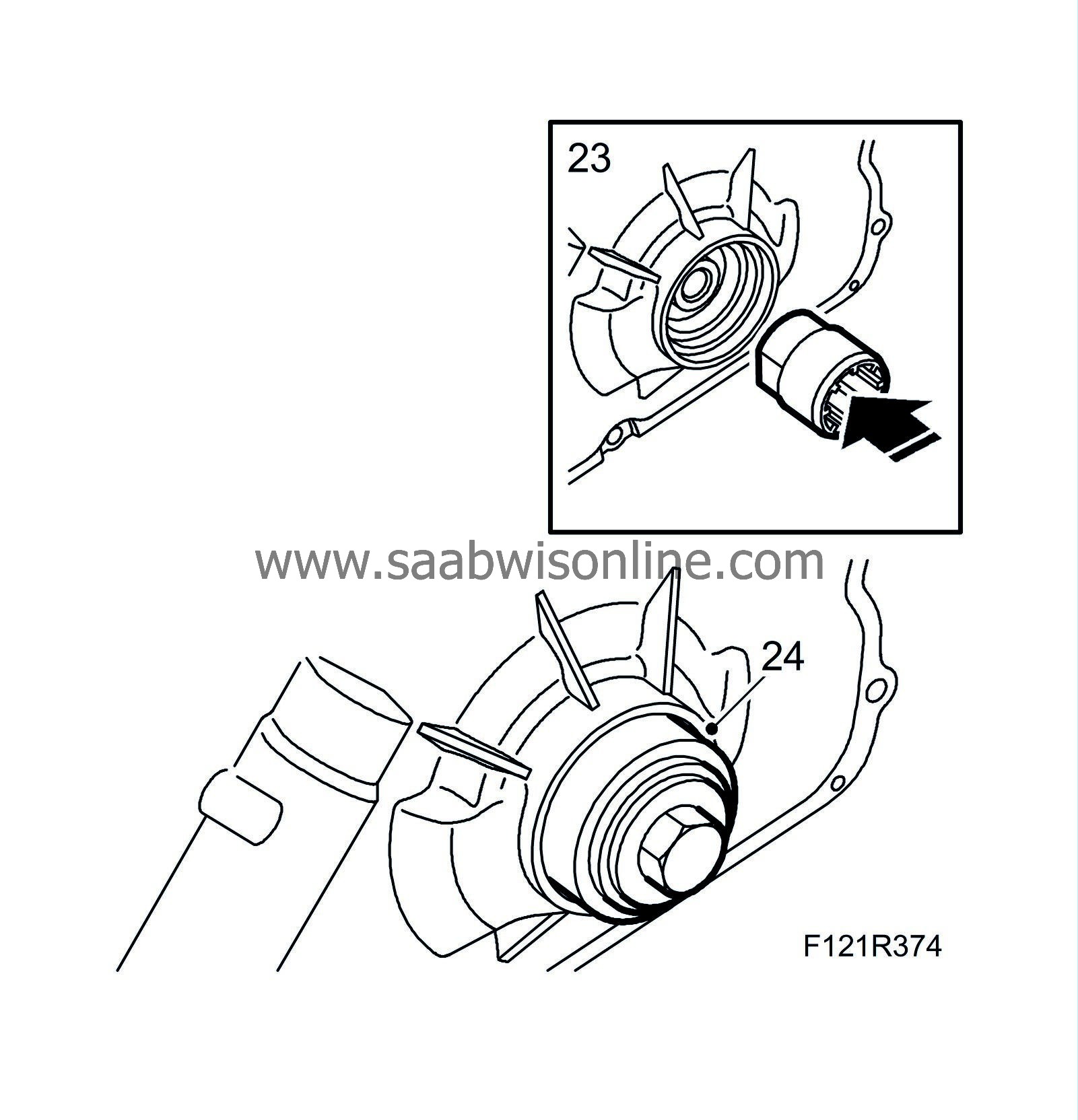

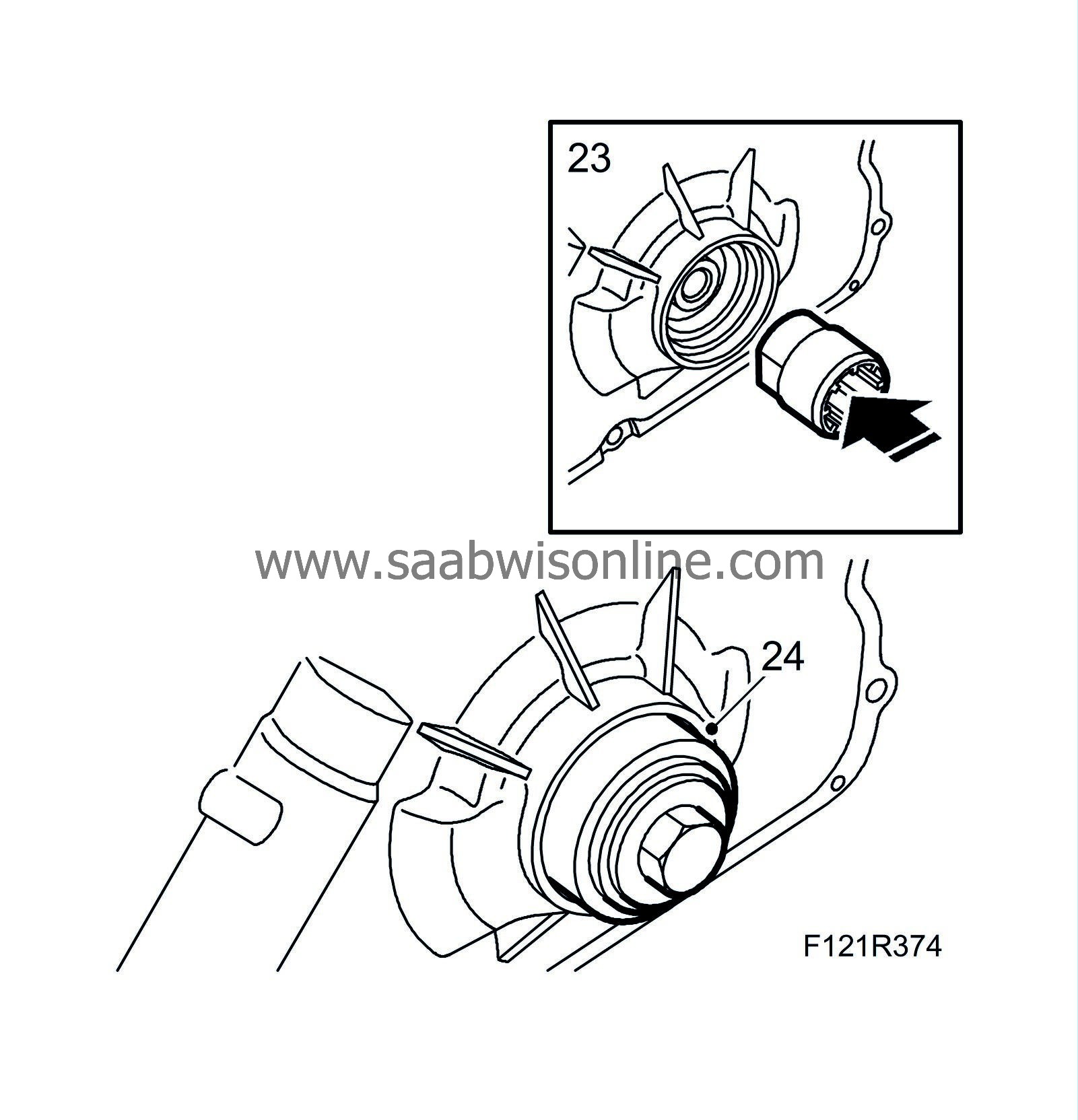

23.

|

Position the 83 96 202 Fitting tool, front crankshaft seal B207 protective collar on the crankshaft. Lubricate the new sealing ring with acid-free Vaseline and position it on the fitting tool.

|

|

24.

|

Position the fitting tool on the crankshaft. Tighten the sealing ring using the crankshaft pulley bolt until it is flush with the timing cover. Remove the tool.

|

|

25.

|

Fit the crankshaft pulley with a new bolt. Use 83 95 360 Holding tool, crankshaft pulley (shaft only) and 83 96 210 Holding tool, crankshaft pulley, B207.

Tightening torque 100 Nm + 75° (74 lbf ft + 75°)

|

|

26.

|

Check that the markings on the crankshaft pulley and the timing cover are aligned. Tighten the camshaft gears a first time. Use a wrench to grip the camshaft flats.

Tightening torque 30 Nm (22 lbf ft)

|

|

27.

|

Remove the adjustment tool and fit the bearing caps.

Tightening torque 8 Nm (6 lbf ft)

|

|

28.

|

Continue to tighten the camshaft gears to the final torque. Use a wrench to grip the camshaft flats.

Tightening torque 85 Nm + 30° (63 lbf ft + 30°)

|

|

29.

|

Turn the crankshaft 2 rotations in the engine direction of rotation until the markings on the crankshaft pulley and the timing cover are aligned. Remove the bearing caps and refit 83 96 046 Adjustment tool, camshaft (B207 150-175 hp) and 83 96 079 Adjustment tool, camshaft (B207 200 hp) to check that the camshaft setting is correct. Remove the adjustment tools and fit the bearing caps.

Tightening torque 8 Nm (6 lbf ft)

|

|

30.

|

Fit the upper timing chain guide rail.

Tightening torque 10 Nm (7 lbf ft)

|

|

31.

|

Fit the belt tensioner.

Tightening torque 50 Nm (37 lbf ft)

|

|

32.

|

Fit the engine mounting bracket.

Tightening torque 93 Nm (69 lbf ft)

|

|

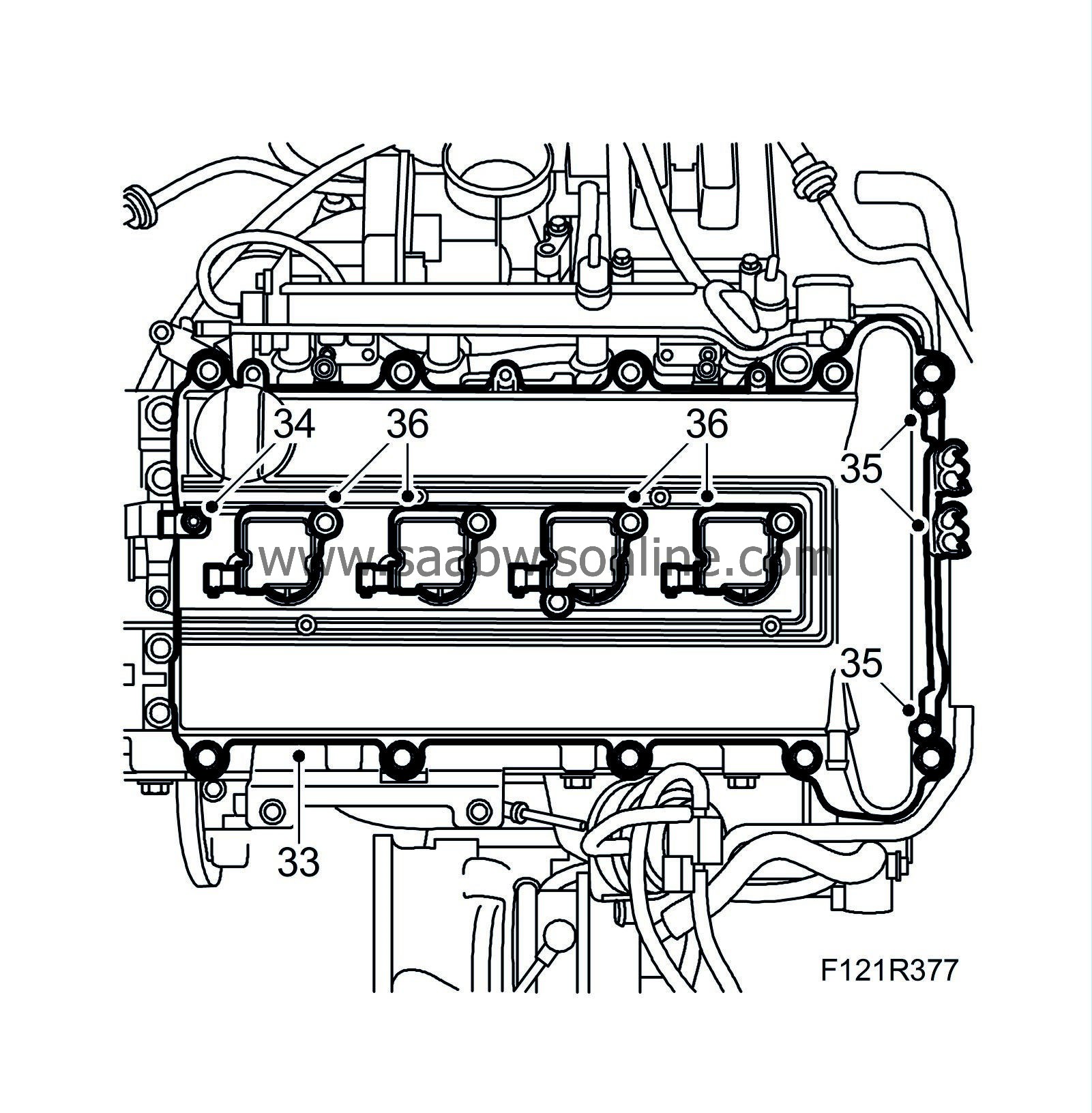

33.

|

Fit the camshaft cover.

