PRE-RELEASE

Gearbox assembly B284

| Gearbox assembly B284 |

| To remove |

| 1. |

When changing gearbox, perform

Before removing a control module

.

|

|

| 2. |

Place covers over the wings to keep the paintwork clean and protect it from damage.

|

|

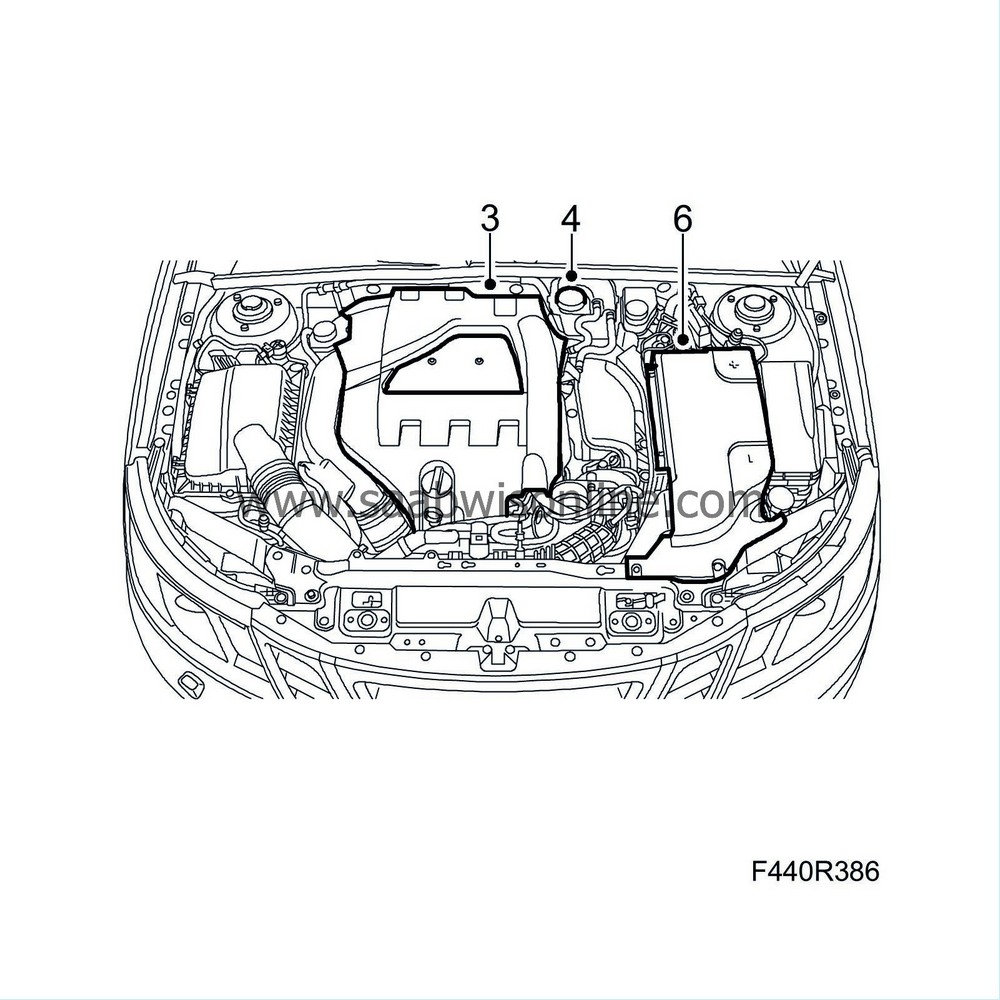

| 3. |

Remove the upper engine cover.

|

|

| 4. |

Undo the expansion tank cap to release any pressure.

|

|||||||||||||||

| 5. |

Remove the battery cover.

|

|

| 6. |

Remove the battery.

|

|

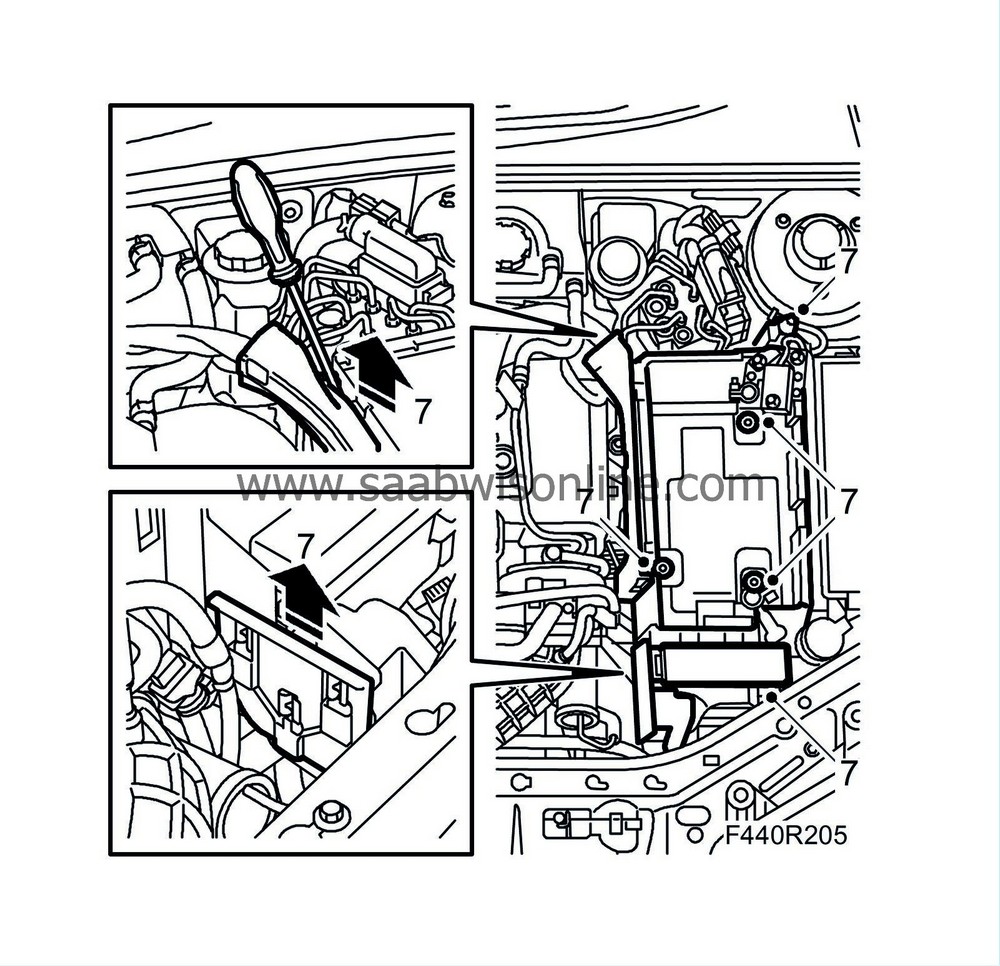

| 7. |

Remove the cable duct, bonnet switch electrical connection and the electrical centre from the battery tray. Remove the battery tray.

|

|

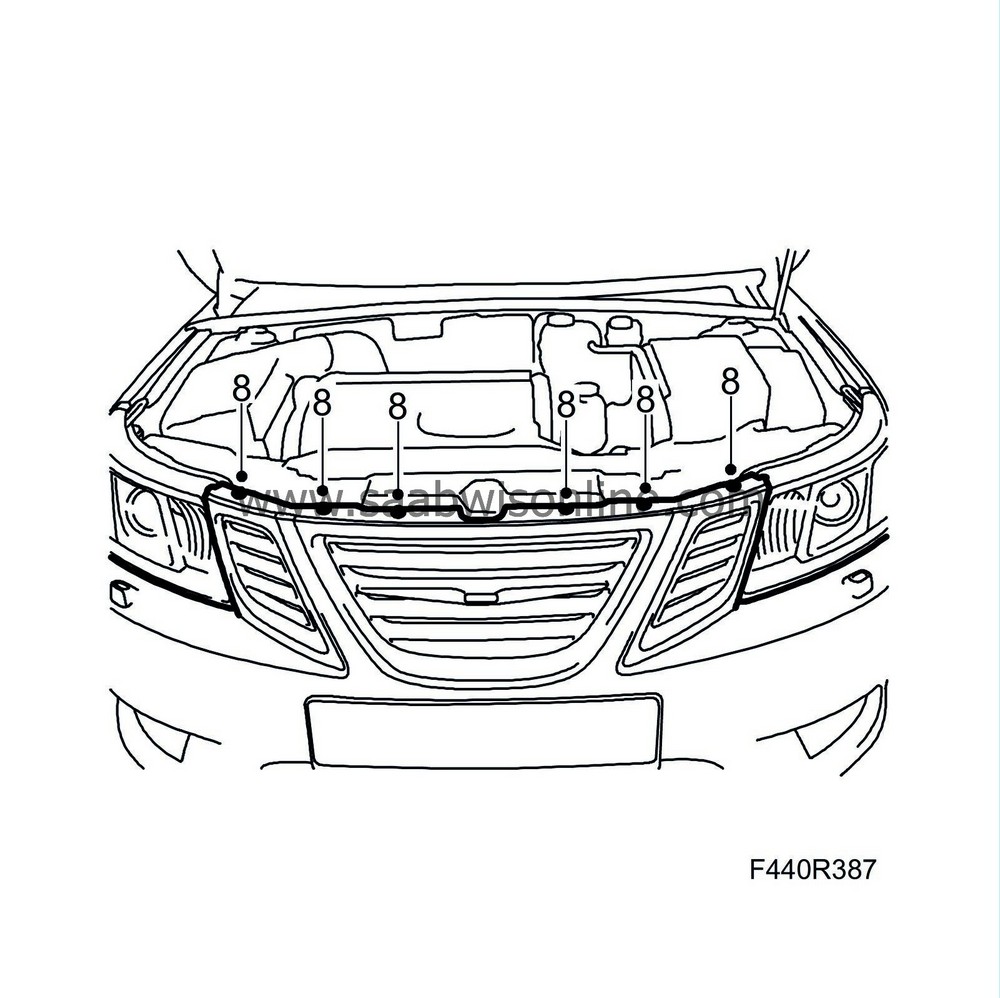

| 8. |

Undo the upper bumper shell mountings.

|

|

| 9. |

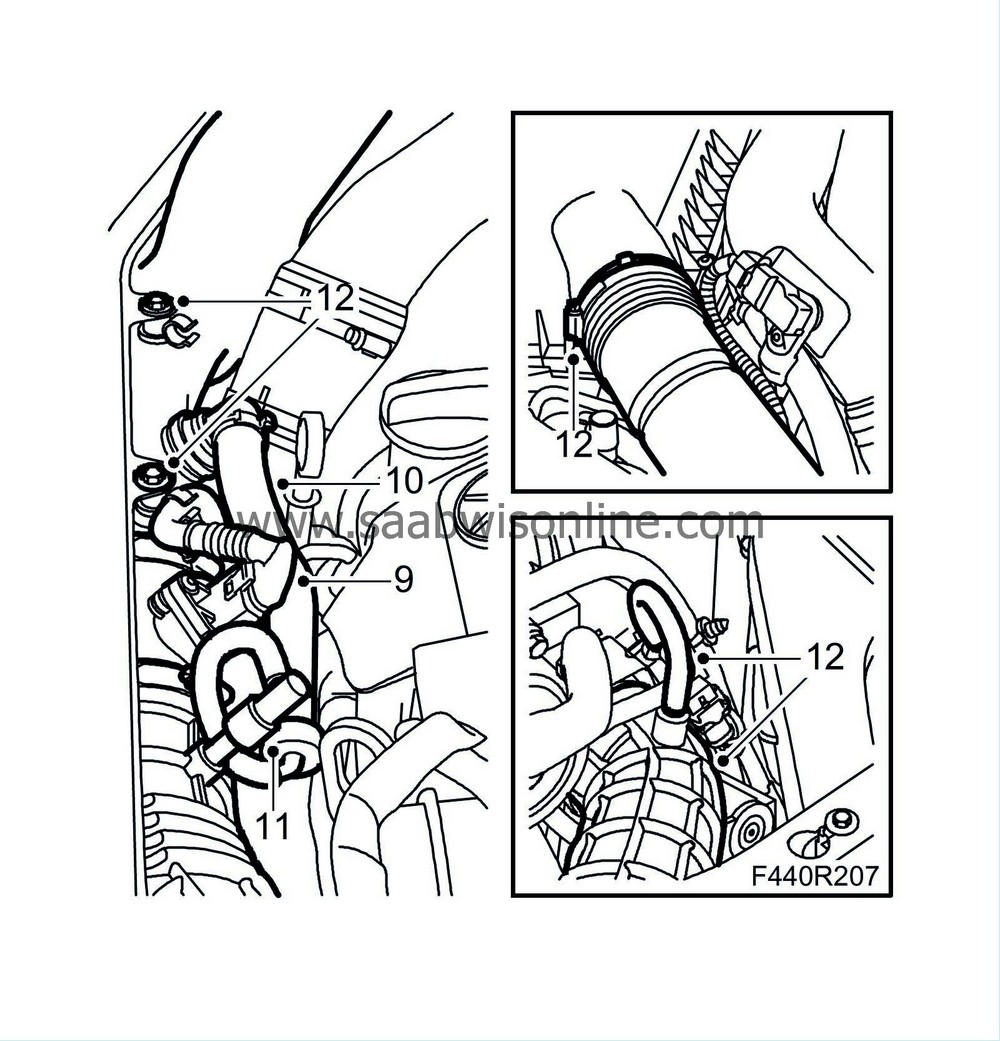

Remove the mass air flow sensor connector.

|

|

| 10. |

Remove the hose from the secondary air injection pump plus the vacuum hoses.

|

|

| 11. |

Remove the air filter cover and the hose of the mass air flow sensor.

|

|

| 12. |

Remove the mass air flow sensor and the hoses of the turbocharger.

|

|

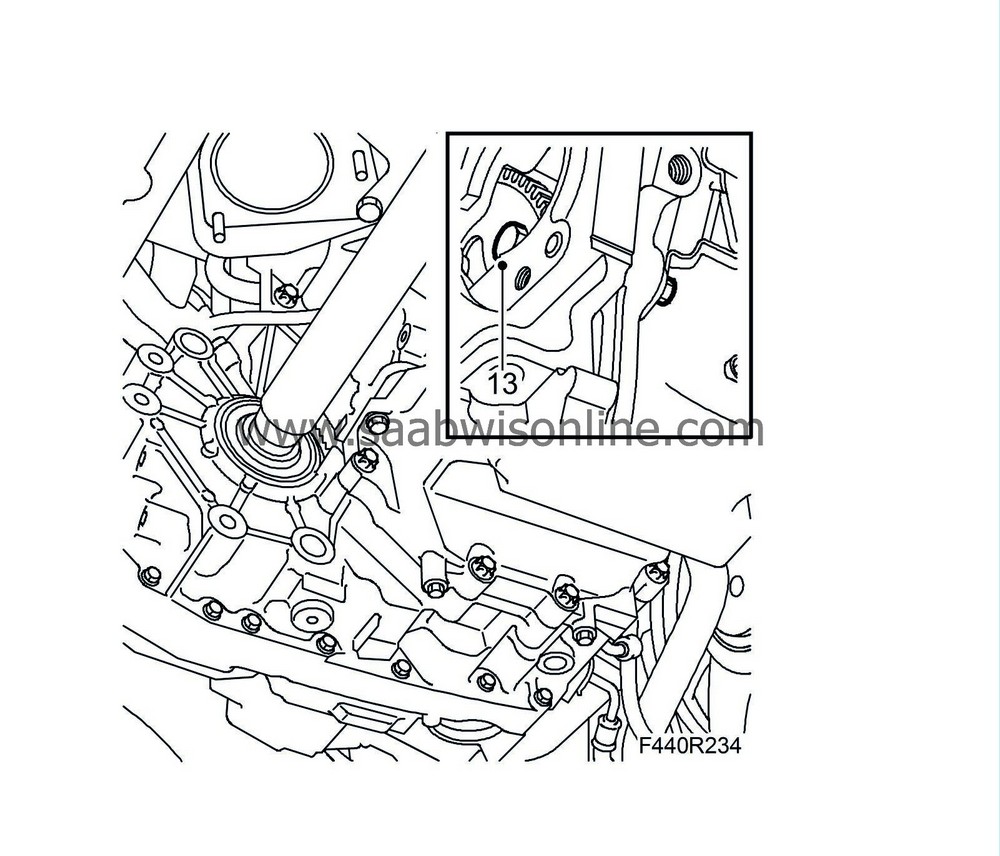

| 13. |

Suspend two

83 95 212 Strap

in place above the radiator core so they are accessible from below.

|

|

| 14. |

Raise the car.

|

|

| 15. |

Drain the coolant. See

Draining the cooling system

.

|

|

| 16. |

Remove the front wheels.

|

|

| 17. |

Remove the spoiler shield.

CV:

Remove

Chassis reinforcement, front subframe, CV

|

|

| 18. |

Secure the radiator core with the straps.

|

|

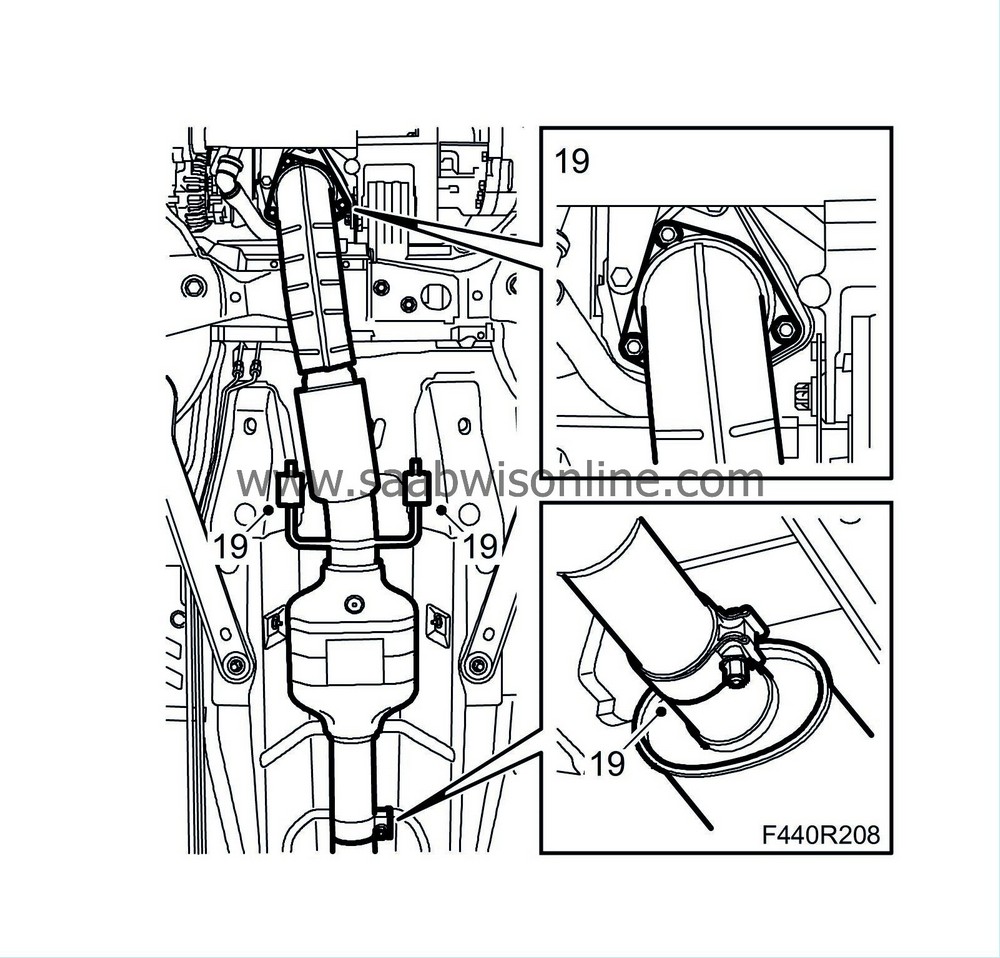

| 19. |

Remove the rear catalytic converter.

