Computerised oil and fluid management

|

|

Computerised oil and fluid management

|

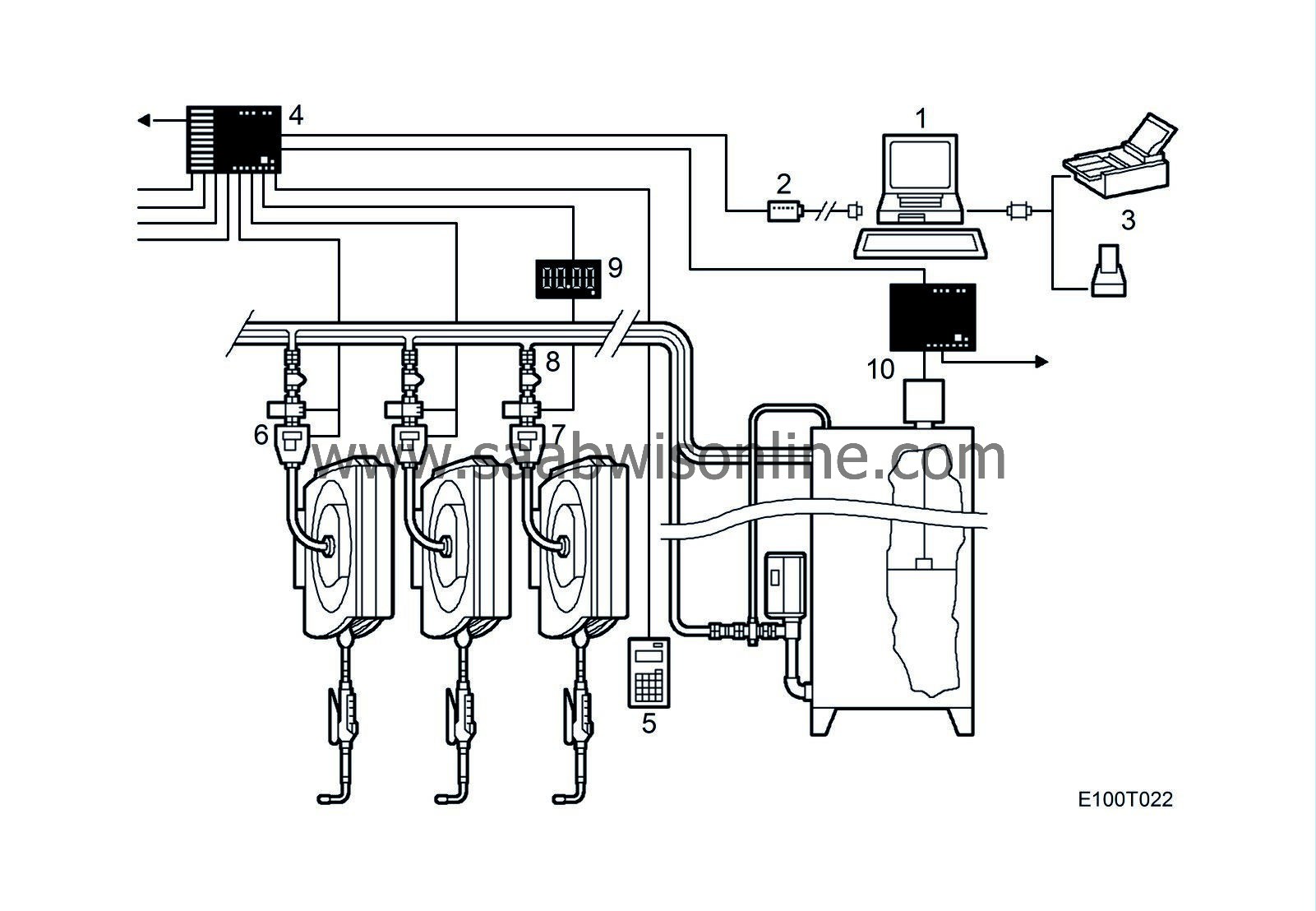

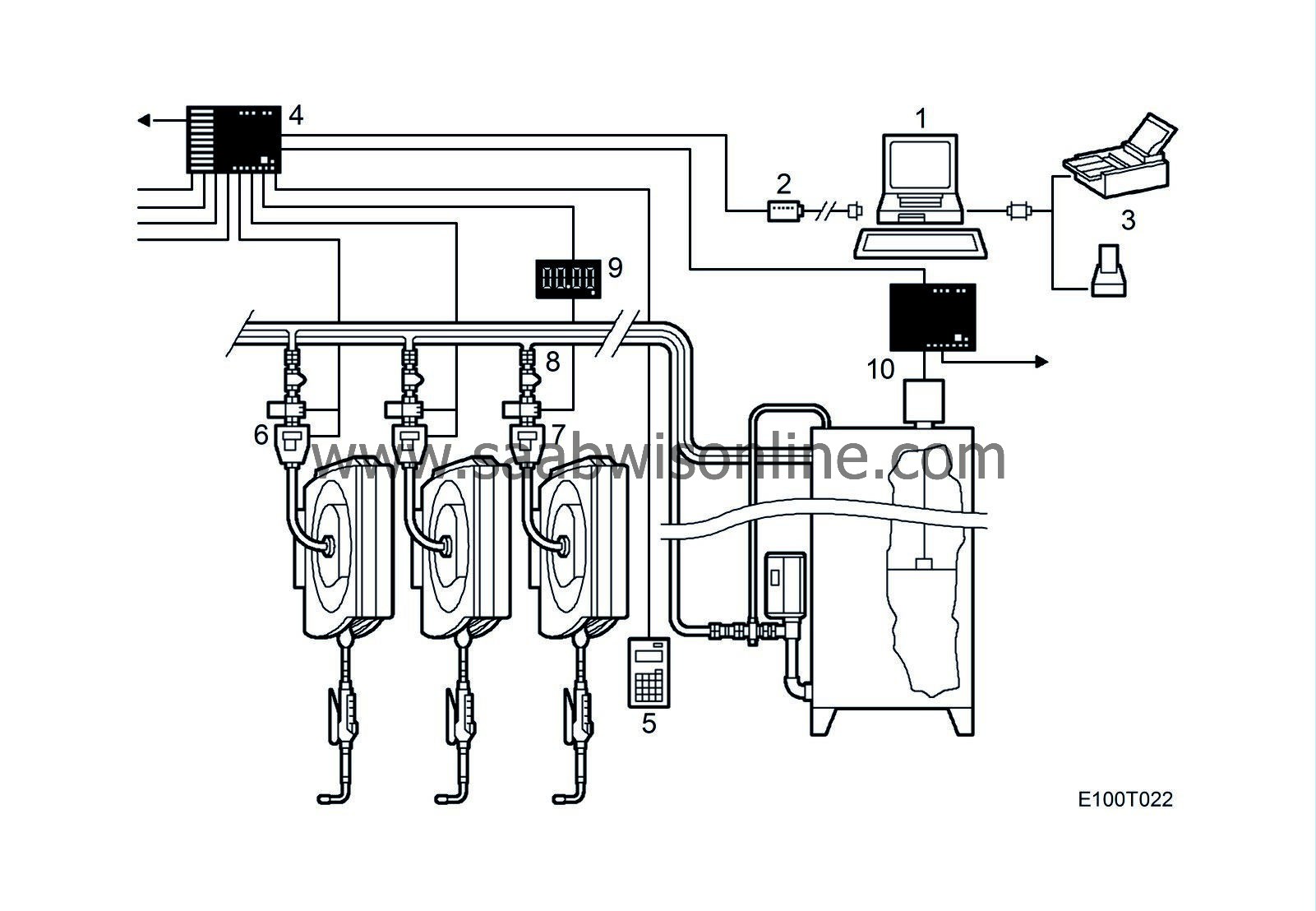

For medium and large workshops, a computerised monitoring system makes the distribution and management of oils and fluids much easier.

The system is flexible and can be expanded for control of several tapping points and fluids. Levels in fresh oil tanks and any overfill protection for waste oil tanks can also be monitored by the system.

With this type of system, you can simply set the desired volumes for tappings and then link these to the relevant work orders.

Several items of data can be generated:

|

•

|

Time, date, user ID, work order number, transaction number.

|

|

•

|

Tapped volume, fluid name, hose reel number.

|

The system can include the following equipment:

|

1.

|

PC with program for controlling and monitoring the system.

Here, you can also get data on how much fluid has been used as well as the levels/quantities in each tank.

|

|

2.

|

Communication adapter.

|

|

3.

|

Printer/receipt printer for printing tappings, reports, etc.

|

|

4.

|

Central unit through which the tapping points are controlled from the PC or the terminals.

|

|

5.

|

Terminals for selecting oil/fluid and quantity. Here, you can also enter data such as work order number, thereby linking a tapping to a specific job.

|

|

6.

|

A number of hose reels with nozzles for various oils and fluids.

|

|

7.

|

Volume meter and solenoid valve.

|

|

10.

|

Tank level module and tank level sensor.

|

Compare with the following equipment:

|

•

|

Assalub

Internet address: www.assalub.com

|

|

•

|

Alentec Orion

Internet address: www.alentec.com

|