Tightening torque 10 Nm (7 lbf ft)

|

|

34.

|

Fit the ground cable.

|

|

36.

|

Fit the ignition coils.

Tightening torque 8 Nm (6 lbf ft)

|

|

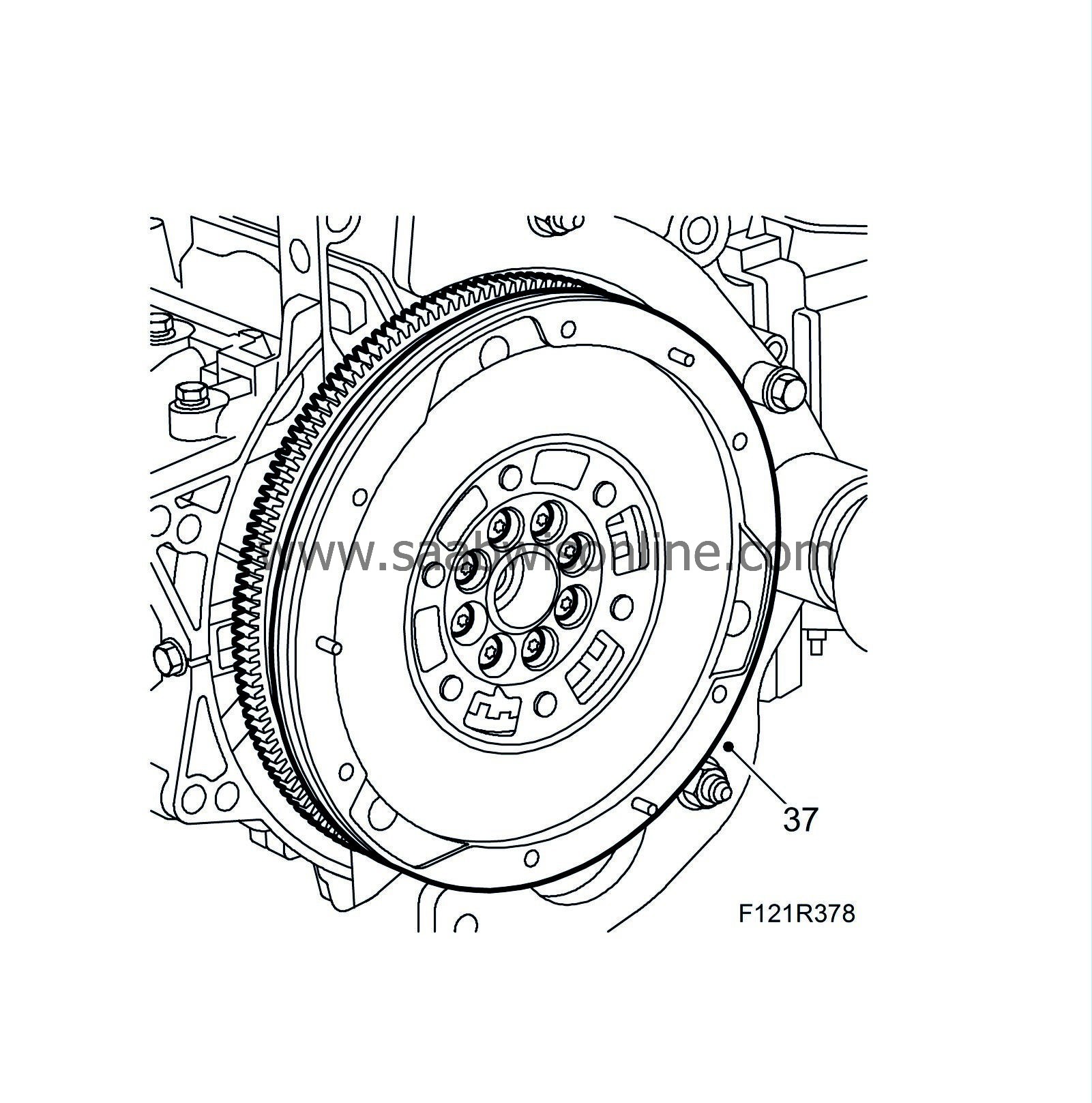

37.

|

Fit the 83 94 868 flywheel locking attachment. Fit the flywheel with new bolts.

Apply 74 96 292 Thread locking adhesive to the bolts. Tighten the bolts alternately.

Tightening torque, single mass flywheel 53 Nm + 25° (49 lbf ft + 25°)

Tightening torque, dual mass flywheel 60 Nm +30° (44 lbf ft +30°)

|

|

38.

|

Cars with automatic transmission

: Fit the driver plate on the crankshaft.

Tightening torque 53 Nm + 25° (49 lbf ft + 25°)

|

|

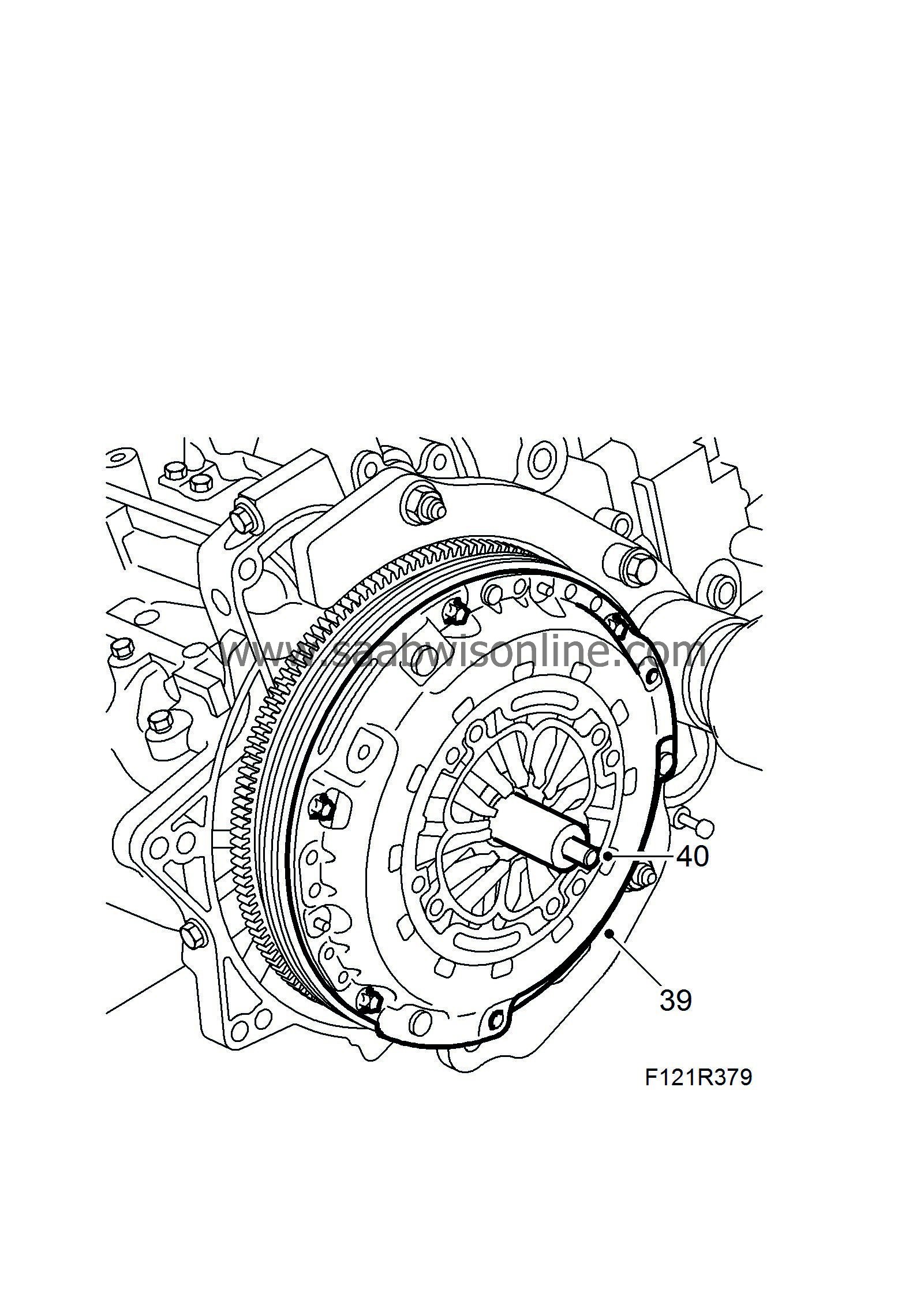

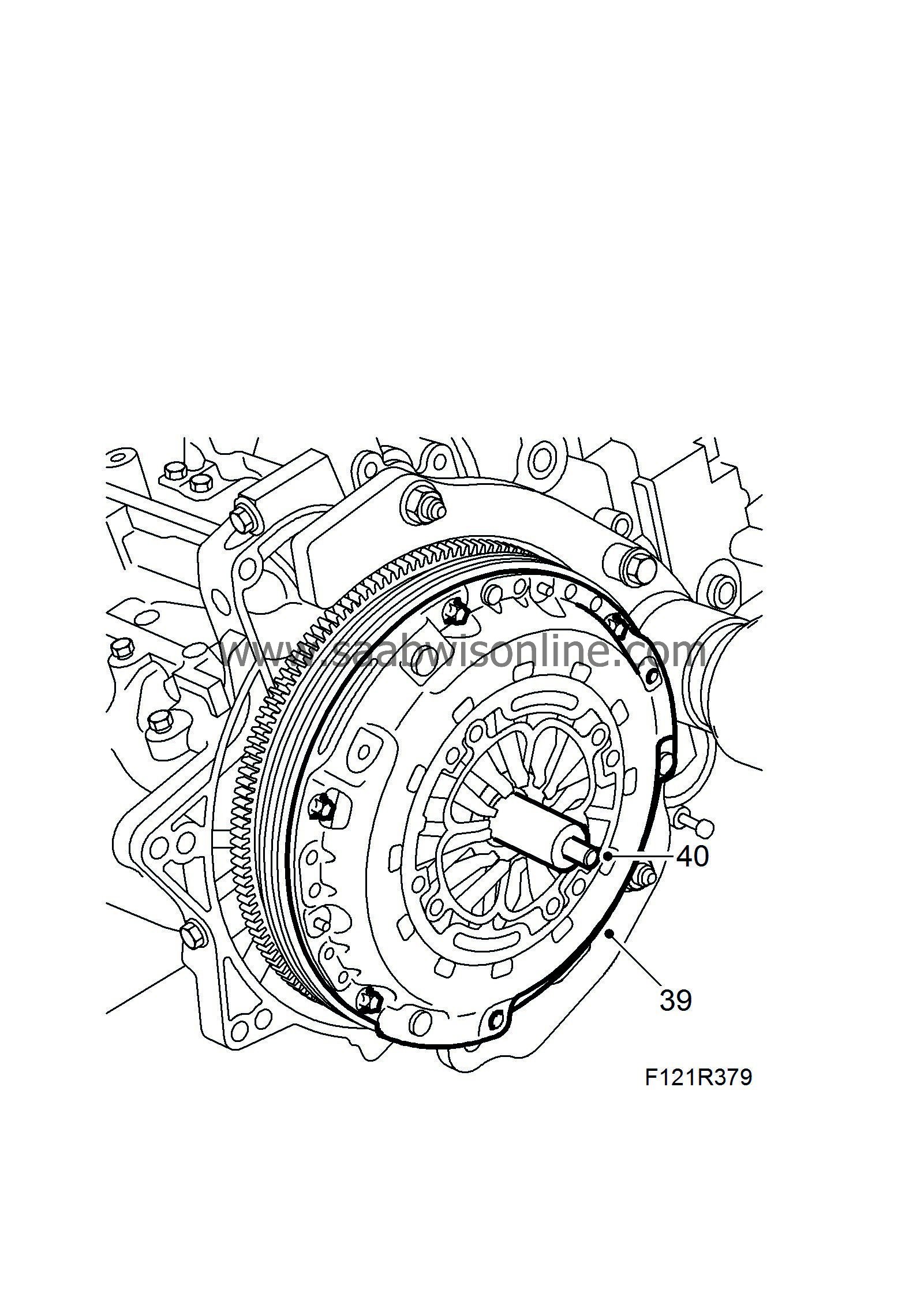

39.

|

Cars with manual gearbox:

Place the driven plate and pressure plate on the flywheel and fit the bolts without tightening.