|

||||||||||

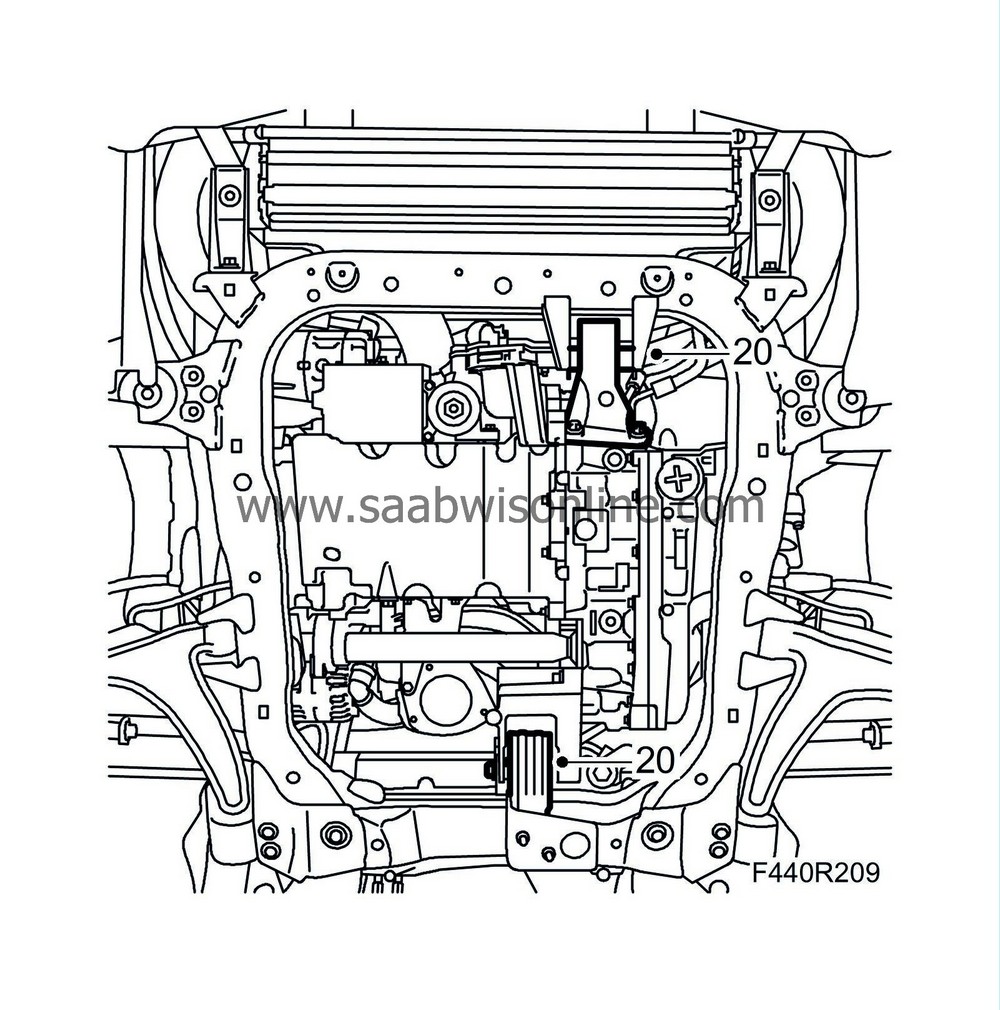

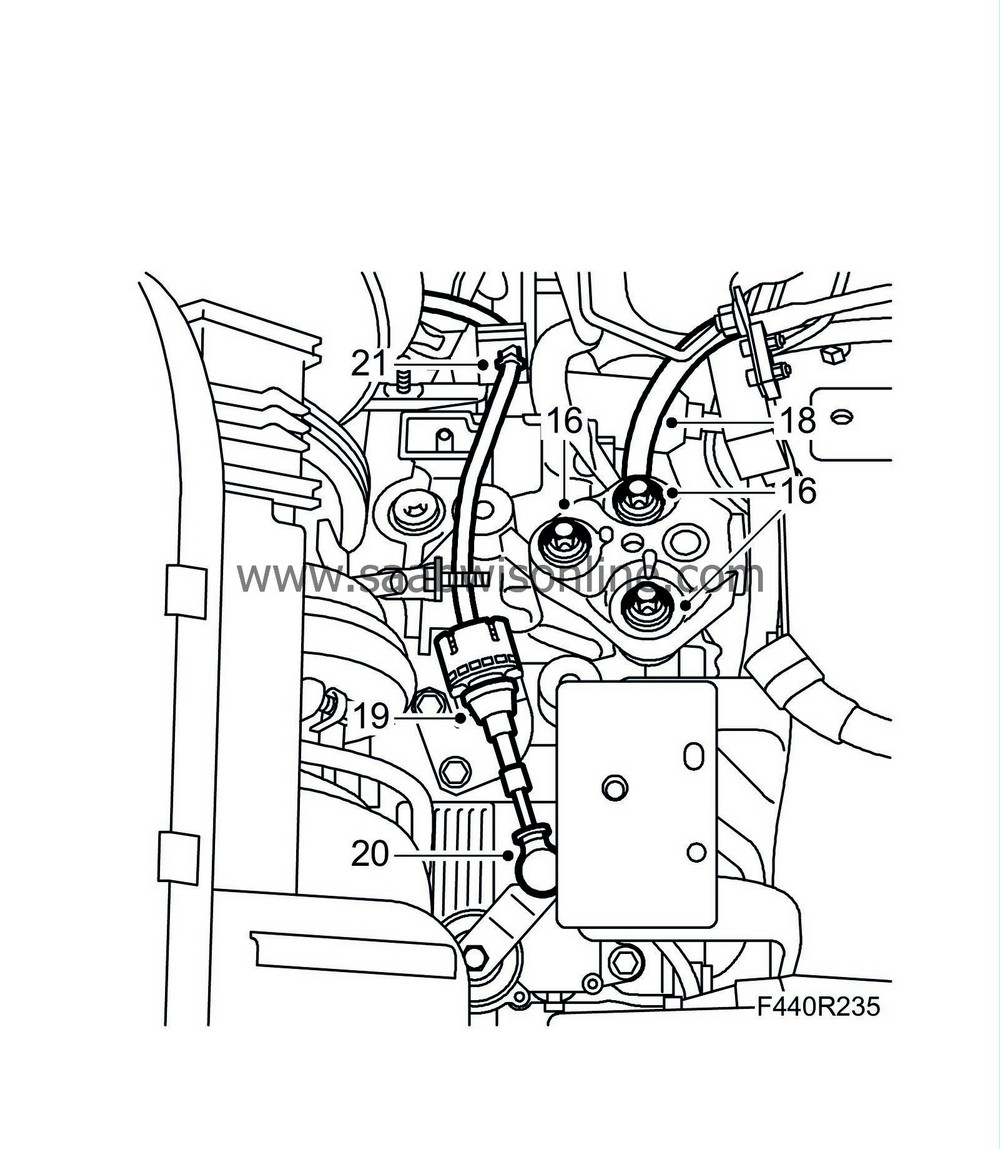

| 20. |

Remove the engine torque rod from the subframe.

|

|

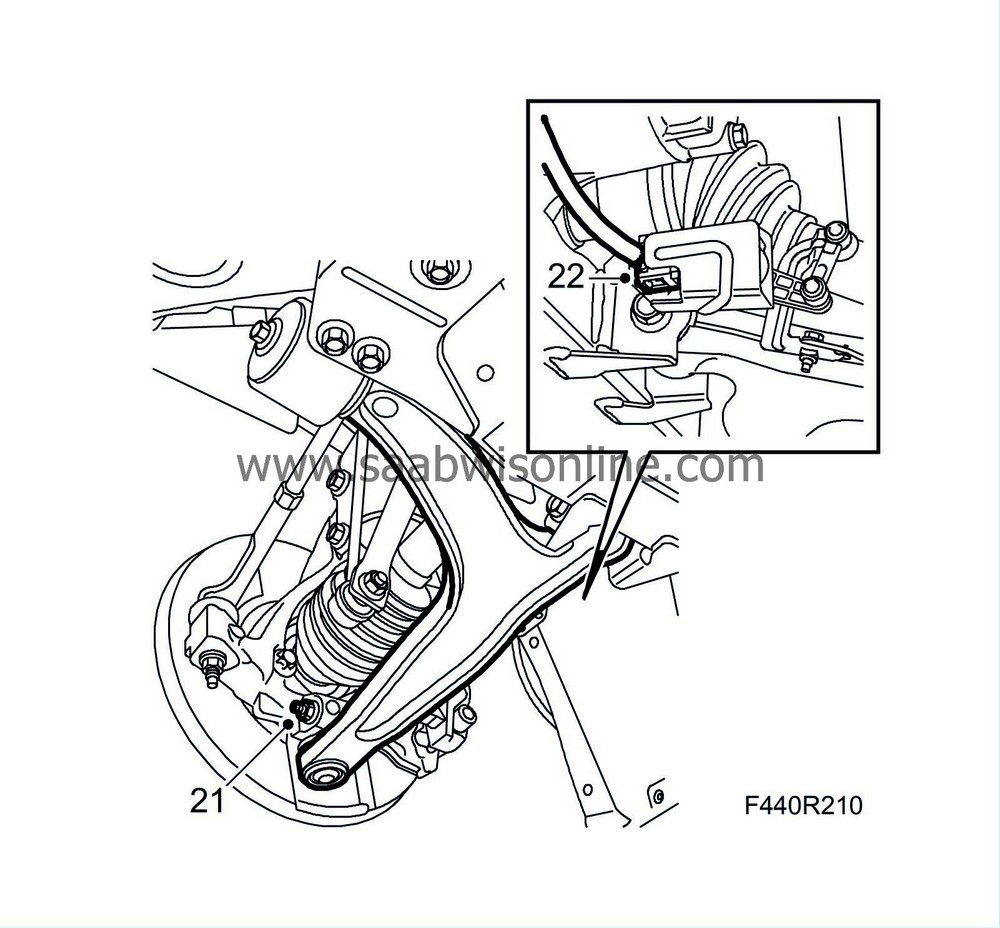

| 21. |

Remove the bolt and nut holding the suspension arm to the steering swivel member on both sides.

|

|

| 22. |

Unplug the connector and detach the cable clip of the headlamp angle sensor (option)

|

|

| 23. |

Remove the front part of the wing liner and bend it out of the way.

|

|

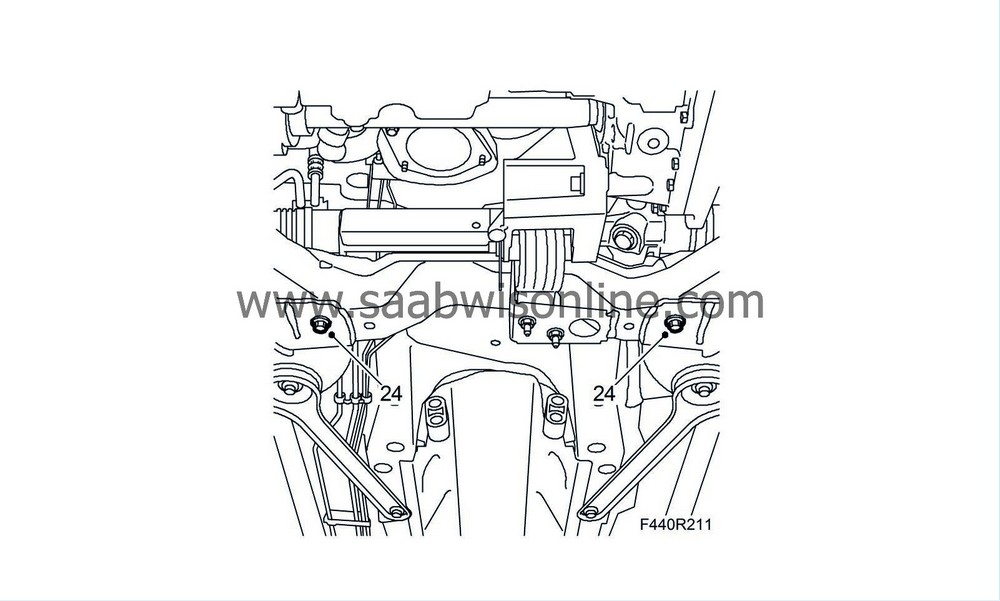

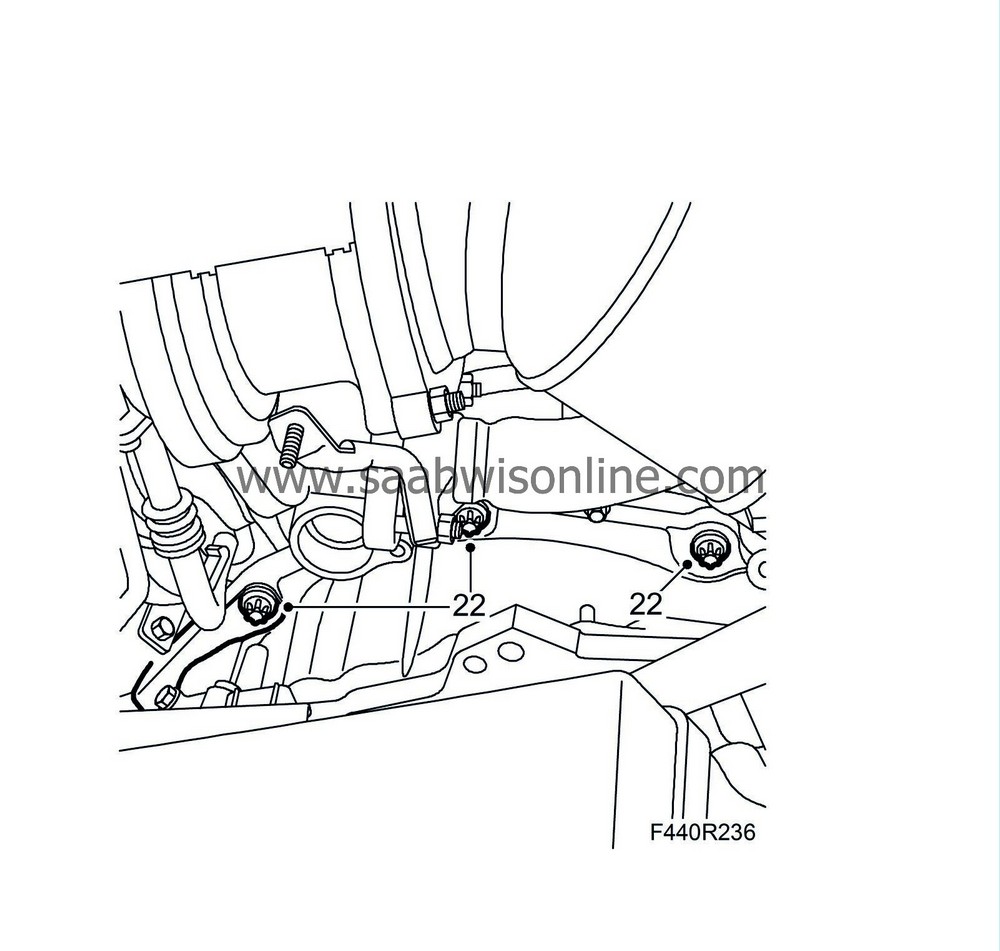

| 24. |

Remove the steering gear from the subframe. Keep the nuts and washers safe. Leave the steering gear hanging.

|

|

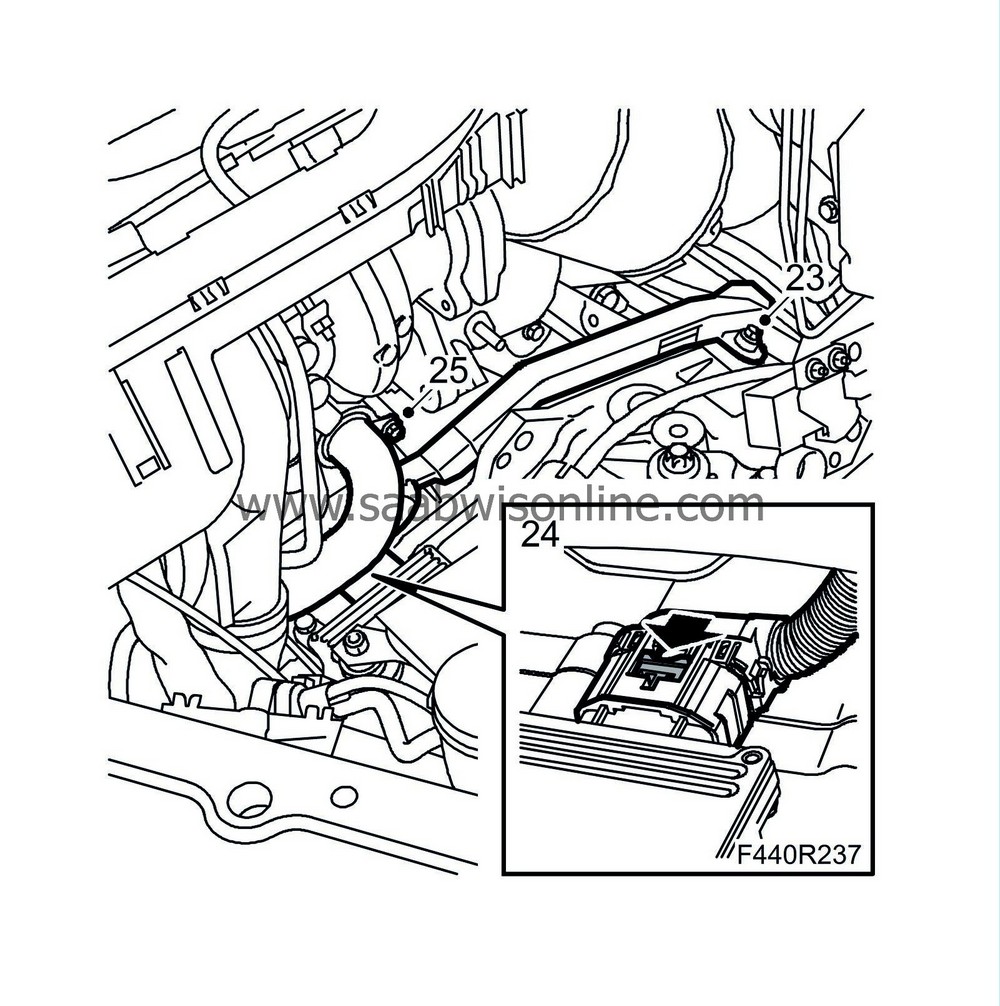

| 25. |

Open the clamps holding the power steering pipe to the subframe.

|

|

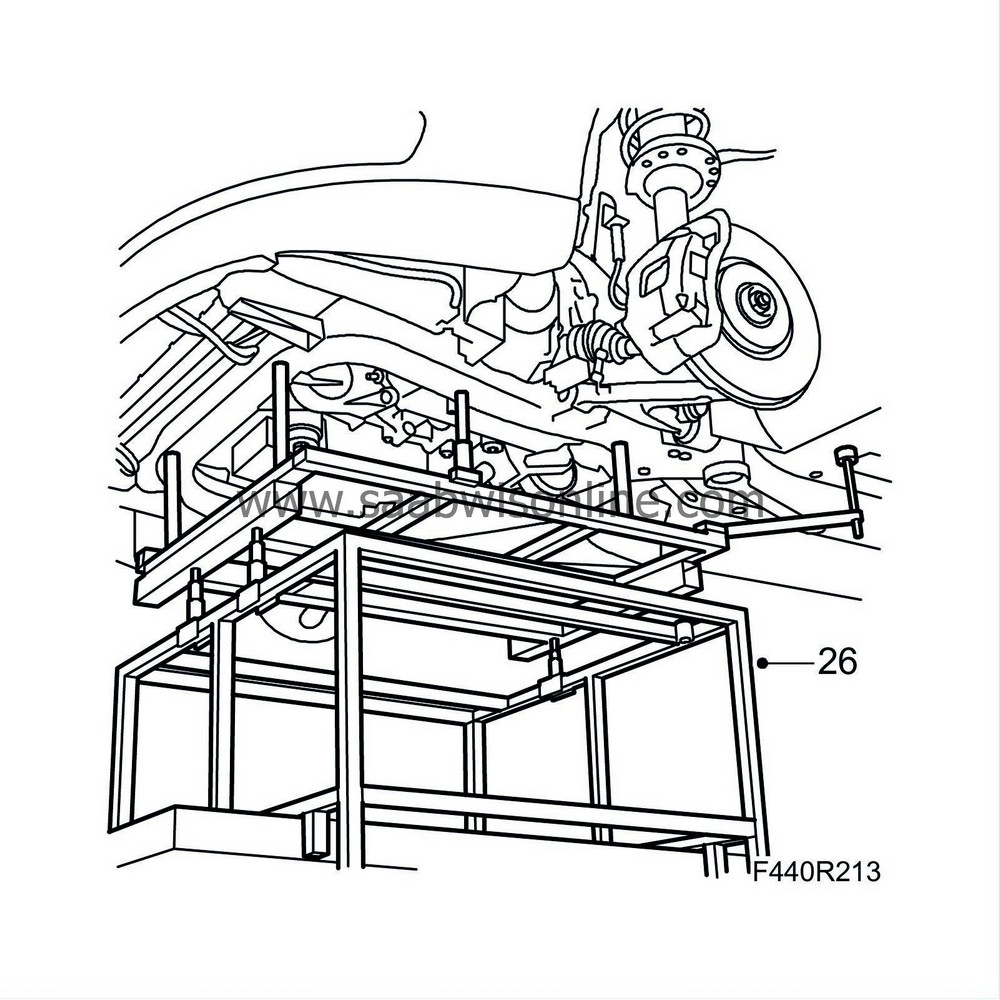

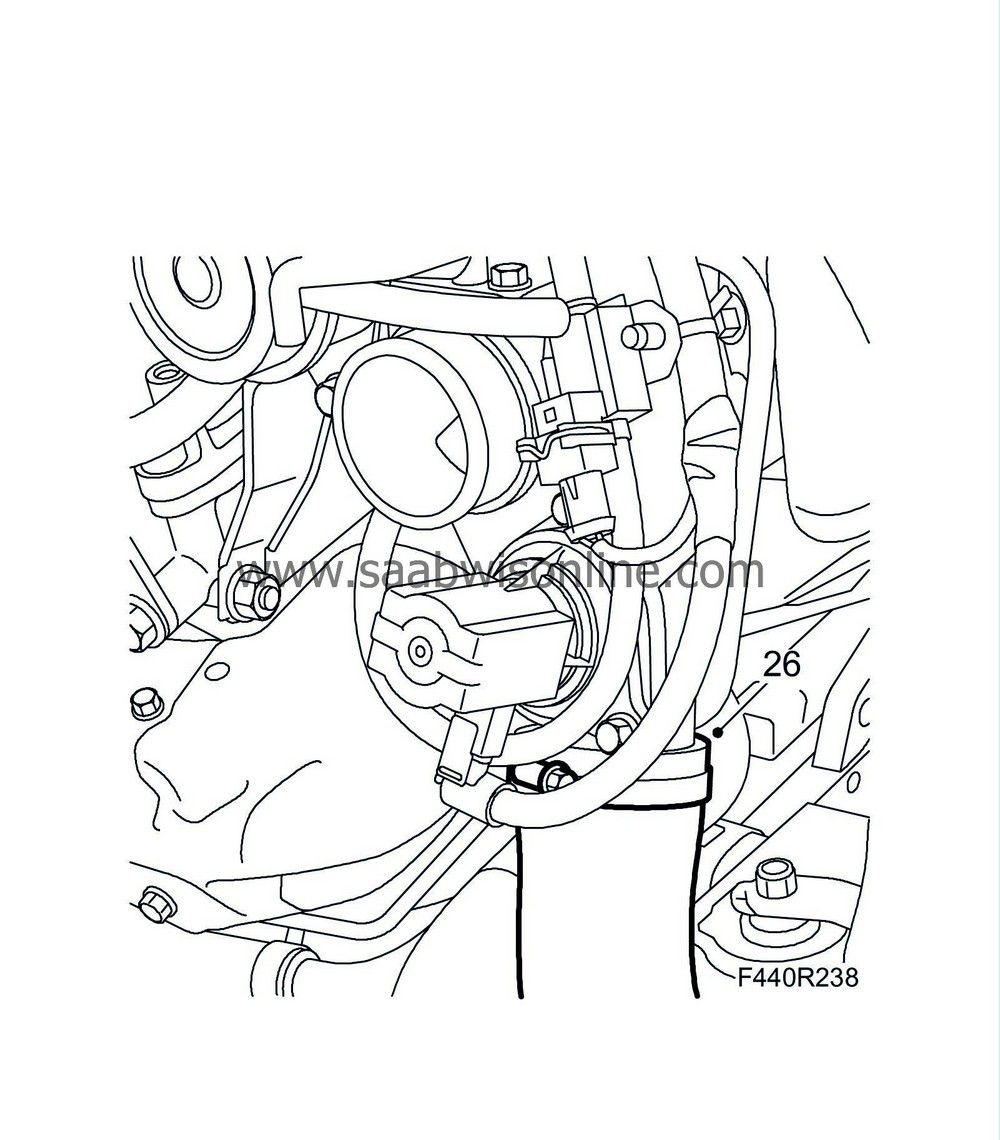

| 26. |

Place

83 95 311 Trolley lift

under the vehicle. Fit

83 94 801 Parent fixture

,

83 95 188 Basic fixture

,

83 95 170 Adapter

(4 pcs) and

83 96 137 Centring tool, subframe - body

. Position the locating pins and adjust the height of the adapters for even pressure.

