PRE-RELEASE

Camshafts in car, Z19DTH

| Camshafts in car, Z19DTH |

|

||||||||||||||||||||||

| To remove |

|

|||||||

| Important | ||

|

Always use wing covers when working in the engine bay. |

||

| 1. |

Remove

Timing belt in-car Z19DTH

|

|

| 2. |

Remove the turbocharger delivery pipe upper bracket.

|

|

| 3. |

Remove the brake servo hose from the vacuum pump and bend aside.

|

|

| 4. |

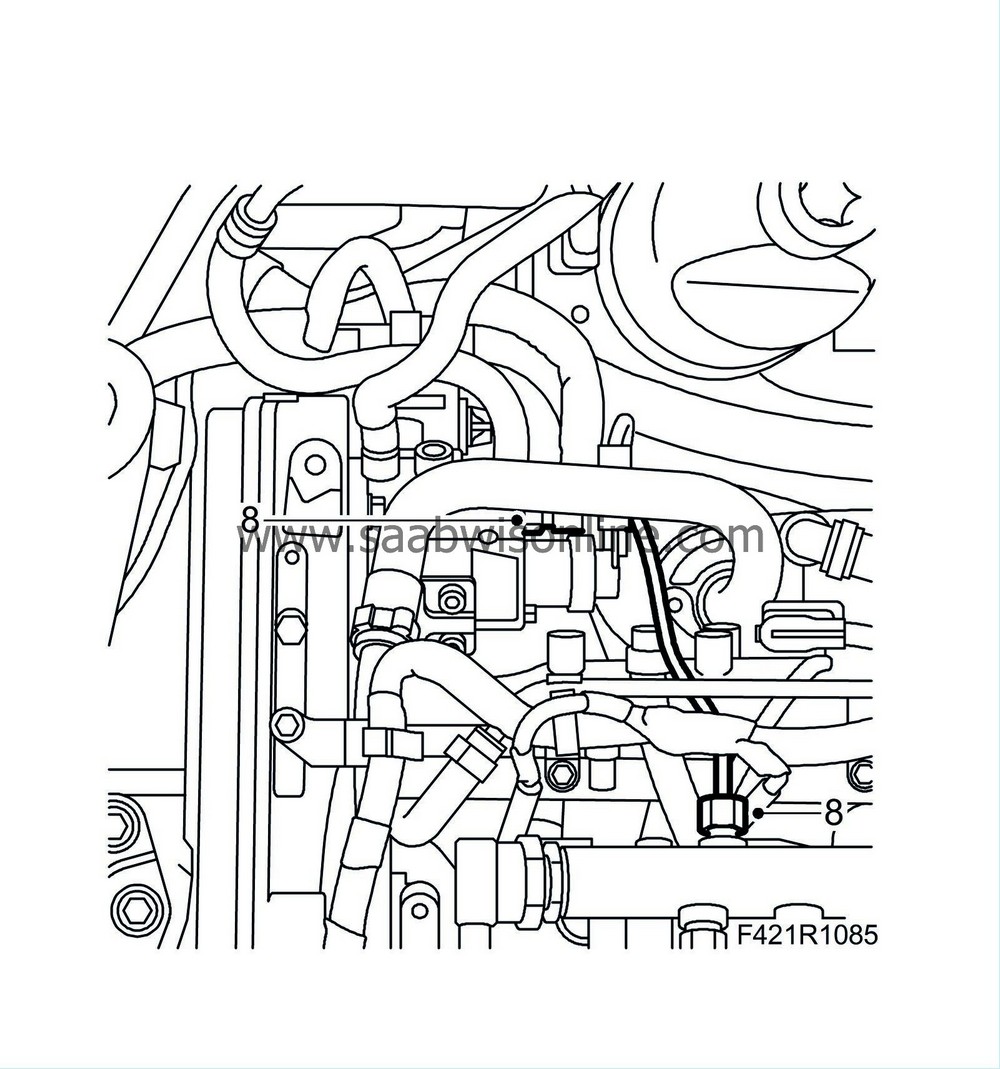

Undo the crankcase ventilation hose from the cylinder head.

|

|

| 5. |

Remove the cable duct retaining screws.

|

|

| 6. |

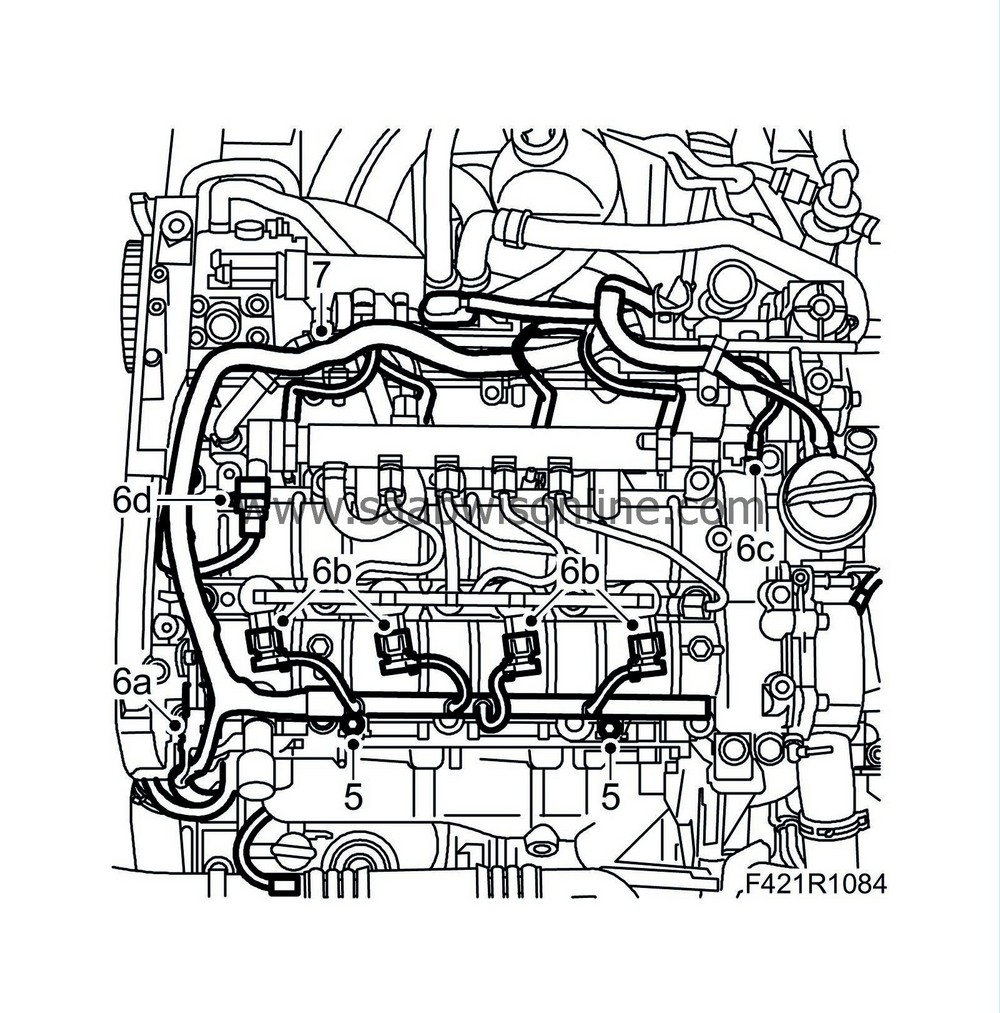

Remove the following connectors:

|

|

| 6.a. |

Camshaft position sensor (555)

|

| 6.b. |

Injectors (206)

|

| 6.c. |

Fuel pressure sensor (653)

|

| 6.d. |

Fuel pressure control valve (652a)

|

| 7. |

Fold away the engine wiring harness.

|

|

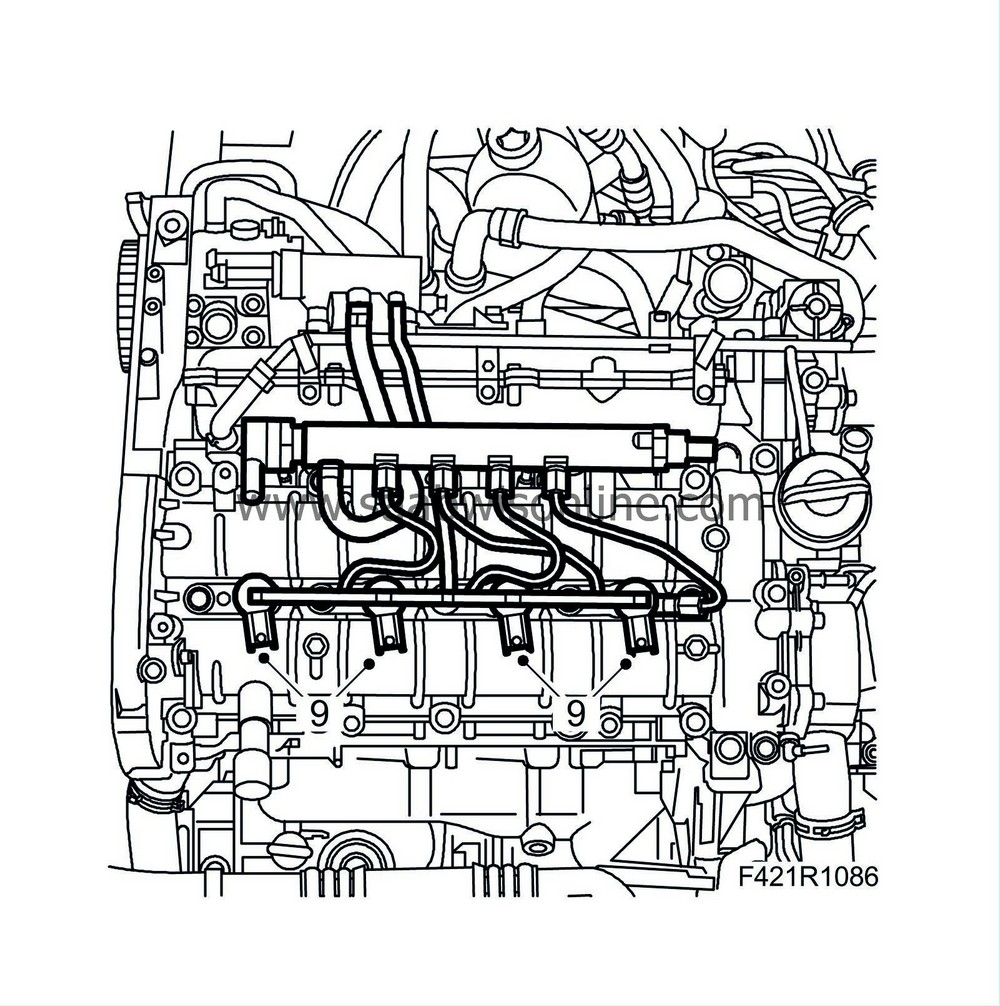

| 9. |

Remove

Injector (206), Z19DTH

.