Cars with dual mass flywheel:

The convex side of the driven plate must be turned towards the gearbox. Fit the bolts that hold the pressure plate and fit the clutch and driven plate hub.

|

|

40.

|

Centre the driven plate with 87 92 327 Mandrel for centring, driven plate for B207 or 83 96 277 Mandrel for centring, 6-speed and tighten the bolts alternately. Apply 74 96 268 Thread locking adhesive to the threads.

Tightening torque 30 Nm (22 lbf ft)

|

|

41.

|

Remove the flywheel locking attachment 83 94 866.

|

|

42.

|

Fit the bolt to the dipstick pipe.

|

|

43.

|

Fit the crankshaft position sensor.

|

|

44.

|

Fit the lower intake manifold attachment bracket.

Tightening torque 22 Nm (16 lbf ft)

|

|

45.

|

Cars with secondary air injection pump

: Fit the pump.

|

|

46.

|

Fit the generator.

Tightening torque 20 Nm (15 lbf ft)

|

|

47.

|

Fit the crankcase ventilation hose to the camshaft cover.

|

|

48.

|

Fit the lower turbocharger attachment bracket.

Tightening torque 22 Nm (16 lbf ft)

|

|

49.

|

Fit the turbocharger oil return pipe with a new gasket and O-ring.

Tightening torque 15 Nm (11 lbf ft)

|

|

50.

|

Fit the turbocharger oil delivery pipe with new gaskets.

Tightening torque 28 Nm (21 lbf ft)

|

|

51.

|

Secure the engine with an engine lift.

|

|

52.

|

Raise the engine from the engine stand and carefully lower it onto a pallet, for example. Remove 83 94 751 from the engine.

|

|

53.

|

Fit 87 92 442 to the gearbox and raise the gearbox slightly. Fit the gearbox to the engine.

|

|

54.

|

Fit the gearbox retaining bolts.

Tightening torque 70 Nm (52 lbf ft)

|

|

55.

|

Raise the engine to the subframe and centre the engine on the subframe with 83 96 152.

|

|

56.

|

Fit the torque arms to the oil sump and gearbox.

Tightening torque,

RH torque arm to the oil sump 37 Nm (27 lbf ft)

LH torque arm to the gearbox 70 Nm + 90° (52 lbf ft + 90°)

|

|

57.

|

Remove the engine lift.

|

|

58.

|

Remove 83 96 178 Lifting eyes, B207.

|

|

59.

|

Cars with automatic transmission

: Remove 87 92 574 Holder that holds the torque converter in place. Press the torque converter toward the driver plate. Fit the plug.

|

|

60.

|

Cars with automatic transmission

: Apply 74 96 268 Thread locking adhesive to the bolts holding the torque converter to the driver plate.

|

Note

|

|

Use the original bolts with accompanying washers. Bolts that are too long can cause damage to the torque converter.

|

|

|

61.

|

Fit the 6 bolts without tightening them.

|

|

62.

|

Turn the engine clockwise with the pulley and tighten the bolts when all are in place.

Tightening torque 30 Nm (22 lbf ft)

|

|

63.

|

Fit the power steering pump to the cylinder head and replace the gasket.

Tightening torque 22 Nm (16 lbf ft)

|

|

64.

|

Fit the coolant-cooled oil cooler with new gaskets.

Tightening torque 22 Nm (16 lbf ft)

|

|

65.

|

Fit the starter motor.

Tightening torque 47 Nm (35 lbf ft)

|

|

66.

|

Cars with secondary air injection pump

: Fit the pipe between the pump and the valve.

|

|

67.

|

Tap the new LH drive shaft seal into place using 87 92 657 Fitting drift, drive shaft seals. Lubricate the seal with gearbox oil.

|

|

68.

|

Fit 83 95 162 Protective collar, drive shafts in the sealing ring.

|

|

69.

|

Tap in the RH seal with 87 92 657 Fitting drift, drive shaft seals.

|

|

70.

|

Position 83 95 162 Protective collar, drive shafts in the shaft seal. Insert the intermediate shaft into the gearbox until approximately 20 mm of the shaft remains. Pull out the collar and push in the rest of the intermediate shaft.

|

|

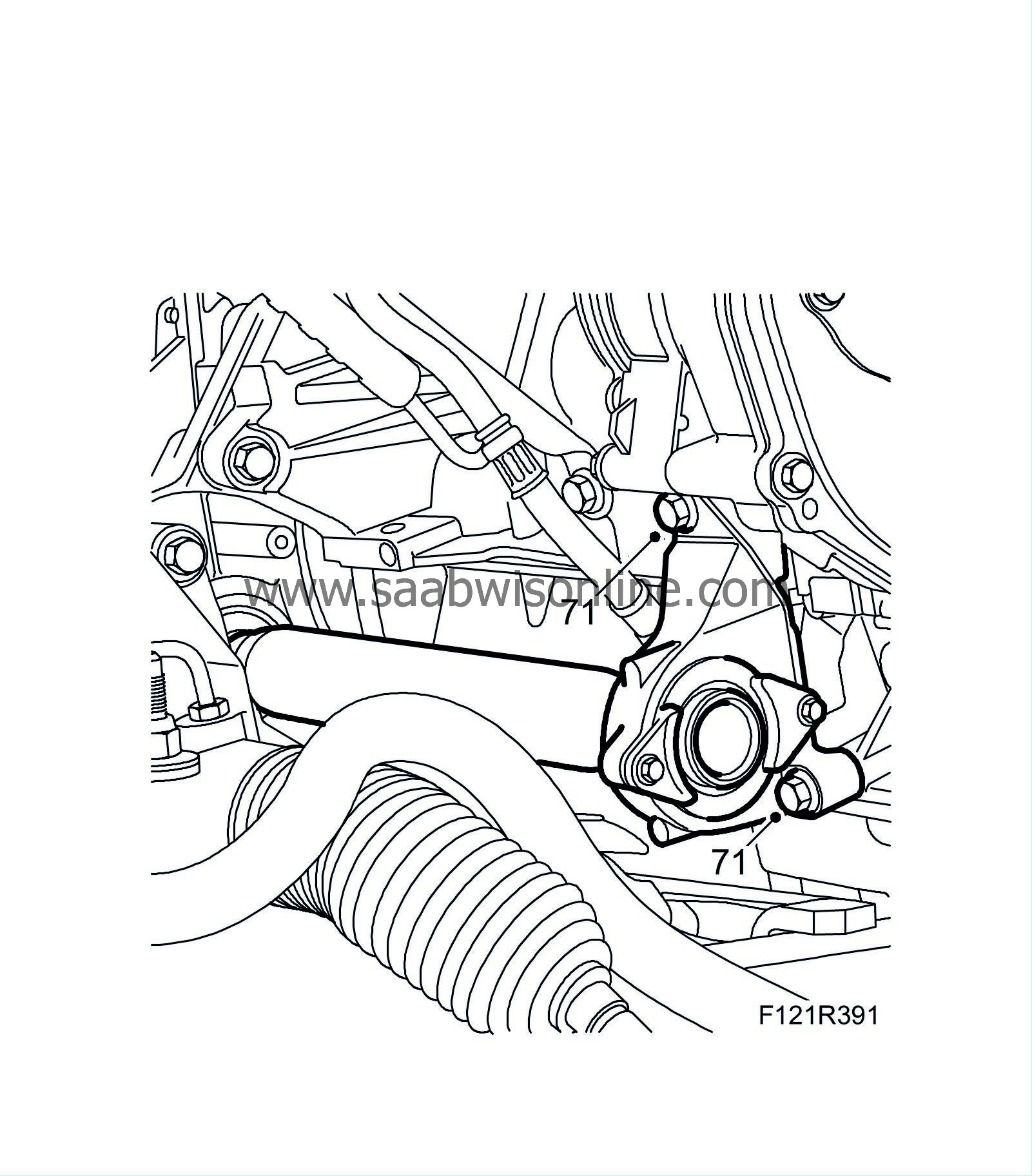

71.

|

Fit the intermediate shaft bracket.

Tightening torque 47 Nm (35 lbf ft)

|

|

72.

|

RH side

: Fit the drive shaft in the intermediate shaft splines. Lubricate the shaft splines with 87 81 684 Universal paste. Make sure the seal against the intermediate shaft has been fitted.

|

|

73.

|

LH side

: Position 83 95 162 Protective collar, drive shafts and fit the drive shaft in the gearbox. Lubricate the shaft splines with gearbox oil. Remove the collar when approximately 20 mm of the shaft remains. Push in the shaft until the circlip snaps into place.