|

|

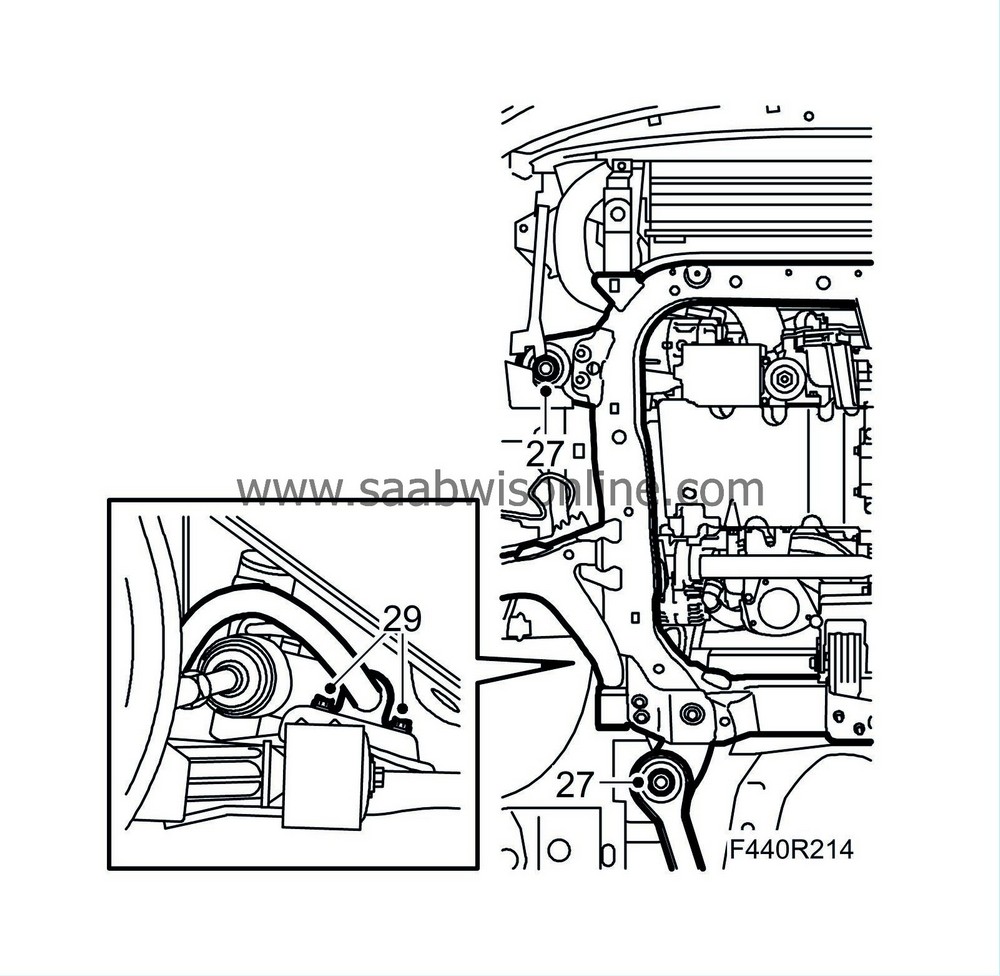

| 27. |

Remove the subframe bolts and the rear brackets.

|

|

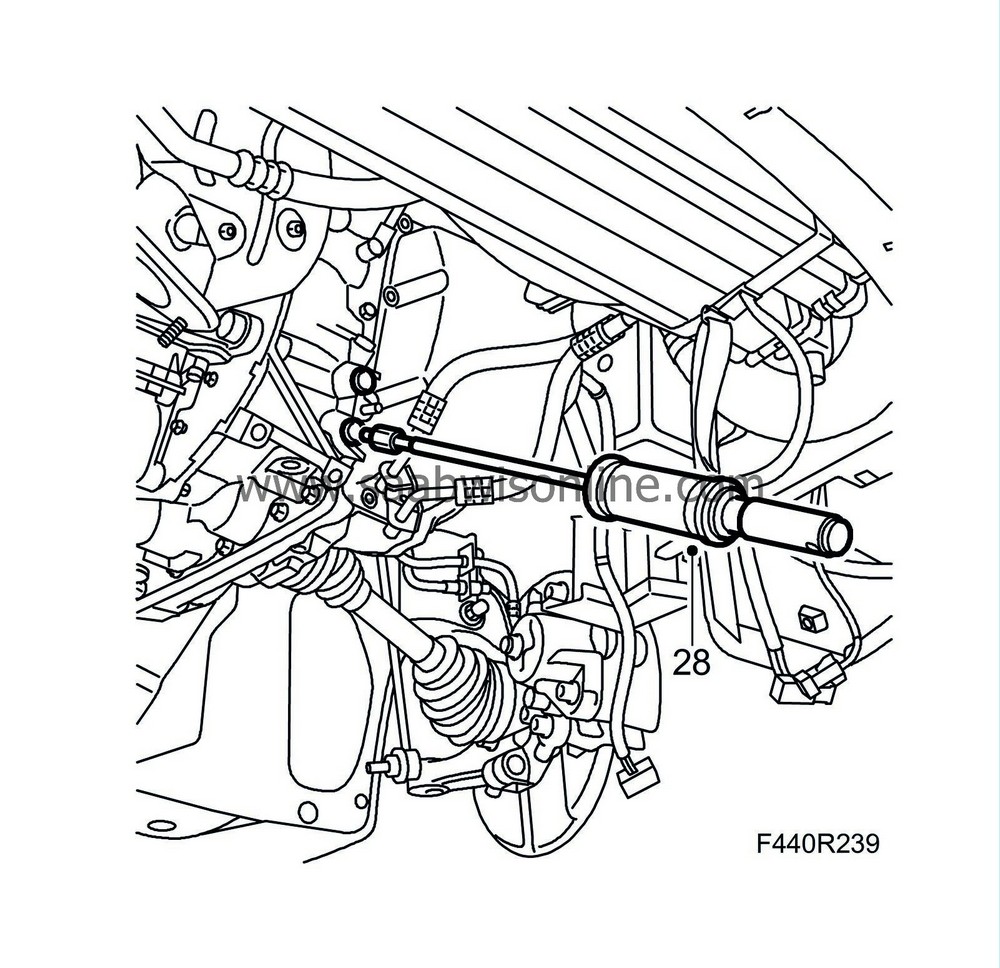

| 28. |

Lower the subframe slightly.

|

|

| 29. |

Remove the anti-roll bar from the subframe.

|

|

| 30. |

Pull out the steering arm ball joints from the steering swivel members.

|

|

| 31. |

Lower the subframe and move away the trolley lift.

|

|

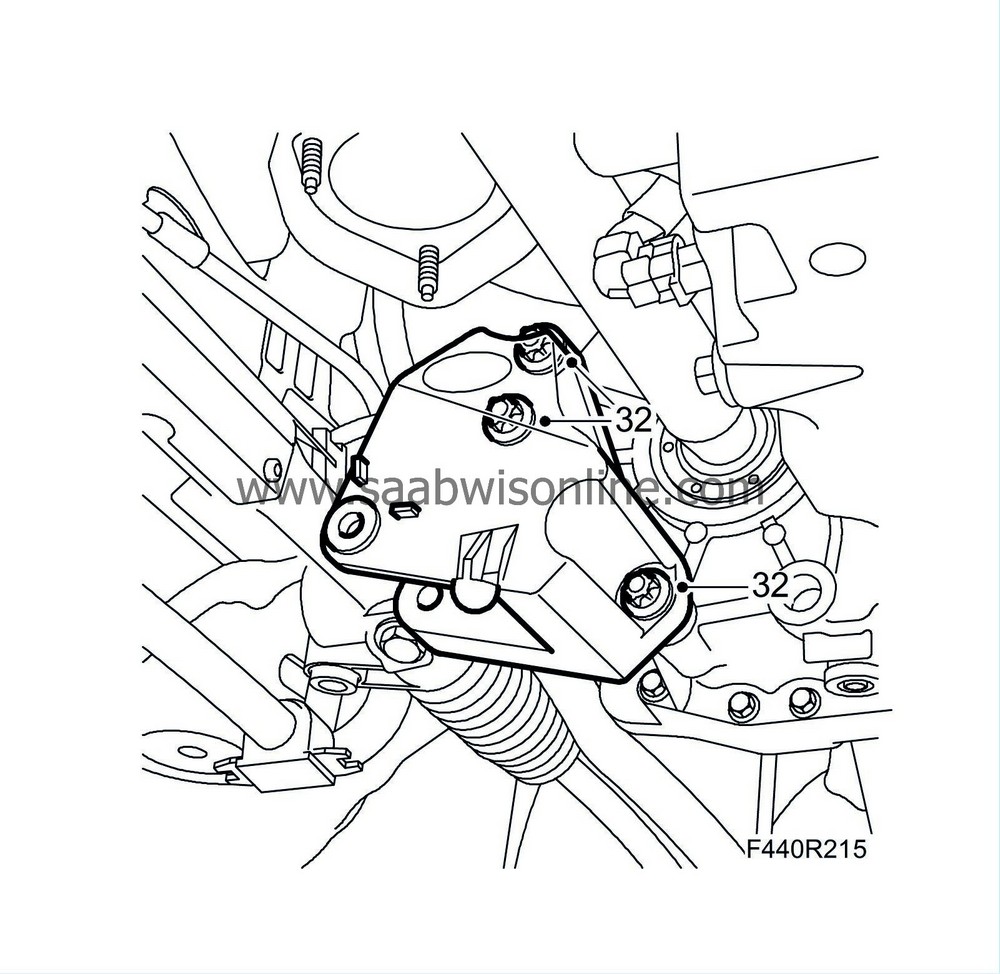

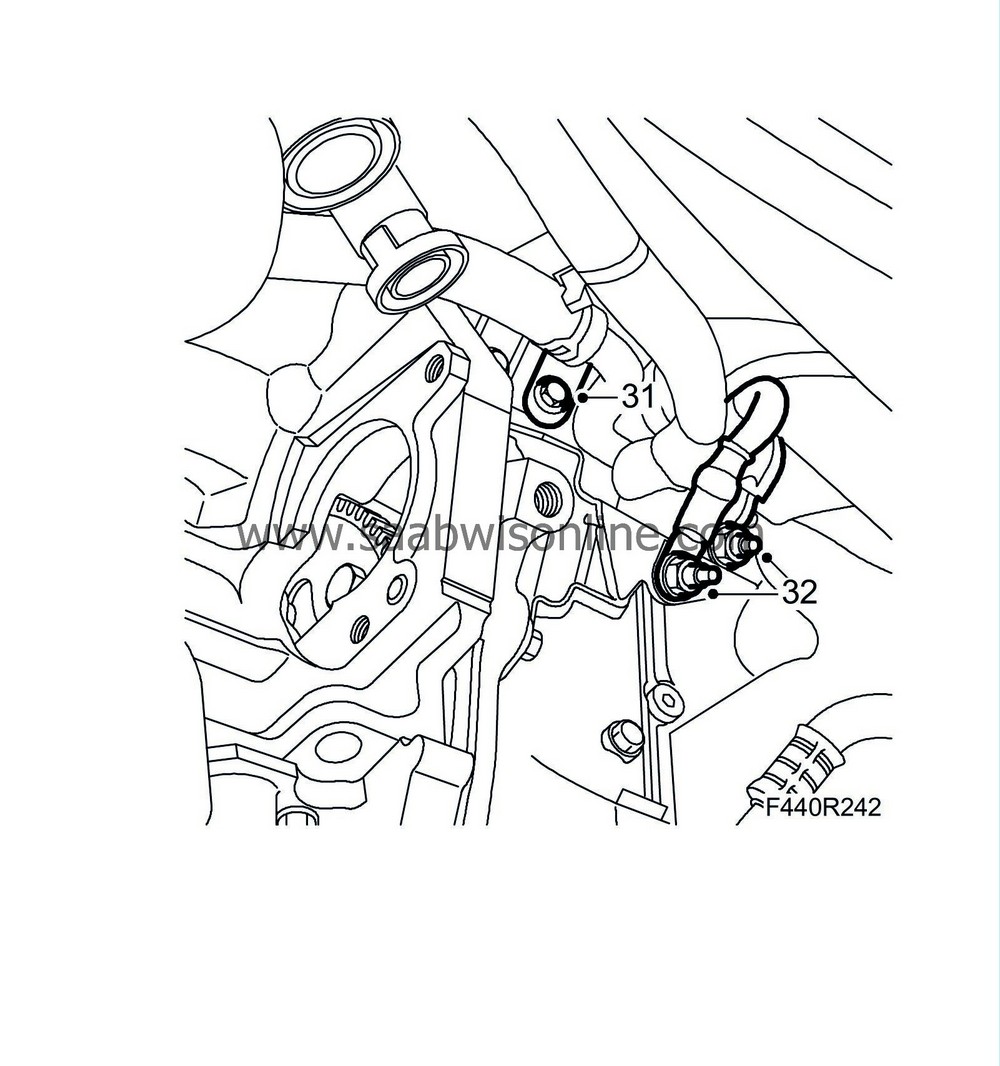

| 32. |

Remove the rear torque rod bracket from the gearbox.

|

|

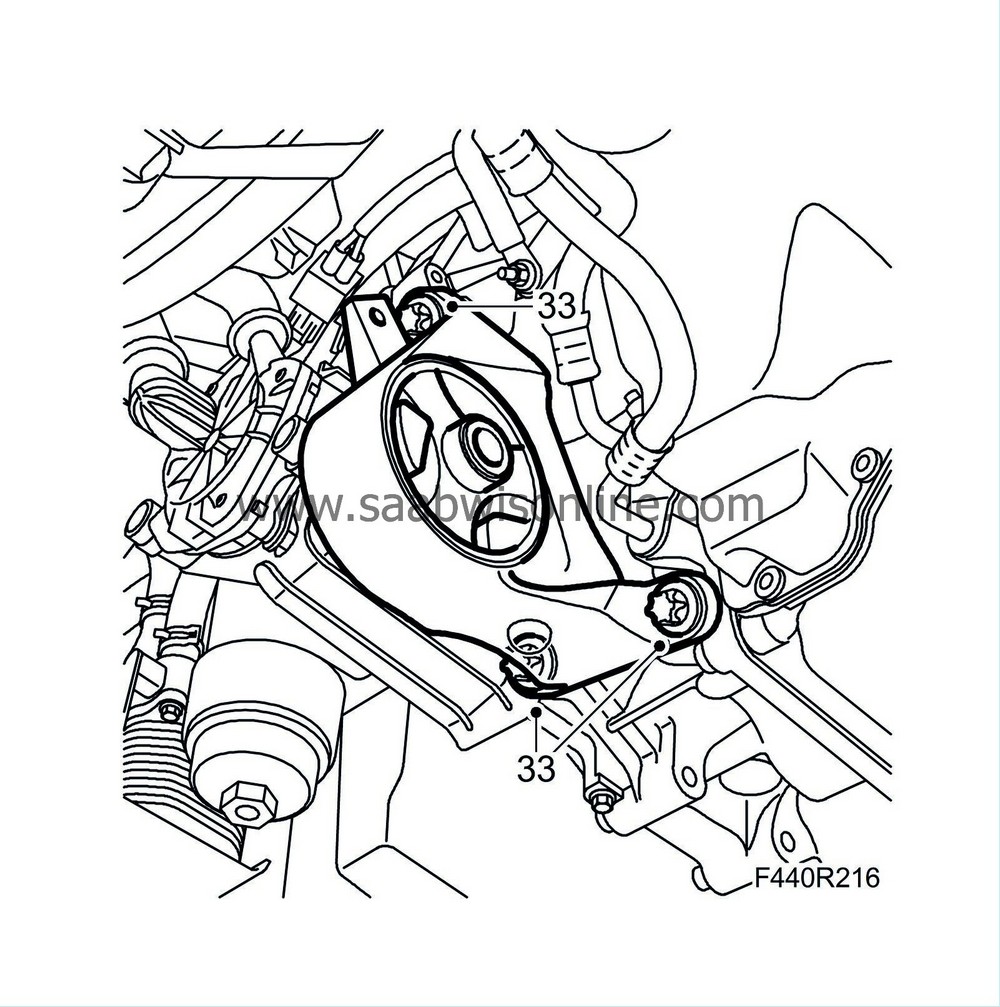

| 33. |

Remove the front torque rod bracket from the gearbox.

|

|

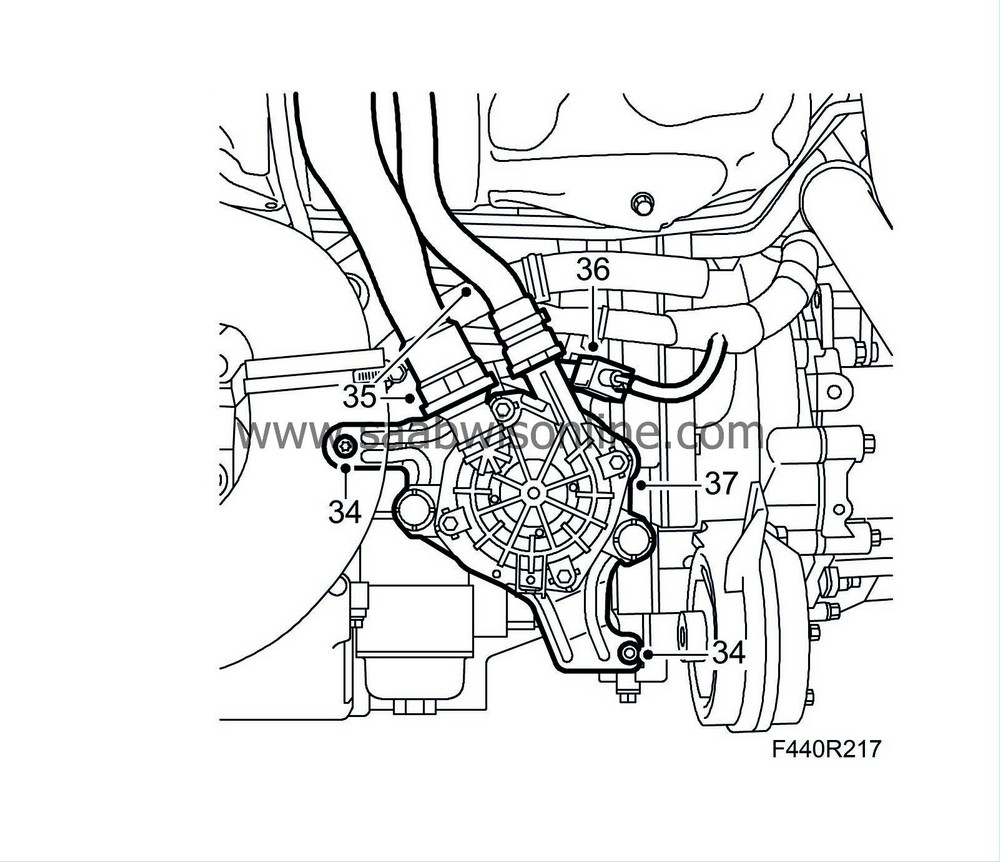

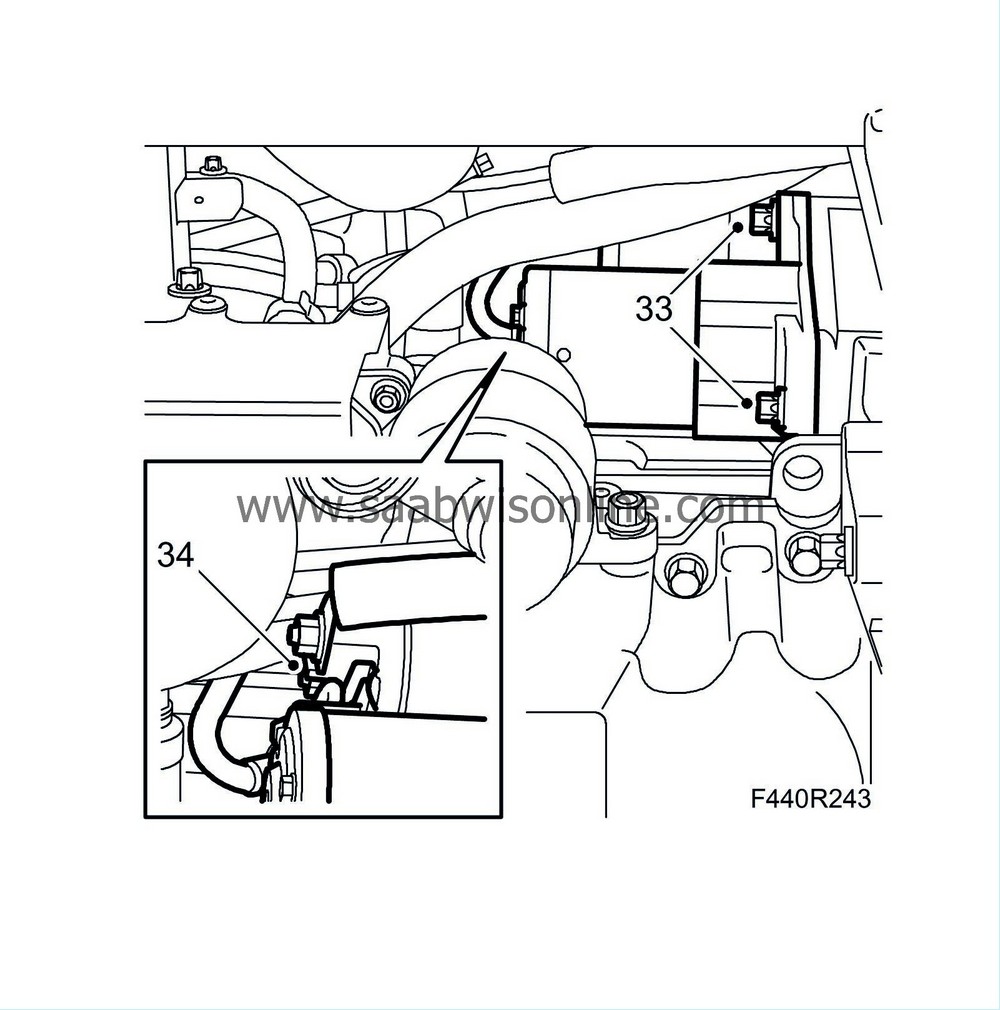

| 34. |

Remove the secondary air pump bolts.

|

|

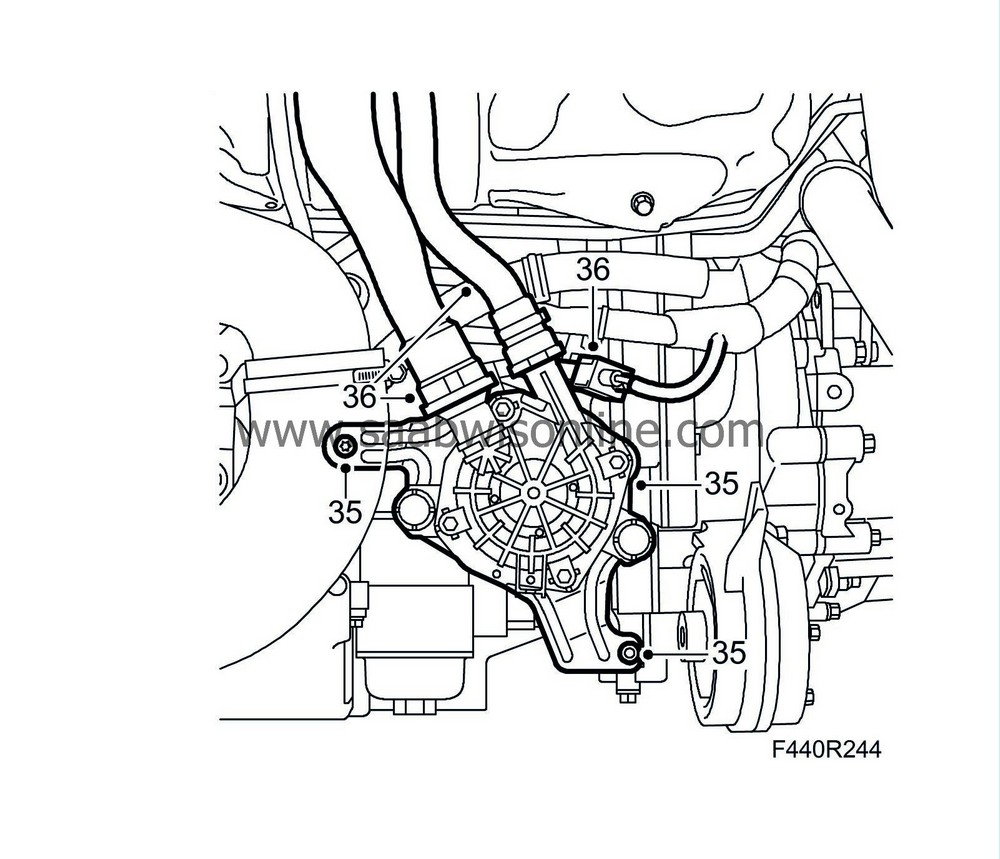

| 35. |

Remove the air connections from the secondary air pump.

