PRE-RELEASE

Rear lamp panel, 5D

| Rear lamp panel, 5D |

Certain welded joints on the car may be MIG brazed with bronze as the filling material. A MIG brazed seam may be recognized from the gold colour of the joint. A MIG brazing must always be replaced by a new MIG brazing.

|

|||||||

| To remove |

| 1. |

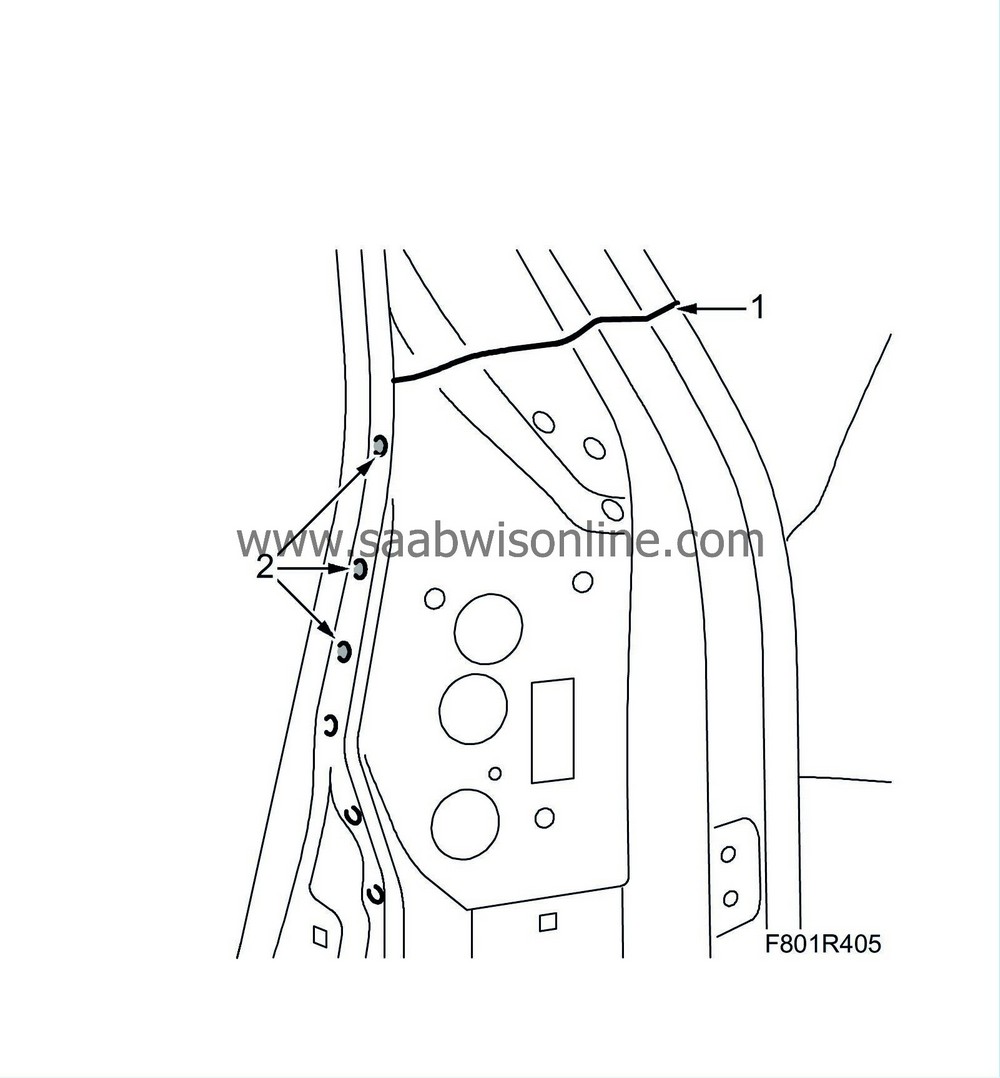

Cut the rear light panel as illustrated.

|

|

| 2. |

Drill out the spot welds through the double panel (shaded grey).