|

|

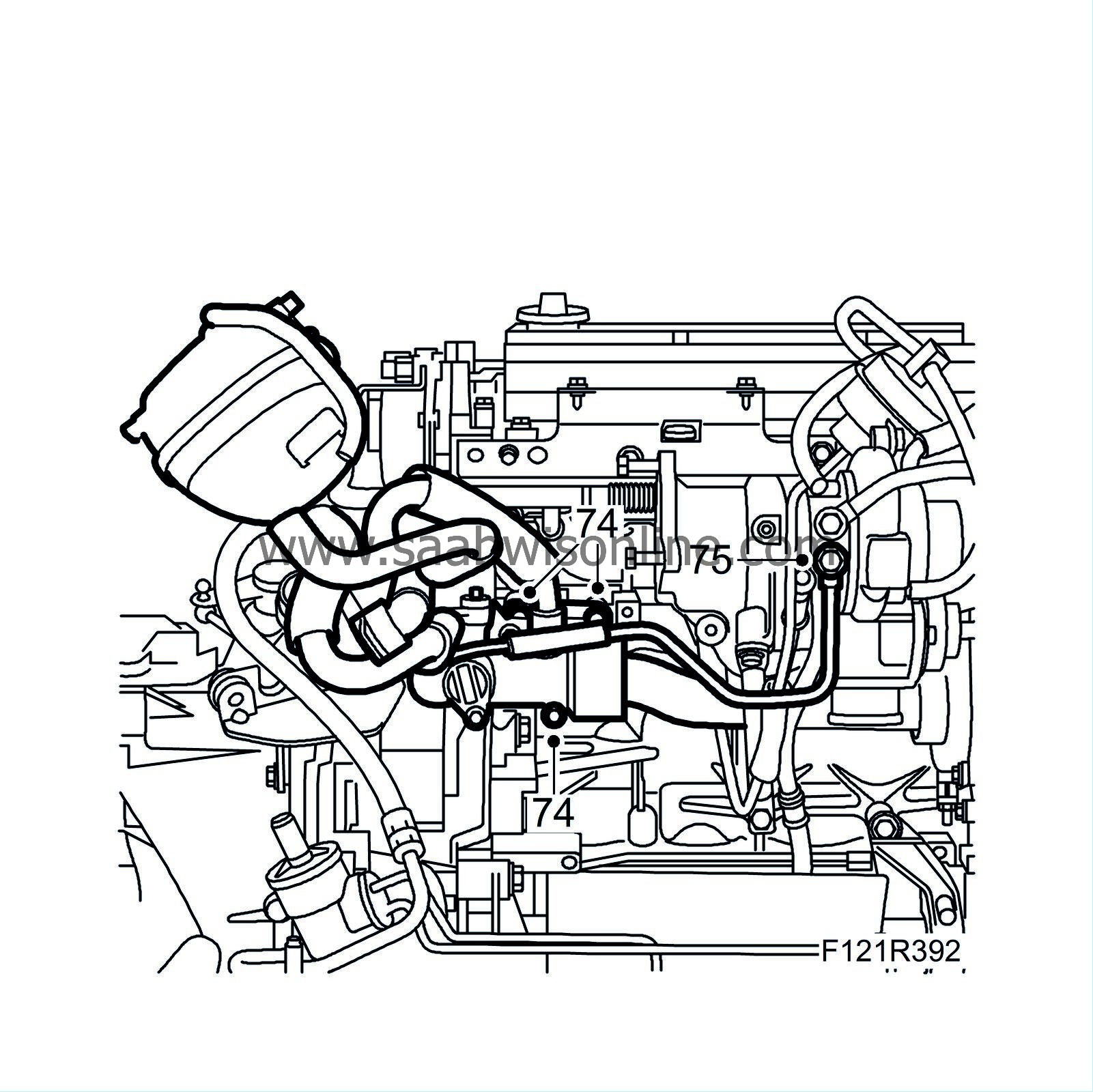

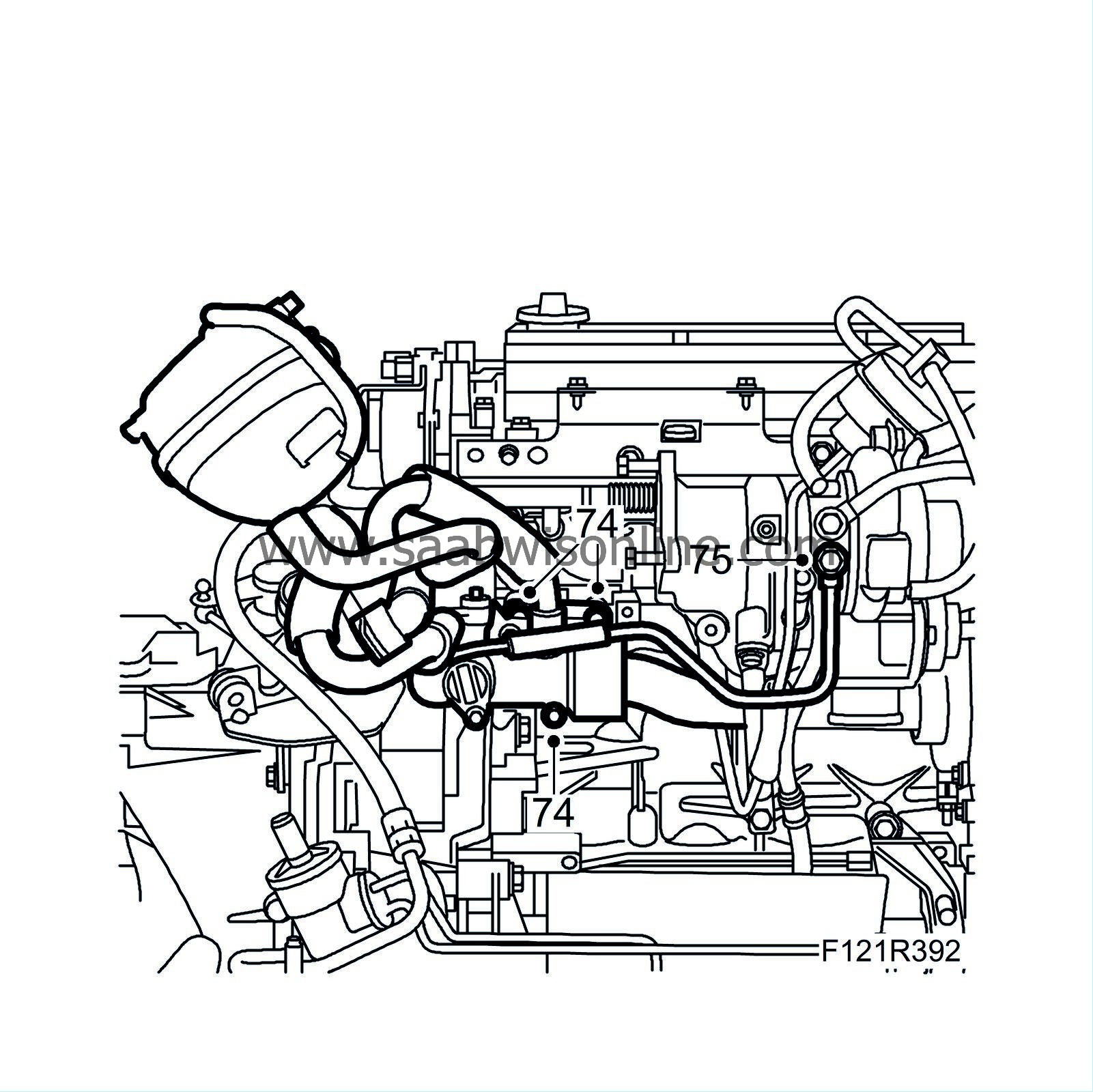

74.

|

Fit the thermostat housing and pipe with new O-rings. Lubricate the pipe O-ring sparingly with 30 06 665 Vaseline.

Tightening torque 10 Nm (7 lbf ft)

|

|

75.

|

Fit the turbocharger coolant pipe. Fit the banjo screws with new gaskets.

Tightening torque M12, 28 Nm (21 lbf ft)

Tightening torque M14, 40 Nm (30 lbf ft)

|

|

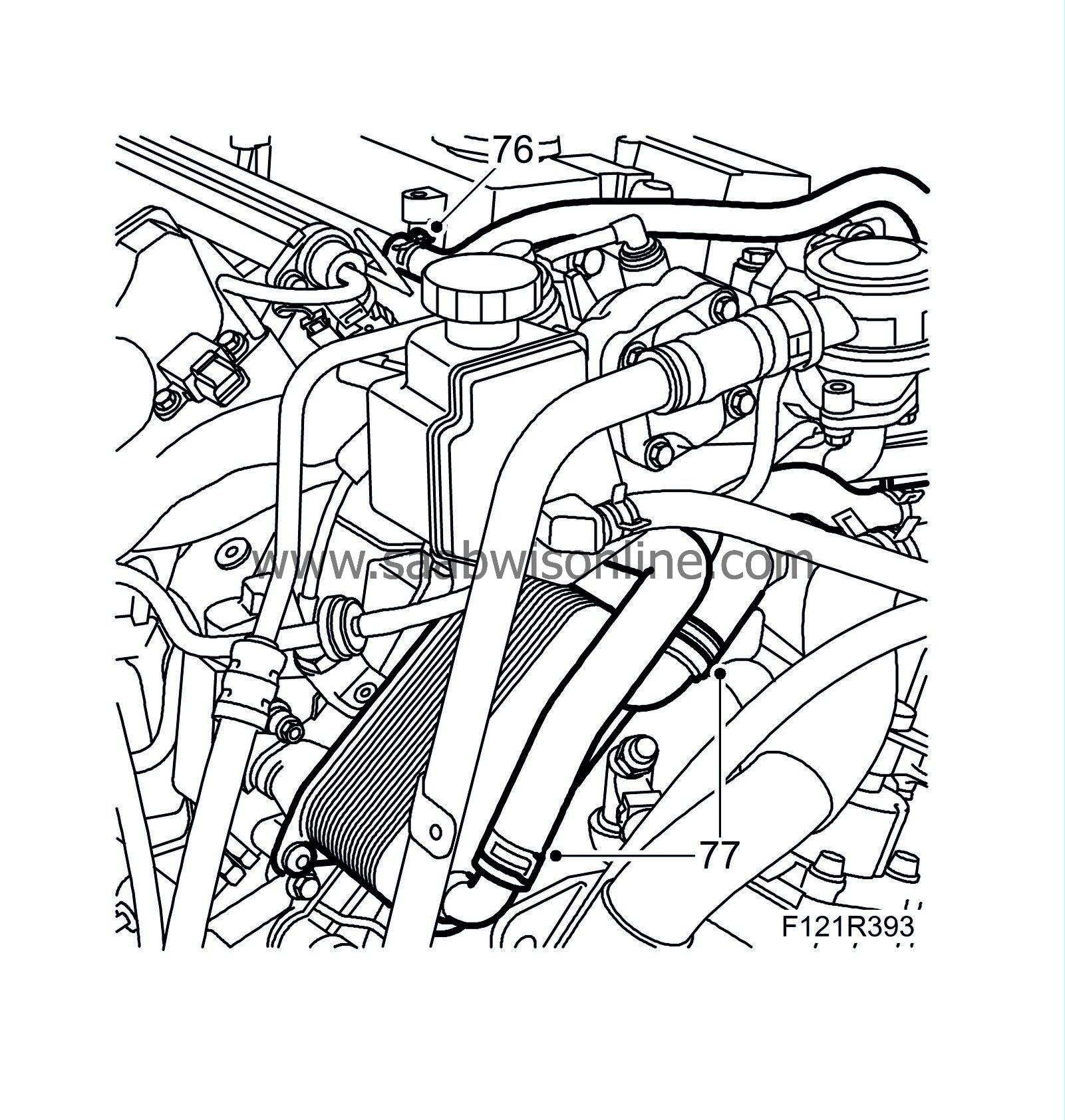

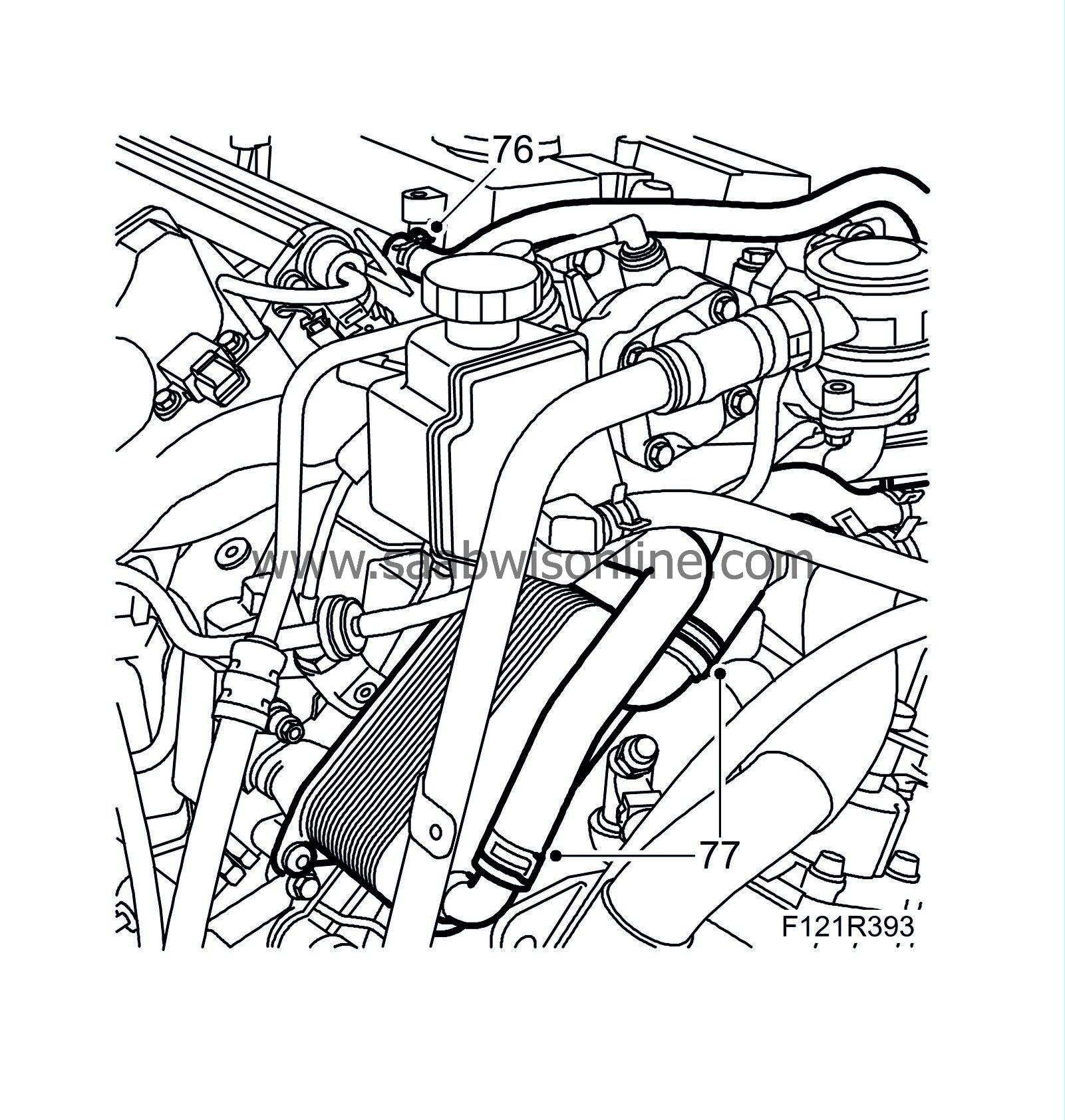

76.

|

Fit the breather hose on the cylinder head.

