PRE-RELEASE

Part of D-pillar

| Part of D-pillar |

| To remove |

Certain welded joints on the car may be MIG brazed with bronze as the filling material. A MIG brazed seam can be identified by the gold colour of the joint. MIG brazing must always be replaced by new MIG brazing.

|

|||||||

| 1. |

Remove

Part of side plate, 5D

.

|

||||||||||

| 2. |

Cut the reinforcement as illustrated.

|

|

| 3. |

Drill out the spot-welds on the outside.

|

|

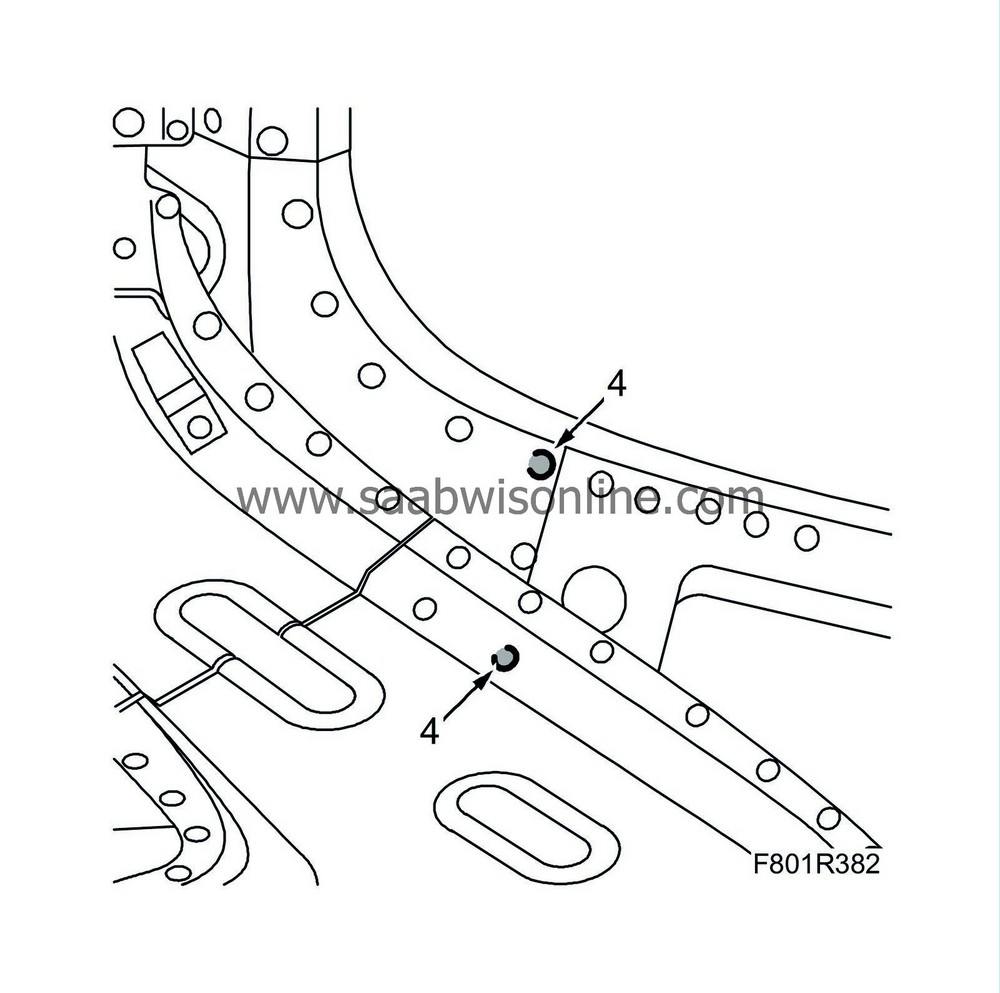

| 4. |

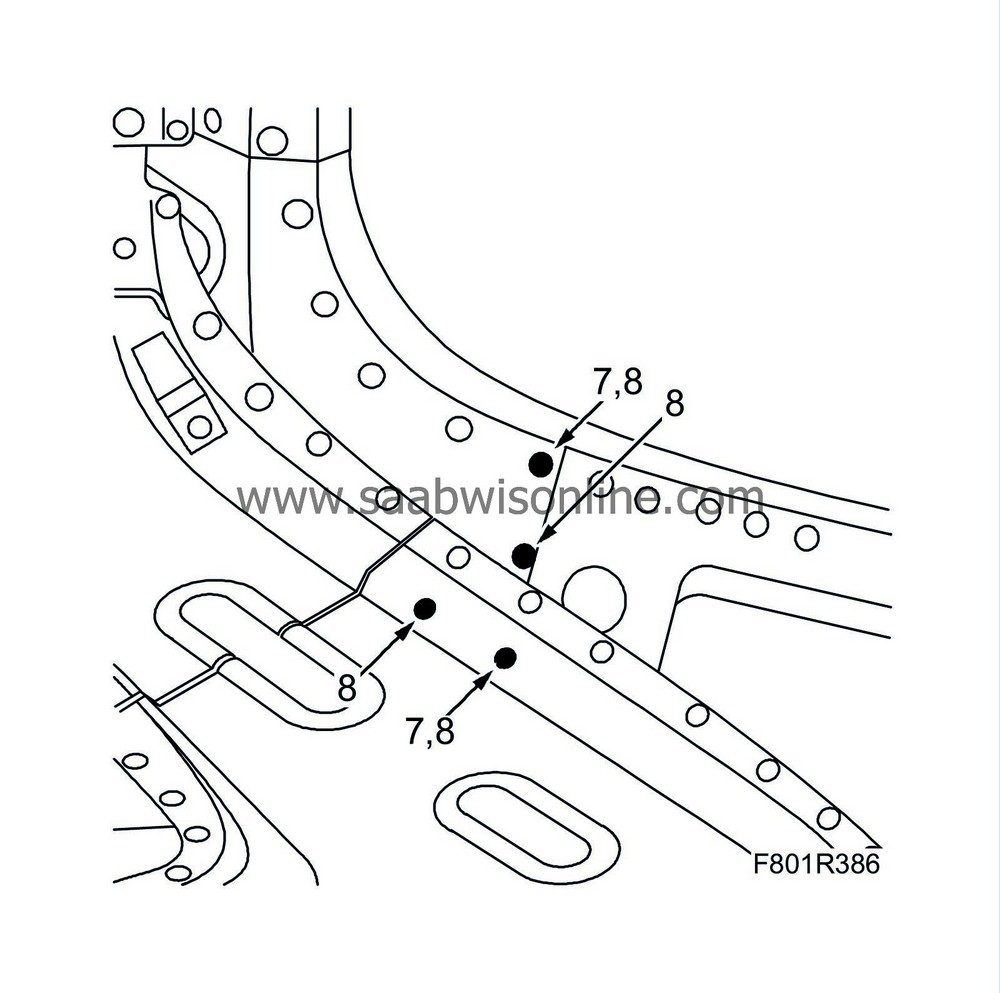

Two spot welds are to be drilled through a double panel as illustrated (shaded grey).