|

|

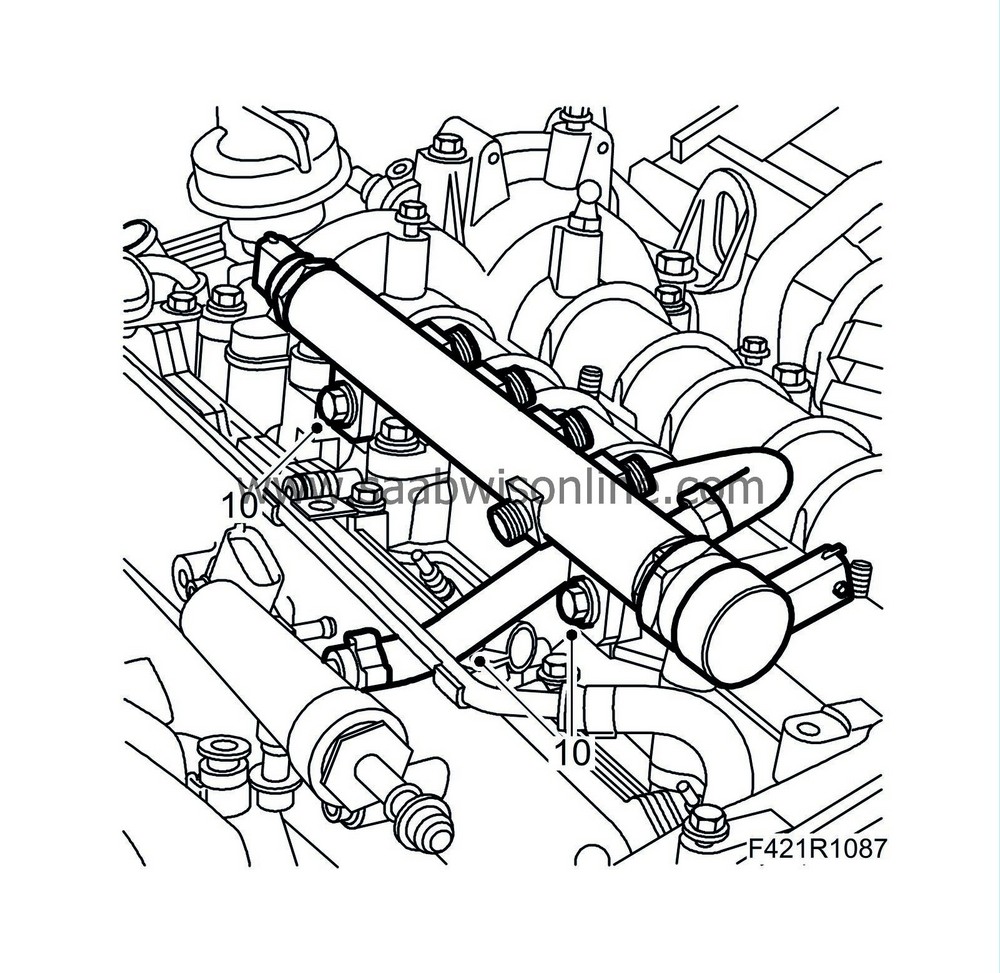

| 10. |

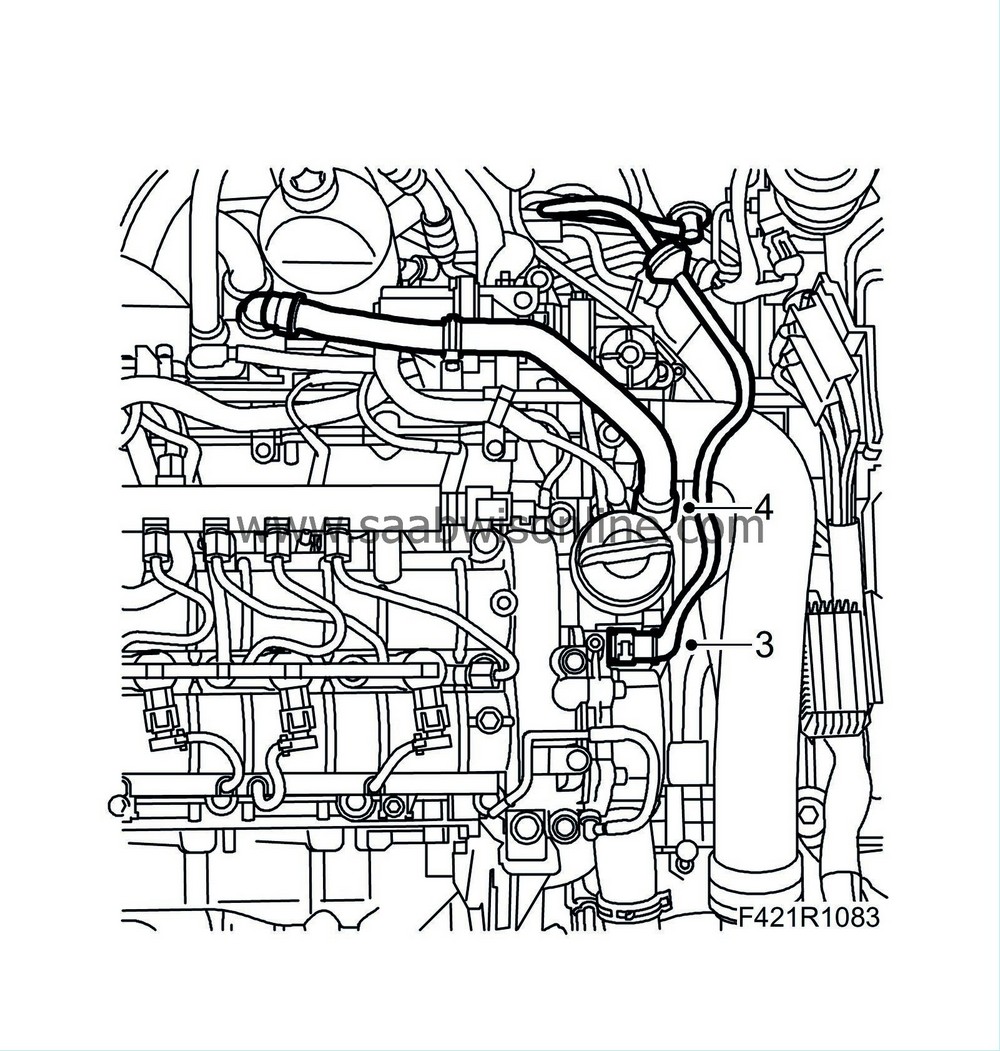

Detach and move aside the fuel rail.

|

|

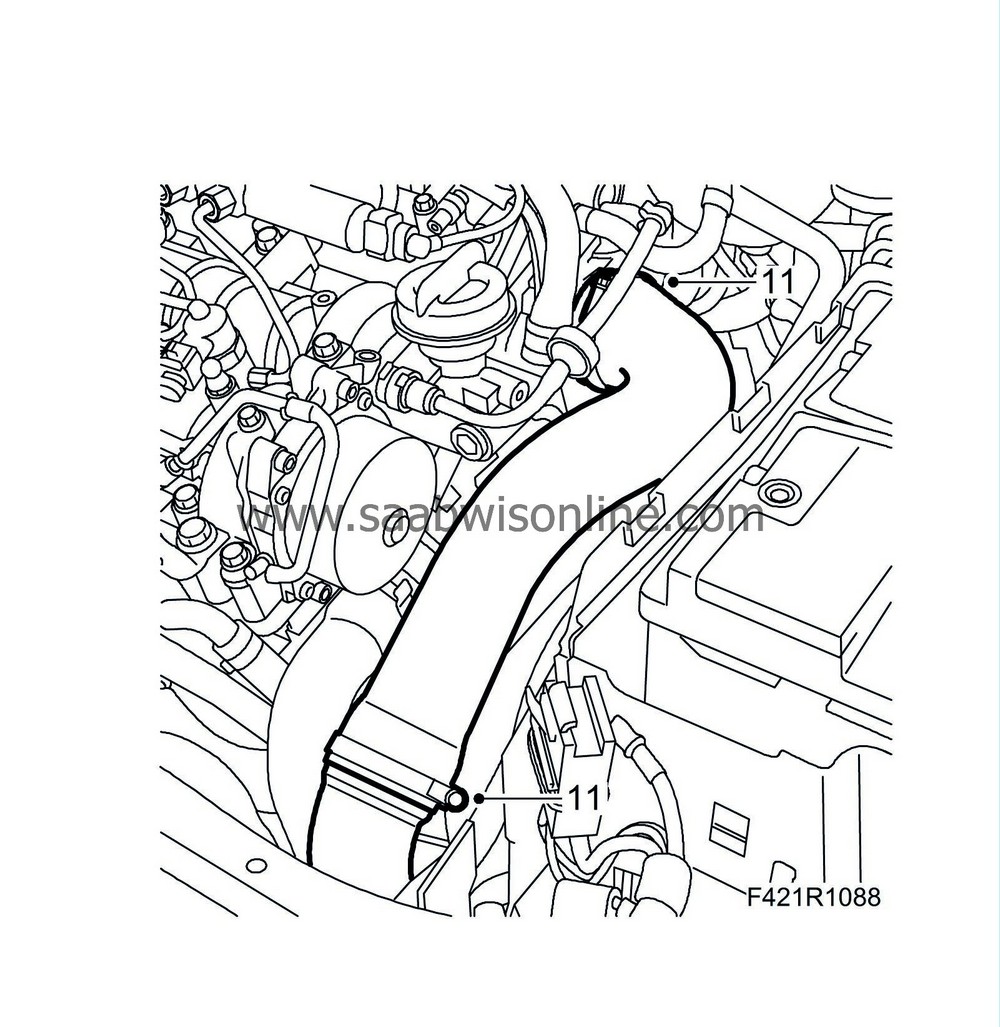

| 11. |

Detach the charge air hose from pipe and throttle body.