|

|

| 36. |

Remove the electrical connection and coolant hose from the secondary air pump.

|

|

| 37. |

Remove the secondary air pump with mounting.

|

|

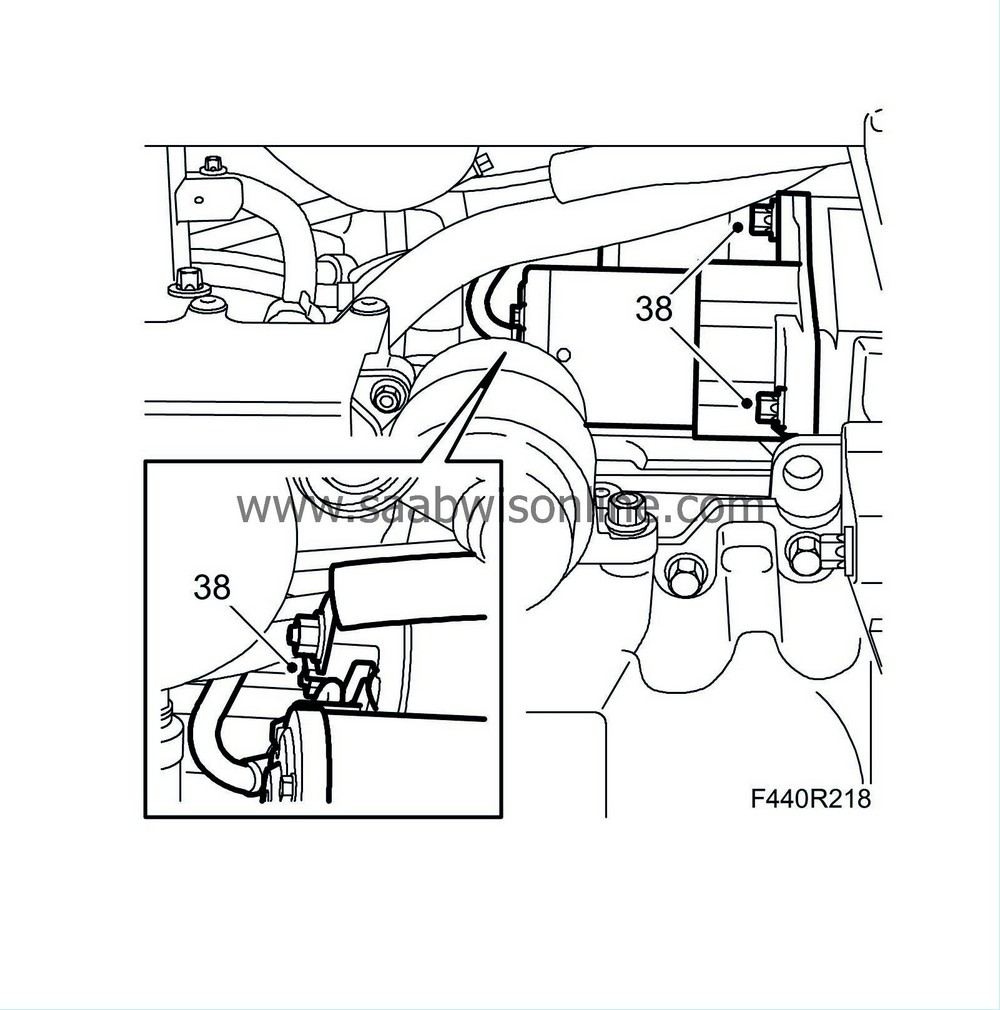

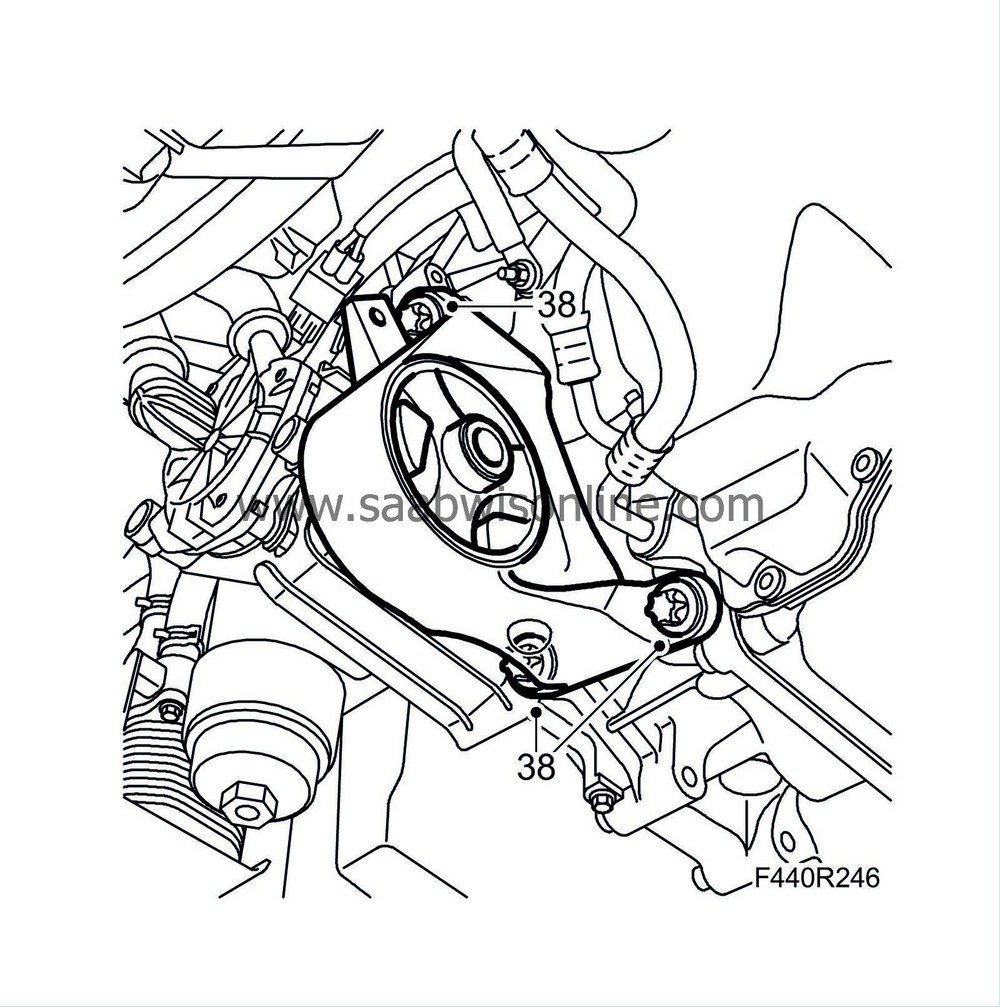

| 38. |

Unplug the starter motor electric connections and remove the starter motor.

|

|

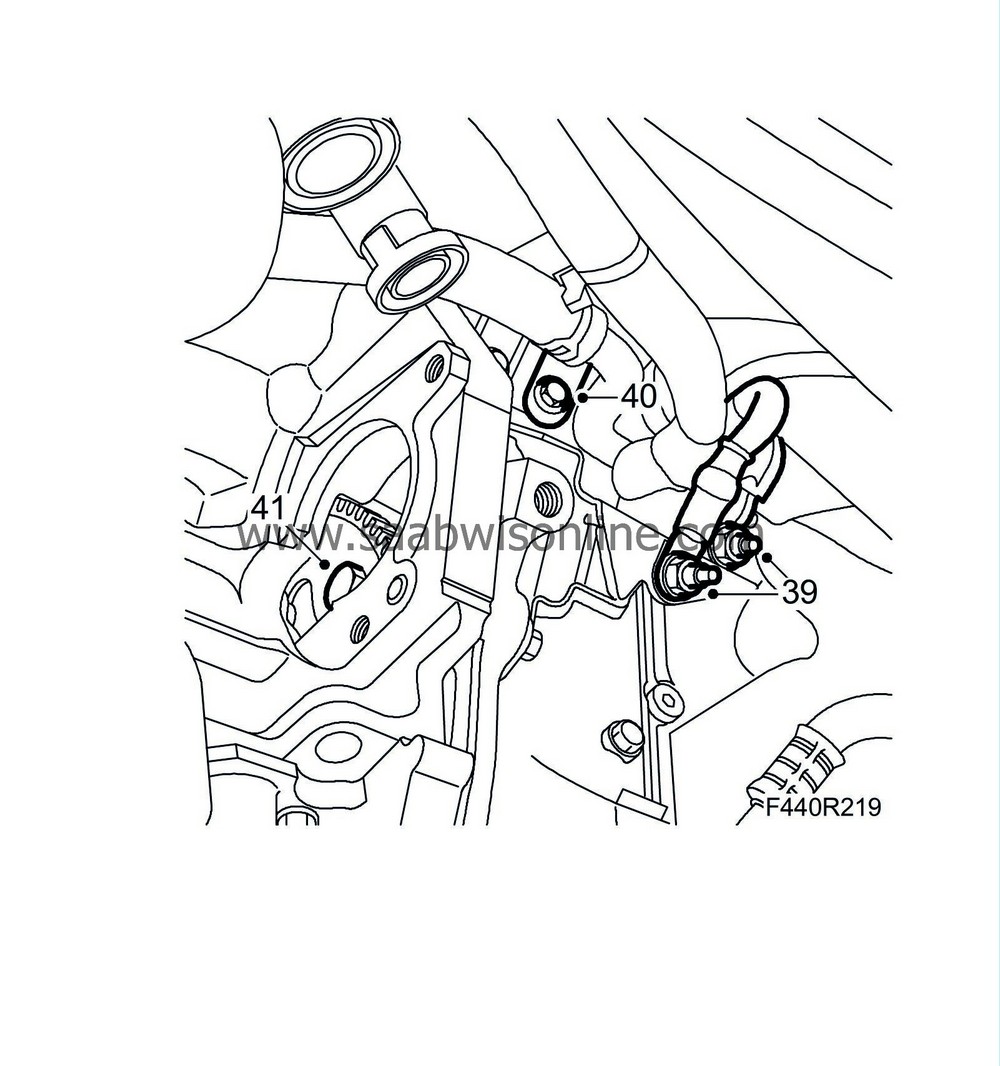

| 39. |

Remove the battery ground cable and wiring harness clamp from the metal bracket.

|

|

| 40. |

Remove the screw from the coolant pipe attaching lug.

|

|

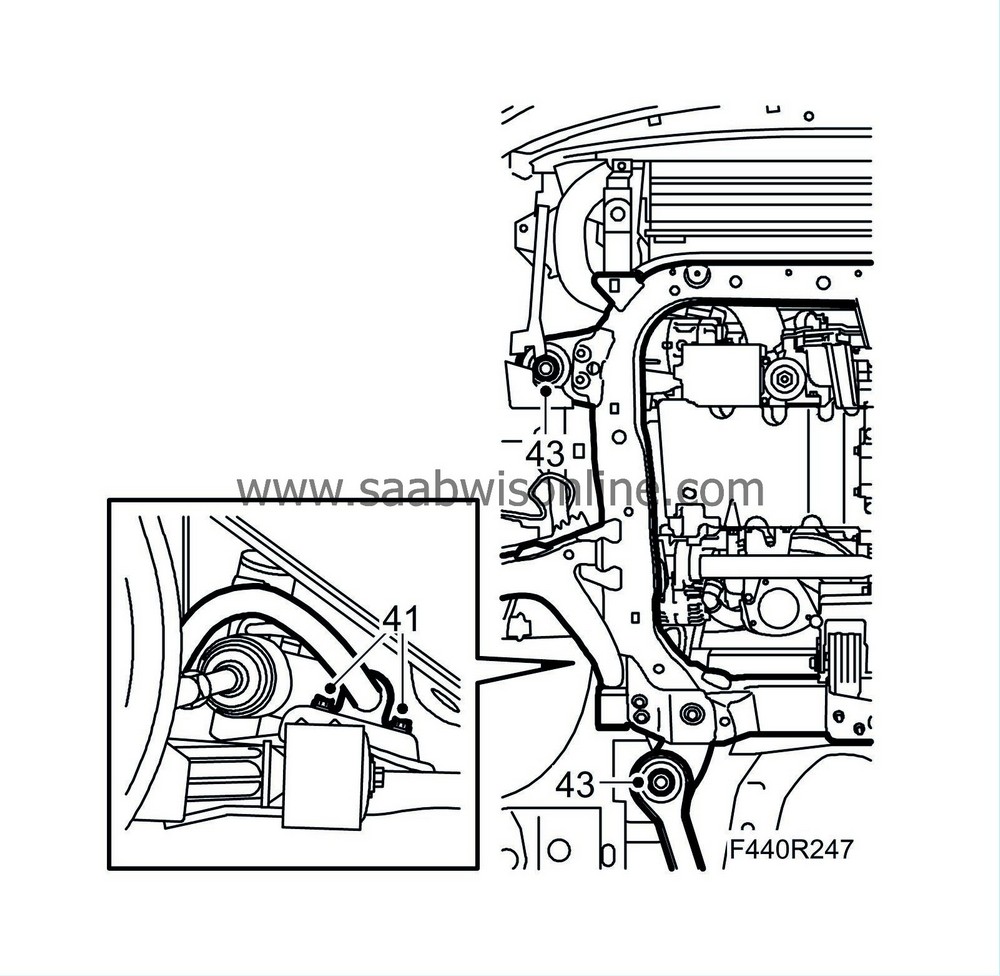

| 41. |

Remove the bolts holding the torque converter to the driver plate. Rotate the engine clockwise with the centre bolt on the belt pulley.

|

|

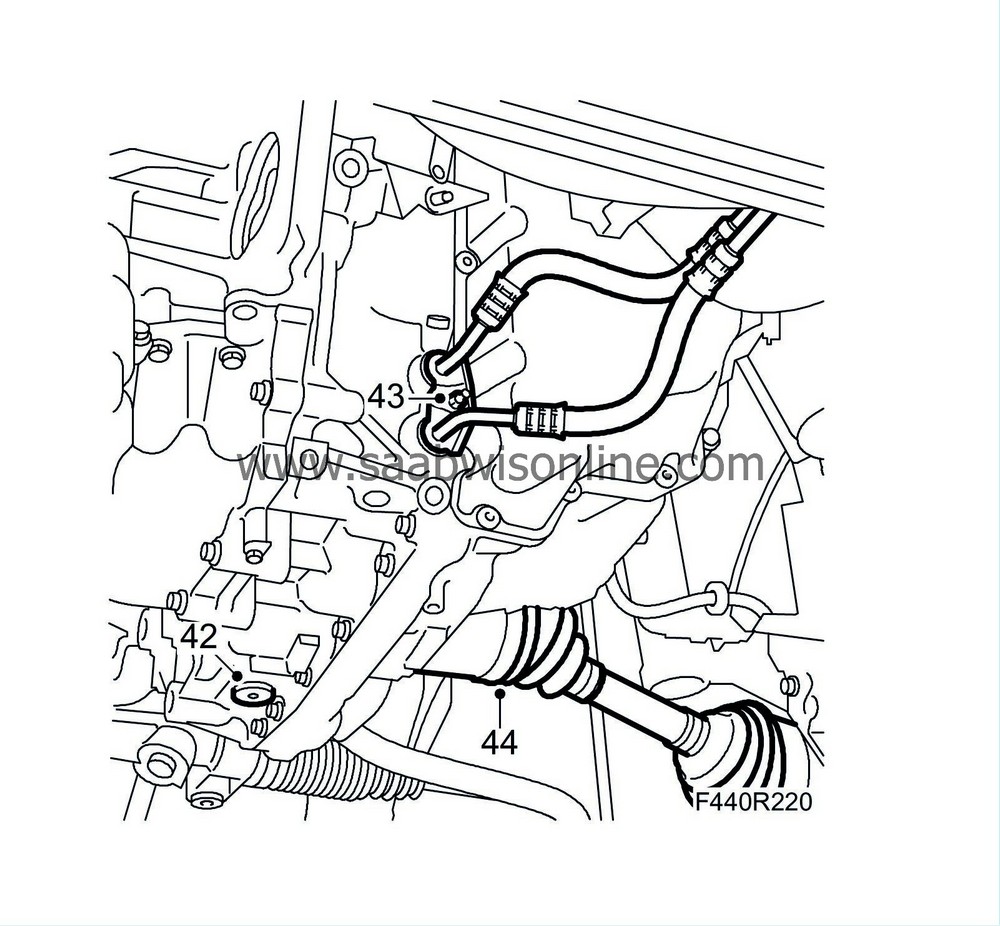

| 42. |

Place a receptacle under the car and drain the transmission fluid. Refit the oil plug with a new seal. Fit also the level plug.

Tightening torque, drain plug 45 Nm (33 lbf ft)

|

|

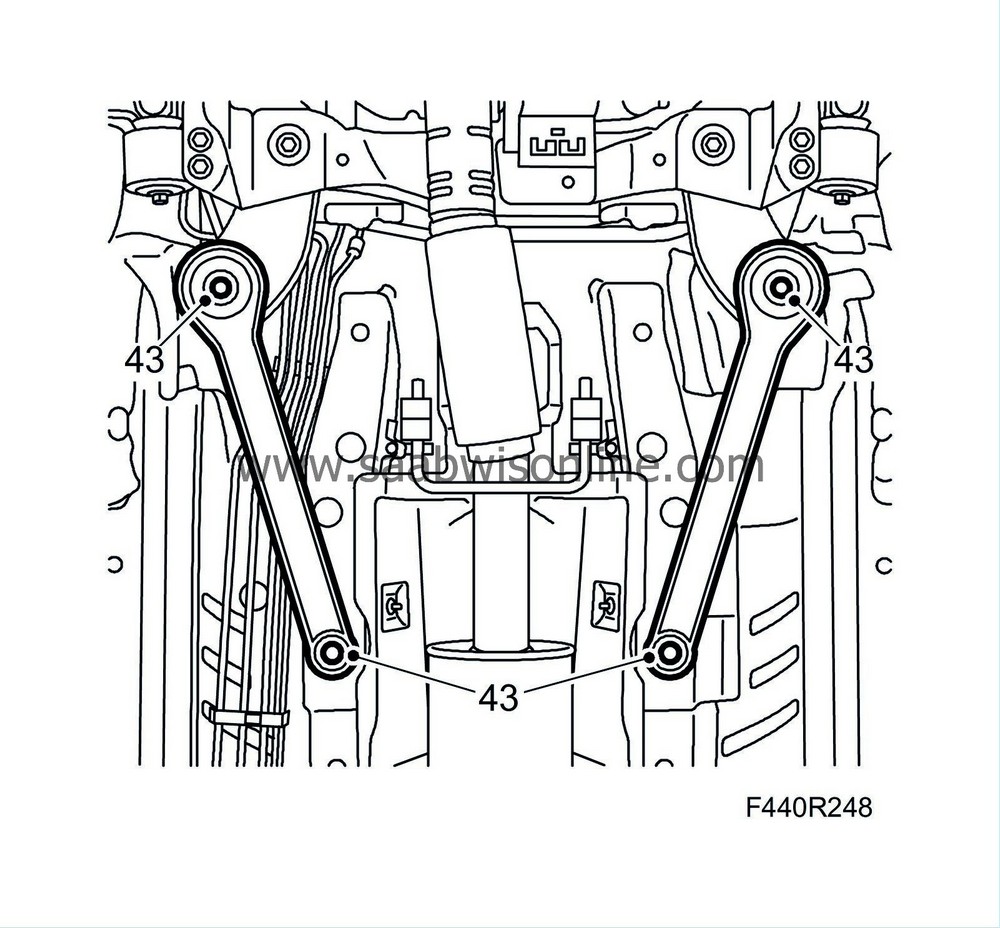

| 43. |

Detach the transmission fluid cooling hoses and plug the holes and hoses with

82 92 955 Plugs, spare part kit

.

|

|

| 44. |

Loosen the left-hand drive shaft using

87 92 616 Removal tool, drive shafts

.

|

|

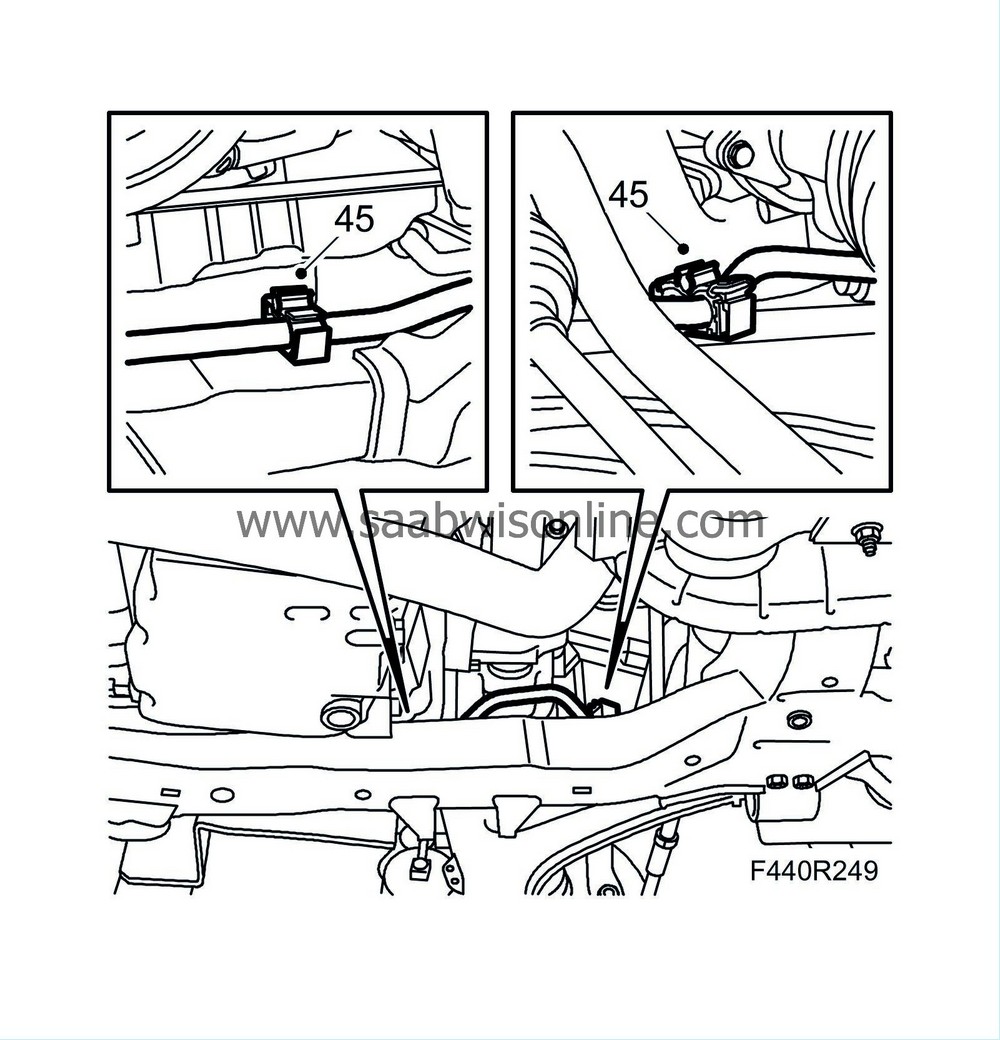

| 45. |

Hang up the shaft with

83 95 212 Strap

.