|

|

77.

|

Fit the hoses to the oil cooler. Check that the oil cooler hose clamps do not rest against the lower radiator hose. Adjust if necessary.

|

|

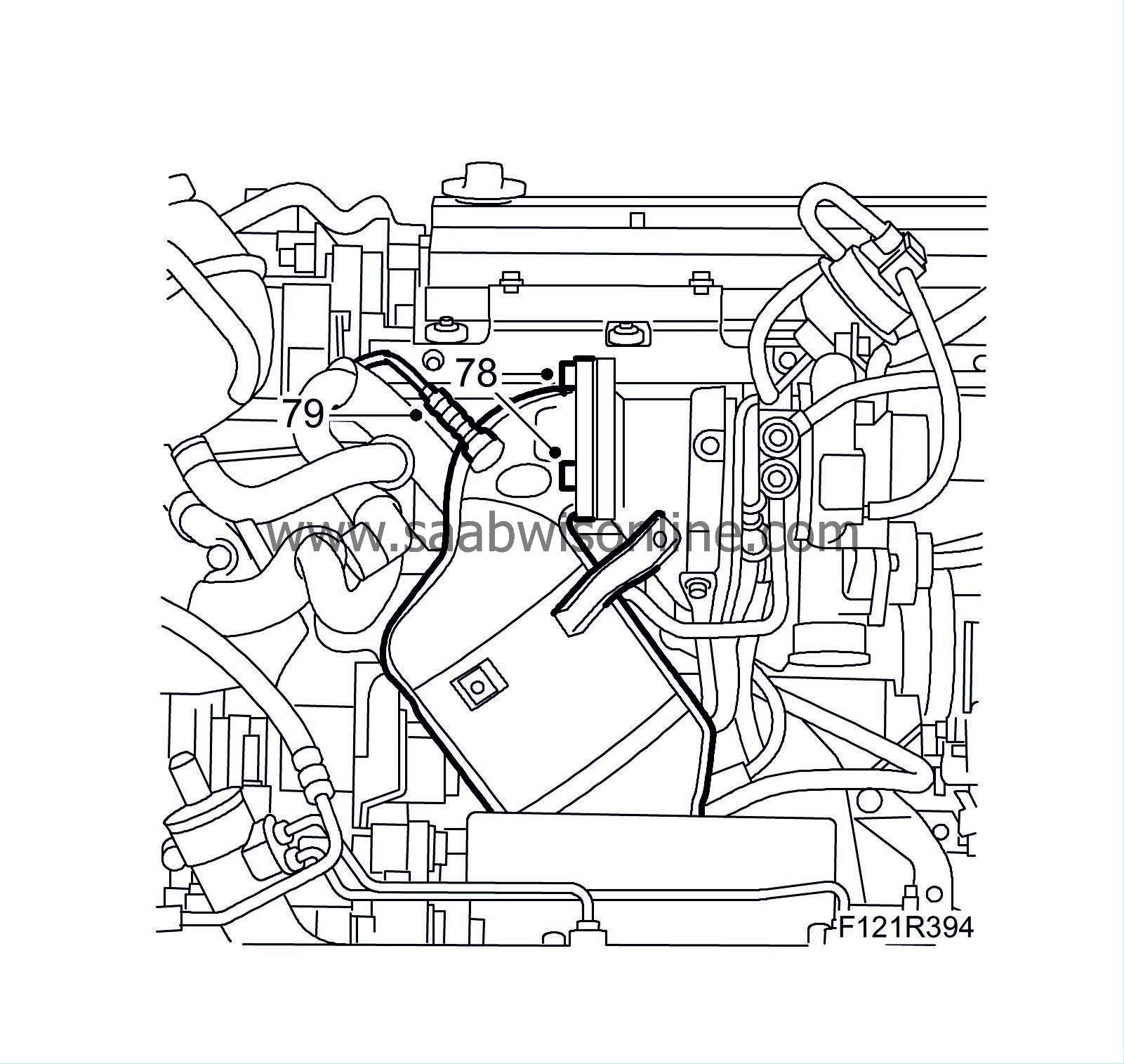

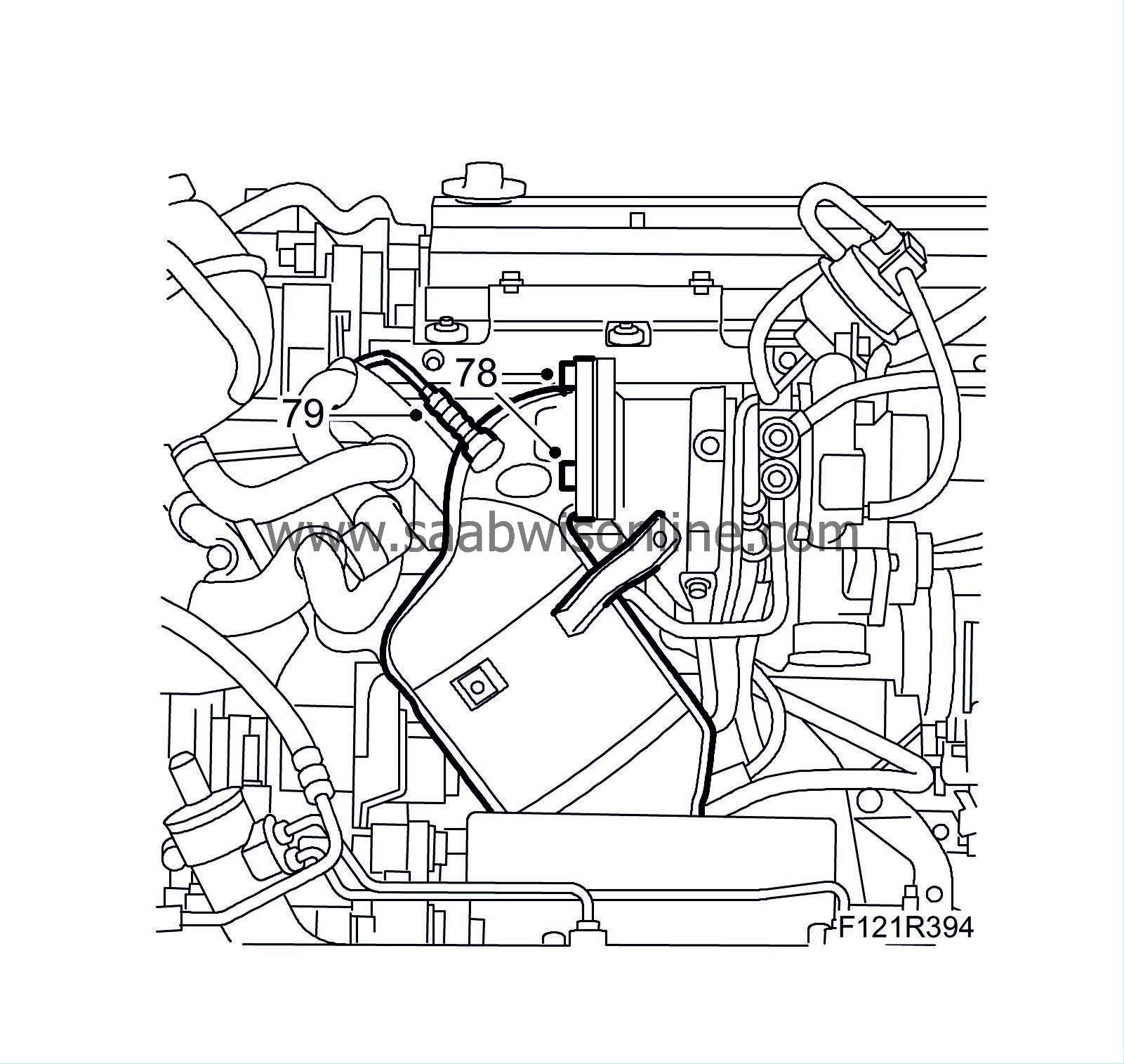

78.

|

Fit the catalytic converter with new nuts. Lubricate with 30 20 971 Screw-thread paste.

Tightening torque 25 Nm (18 lbf ft)

|

|

79.

|

M03

: Plug in the temperature sensor connector.

|

|

80.

|

Press the oxygen sensor connectors firmly into place.