|

|

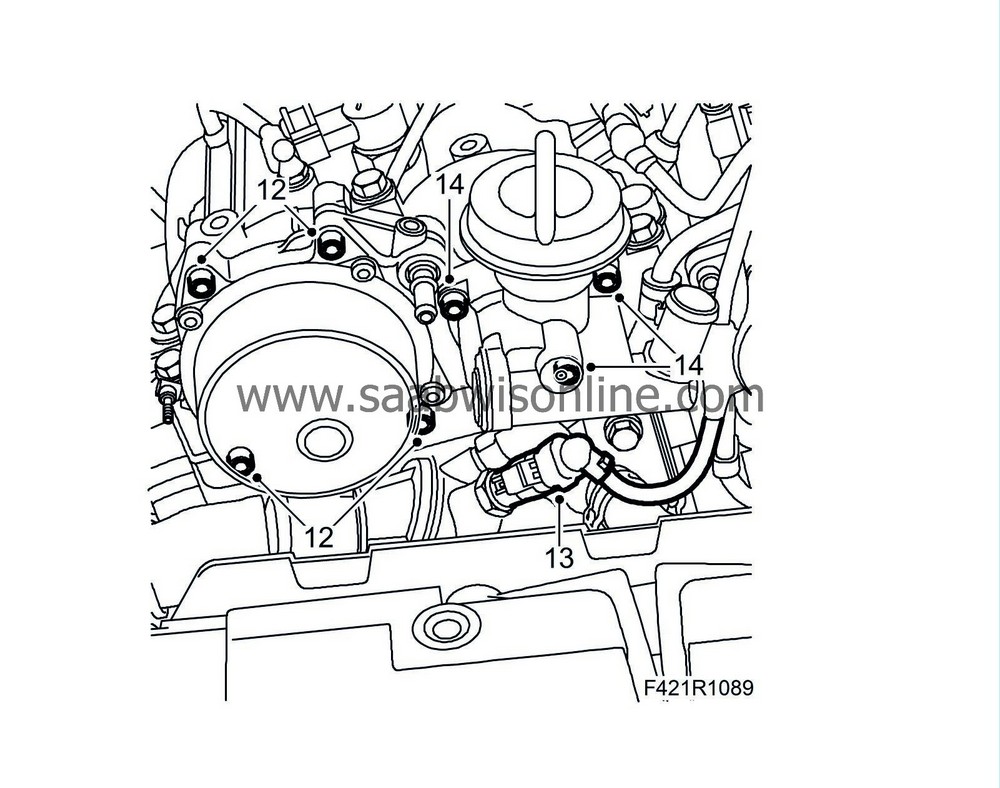

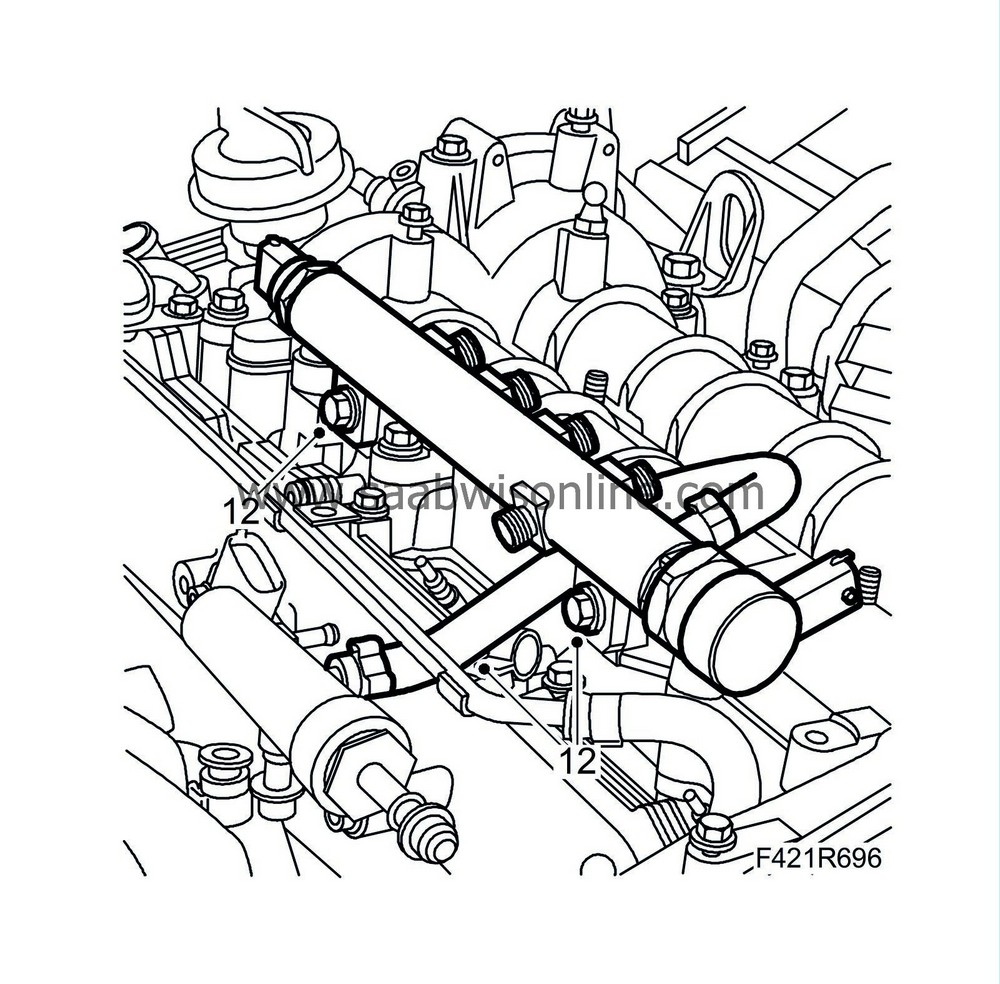

| 12. |

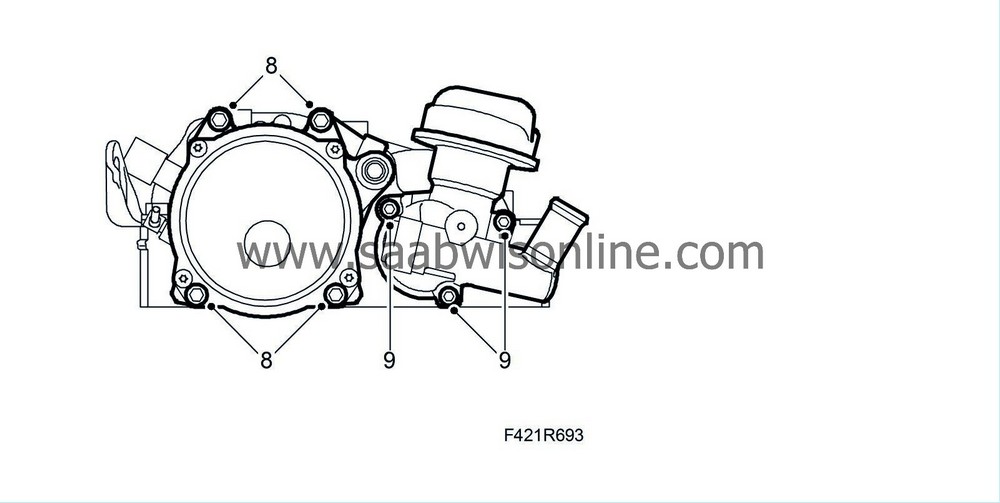

Remove the vacuum pump.

|

|

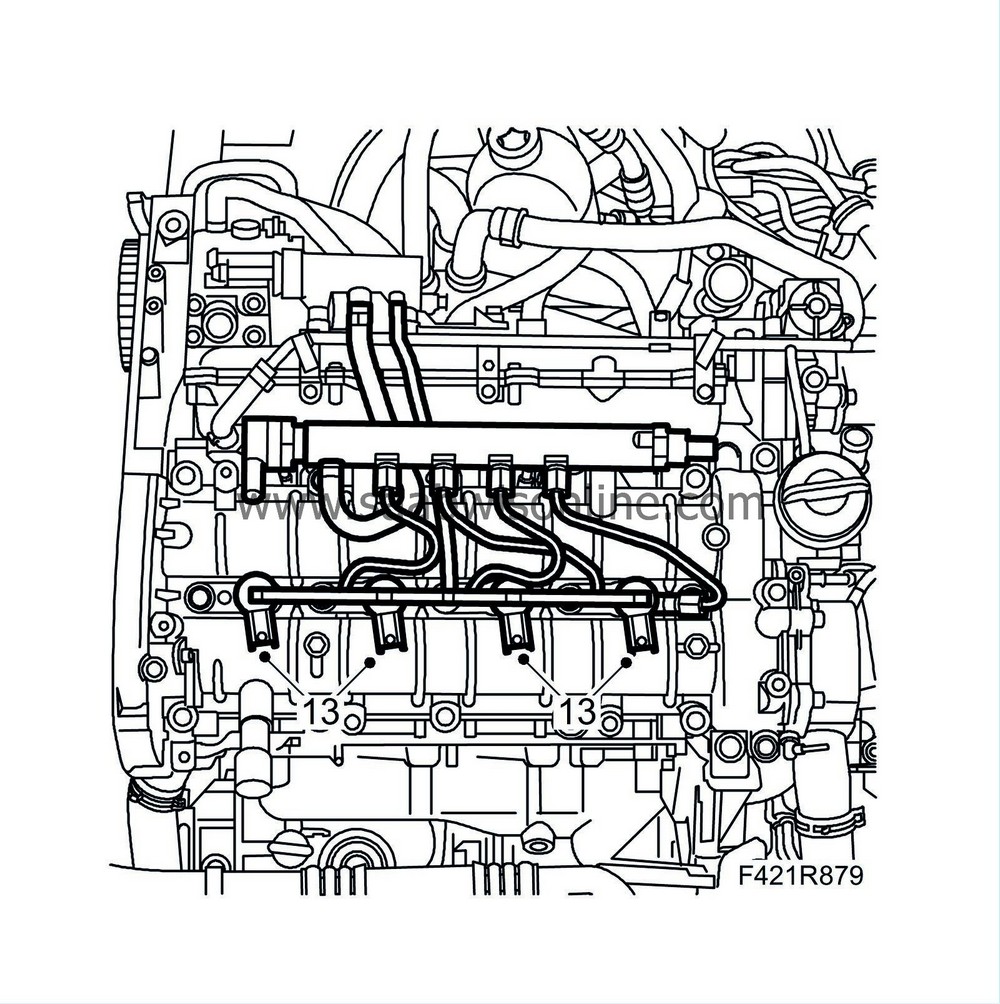

| 13. |

Remove the temperature sensor connector.