|

|

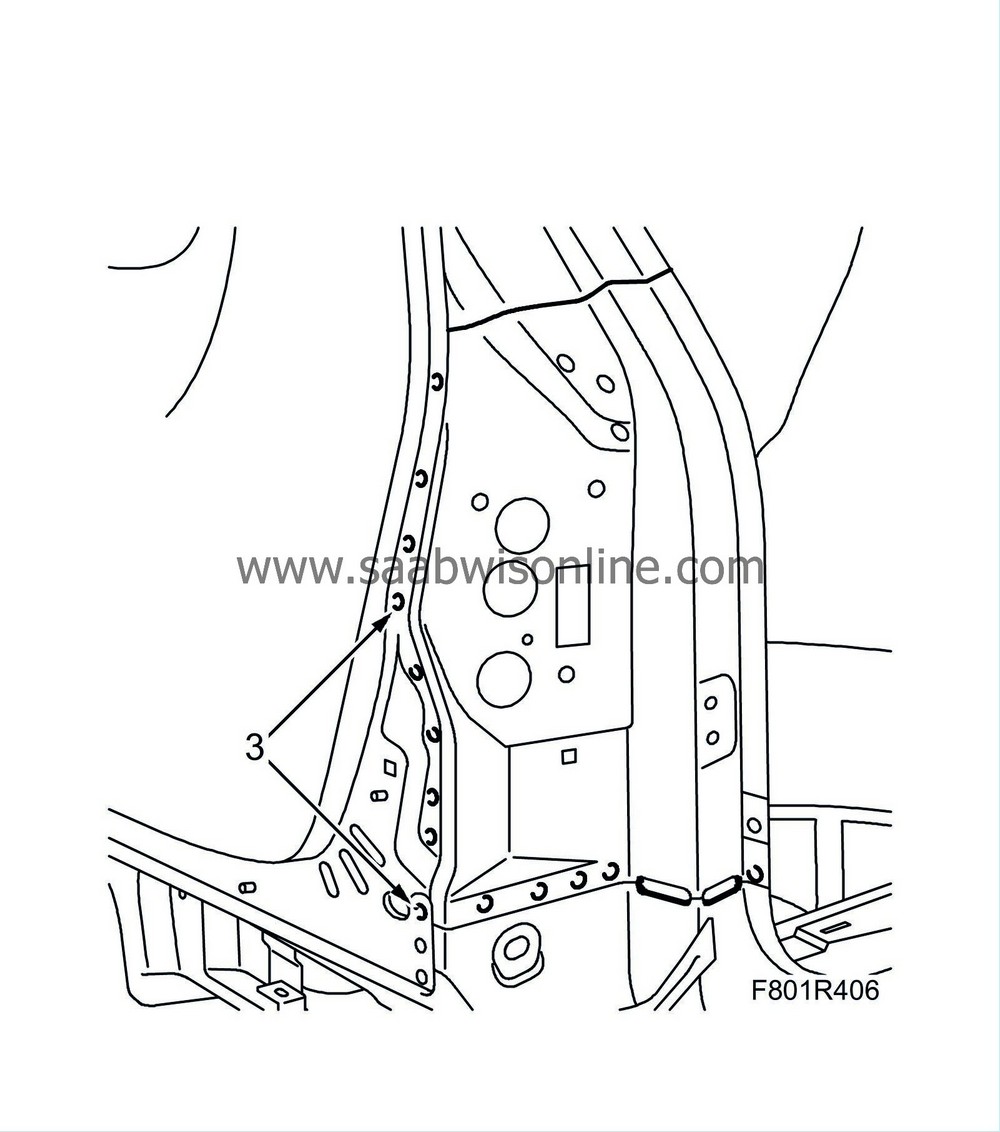

| 3. |

Drill out the spot welds.