|

|

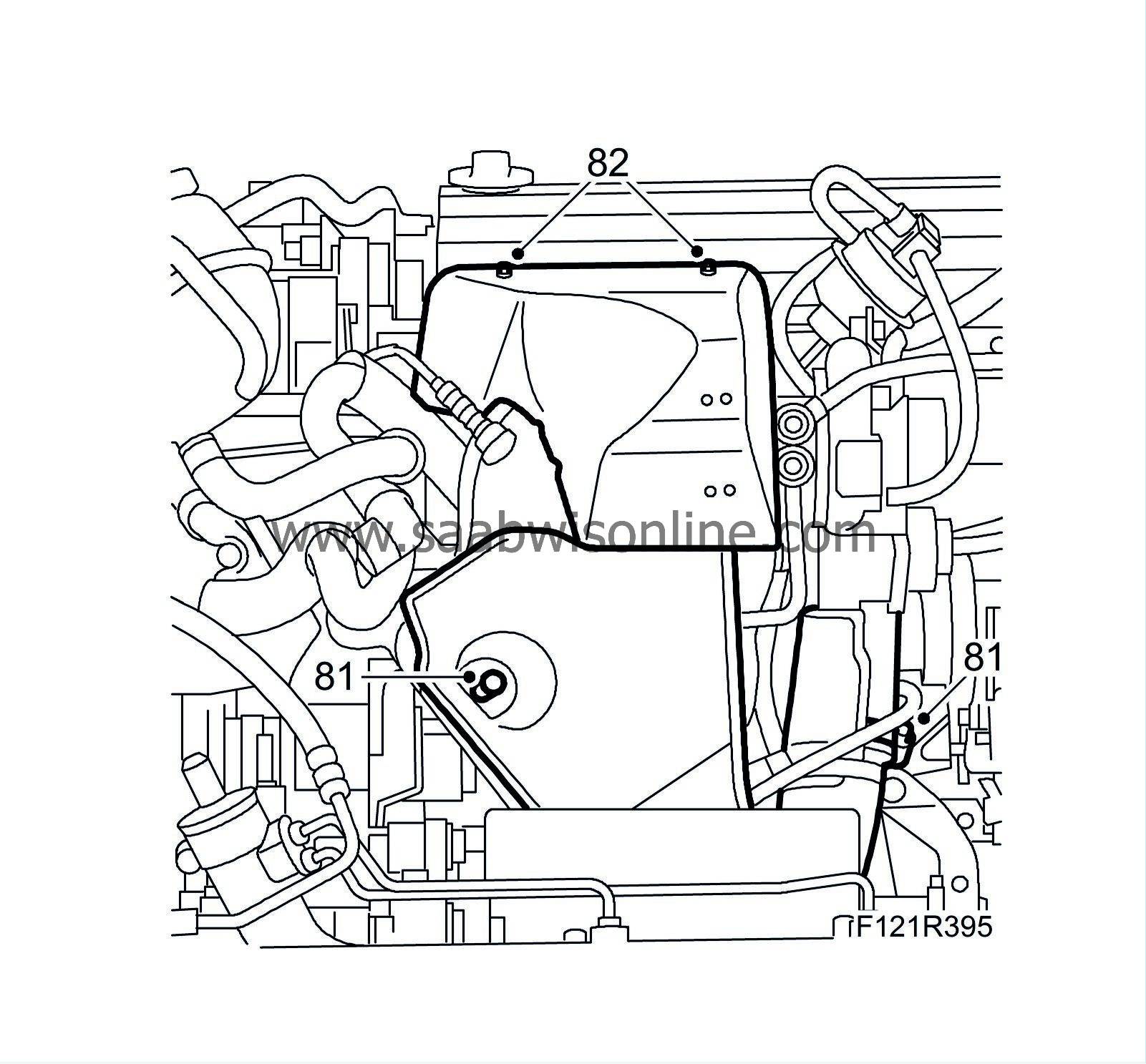

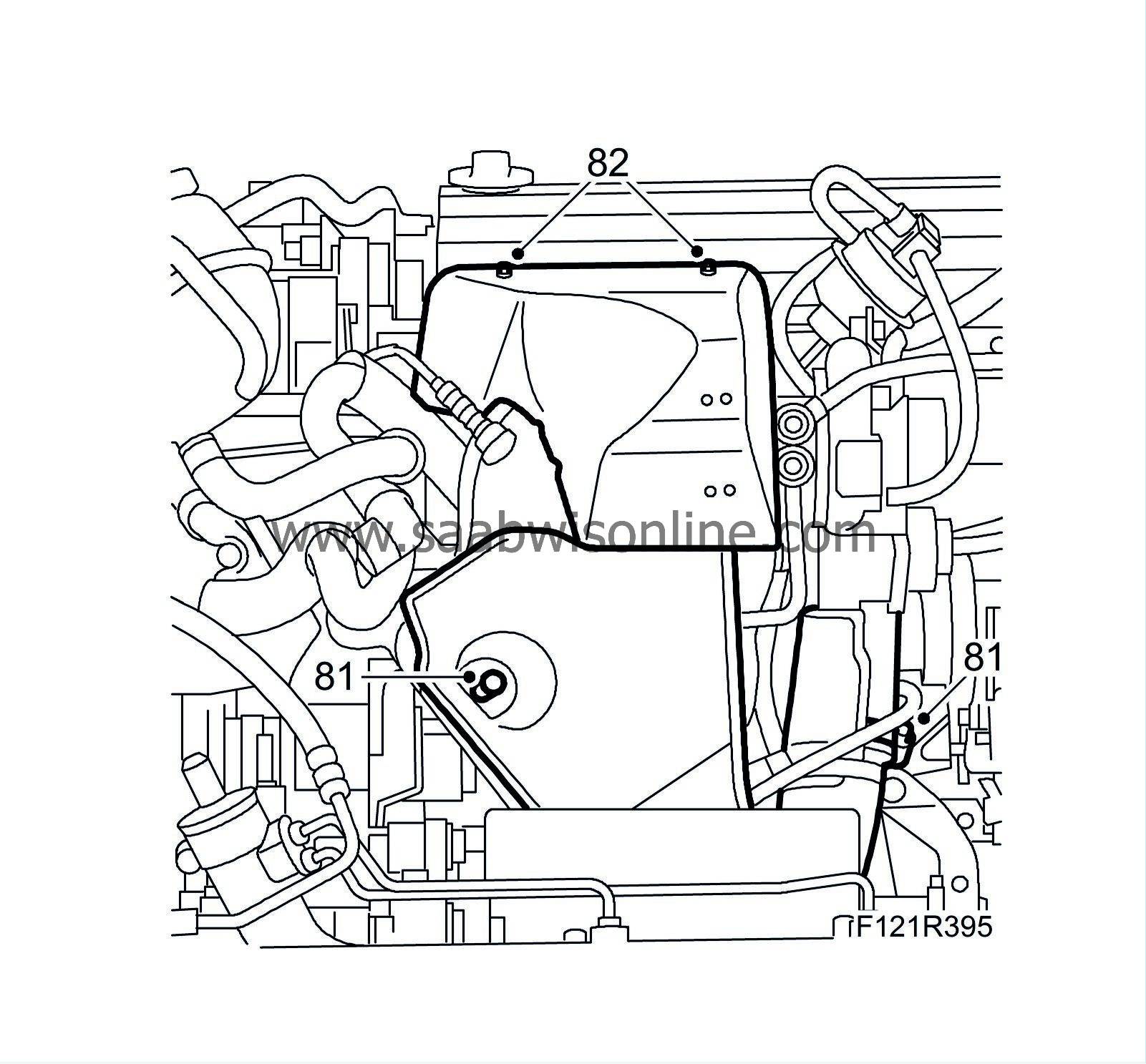

81.

|

Fit the catalytic converter heat shield.

Tightening torque 10 Nm (7 lbf ft)

|

|

82.

|

Fit the turbocharger heat shield.

Tightening torque 10 Nm (7 lbf ft)

|

|

83.

|

Fit the lower charge air pipe.

Tightening torque 22 Nm (30 lbf ft)