|

|

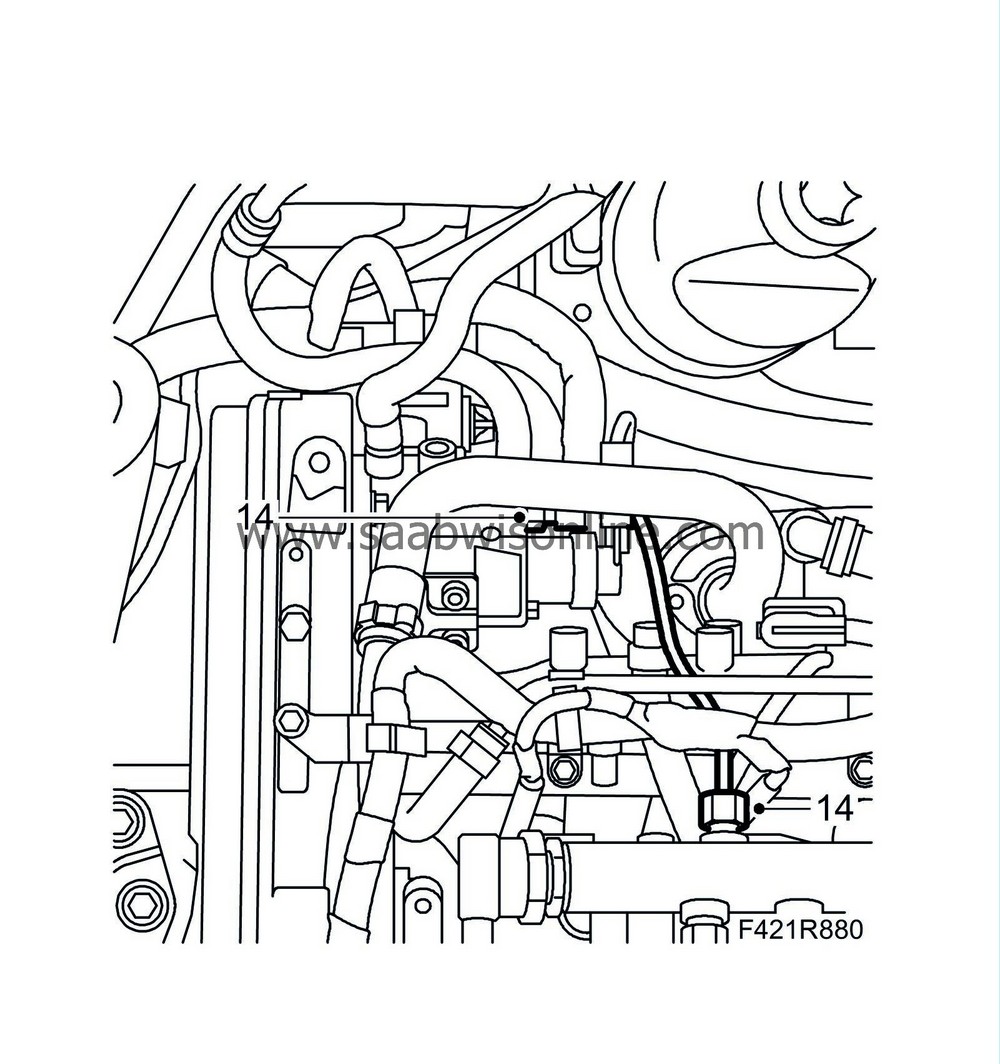

| 14. |

Remove the oil filler pipe.

|

|

| 15. |

Check that

32 025 008 Fixing tool, camshaft

has locked the exhaust camshaft.

|

|||||||

| 16. |

Undo the bolts to the camshaft gears.

|

|

| 17. |

Undo the bolt to the camshaft drive wheels.