|

|

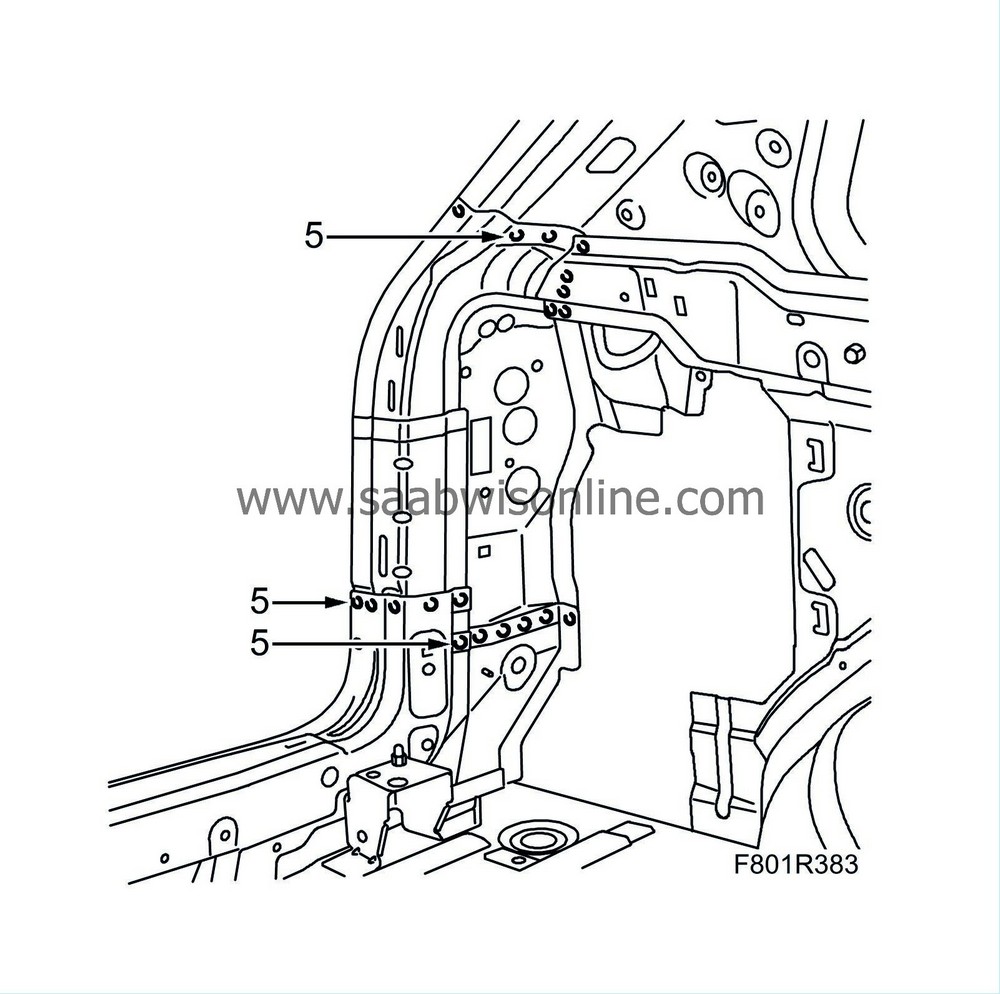

| 5. |

Drill out the spot-welds in the luggage compartment.