|

|

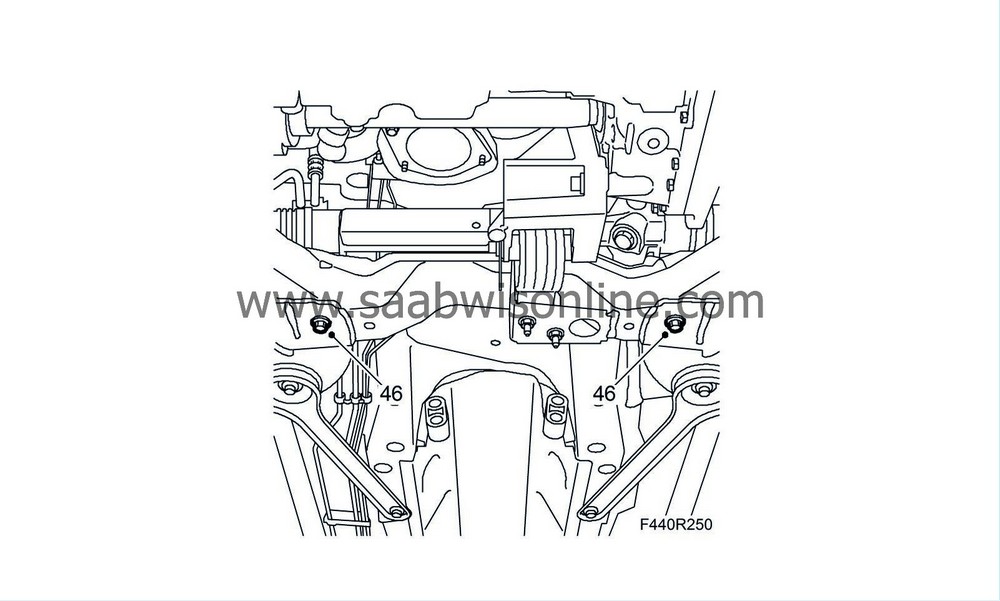

| 46. |

Lower the car to the floor.

|

|

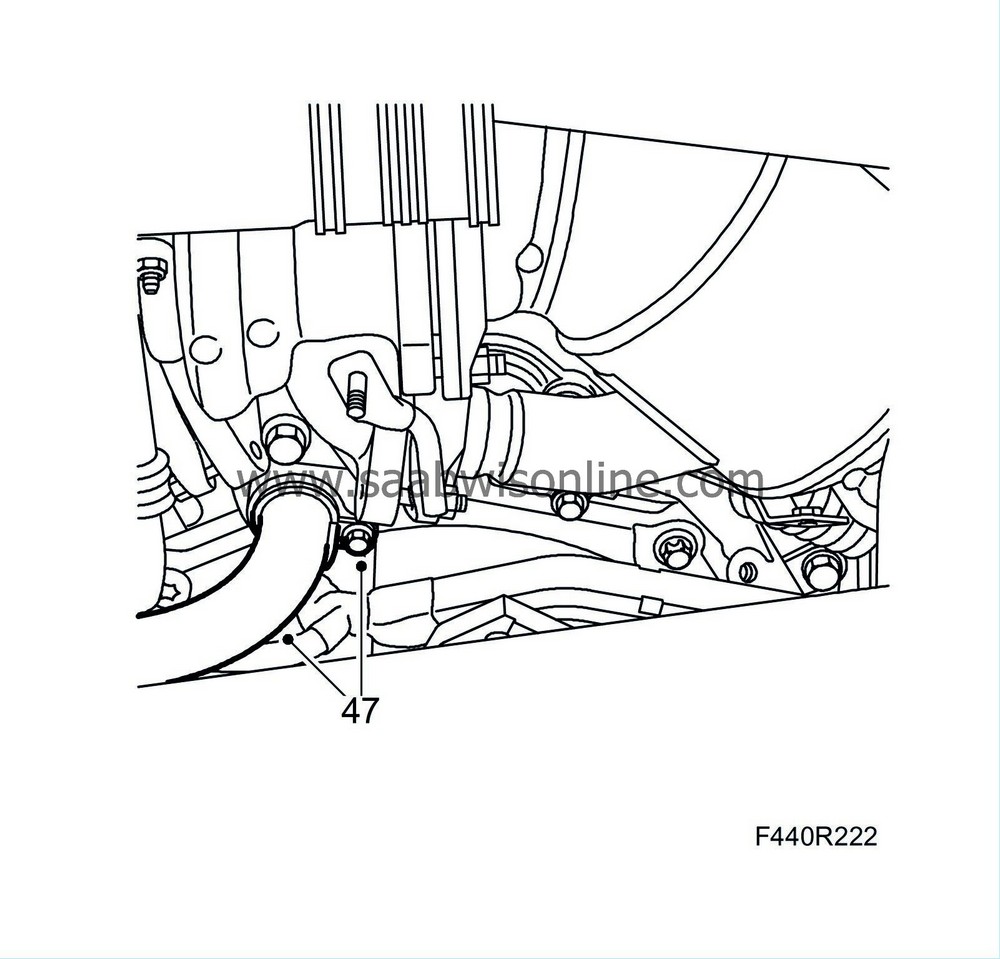

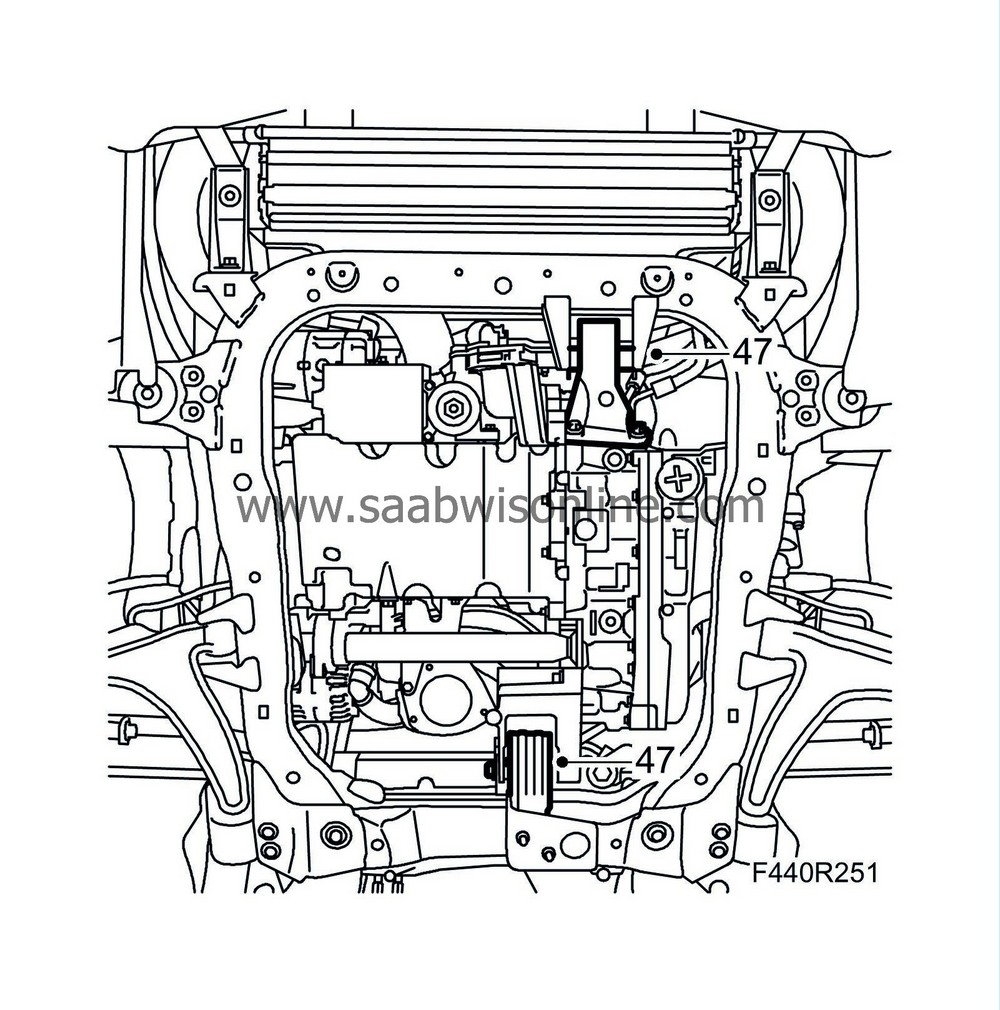

| 47. |

Remove the coolant pipe from the thermostat housing.

|

|

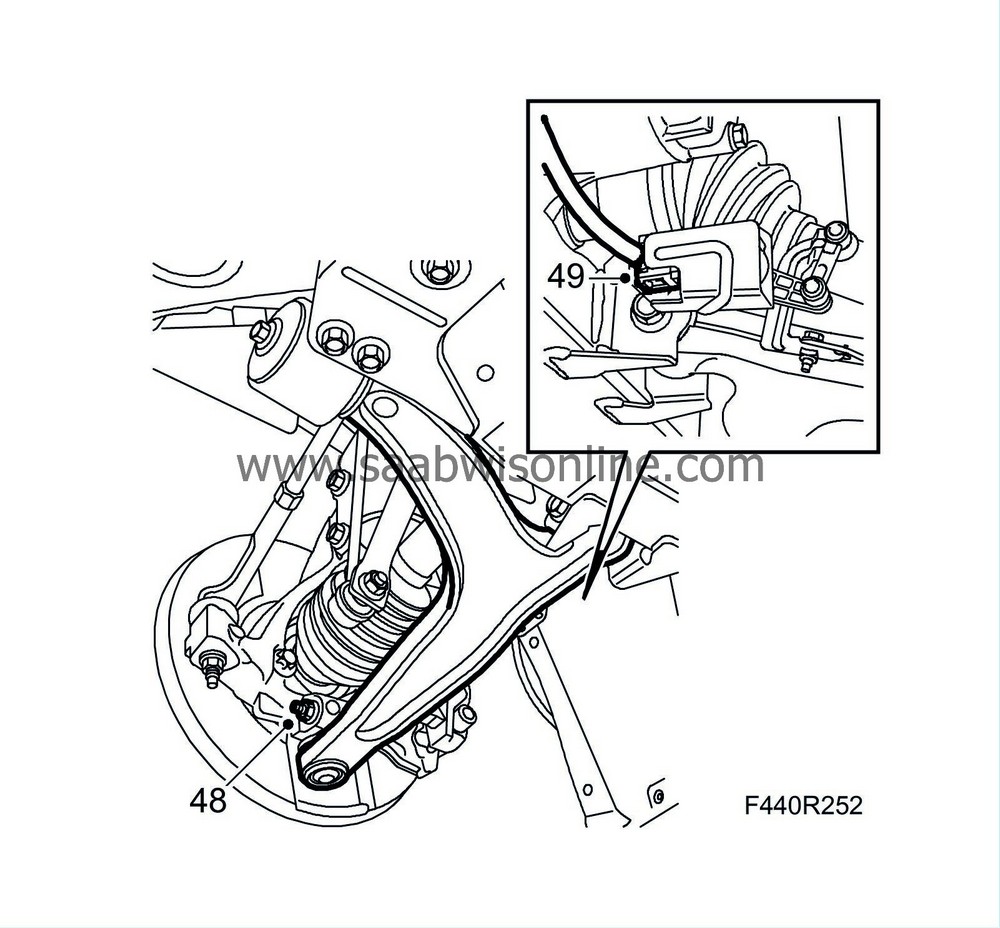

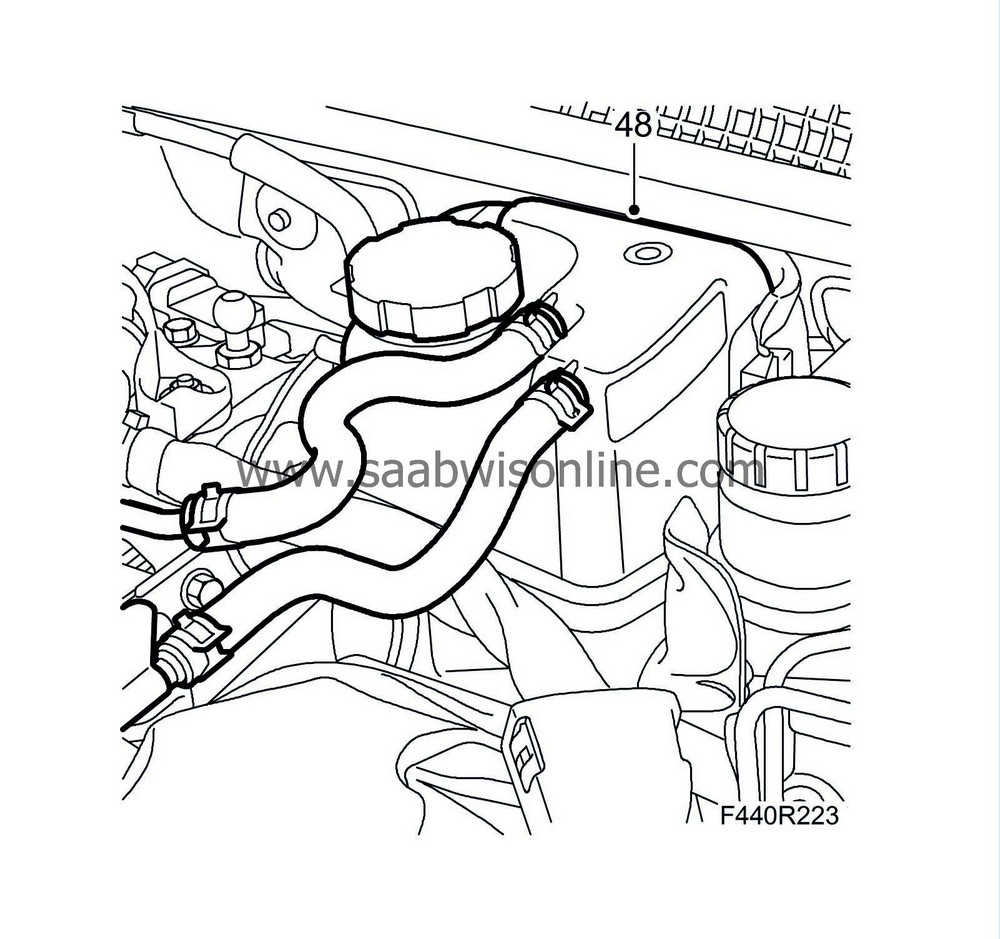

| 48. |

Unhook the expansion tank from its mounting on the bulkhead wall.

|

|

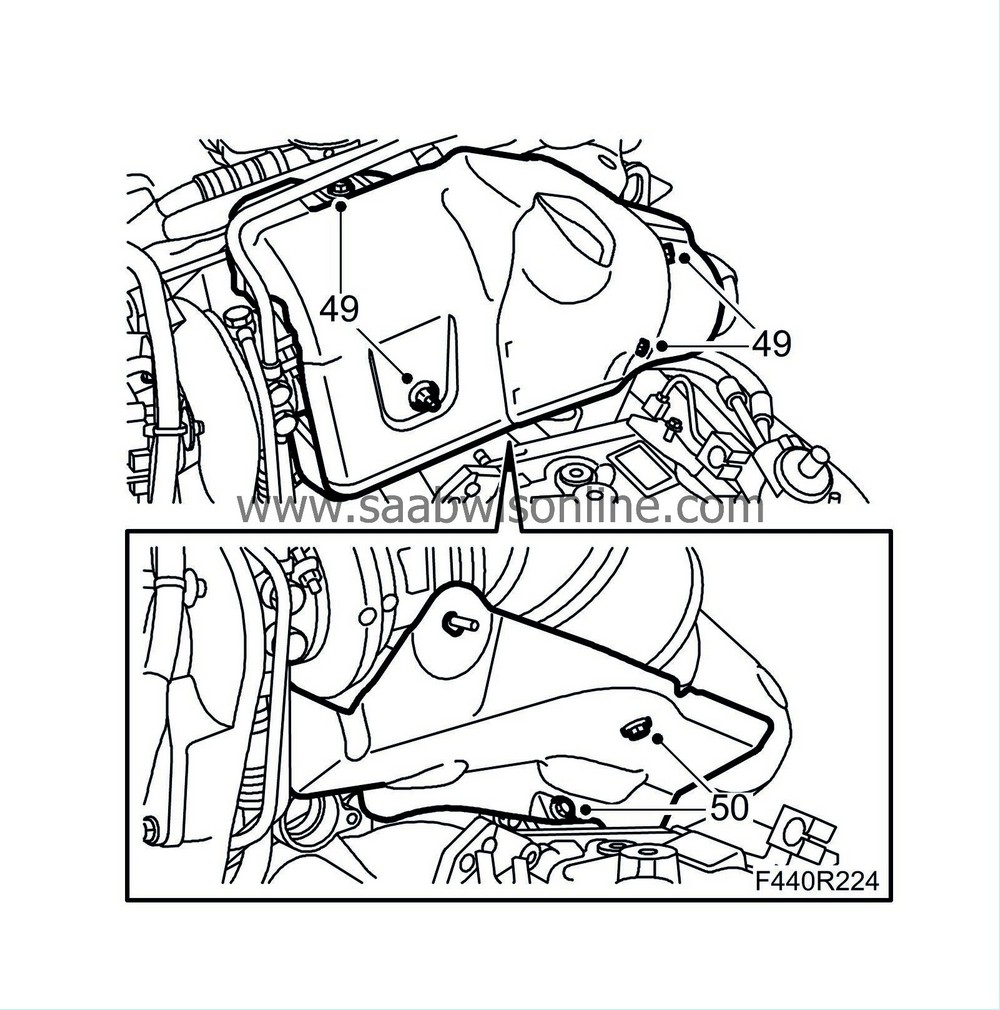

| 49. |

Remove the upper heat shield from the catalytic converter.

|

|

| 50. |

Remove the lower heat shield from the catalytic converter.

|

|

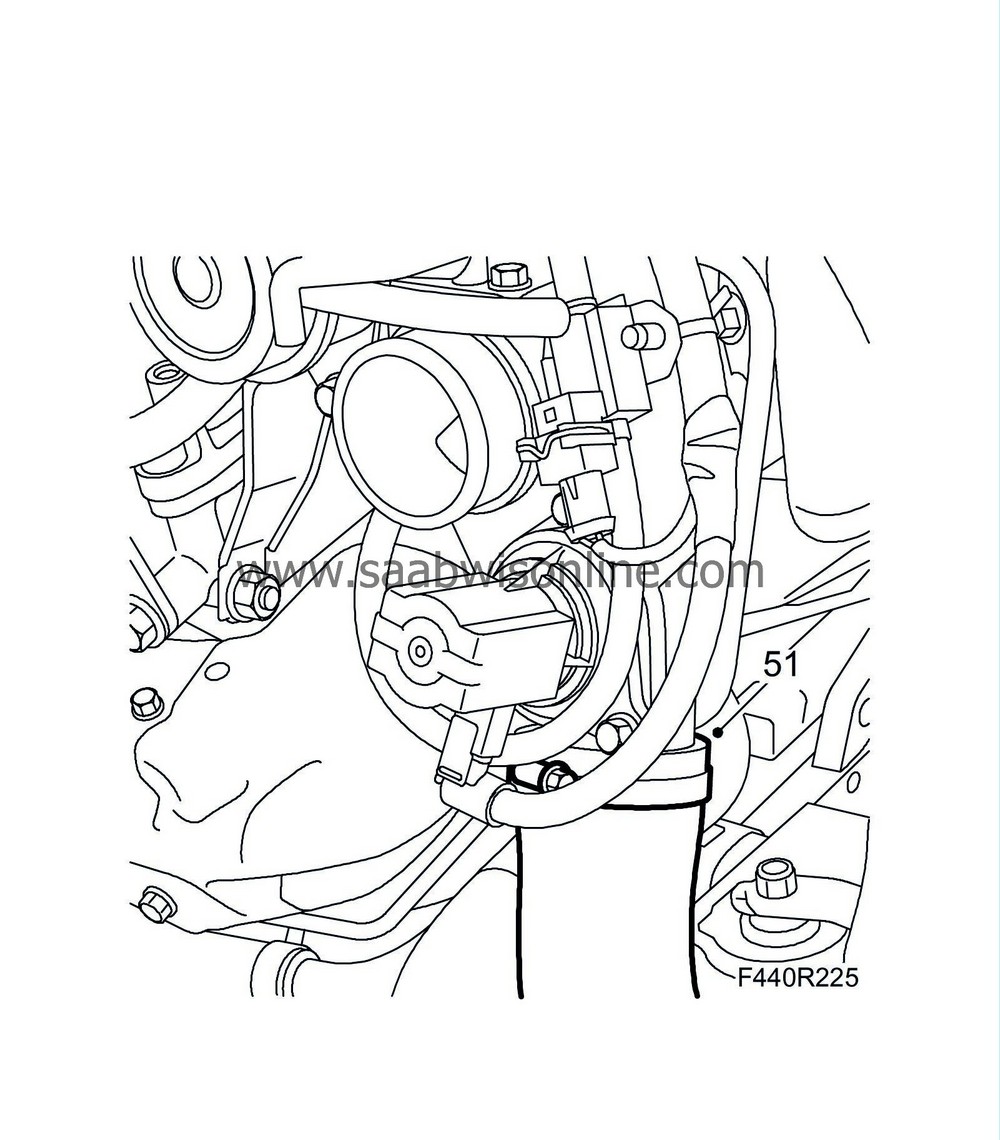

| 51. |

Remove the turbo delivery hose from the turbo.