|

|

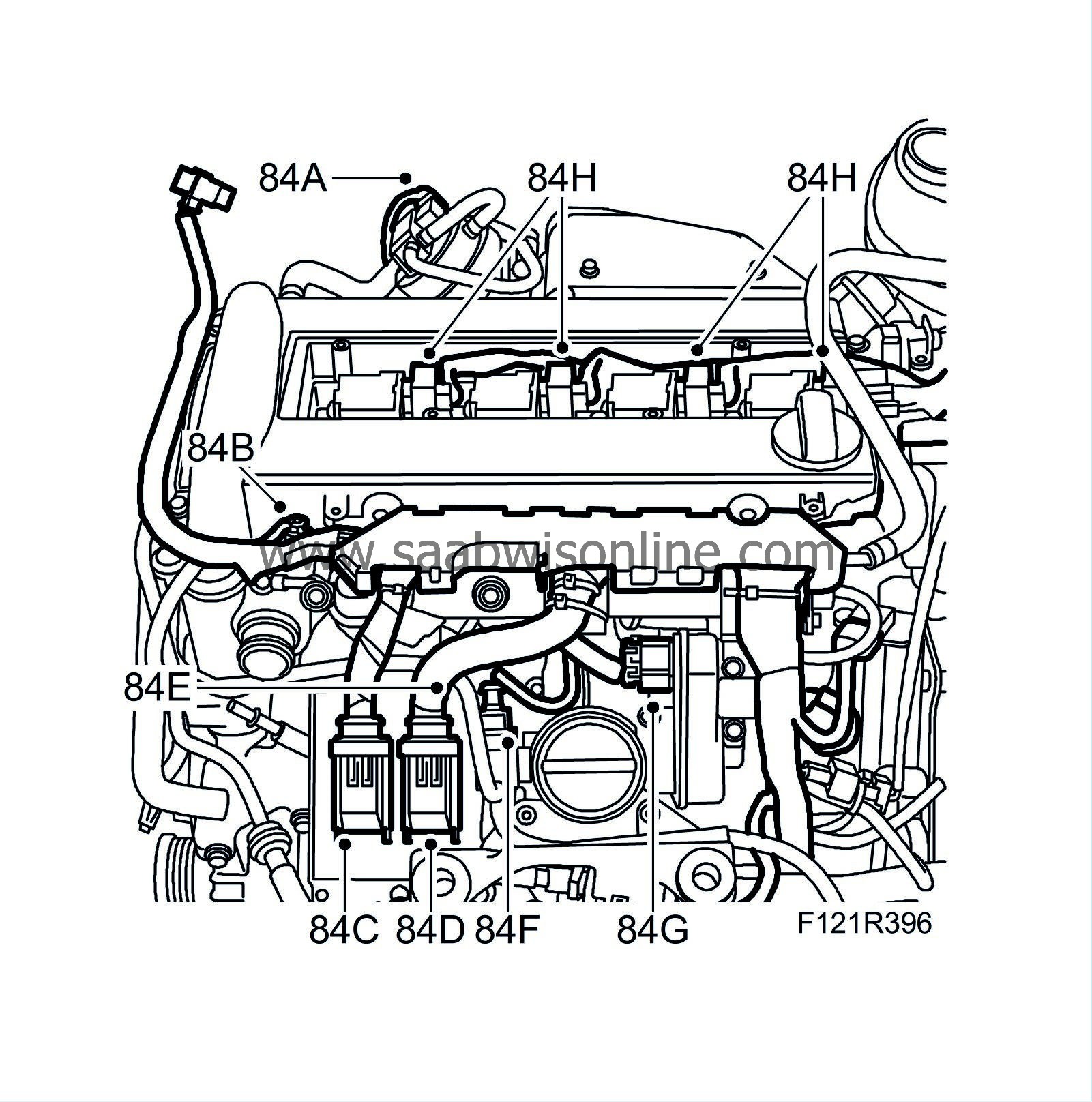

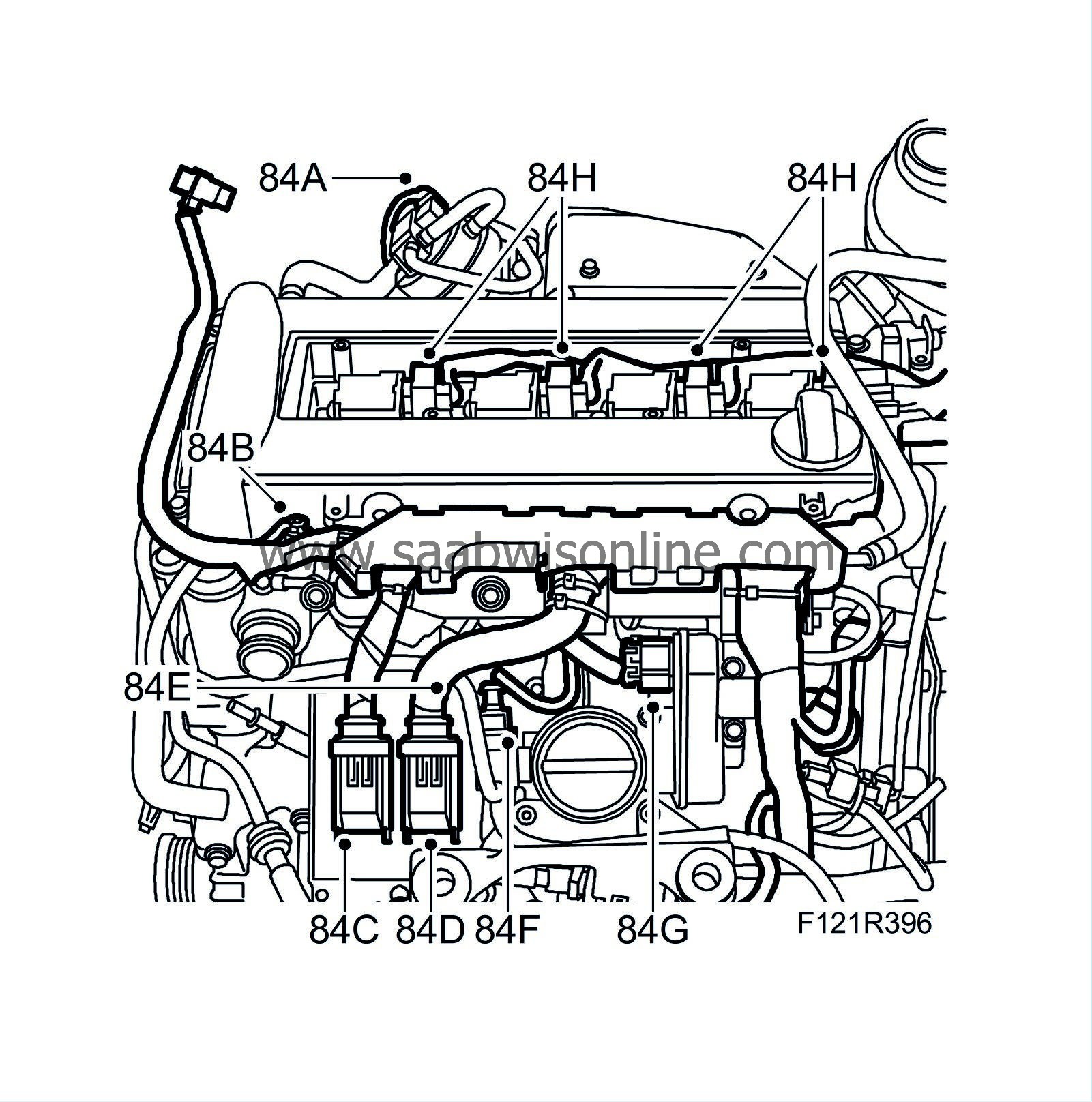

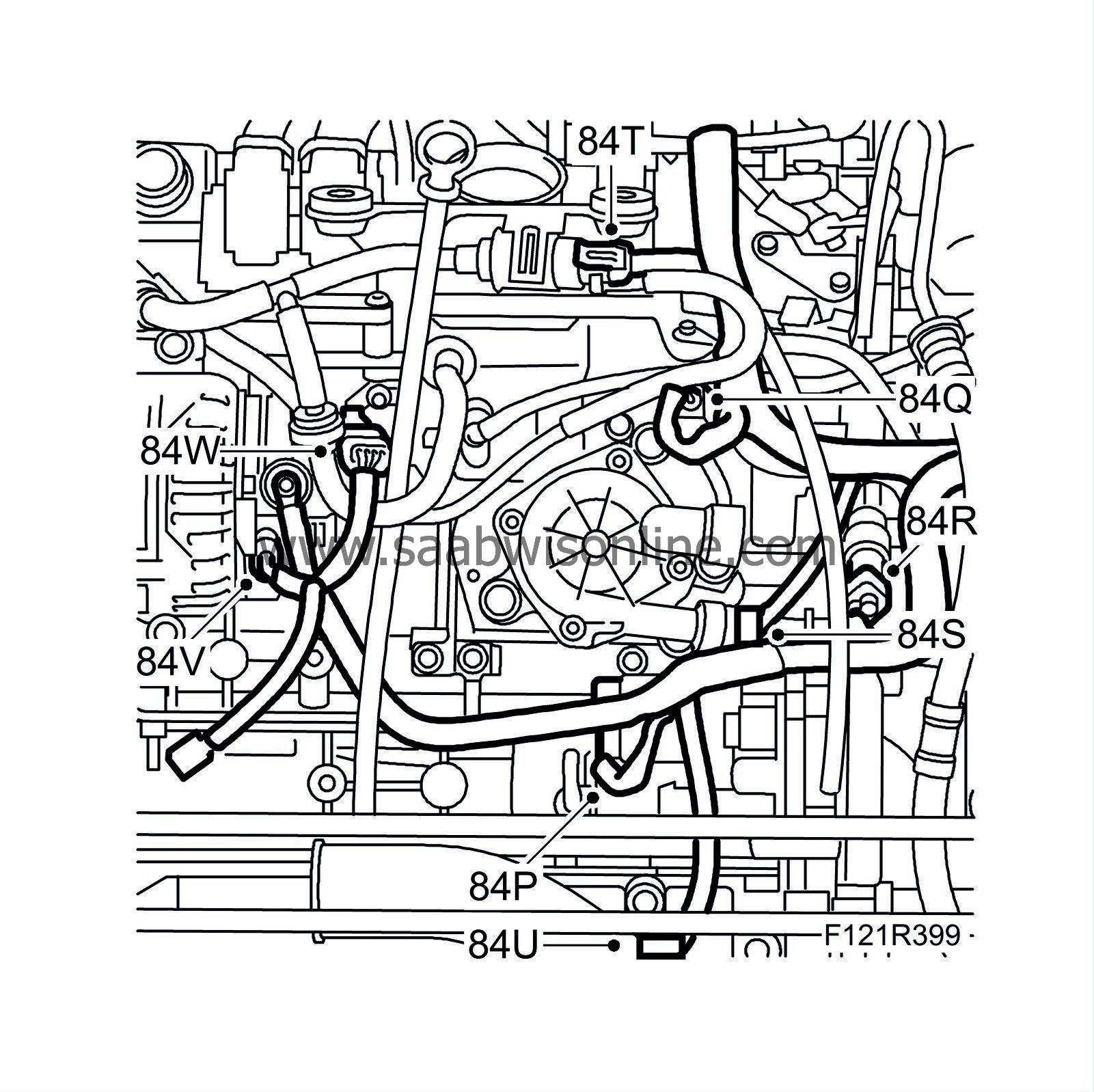

84.

|

Position the engine wiring harness and plug in the following connectors:

|

|

|

84.A.

|

Plug in the connector to the charge air control valve.

|

|

|

84.B.

|

Plug in the connector to the coolant temperature sensor.

|

|

|

84.C.

|

Plug in the engine control module connector.

|

|

|

84.D.

|

Plug in the engine control module connector.

|

|

|

84.E.

|

Plug in the connector to grounding point G7.

|

|

|

84.F.

|

Plug in the bypass valve connector.

|

|

|

84.G.

|

Plug in the throttle body connector.

|

|

|

84.H.

|

Plug in the 4 ignition coil connectors.

|

|

|

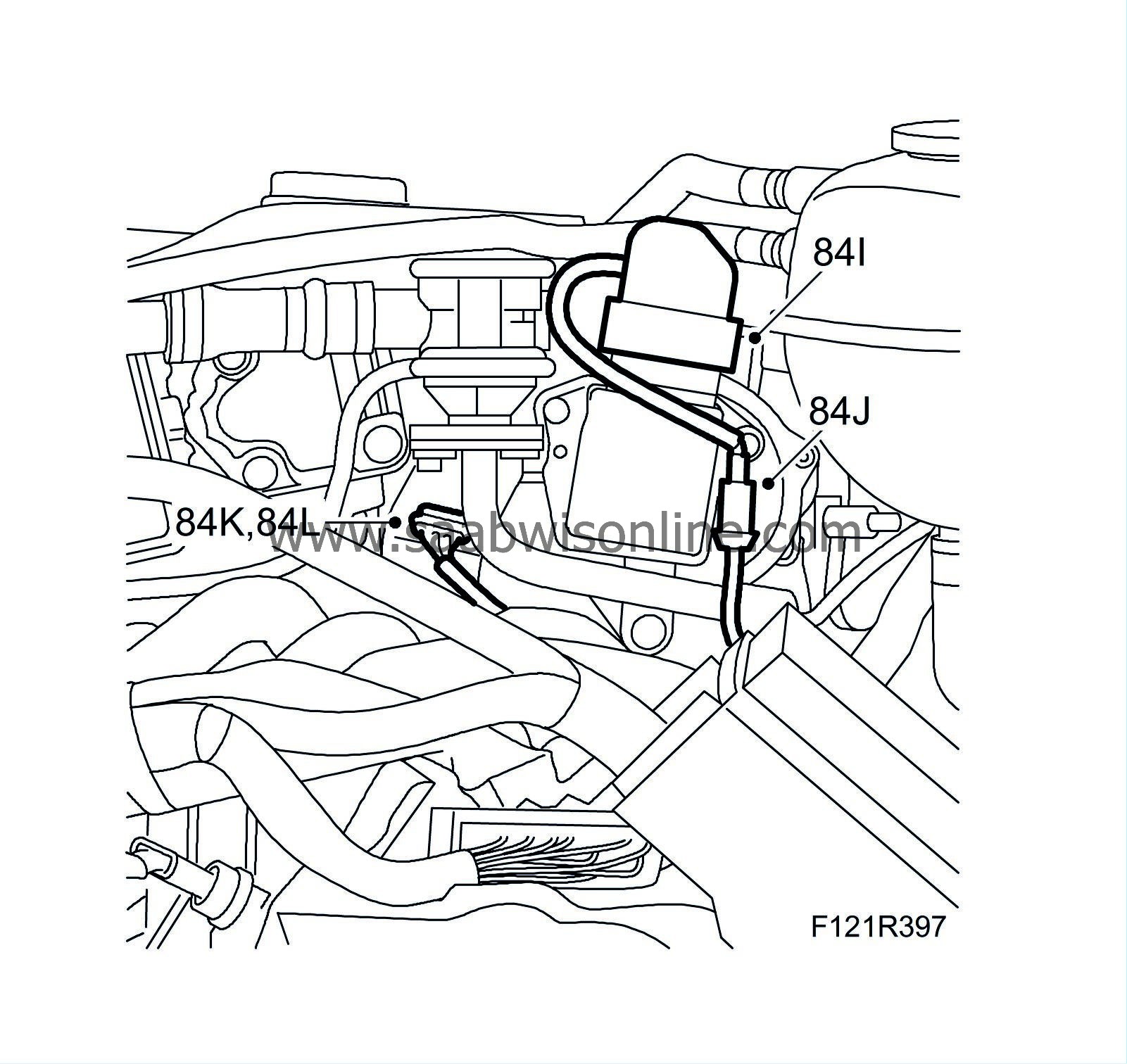

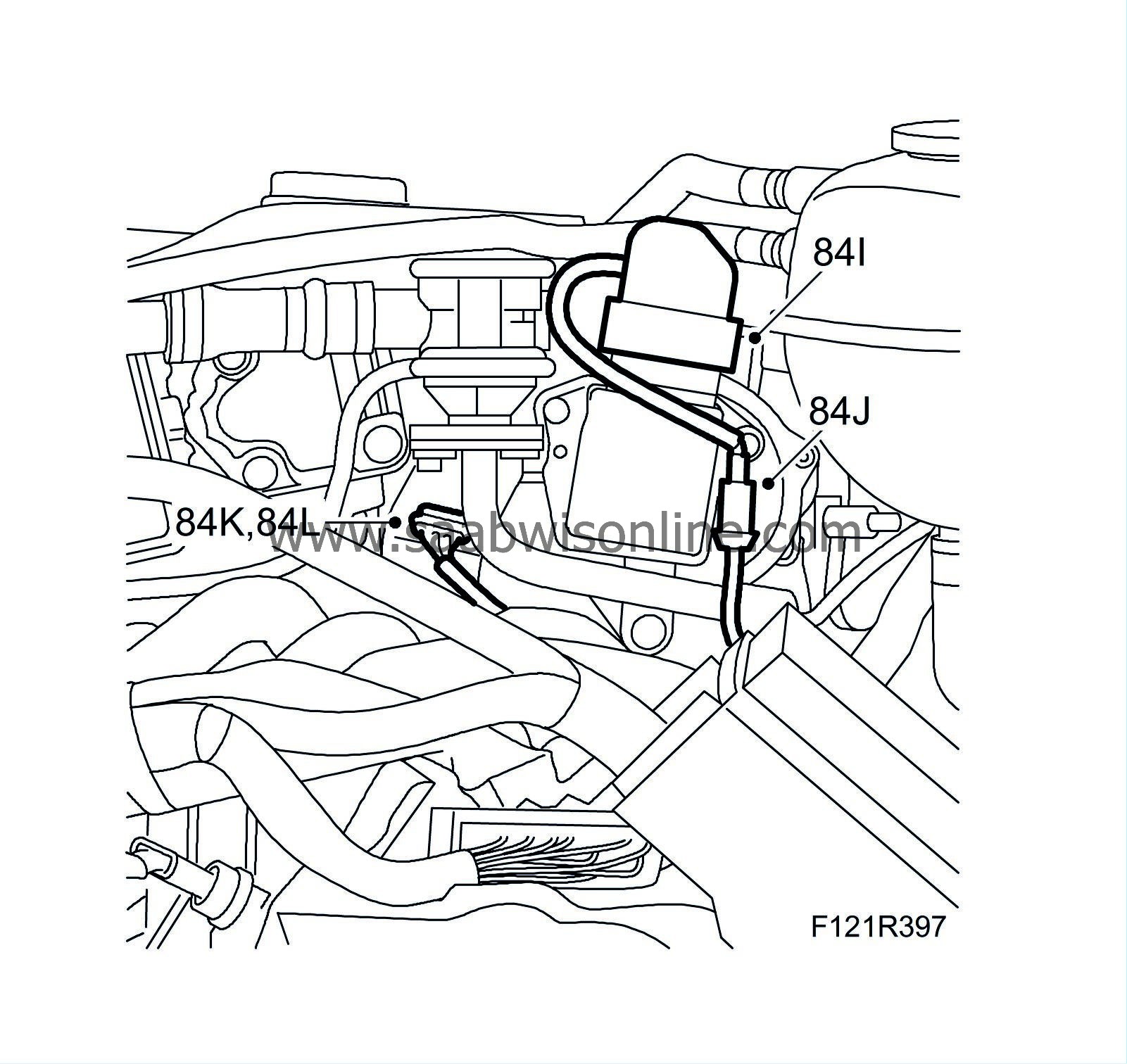

84.I.

|

Plug in the connector to the ionization detection module.

|

|

|

84.J.

|

M03

: Plug in the connector to the exhaust temperature sensor.

|

|

|

84.K.

|

Plug in the connector to the front oxygen sensor.

|

|

|

84.L.

|

Plug in the connector to the rear oxygen sensor.

|

|

|

84.M.

|

Plug in the connector to the atmospheric pressure sensor.

|

|

|

84.N.

|

Plug in the connector to the intake manifold pressure sensor.