|

|

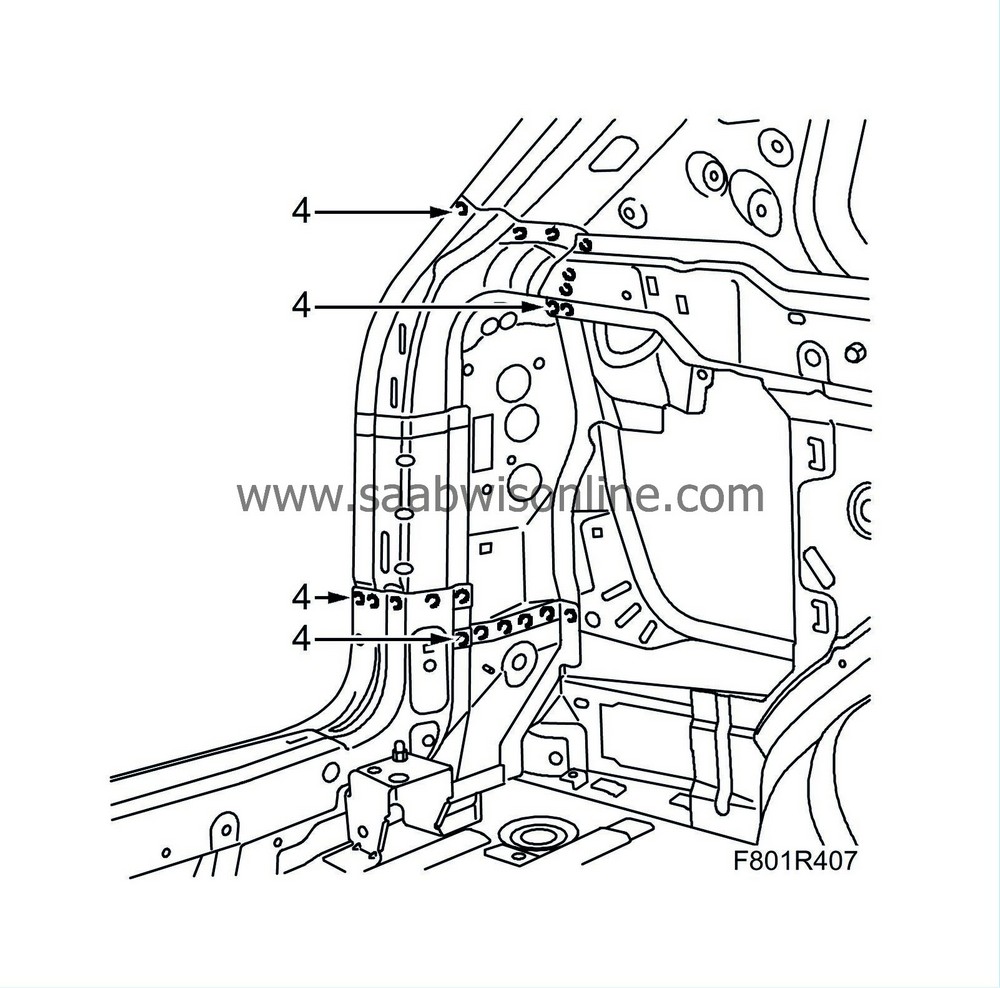

| 4. |

Drill out the spot-welds on the inside.