|

|

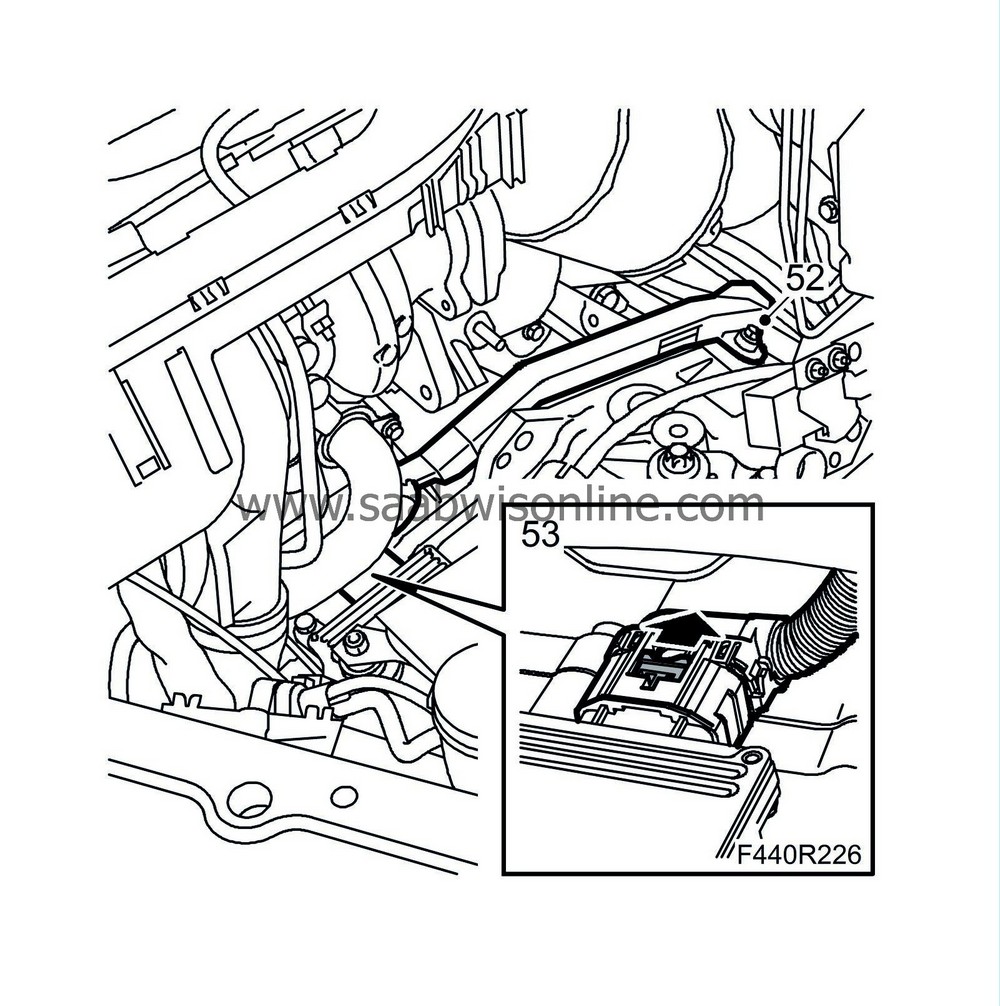

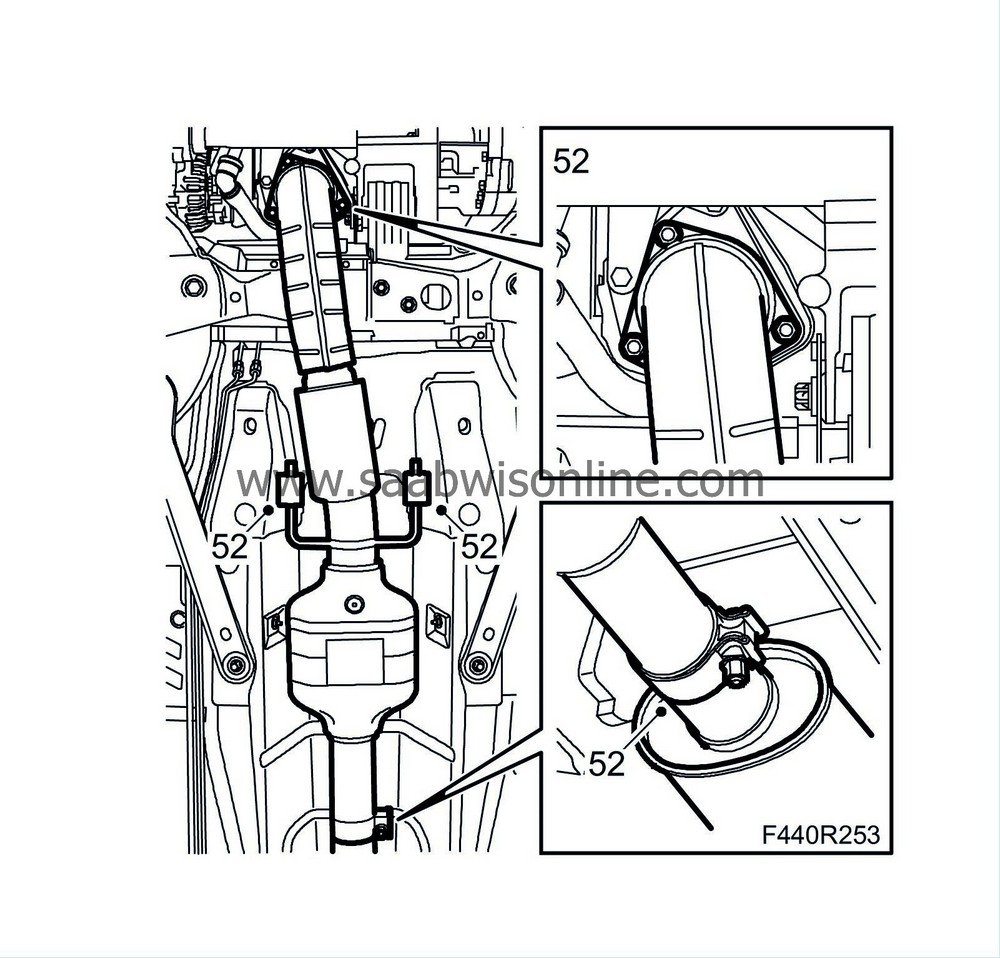

| 52. |

Remove the cable duct from the gearbox.

|

|

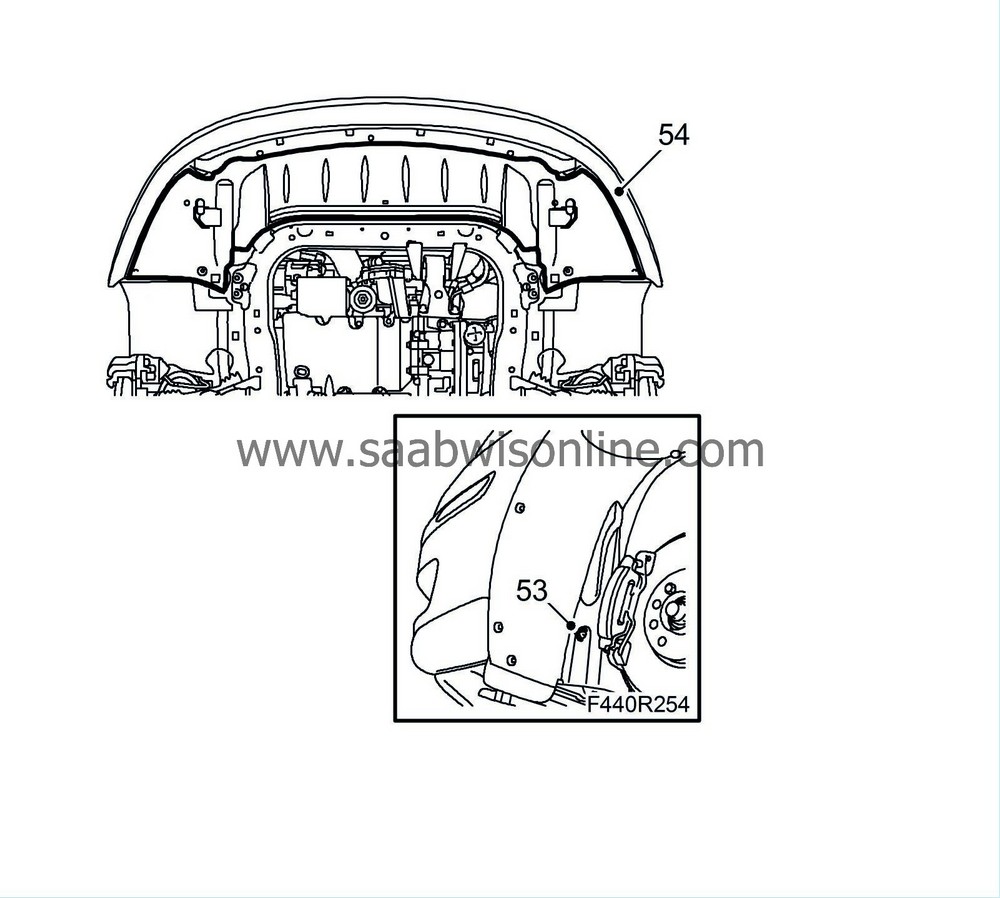

| 53. |

Pull out the lock pin, press down the lock and unplug the control module connector. Pull up the wiring harness.

|

|

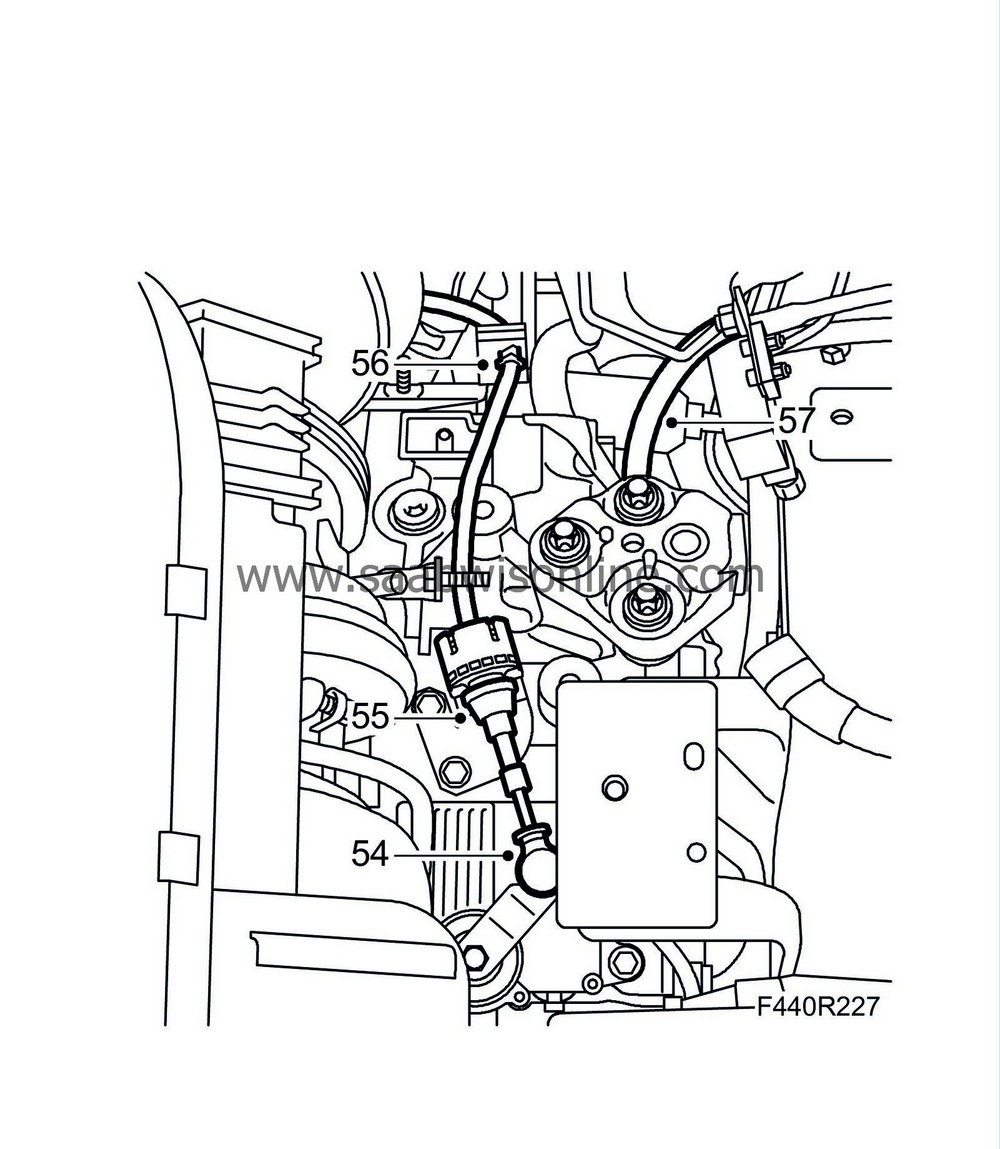

| 54. |

Remove the gear cable from the selector lever arm.

|

|

| 55. |

Remove the cable from the cable retainer by pulling back the locking sleeve.

|

|

| 56. |

Undo the cable from the rear mounting.

|

|

| 57. |

Remove the gearbox ventilation hose.

|

|

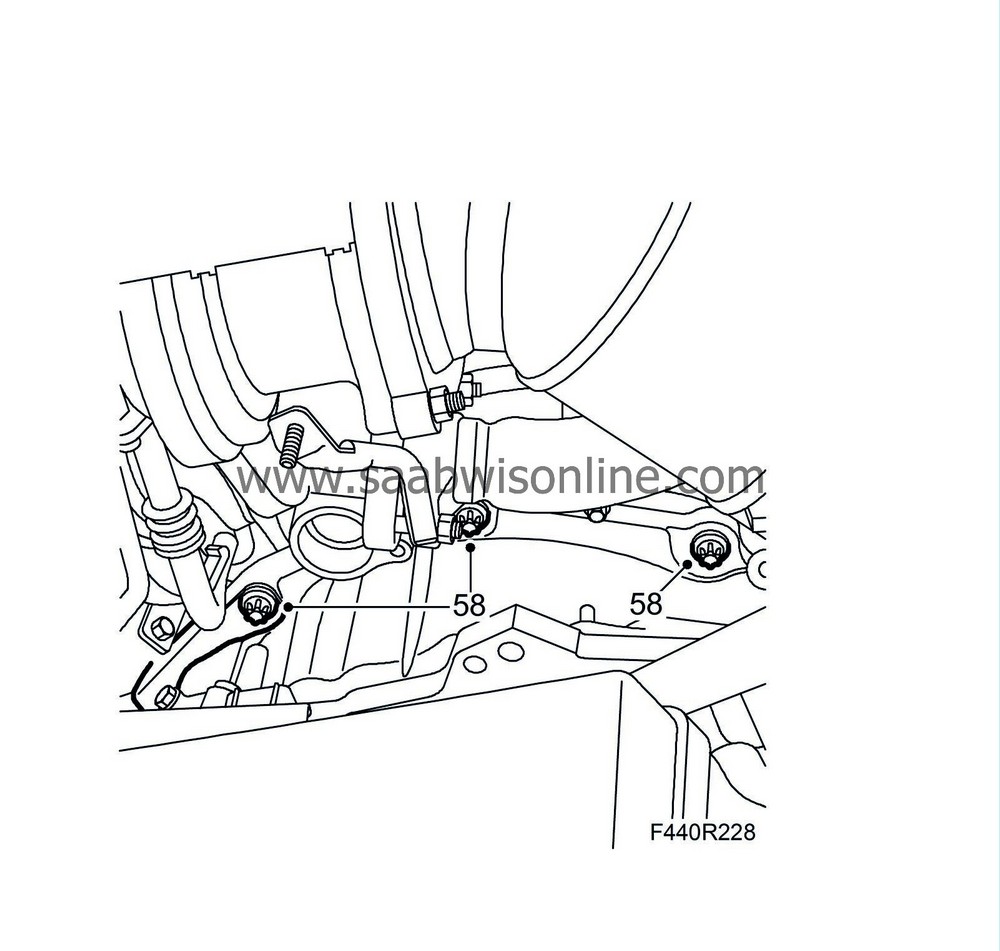

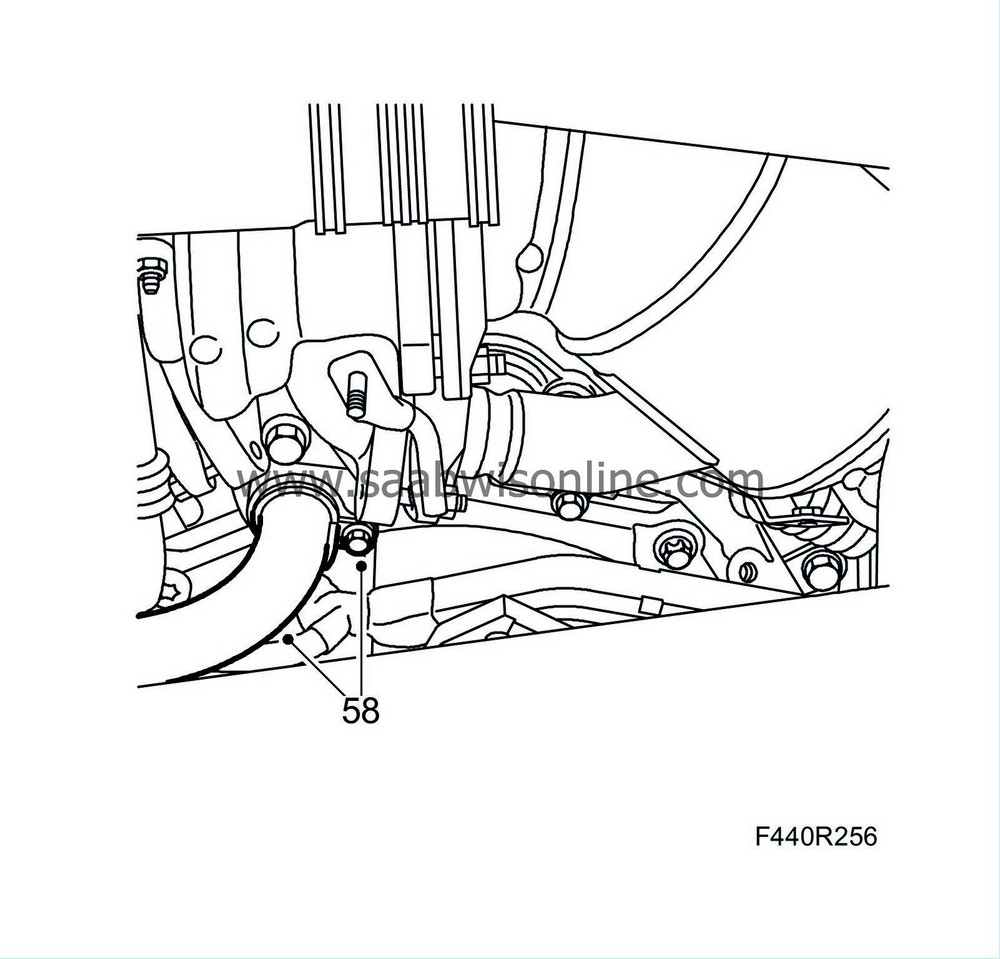

| 58. |

Remove the upper bolts from the gearbox. Use

32 025 063 Special socket

.

|

|

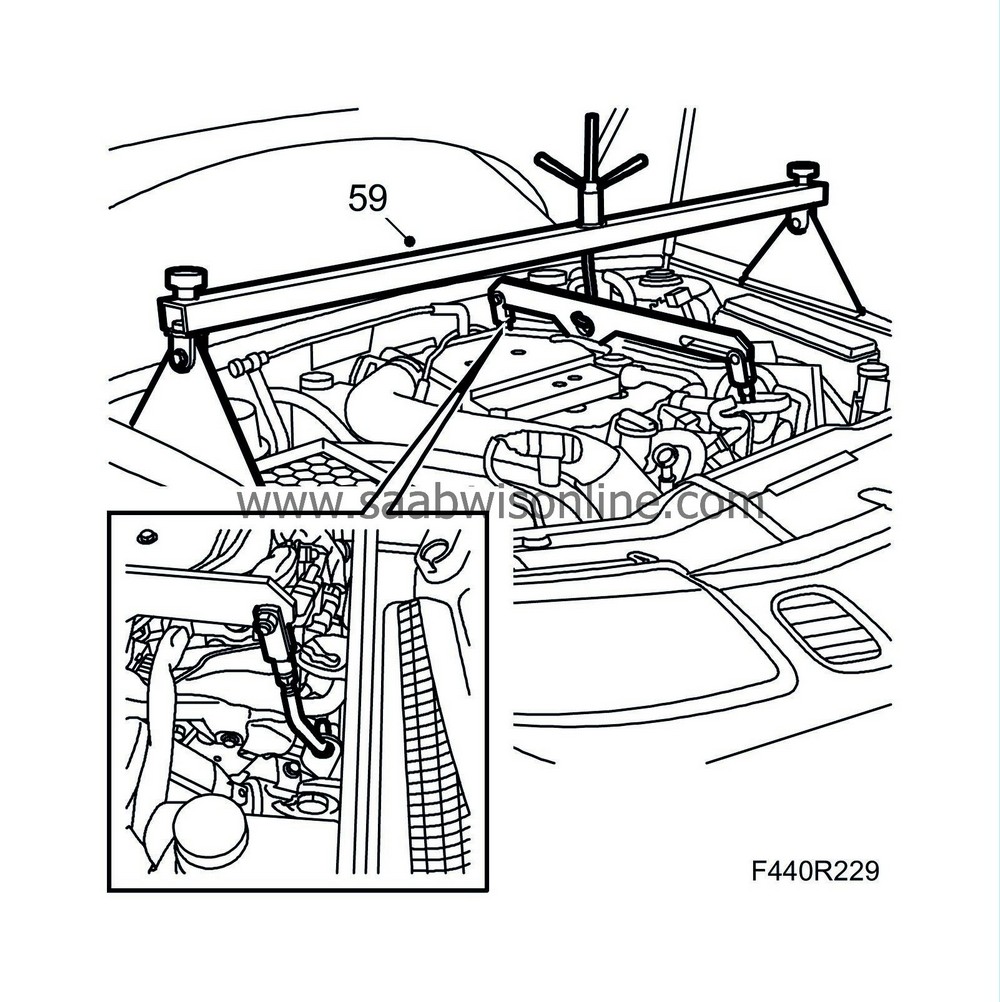

| 59. |

Fit

83 94 850 Lifting beam

and

83 95 287 Holder

with

32 025 037 Hook for lifting beam

on the engine. Take the weight off the engine and gearbox.

|

|

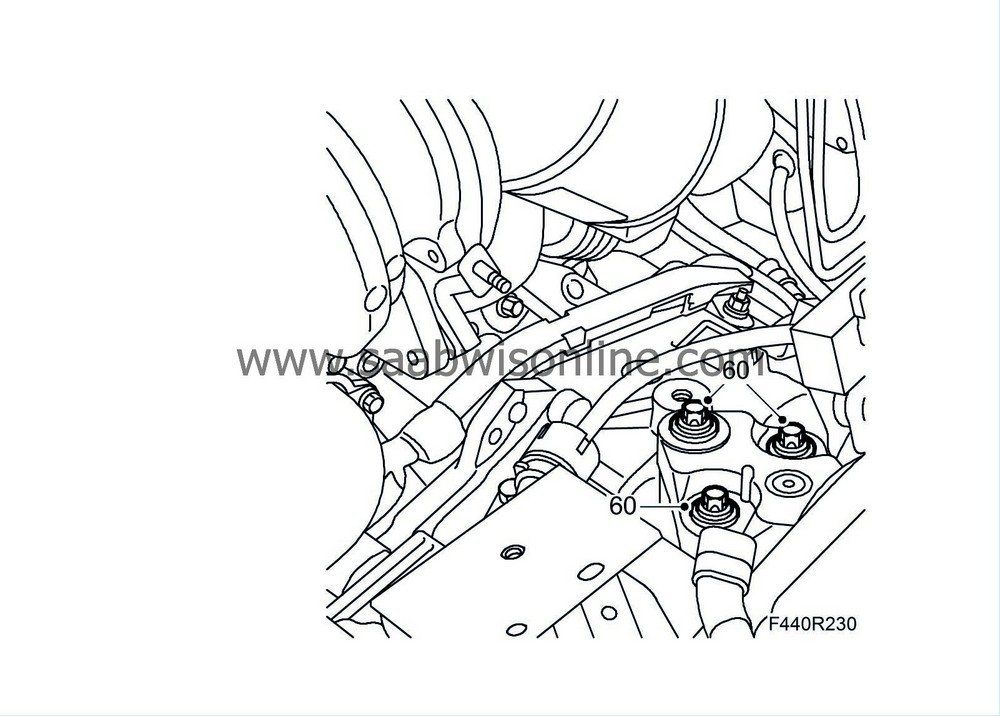

| 60. |

Mark the location of the bolts on the left-hand engine bracket with a marker pen for correct refitting and remove the bracket from the gearbox.

|

|

| 61. |

Lower the power train with the lifting beam to facilitate removal of the transmission.