|

|

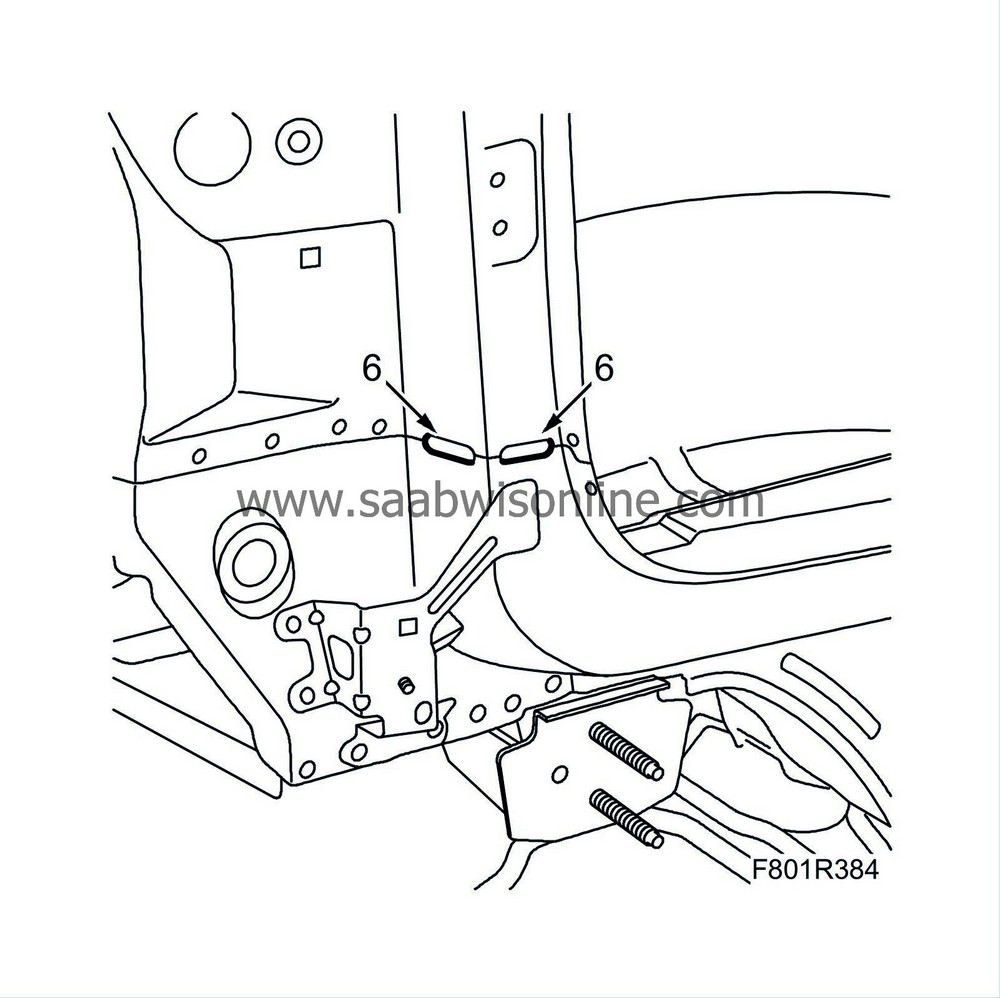

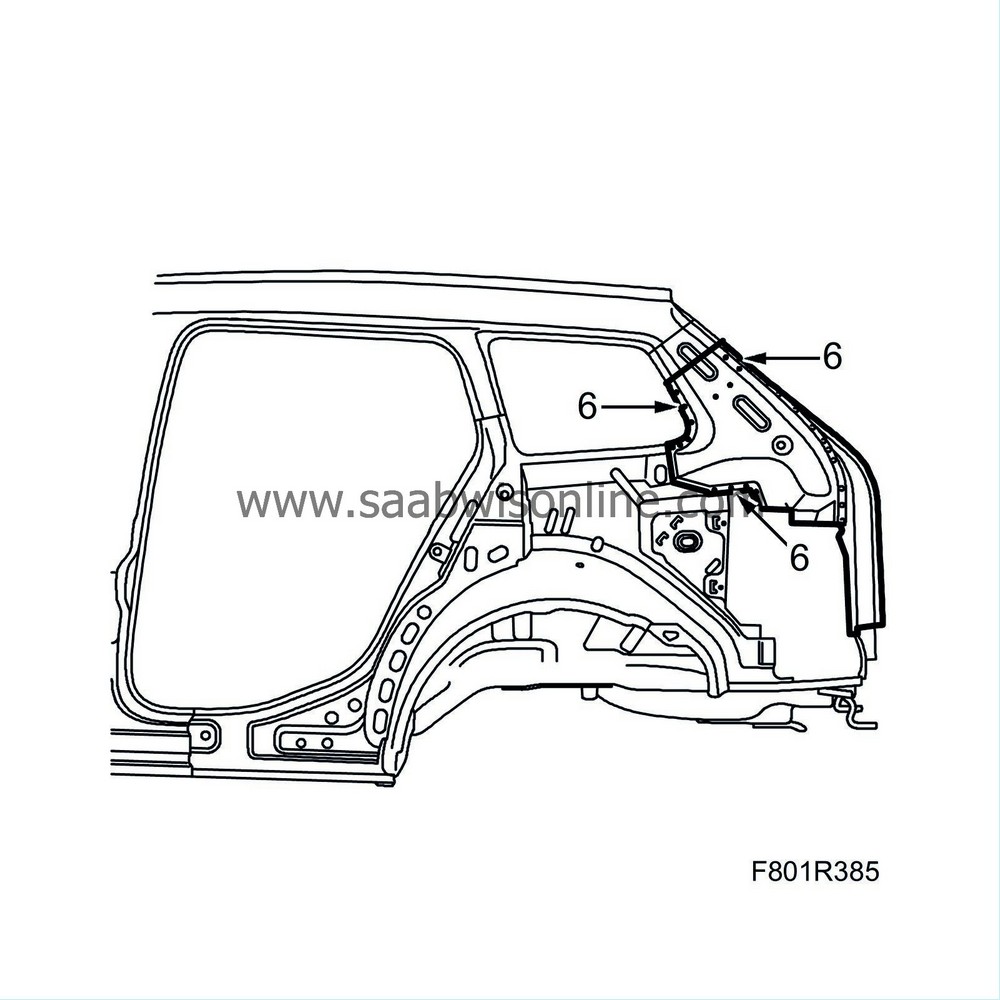

| 6. |

Grind away the MIG brazing.

|

|

| 7. |

Knock loose the panel.

|

|

| 8. |

Align any deformed sheet metal or panels.

|

|

| To fit |

| 1. |

Cut and position the spare part.

|

|

| 2. |

Drill holes for plug-welding in the spare part.

|

|

| 3. |

Grind all surfaces that are to be welded.

|

|

| 4. |

Apply welding primer on the surfaces to be welded. Use Teroson Zink Spray.

|

|

| 5. |

Position the spare part and secure it with a few welding clamps. Measure the precise position of the D-pillar using the alignment jig measurement system and

Body dimensions, 4D, 5D

.

|

|

| 6. |

Spot and plug weld on the spare part.

|

|

| 7. |

Drill holes for plug welding. Drill the holes through two panels.

|

|

| 8. |

Spot and plug weld on the spare part on the outside.