|

|

|

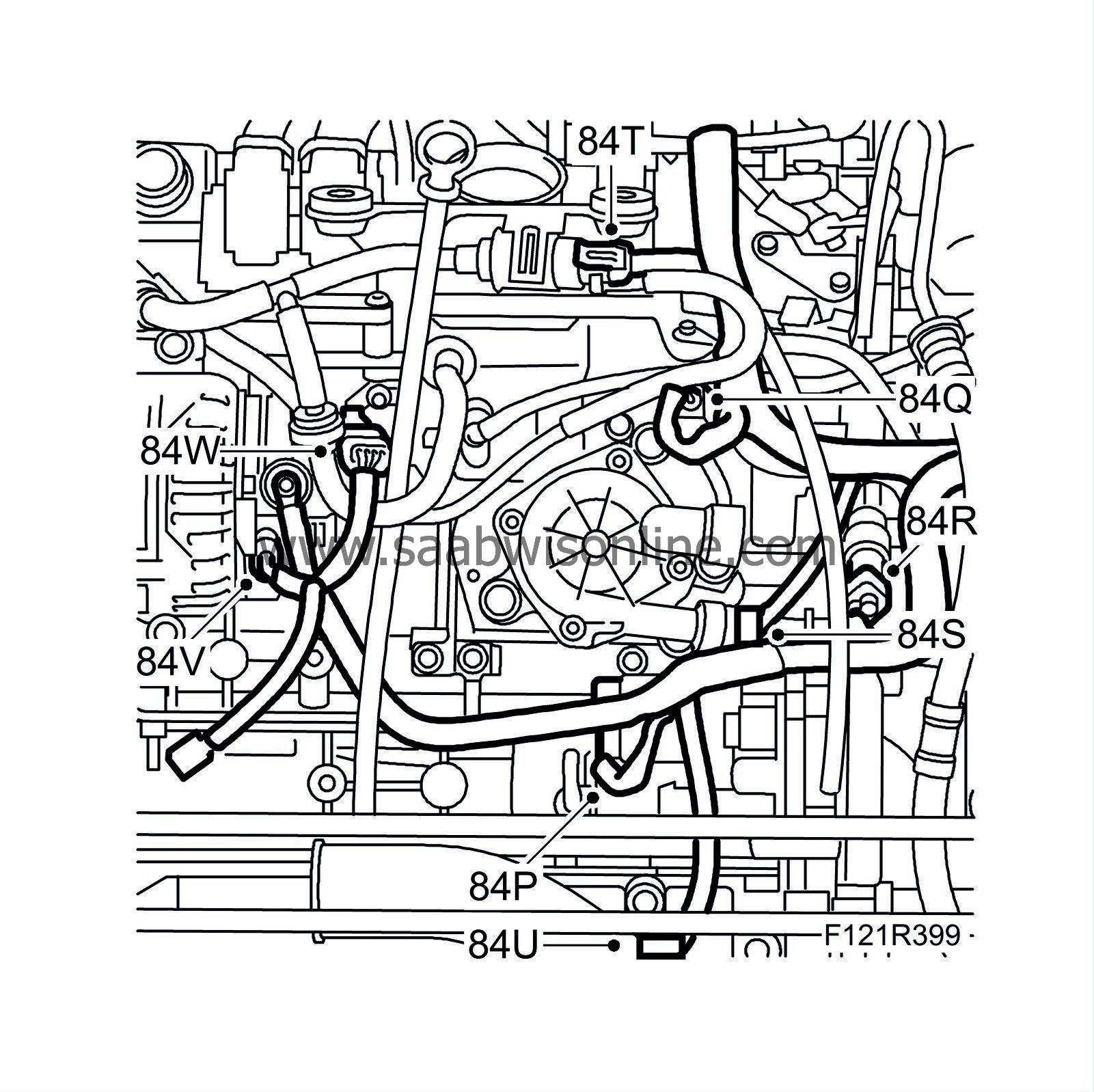

84.O.

|

Fit the power steering fluid pressure switch.

|

|

|

84.P.

|

Fit the starter motor contacts.

|

|

|

84.Q.

|

Cars with secondary air injection pump

: Plug in the secondary air injection pump connector.

|

|

|

84.R.

|

Fit the oil pressure switch.

|

|

|

84.S.

|

Plug in the connector to the crankshaft position sensor.

|

|

|

84.T.

|

Plug in the EVAP canister purge valve connector.

|

|

|

84.U.

|

Plug in the oil level sensor connector.

|

|

|

84.V.

|

Plug in the generator connector.

|

|

|

84.W.

|

Plug in connector H8-9.

|

|

|

84.X.

|

Cars with manual gearbox

: Plug in the reverse light connector.

|

|

|

84.Y.

|

Fit the wiring harness retaining bolts.

|

|

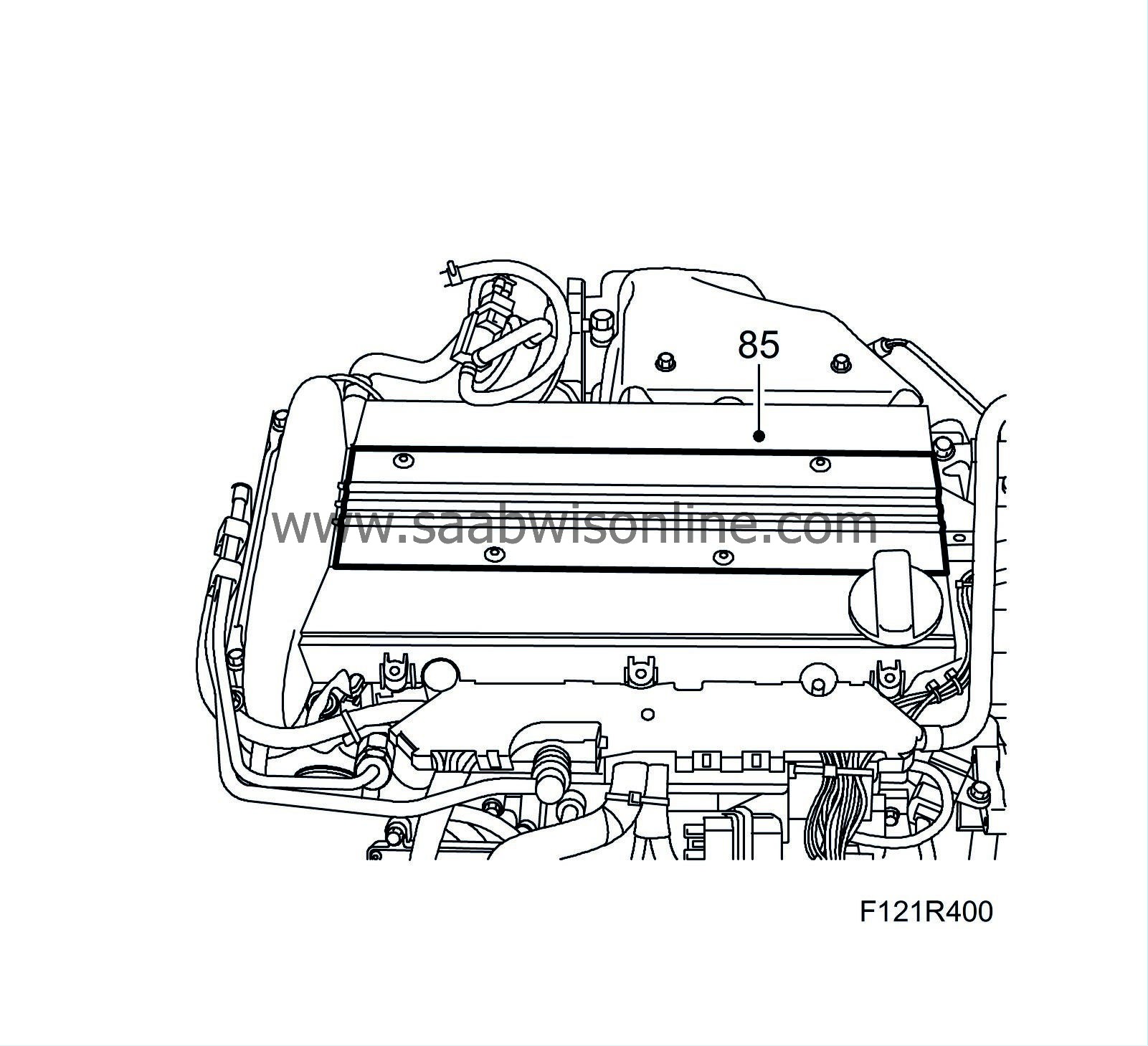

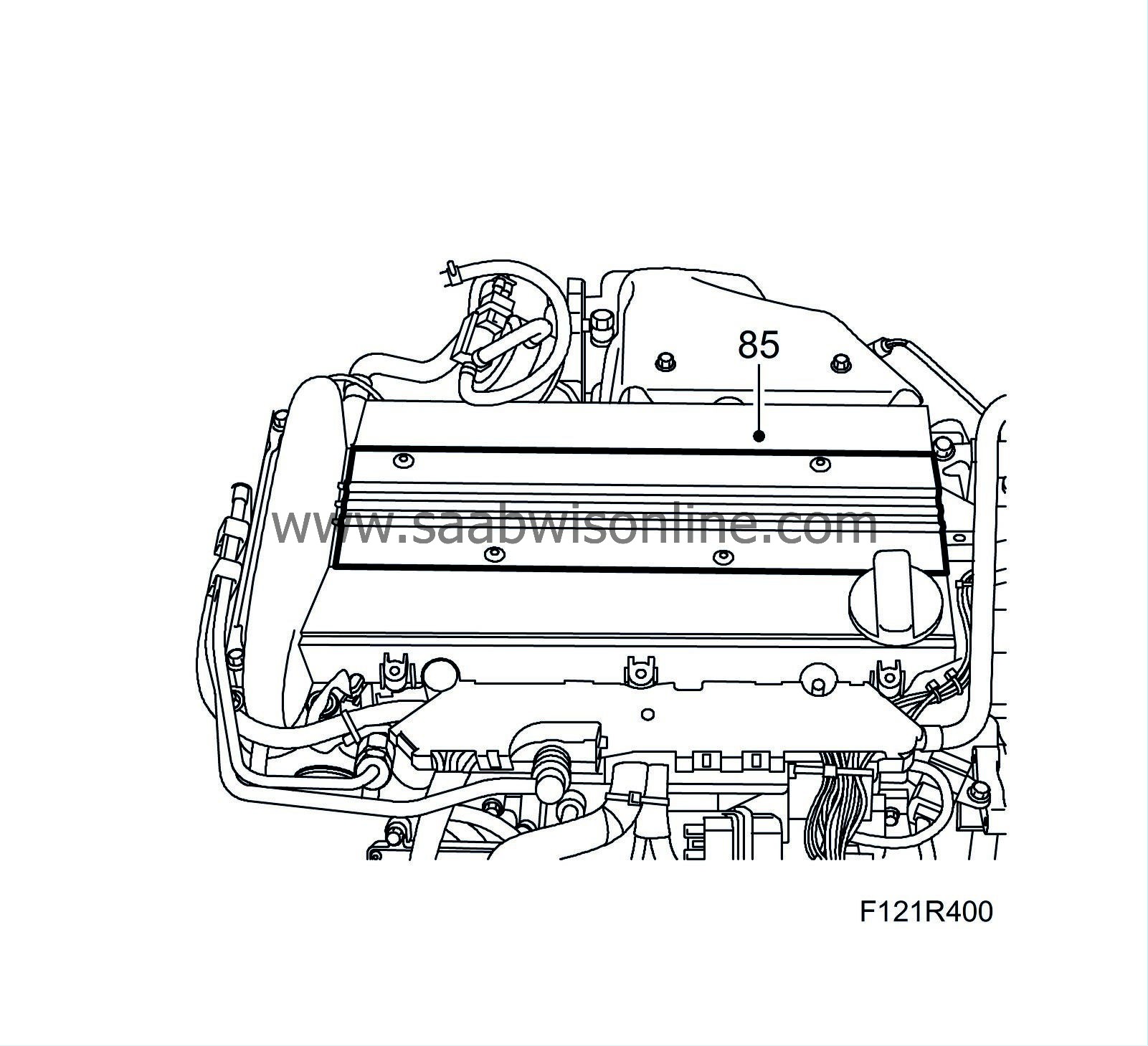

85.

|

Fit the cover to the spark plugs.

|

|

86.

|

Fit the engine assembly, see WIS - 9-3 (9440) - Engine - 4-cylinder petrol - Basic engine - Adjustment/Replacement - Fitting the power train.

|

|

87.

|

Fill with engine oil, see WIS - 9-3 (9440) - Engine - 4 cylinder petrol - Basic engine - Adjustment/Replacement - Changing engine oil and oil filter.

|

|

88.

|

Fill with gearbox oil:

Cars with automatic transmission

: See WIS - 9-3 (9440) - Transmission - Automatic transmission - Adjustment/Replacement - Checking transmission fluid level.

Cars with manual gearbox

: See WIS - Transmission - Manual gearbox - Adjustment/Replacement - Refilling with gearbox oil.

|

|

89.

|

CV

: Fit the chassis reinforcement, front subframe.

|

|

91.

|

Complete the procedures after disconnecting the battery, see WIS - 9-3 (9440) - Electrical System - Charging system - Adjustment/Replacement - Procedures after disconnecting the battery.

|

|

Warranty/Time Information

|

In the case of customer complaint and if the car is

within the warranty period,

use the following information to fill out the claim:

Failed object: 21210

Repair/Action code: 01

Labour Operation (US): Cars with manual gearbox: 21210-02, cars with automatic transmission: 21210-03

Time excluding removed 20000:

Cars with manual gearbox: 6.5 hr

Cars with automatic transmission: 6.4 hr