|

|

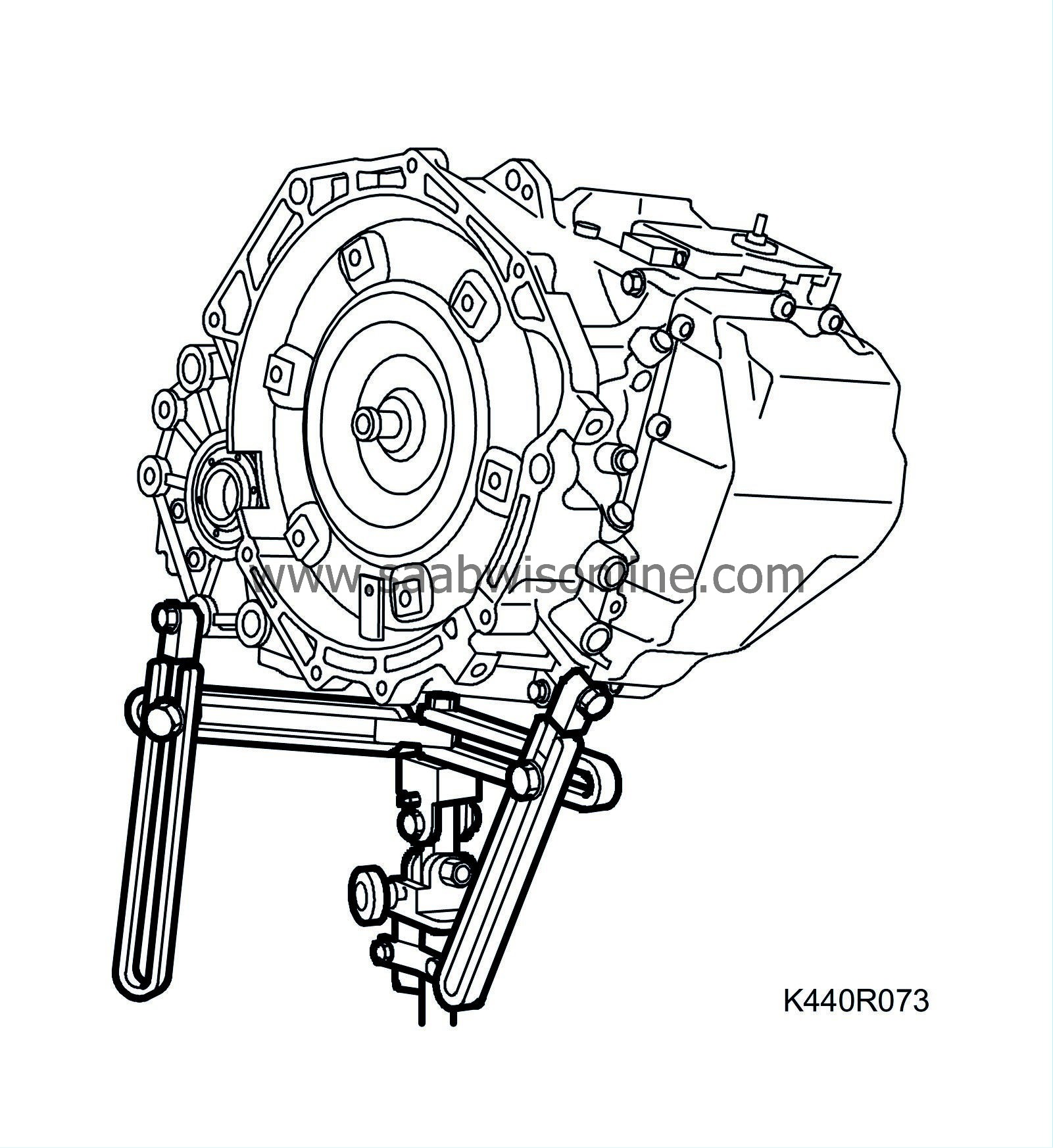

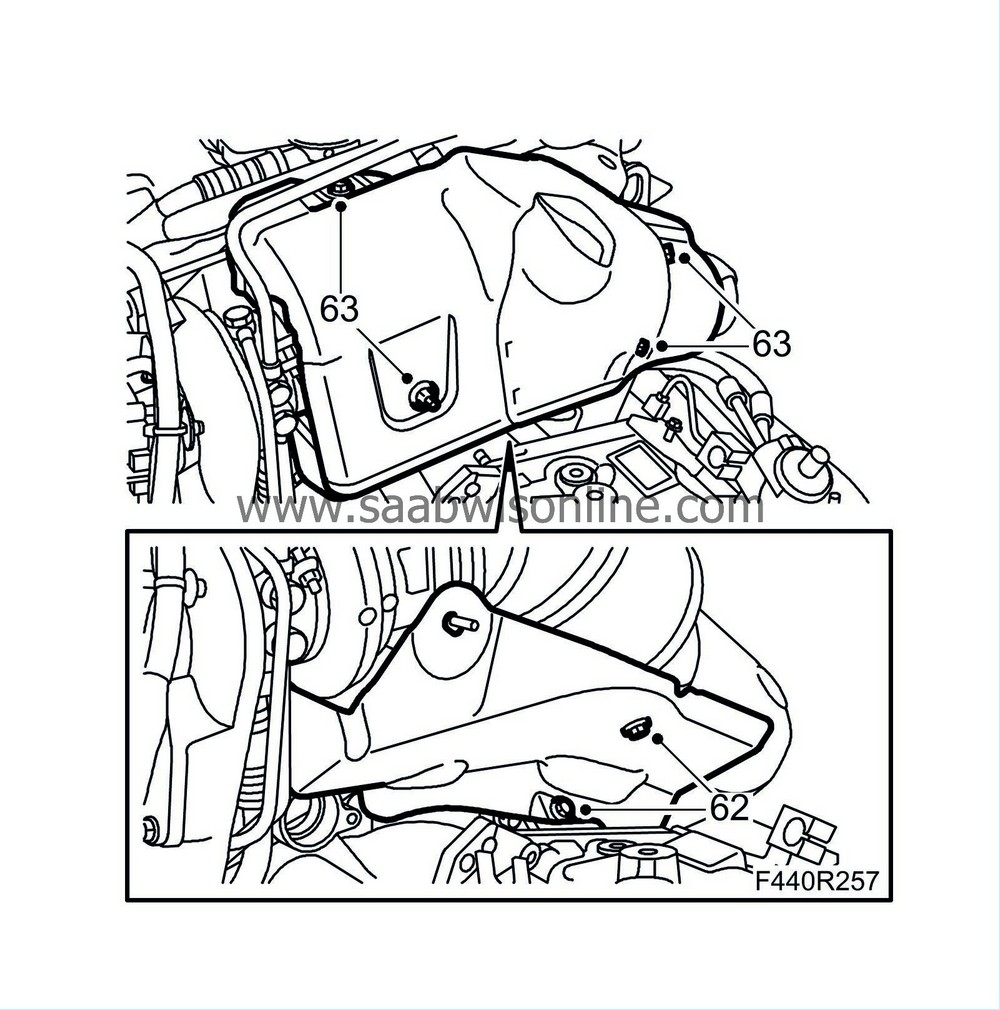

| 62. |

Raise the car and fit

87 92 608 Holder for single-column lift

onto a column jack.

|

|

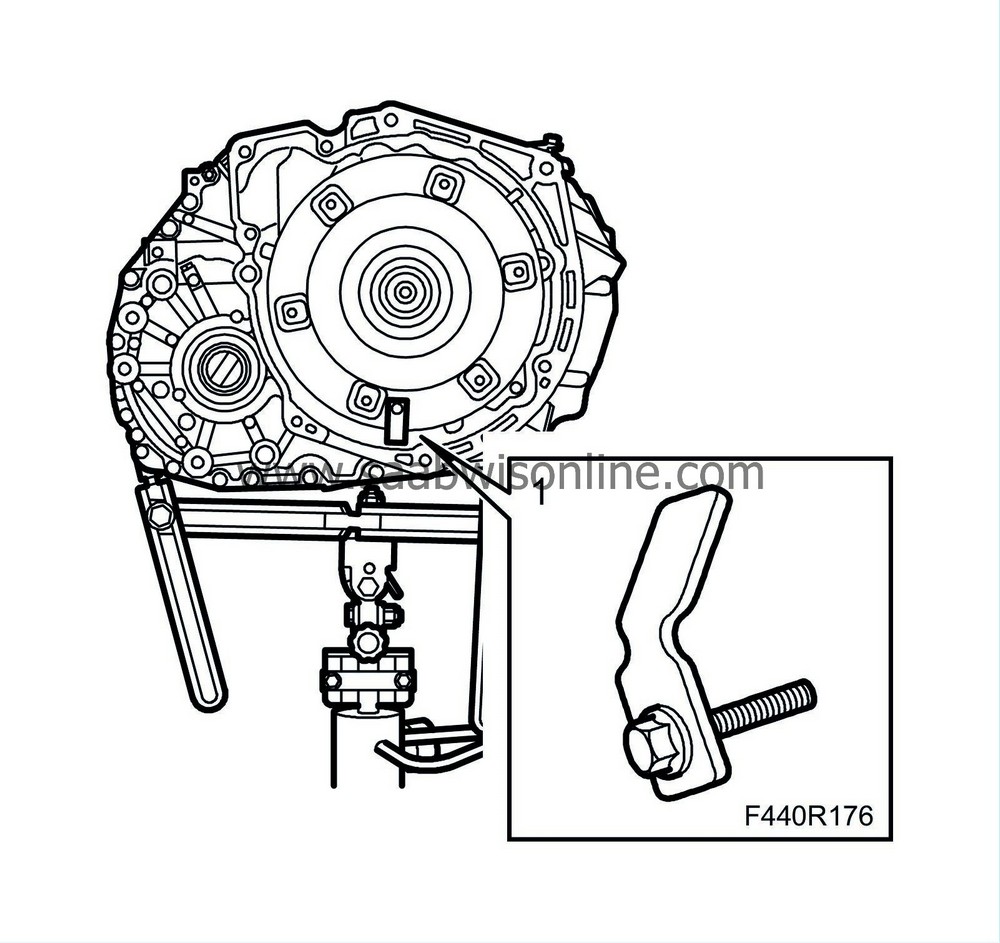

| 63. |

Adjust and fasten the tool in the gearbox as illustrated. Use the M12 holes for the torque rods.

|

|

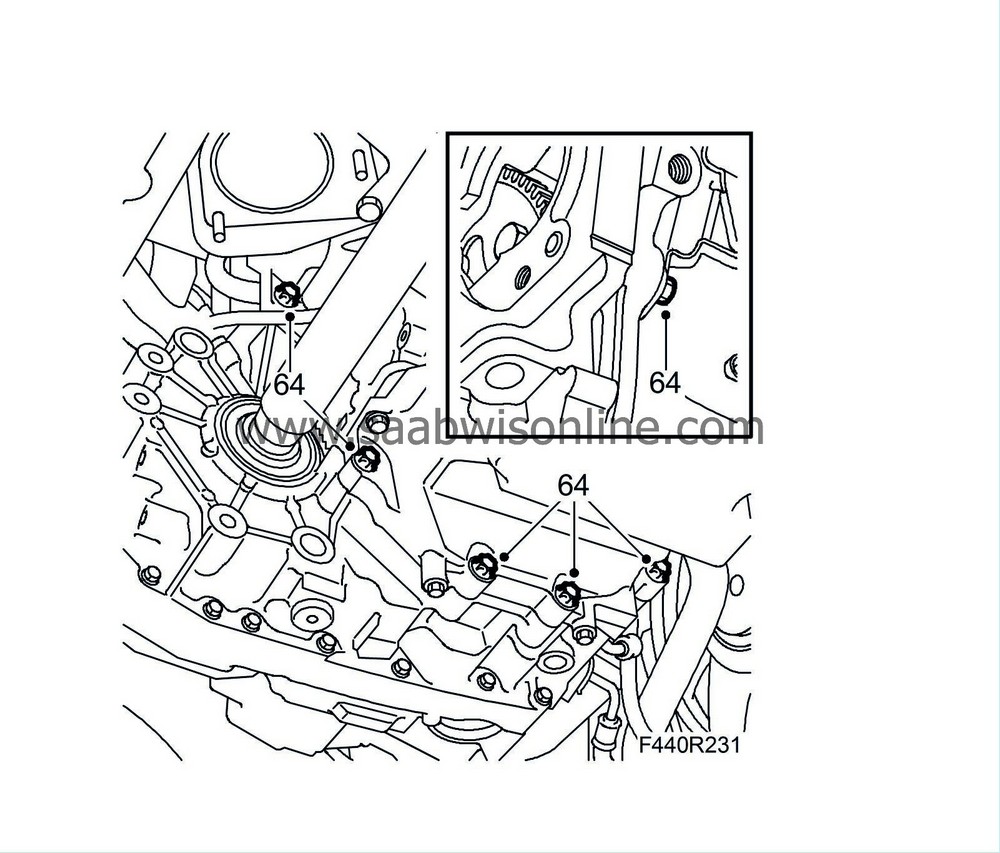

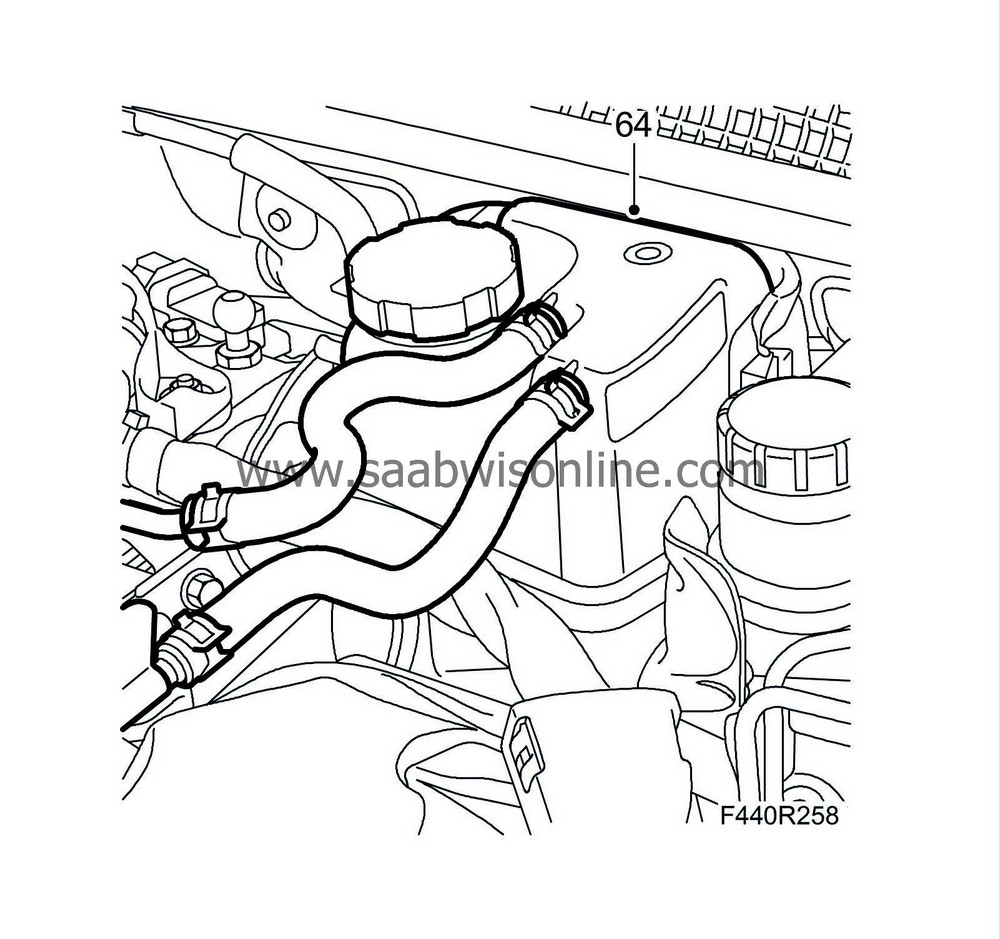

| 64. |

Remove the lower bolts holding the gearbox to the engine and retain the wiring harness mounting at the front bolt.

|

|

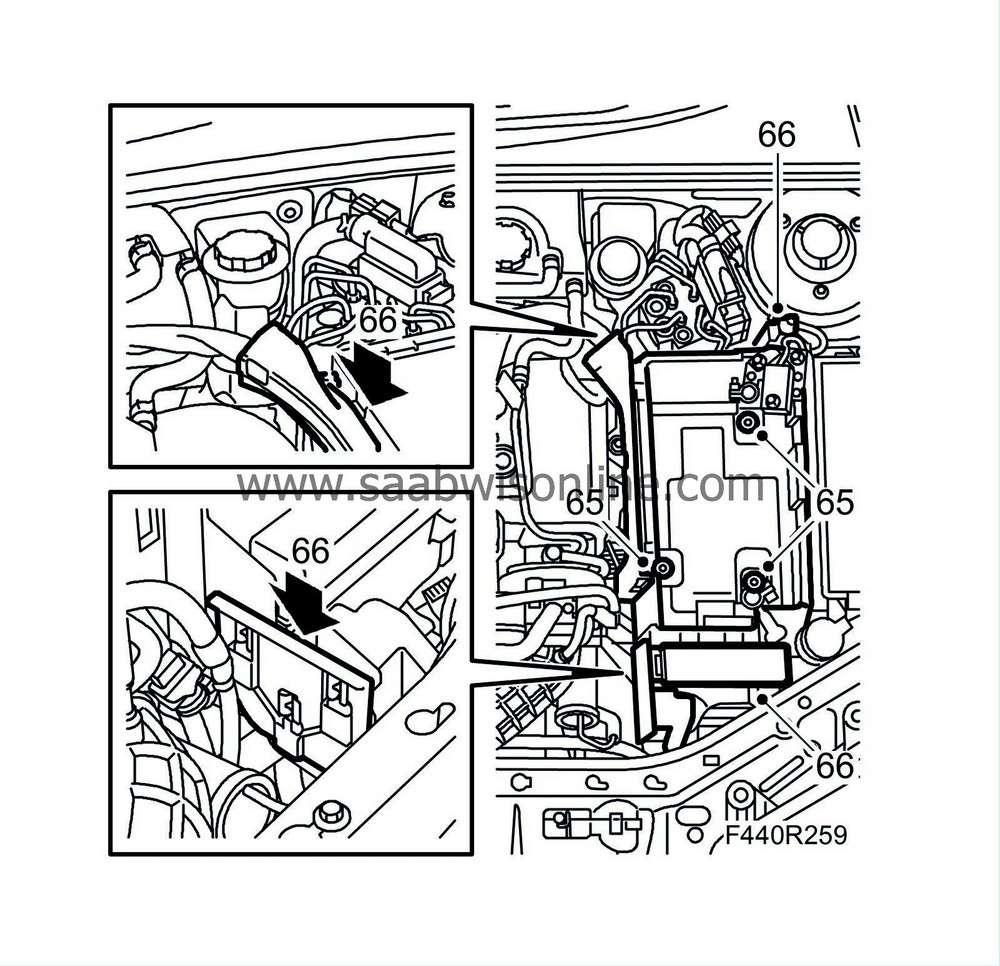

| 65. |

Pull out the gearbox about 10 mm.

|

|

| 66. |

Undo the plug and press the torque converter towards the transmission and fit

87 92 574 Holder

for holding the torque converter in place while removing the transmission.

|

|

| 67. |

Pull out and let down the gearbox.

|

||||||||||

| 68. |

Lift the transmission down from the column jack with an engine lift and

87 92 442 Lifting cable

while undoing the lifting tool from the transmission.

|

|

| 69. |

Plug the holes for the drive shafts if the gearbox is being transported or washed. Use

87 92 665 Protective plug, drive shaft hole

|

|

| To fit |

When fitting a new gearbox, transfer the holder for the torque converter and the plugs form the new gearbox to the old one and the gear shift cable lever to the new gearbox.

| 1. |

Turn the torque converter so the holes are aligned with the holes on the driver plate and turn the engine so the oval hole in the driver plate is opposite the starter motor opening. Fit

87 92 574 Holder

to secure the torque converter in place while fitting. Lubricate the torque converter locating pin with grease.

|

|

| 2. |

Make sure the two guide sleeves are on the engine and apply grease to the sleeves.

|

|

| 3. |

Lubricate and fit new drive shaft seals (does not apply to new gearboxes). Use

87 92 657 Fitting drift, drive shaft seals

for the left and

32 025 025 Fitting drift, drive shaft seals

for the right-hand drive shaft seal.

|

|

| 4. |

Fit

83 95 162 Protective collar, drive shafts

in the right shaft seal in the transmission. This is done to protect the seal while the transmission is being fitted. Lubricate the seal.

|

|

| 5. |

Fit

87 92 608 Holder for single-column lift

onto a column jack.

|

|

| 6. |

Secure the tool to the transmission as for removal.

|

||||||||||

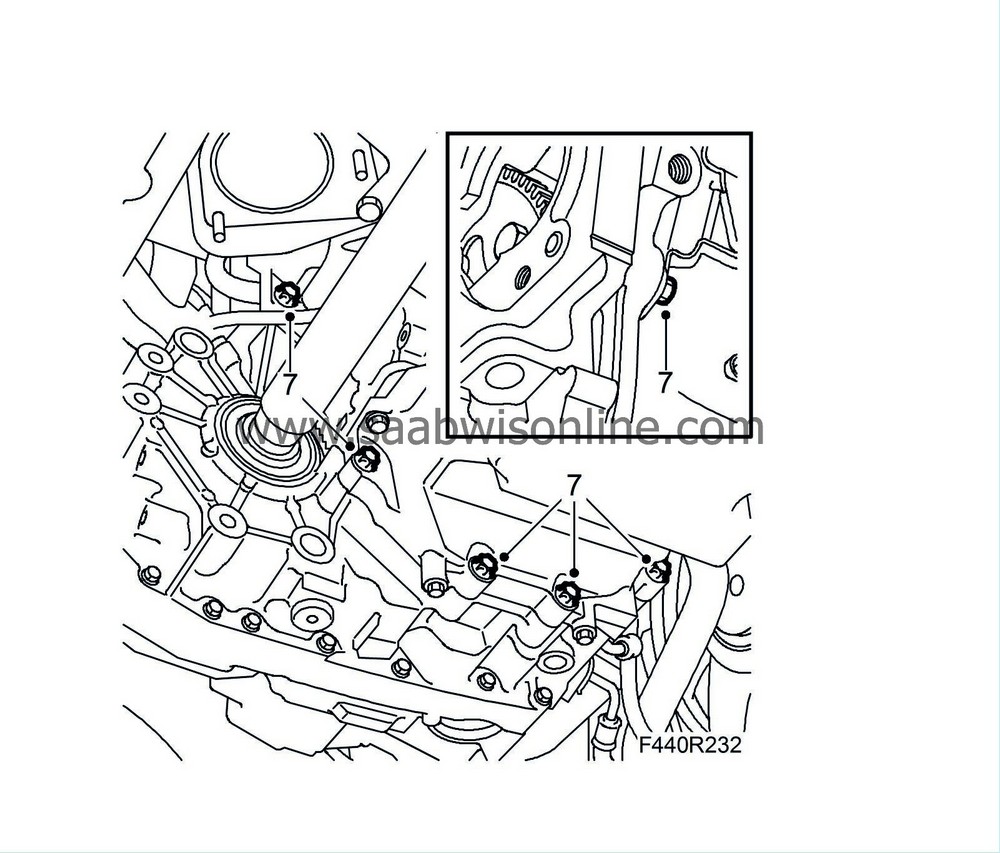

| 7. |

Fit the gearbox to the engine. Remove

87 92 574 Holder

just before the gearbox is in place. Tighten the lower bolts between the engine and the gearbox. Fit the upper bolt loosely at the same time to the wiring harness metal bracket.