|

|

| 9. |

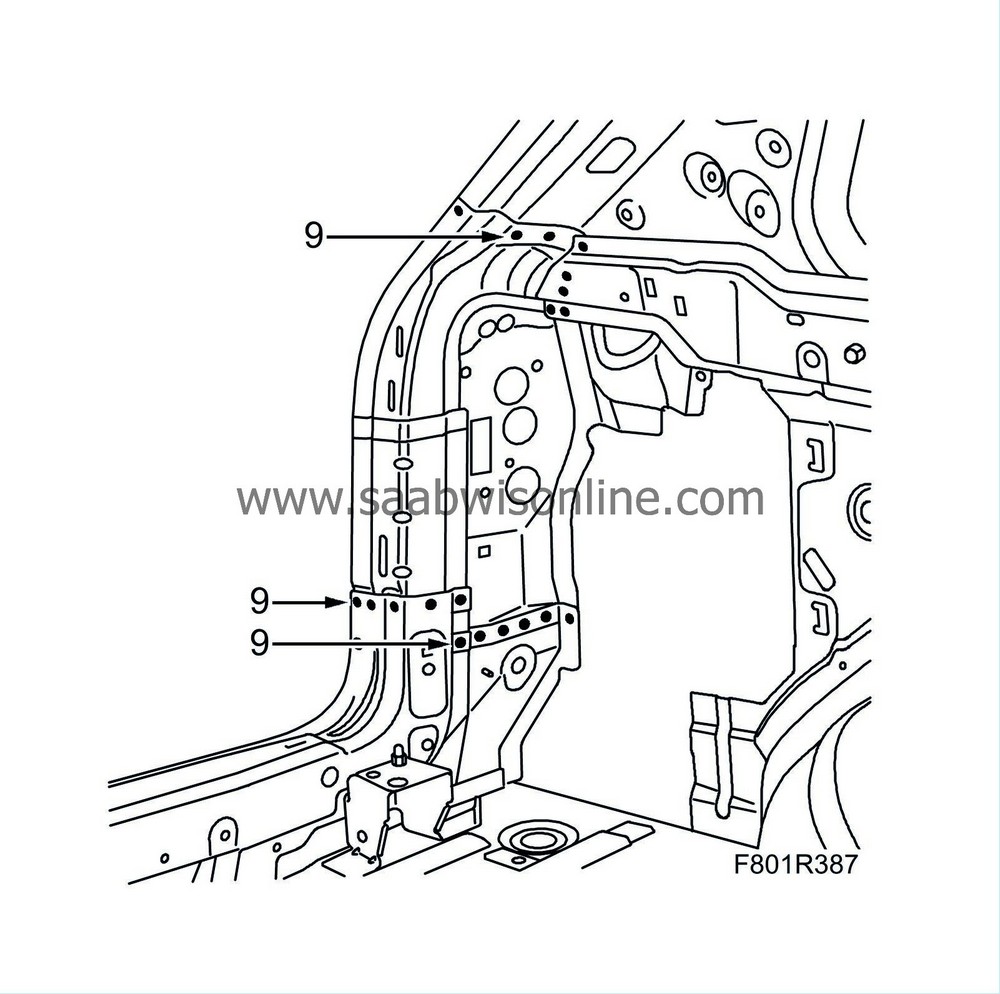

Position the new reinforcement pieces on the outside. Spot and plug weld on the reinforcement pieces.

|

|

| 10. |

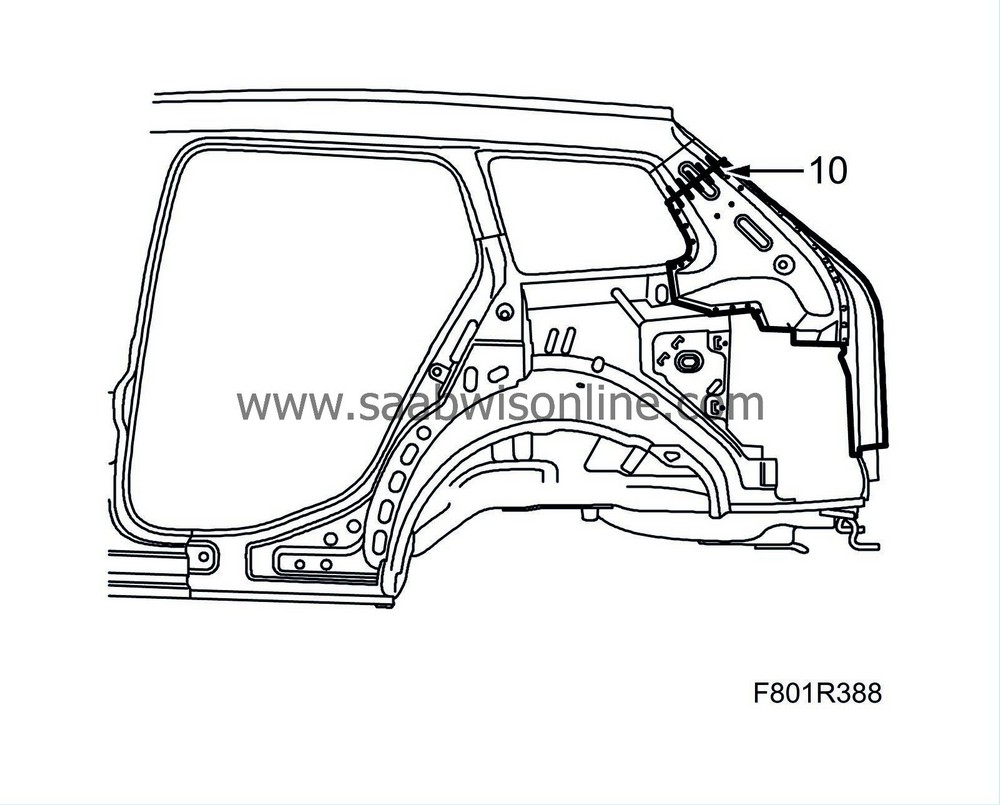

Seam weld the joint.