|

|

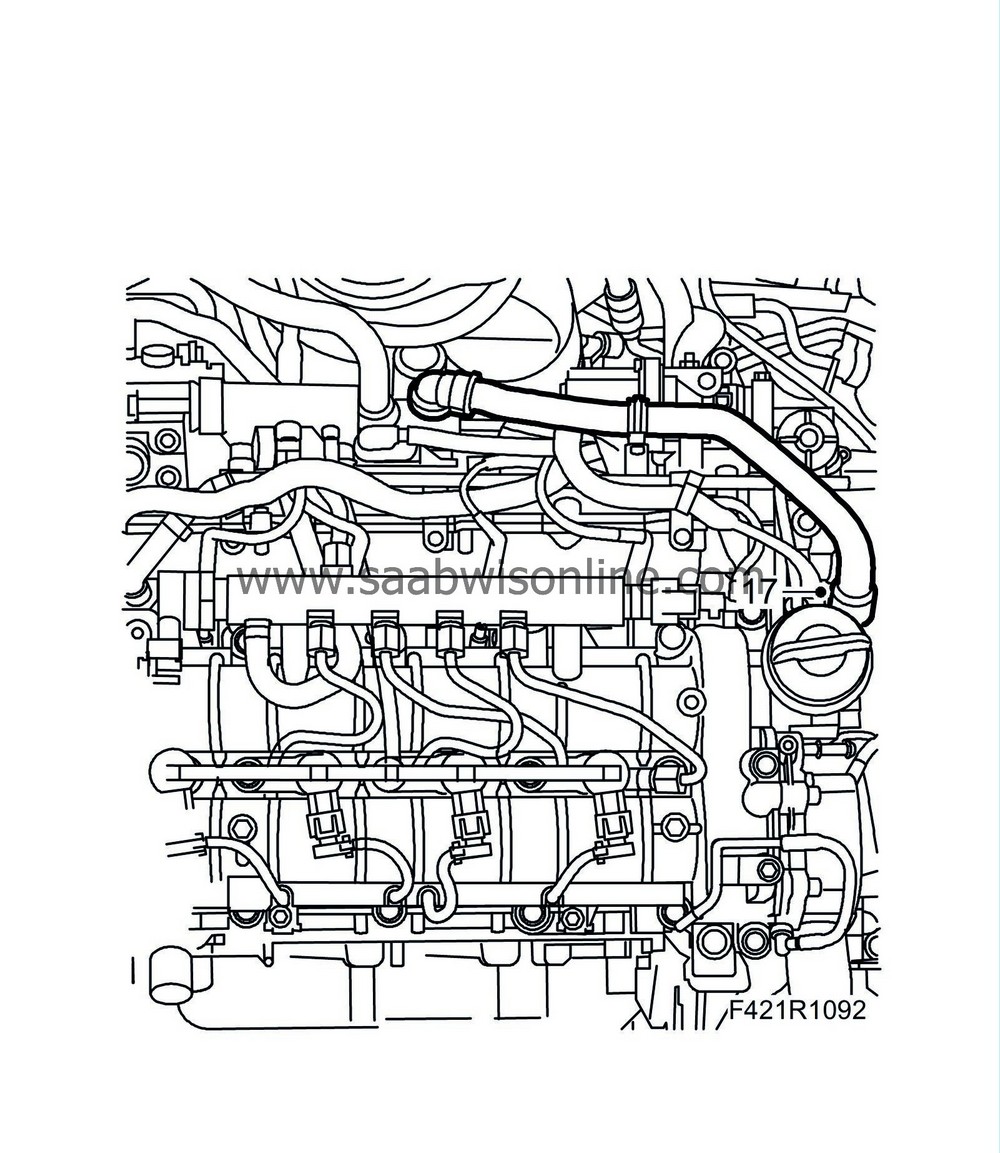

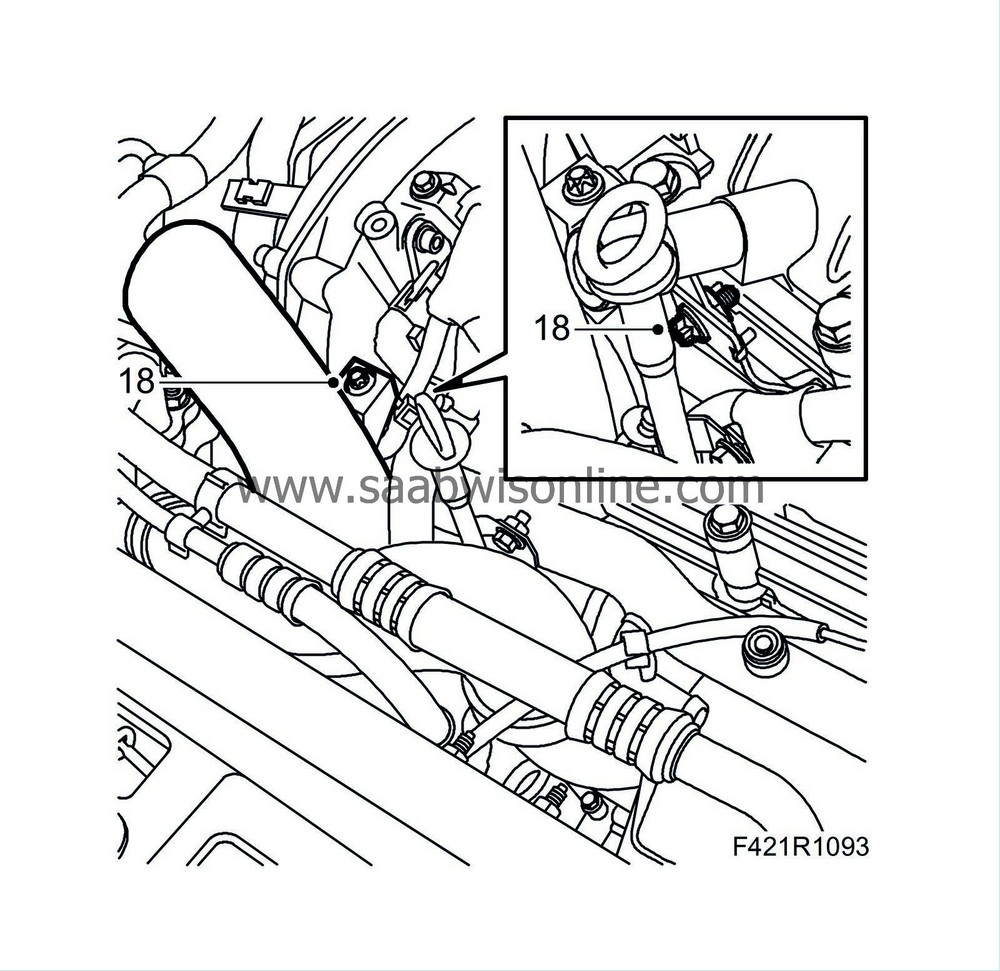

| 18. |

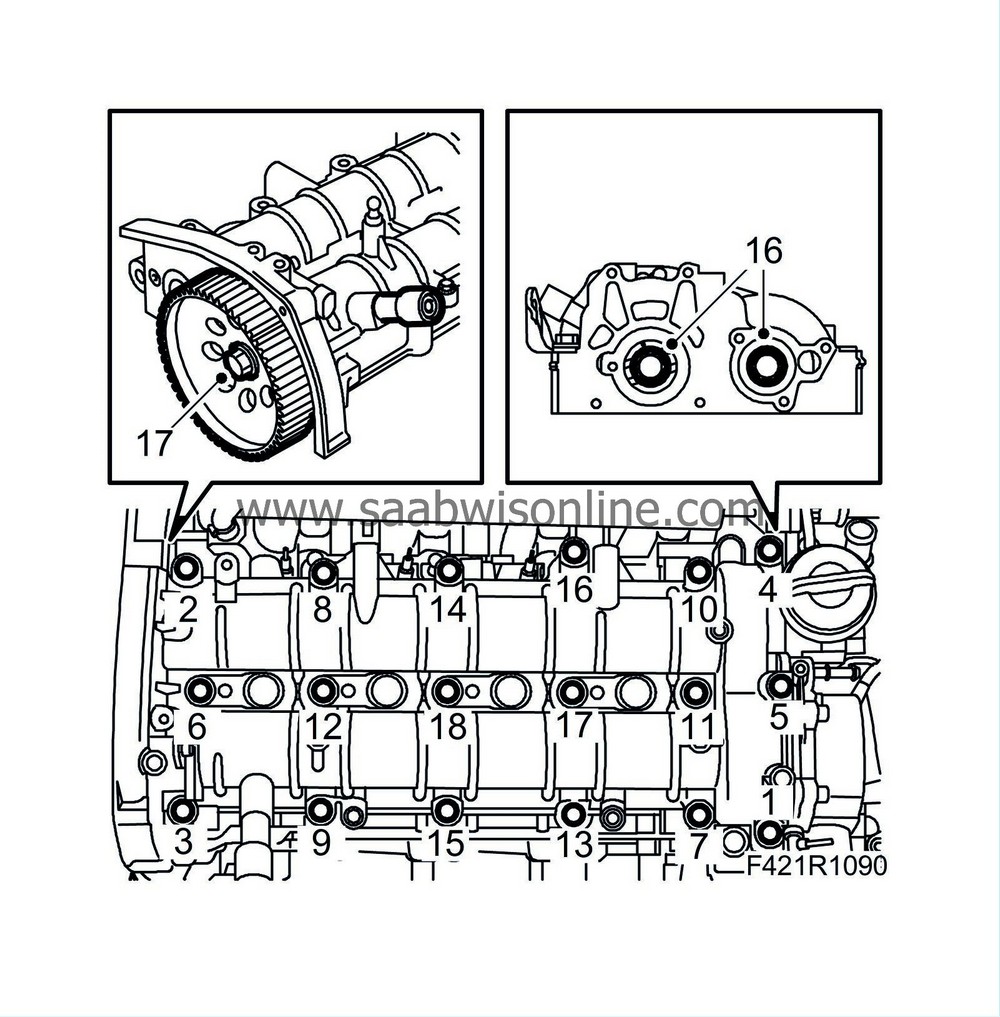

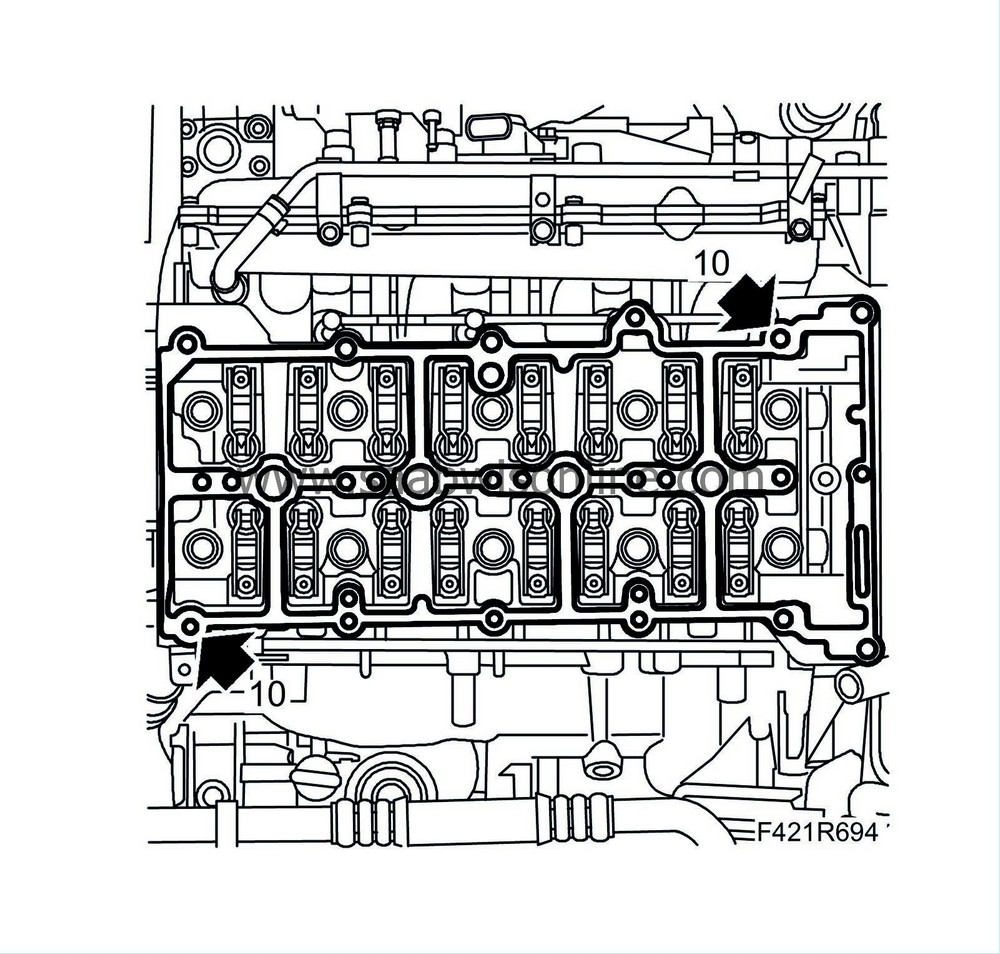

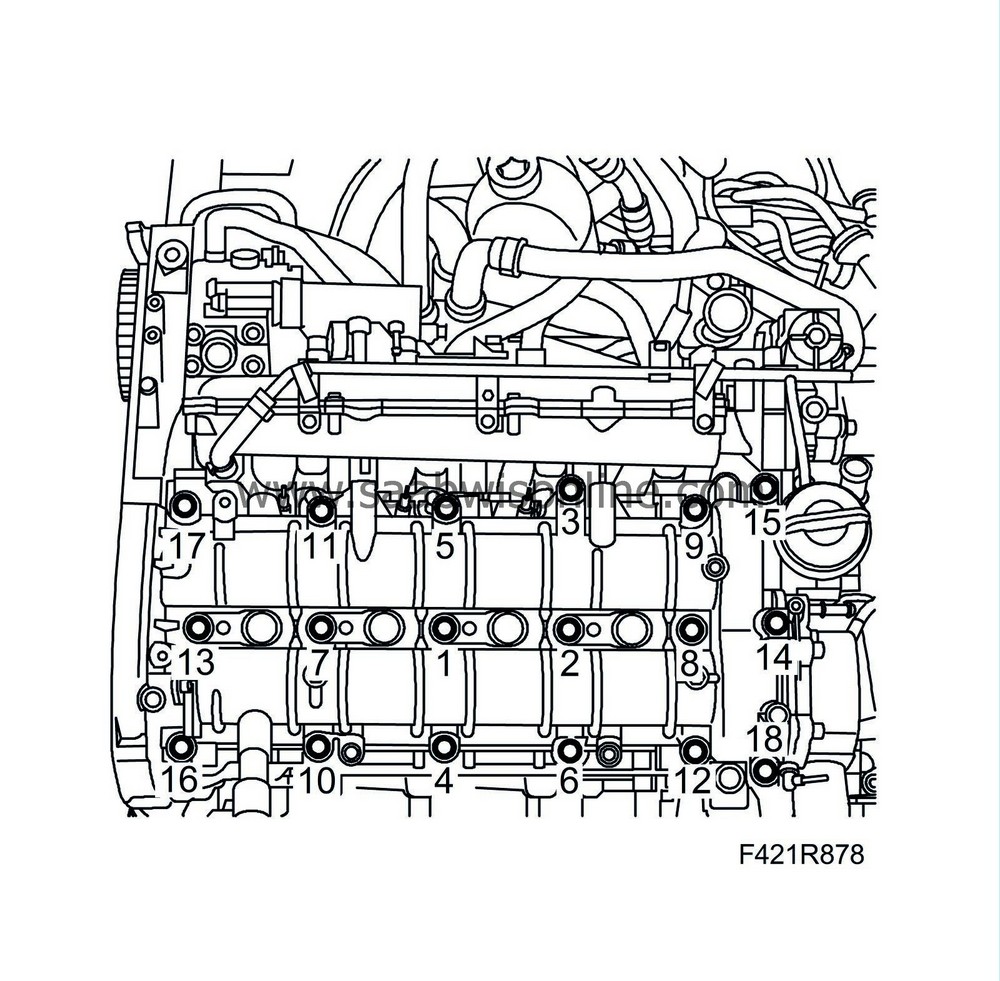

Undo and remove the camshaft housing and guide sleeves. Loosen bolts alternately as illustrated.