Tightening torque 60 Nm (44 lbf ft)

|

|

| 8. |

Fit

83 95 162 Protective collar, drive shafts

into the sealing ring. Lubricate the sealing ring.

|

|

| 9. |

Make sure that the drive shaft is clean and then align it with the tool.

|

||||||||||

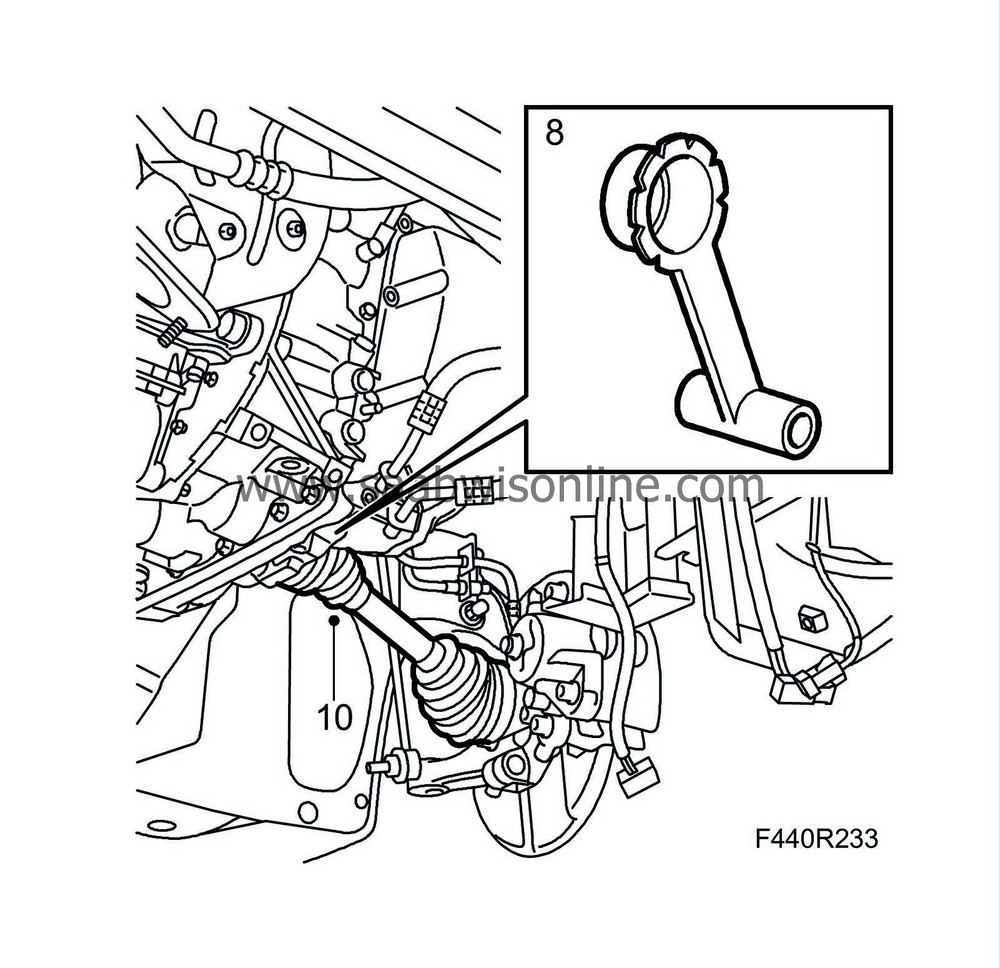

| 10. |

Push in the rest of the shaft until the circlip clicks in.

|

|

| 11. |

Press the torque converter against the driver plate. Fit the plug.

|

|

| 12. |

Apply

Thread locking adhesive, Loctite 242

to the bolts holding the torque converter to the driver plate.

|

|||||||

| 13. |

Turn the engine clockwise with the belt pulley and tighten the bolts one at the time starting at the oval hole in the driver plate.

Tightening torque 60 Nm (44 lbf ft)

|

|

| 14. |

Remove the lifting tool from the transmission and move away the jack. Fit the bolt into the transmission.

Tightening torque 22 Nm (16 lbf ft) |

|

| 15. |

Lower the car to the floor.

|

|

| 16. |

Lift up the unit and fit the bolts to the engine bracket according to the marks made earlier.

Tightening torque 53 Nm (39 lbf ft)

|

|

| 17. |

Remove the lifting beam and the holder.

|

|

| 18. |

Connect the air exhaust hose.

|

|

| 19. |

Fasten the cable to the cable retainer by pulling back the locking sleeve.

|

|

| 20. |

Fit the gear cable to the selector lever arm.

|

|

| 21. |

Fit the cable to the rear mounting.

|

|

| 22. |

Fit the upper bolts between the engine and the gearbox.

Tightening torque 60 Nm (44 lbf ft)

|

|

| 23. |

Put the wiring harness in place and fit the cable duct to the gearbox.

|

|

| 24. |

Connect and secure the control module connector.

|

|

| 25. |

Fit the coolant pipe with a new O-ring to the thermostat housing. Lubricate with Vaseline. Do not tighten the screw until the screw for the attaching lug has been fitted.

|

|

| 26. |

Fit the turbo delivery hose.

|

|

| 27. |

Raise the car.

|

|

| 28. |

Remove the oil cooler hose seals (does not apply to new gearboxes). Use

83 90 270 Sliding hammer

,

87 92 319 Adapter, 3/8" - M10

and

87 92 756 Puller, oil pipe seal, automatic transmission

.

|

||||||||||

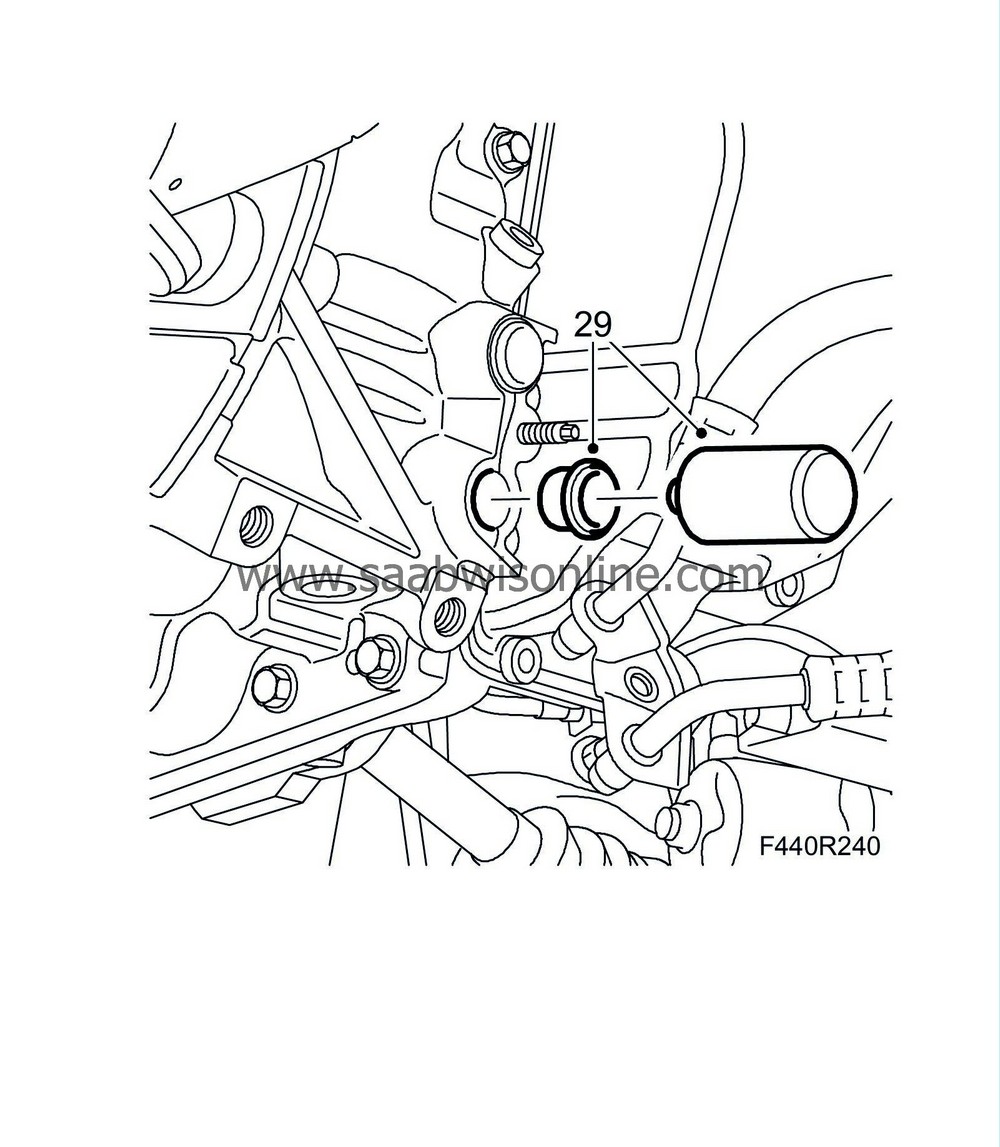

| 29. |

Fit new seals lubricated with Vaseline for the oil cooler hoses (does not apply to gearbox). Use

87 92 814 Fitting, oil pipe seal, automatic transmission

.

|

|

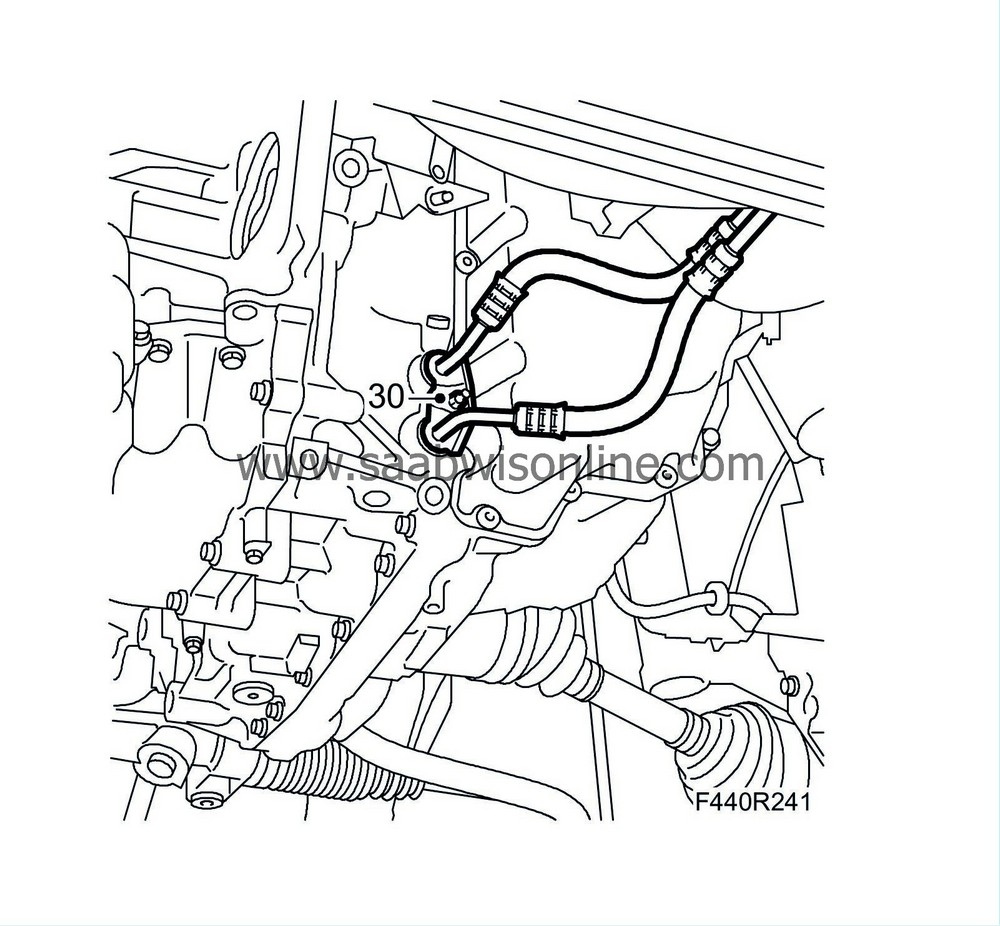

| 30. |

Lubricate the pipes with Vaseline, non-acidic and attach the oil cooler hoses. The pipes press holes into the seals during fitting.

|

|

| 31. |

Fit the screws to the coolant pipe attaching lugs.

|

|

| 32. |

Fit the battery ground cable and the wiring harness clamp to the metal bracket.

|

|

| 33. |

Fit the starter motor.

Tightening torque 47 Nm (35 lbf ft)

|

|

| 34. |

Fit the electrical connections to the starter motor.

|

|

| 35. |

Fit the secondary air pump with mounting.

|

|

| 36. |

Fit the air connections and electrical connections plus the coolant hose to the secondary air pump.

|

|

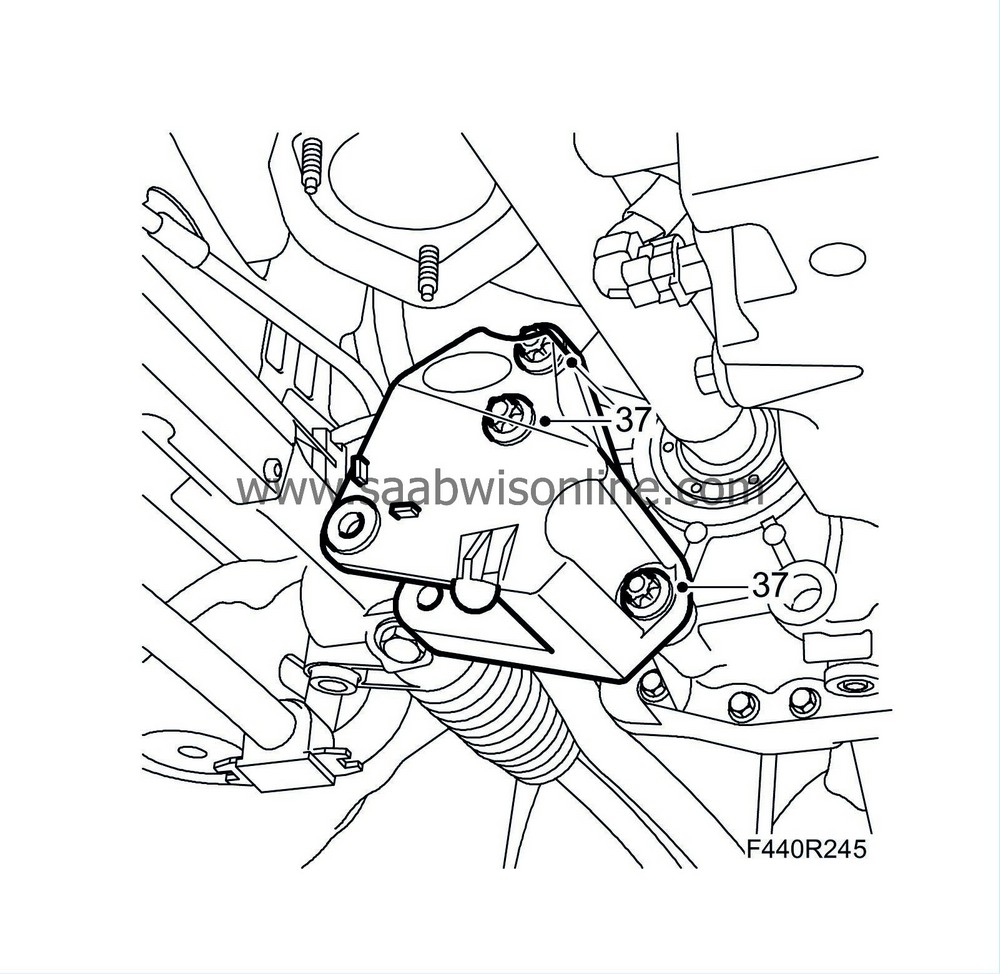

| 37. |

Fit the rear torque rod bracket to the gearbox.

Tightening torque 80 Nm (69 lbf ft)

|

|

| 38. |

Fit the front torque rod bracket to the gearbox.

Tightening torque 80 Nm (69 lbf ft)

|

|

| 39. |

Roll the trolley lift with subframe under the car.

|

|

| 40. |

Lift the frame. Position the suspension arm ball joints in the steering swivel member and the radiator guide pins. Make sure the upper radiator guides are against their brackets.

|

||||||||||||||||

| 41. |

Fit the anti-roll bar to the subframe.

|

|

| 42. |

Lift in place the subframe. Steer the guide pins in the fixture to the holes in the body.

|

|

| 44. |

Remove the trolley lift.

|

|

| 45. |

Fit the power steering pipe to the subframe plastic clips.

|

|

| 46. |

Fit the steering gear with bolts, washers and nuts.

Tightening torque 50 Nm +60° (37 lbf ft +60°)

|

|

| 47. |

Fit the engine torque rod to the subframe.

Tightening torque, front nut 60 Nm +90° (44 lbf ft +90°) Tightening torque, rear bolt 80 Nm (59 lbf ft)

|

|

| 49. |

Fit the connector and cable clip to the headlamp angle sensor. (Option)

|

|

| 50. |

Remove the straps.

|

|

| 51. |

Set up

83 96 145 Centring tool, subframe - engine

and

83 96 152 Centring tool, power train

with

32 025 059 Support

, without the long supports. Check that the engine is correct in relation to the subframe. Remove the centring tool.

|

|

| 52. |

Fit the rear catalytic converter. Lubricate the threads with

90 513 210 Universal paste

.

Tightening torque, exhaust flanges 30 Nm (22 lbf ft) Tightening torque, exhaust clamp 40 Nm (30 lbf ft)

|

|

| 53. |

Fit the front wing liner section on both sides of the car.

|

|

| 54. |

Fit the spoiler shield.

CV:

Fit

Chassis reinforcement, front subframe, CV

.

|

|

| 55. |

Fit the wheels. See

Wheels

.

|

|

| 56. |

Lower the car to the floor.

|

|

| 57. |

Fit the upper bumper shell mountings.

|

|

| 58. |

Tighten the screw on the thermostat housing.

|

|

| 59. |

Test pressurise the cooling system, see

Cooling system, test pressurising

.

|

|

| 60. |

Fill with three litres of gearbox oil, refer to List of lubricants and sealing compounds. If a new or reconditioned gearbox is being fitted, more oil may be needed as the gearbox can be empty.

|

|

| 61. |

Fit the filler plug.

Tightening torque 45 Nm (33 lbf ft). |

|

| 62. |

Fit the lower heat shield from the catalytic converter.

|

|

| 63. |

Fit the upper heat shield over the catalytic converter.

|

|

| 64. |

Fit the expansion tank.

|

|

| 65. |

Fit the battery tray.

|

|

| 66. |

Fit the cable duct, bonnet switch electrical connection and the electrical centre to the battery tray.

|

|

| 67. |

Fit the battery.

|

|

| 68. |

Fit and connect the battery cables.

|

|

| 69. |

Fit the battery cover.

|

|

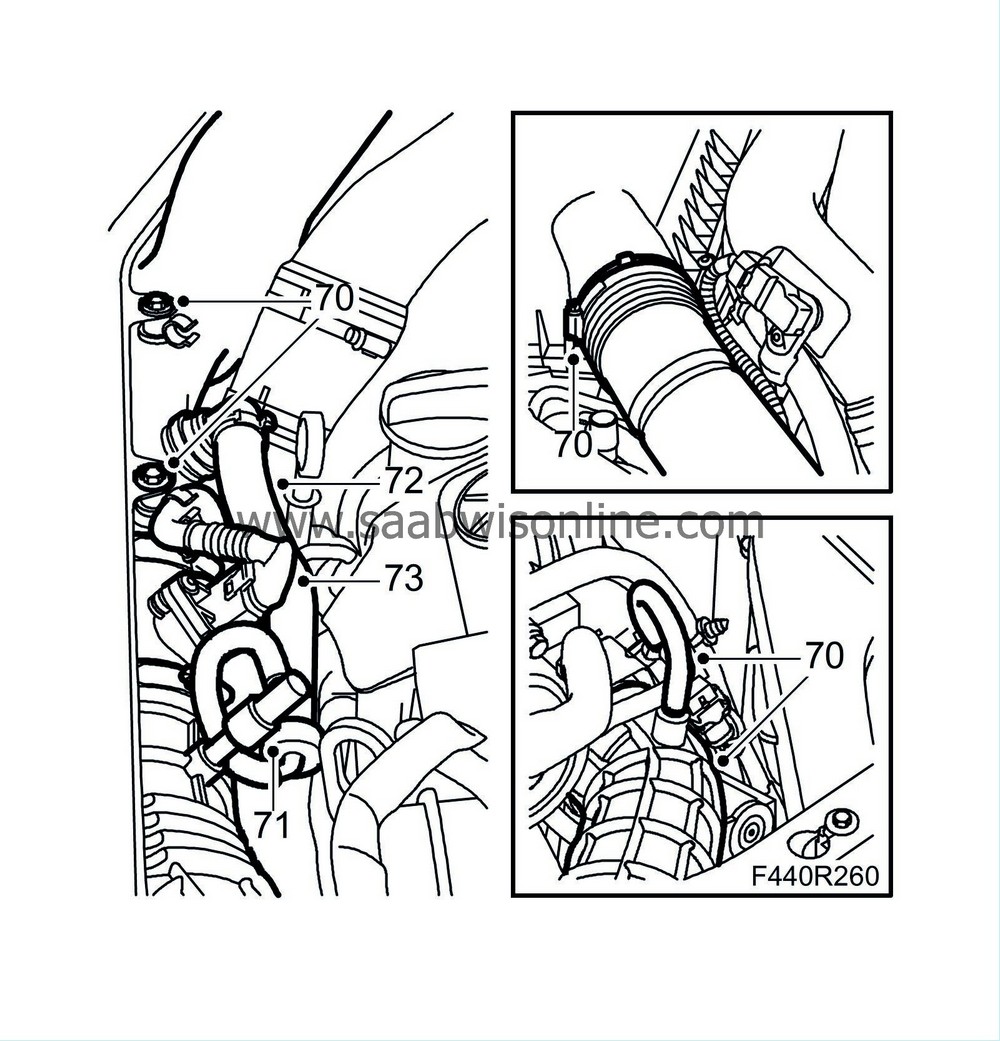

| 70. |

Fit the hose to the mass air flow sensor and the air filter cover.

|

|

| 71. |

Fit the vacuum hoses.

|

|

| 72. |

Fit the hose to the secondary air pump.

|

|

| 73. |

Fit the mass air flow sensor connector.

|

|

| 74. |

Fit the upper engine cover.

|

|

| 75. |

Fill with coolant, see

Bleeding and topping up the cooling system

.

|

|

| 76. |

If the gearbox has been changed, perform

Checking and adjustment, selector lever cable

.

|

|

| 77. |

Check the transmission fluid level. See

Check/adjust fluid level, B284

|

|

| 78. |

If the gearbox has been changed, perform

After changing a control module

.

|

|

| 79. |

Carry out

Measures after disconnecting the battery

.

|

|

| 80. |

Remove the wing covers.

|

|

| 81. |

After gearbox replacement, carry out

Adaptation, resetting

.

|

|

| 82. |

Test drive the car with varying engine loads and speeds and delete eventual trouble codes. Also check the position of the steering wheel when driving straight ahead on a level road. Adjust if needed.

|

|

Warning

Warning