|

|||||||||

| 11. |

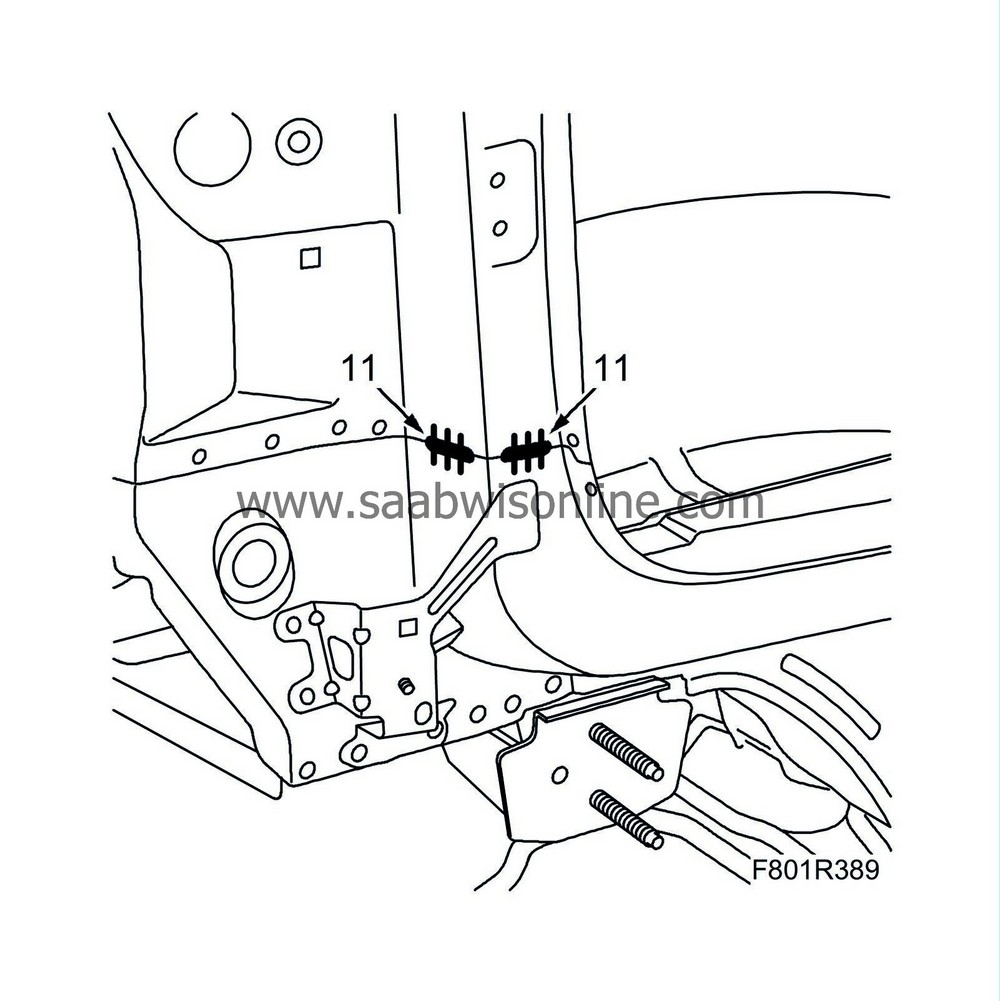

MIG braze as illustrated.

|

|

| 12. |

Grind the welds.

|

|

| 13. |

Apply rust proofing to the joint.

|

|

| 14. |

Apply welding primer to the surfaces to be spot and plug welded.

|

|

| 15. |

Fit

Part of side plate, 5D

.

|

|

Warning

Warning