|

|

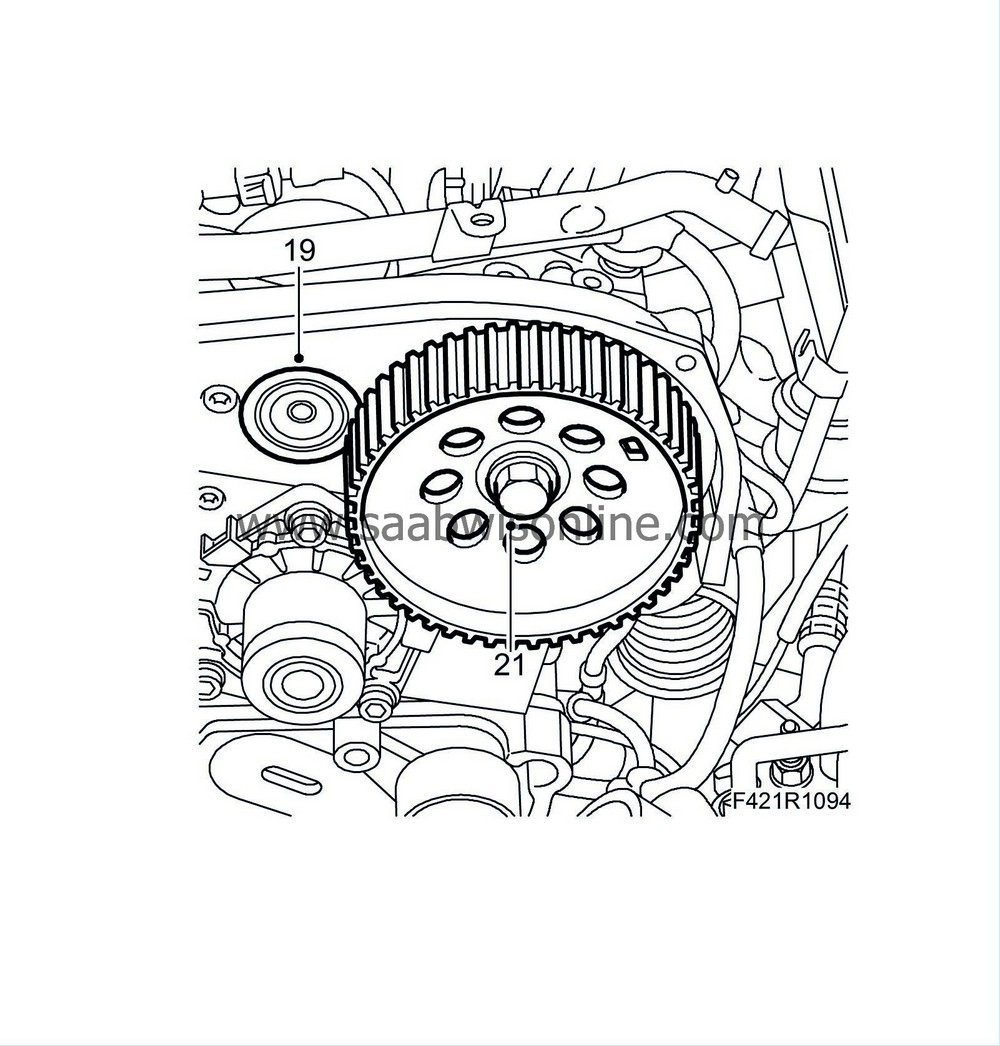

| 19. |

Remove the camshaft drive wheels.

|

|

| 20. |

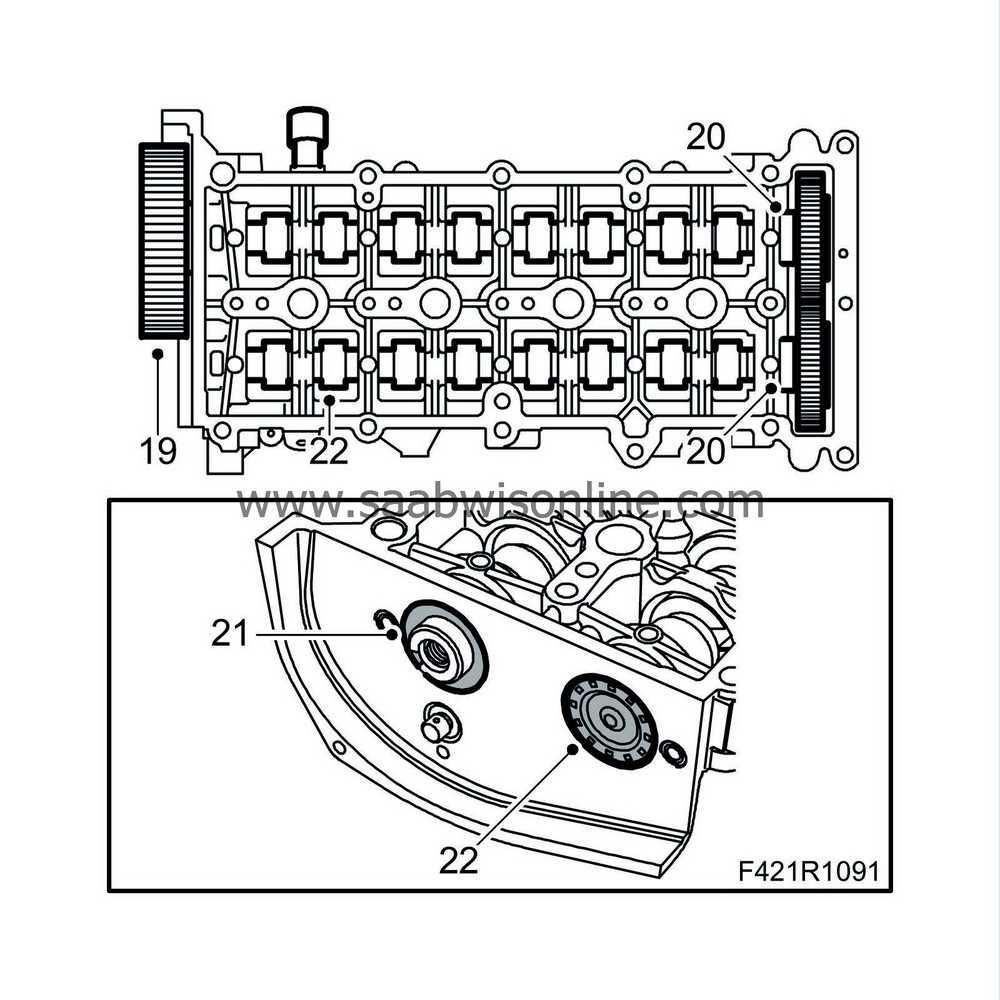

Remove the camshaft gears.

|

|

| 21. |

Remove the exhaust camshaft sealing ring with a suitable tool. Take care not to damage the sealing surface. Remove the exhaust camshaft.

|

|

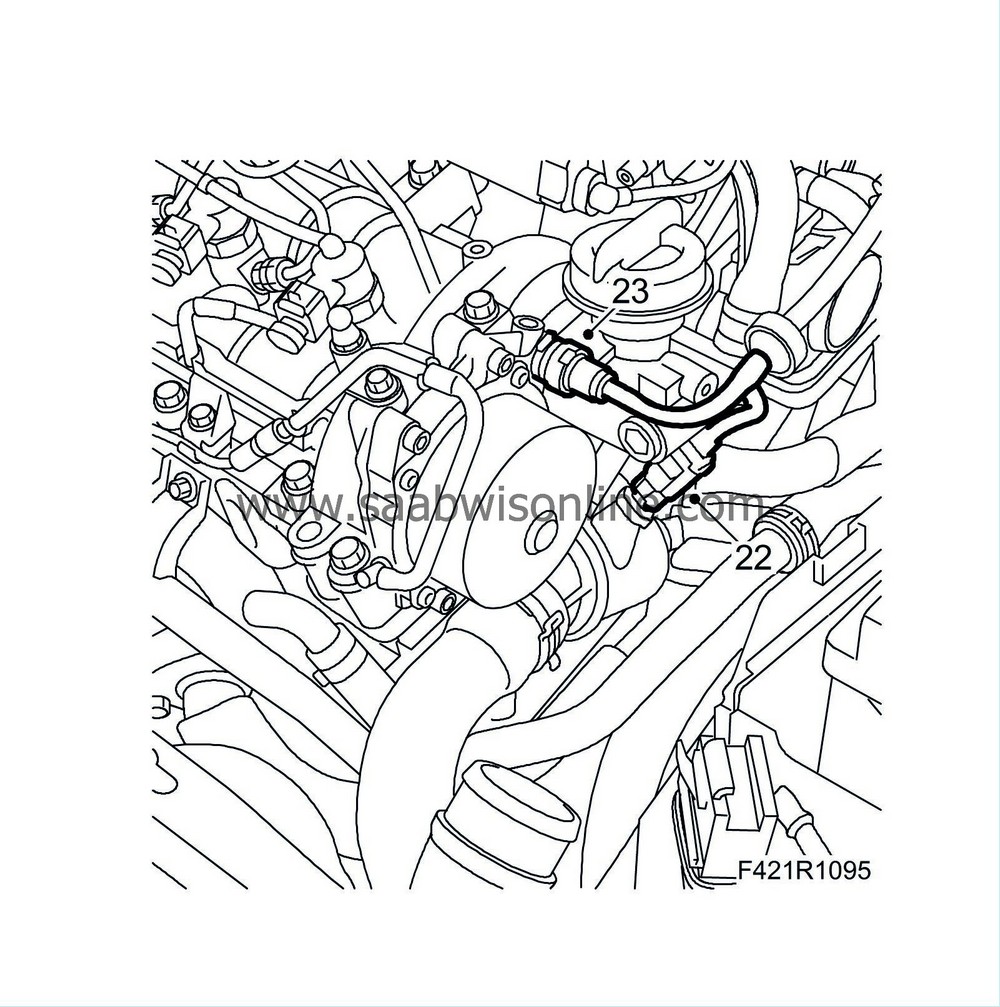

| 22. |

Press out the intake camshaft and the sealing plug.

|

|

| To fit |

| 1. |

Lubricate the bearing surfaces with engine oil. Fit the camshafts.

|

|

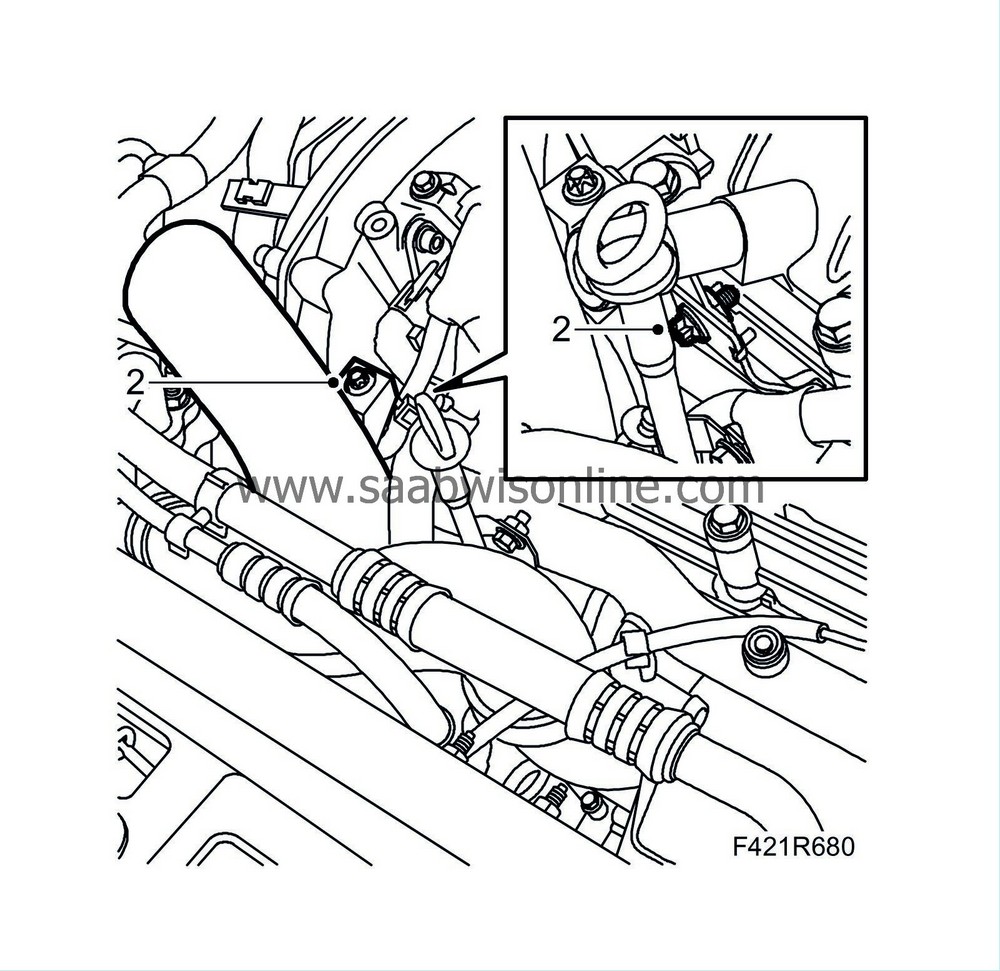

| 2. |

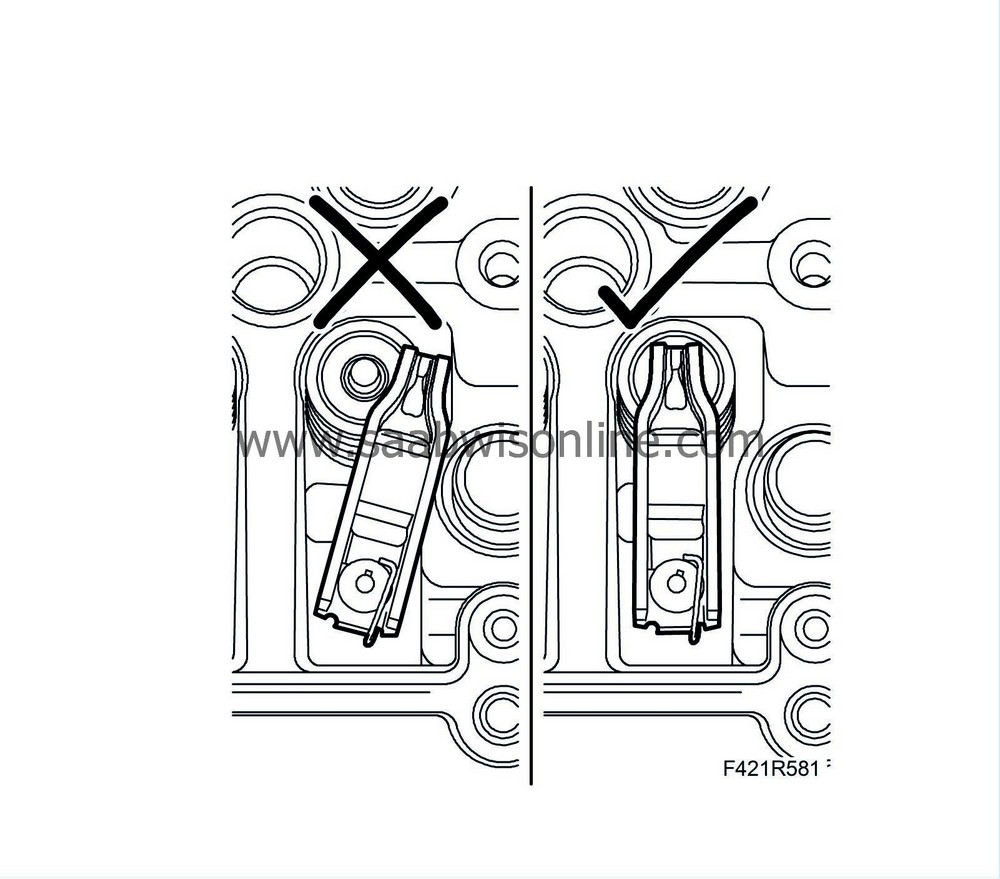

Lock both camshafts with

32 025 008 Fixing tool, camshaft

. Make sure the tool is fitted correctly, the reference pins must snap in audibly.

|

|

| 3. |

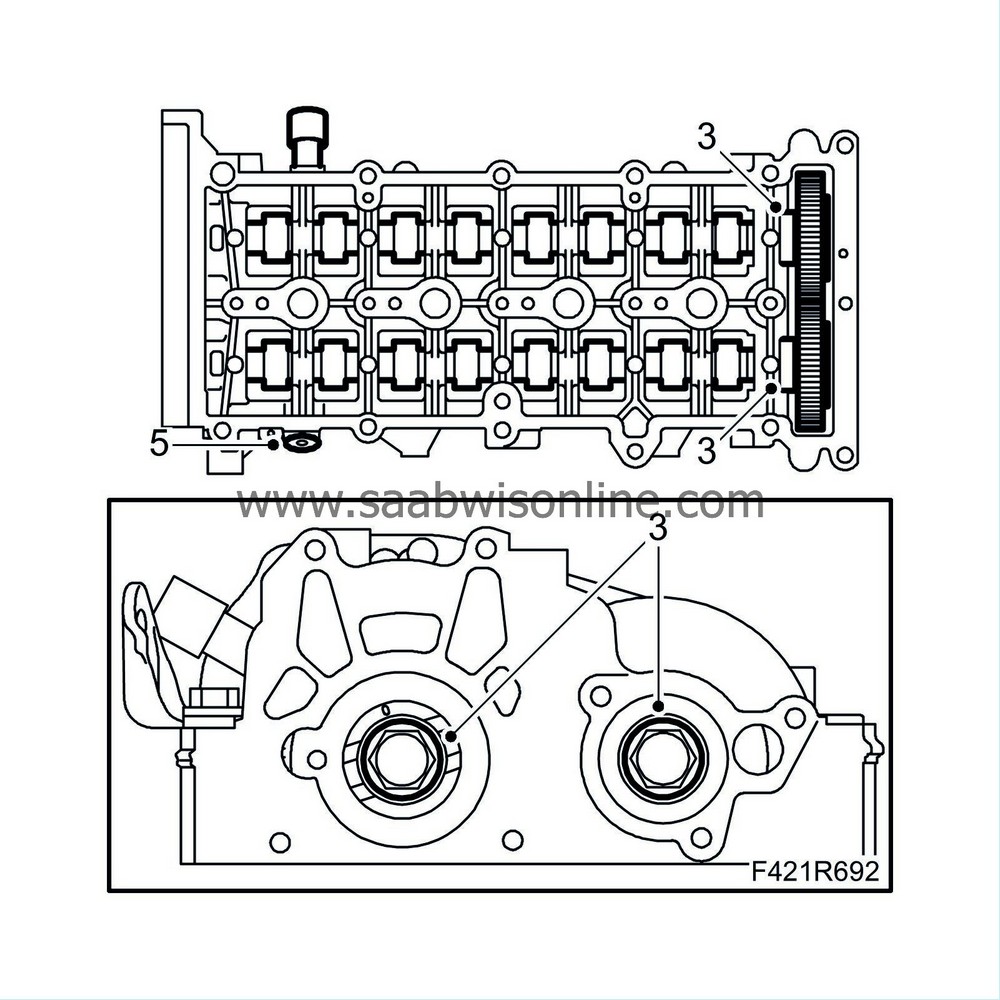

Fit the camshaft gear wheels. The gear wheel with dogs is to be mounted onto the exhaust camshaft.

Tightening torque 120 Nm (88 lbf ft)

|

|

| 4. |

Remove the fixing tool from the intake side.

|

|

| 5. |

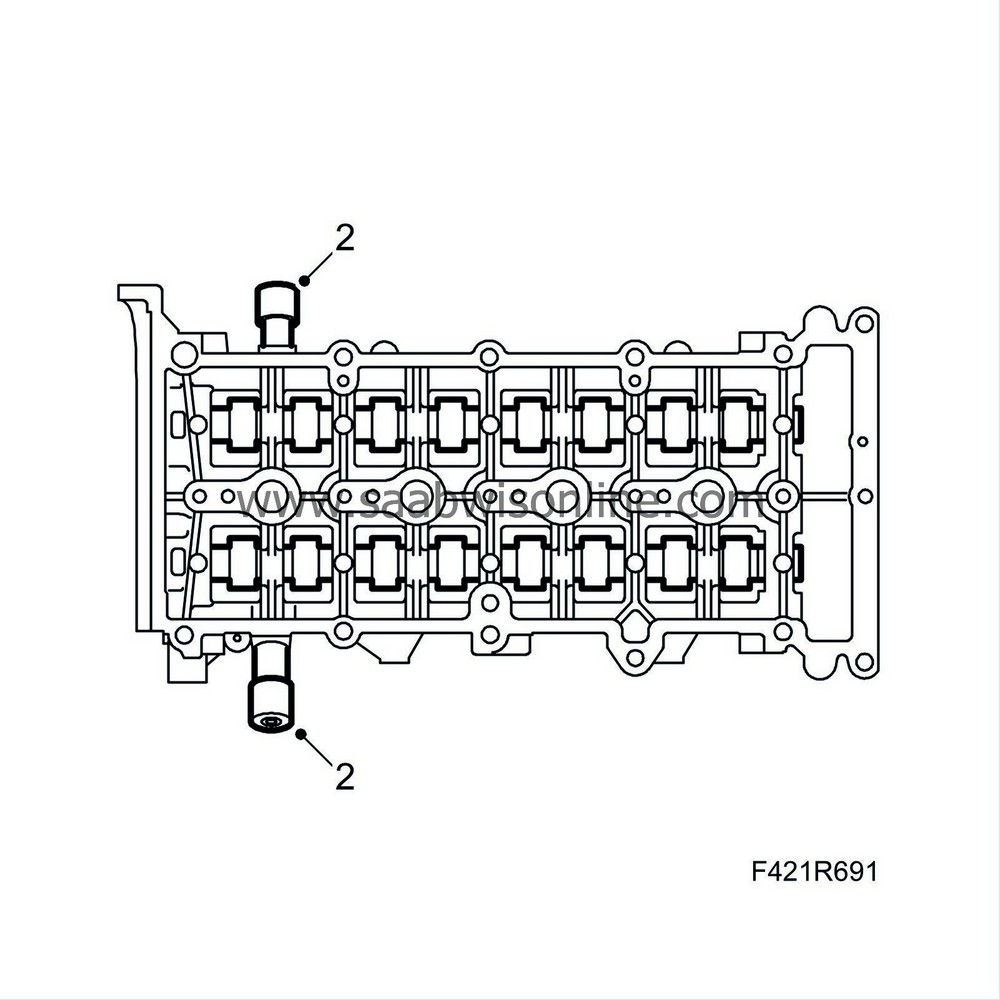

Fit the sealing plug with a new O-ring.

|

|

| 6. |

Clean the vacuum pump and oil filler pipe sealing surfaces.

|

|

| 7. |

Clean the cylinder head and camshaft housing sealing surfaces from any gasket residue.

|

|

| 8. |

Fit the vacuum pump with a new seal.

Tightening torque 9 Nm (7 lbf ft).

|

|

| 9. |

Fit the oil filler pipe with a new seal.

Tightening torque 9 Nm (7 lbf ft). |

|

| 10. |

Fit the guide sleeves and fit a new gasket onto the cylinder head.

|

||||||||||

| 11. |

Fit the camshaft housing, tighten the bolts alternately. Make sure the guide sleeves are positioned correctly in the camshaft housing.

Tightening torque 25 Nm (15 lbf ft).

|

|

| 12. |

Fit the fuel rail.

|

|||||||||||||

| 13. |

Fit

Injector (206), Z19DTH

.

|

|

| 14. |

Fit the fuel delivery pipe between the pump and the fuel rail.

Tightening torque 25 Nm (18 lbf ft).

|

|

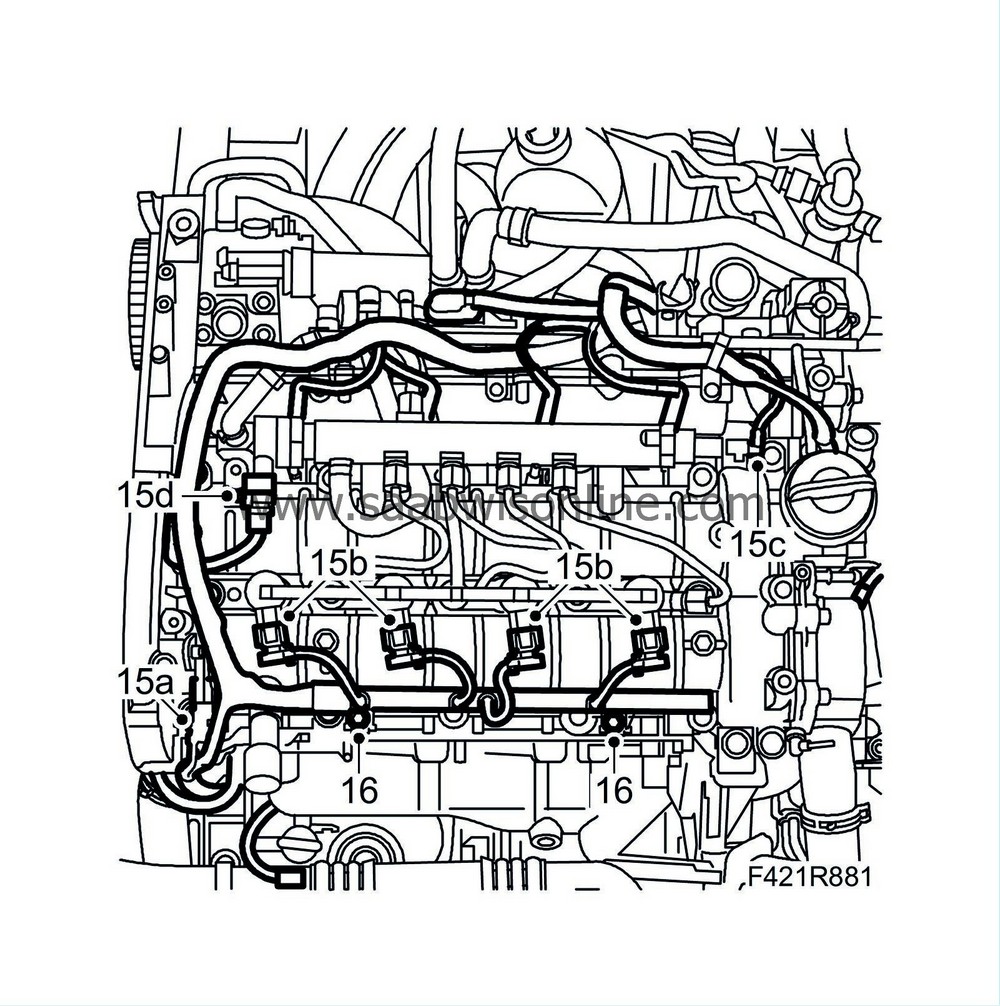

| 15. |

Fit the following connectors:

|

|

| 15.a. |

Camshaft position sensor (555)

|

| 15.b. |

Injectors (206)

|

| 15.c. |

Fuel pressure sensor (653)

|

| 15.d. |

Fuel pressure control valve (652a)

|

| 16. |

Fit the cable duct retaining screws and fix the wiring harness.

|

|

| 17. |

Fit the crankcase ventilation hoses onto the cylinder head.

|

|

| 18. |

Fit the vacuum pipe onto the camshaft housing and the oil trap bracket. Connect the hoses to the pump and turbocharger control valve.

|

|

| 19. |

Fit the bracket to the turbocharger intake pipe.

|

|

| 20. |

Fit the intake camshaft sealing plug.

|

|

| 21. |

Lubricate the sealing ring with

90 167 353 Silicone paste

. Fit the camshaft sealing ring with

32 025 050 Fitting tool, camshaft seal

.

|

|

| 22. |

Fit the camshaft drive wheels with new bolt. Screw in the bolt loosely so that it is pressing against the drive wheel but so the drive wheel can still be turned in relation to the exhaust camshaft. The exhaust camshaft must be locked with

32 025 008 Fixing tool, camshaft

.

|

|

| 23. |

Plug in the temperature sensor connector.

|

|

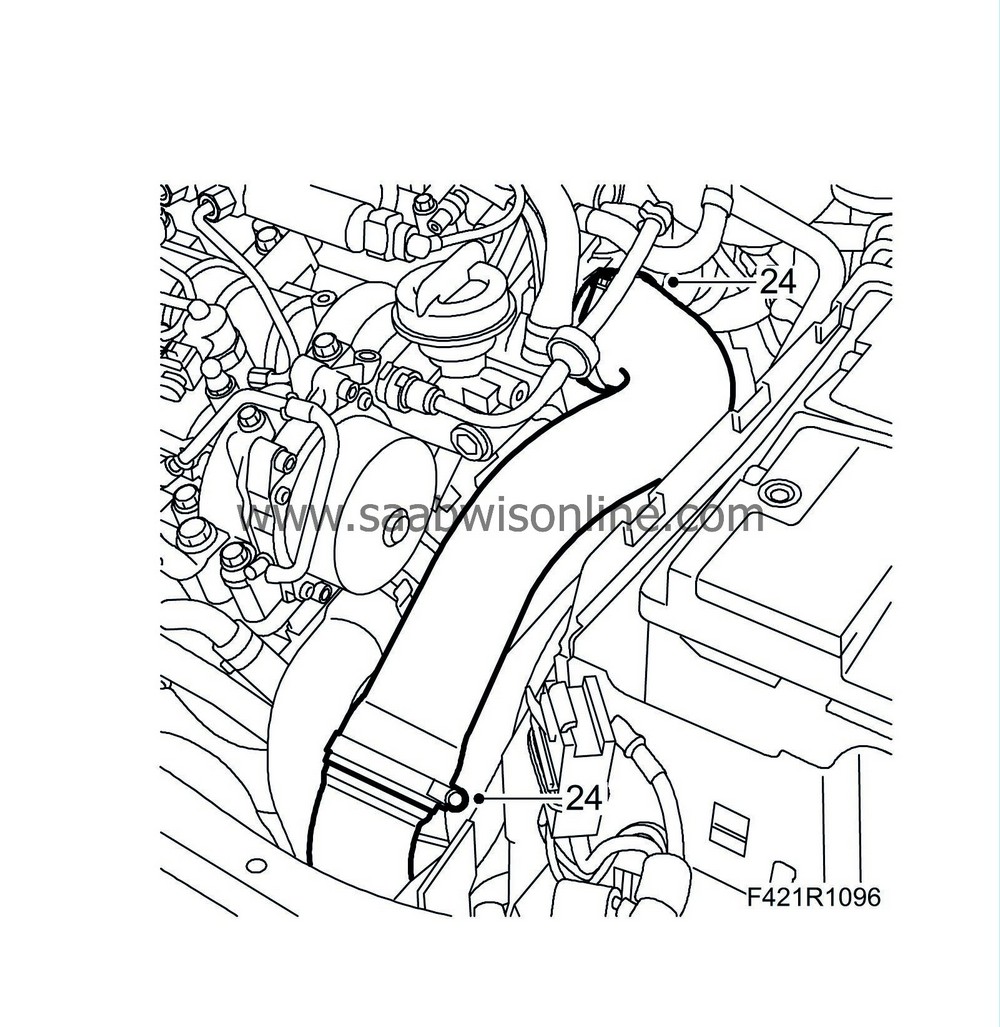

| 24. |

Fit the brake servo hose to the vacuum pump.

|

|

| 25. |

Fit the charge air hose.

Tightening torque 4 Nm (3 lbf ft)

|

|

| 26. |

Fit

Timing belt in-car Z19DTH

. Before removing

32 025 008 Fixing tool, camshaft

, tighten the bolt for the camshaft drive wheel after setting the timing belt. The drive wheel must not turn when the bolt is tightened.

Tightening torque 120 Nm (89 lbf ft). |

|

Warning

Warning