|

|

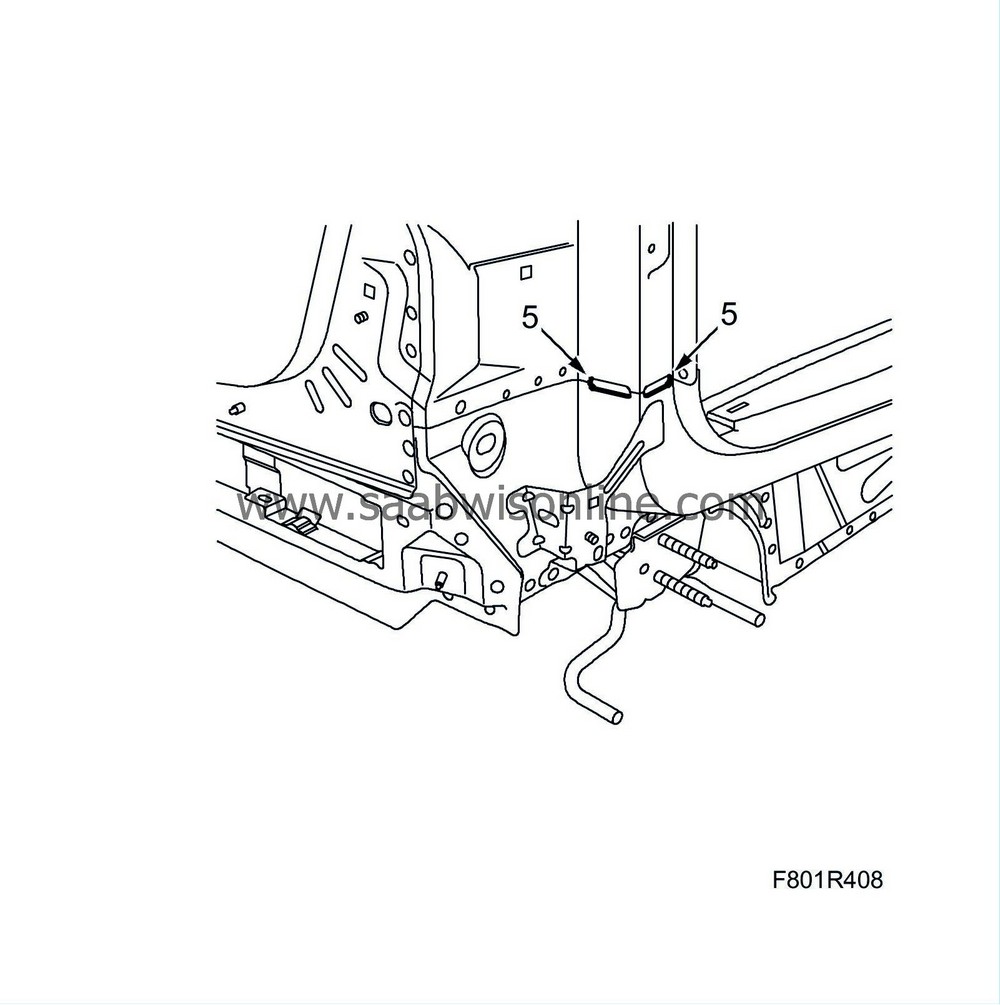

| 5. |

Grind away the MIG brazed seam welds.

|

|

| 6. |

Knock loose the panel.

|

|

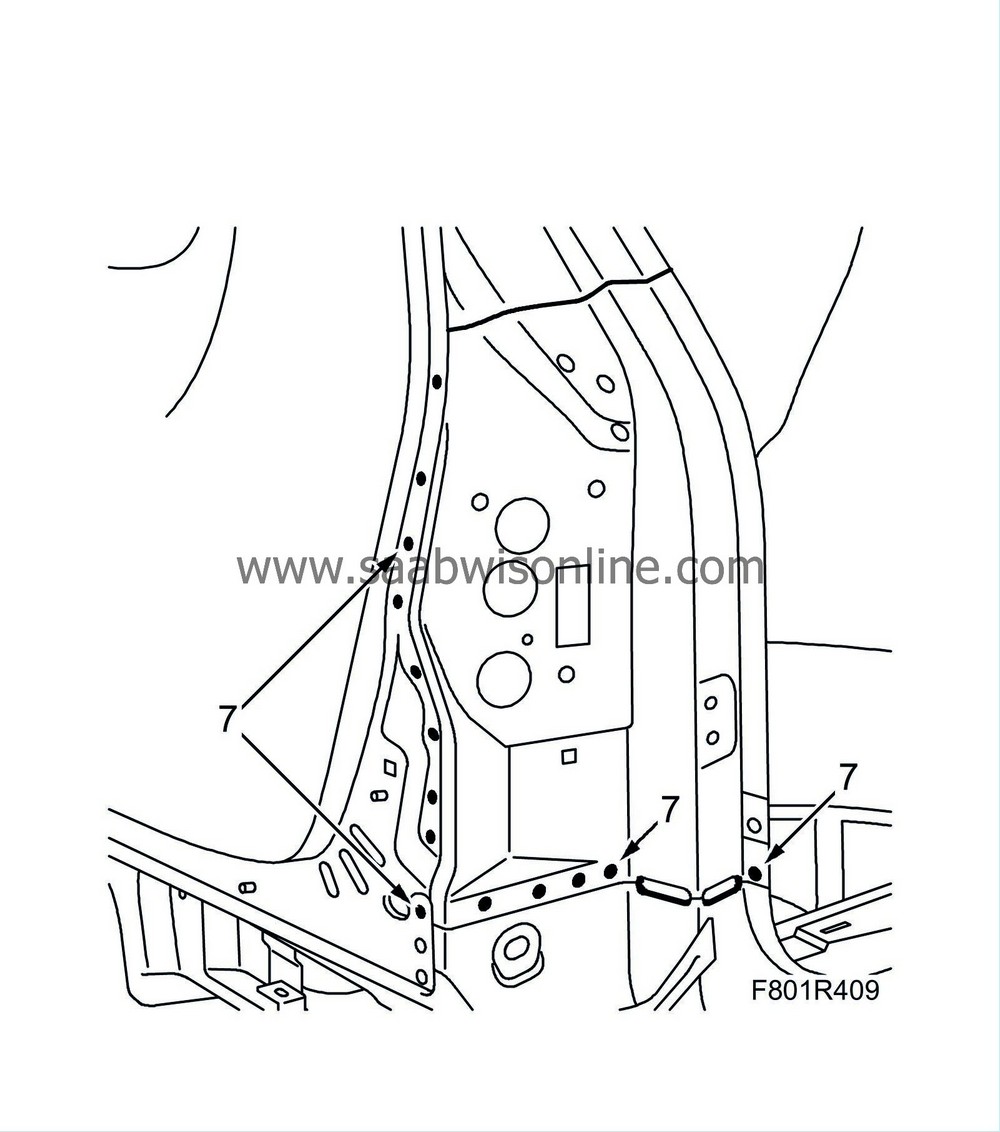

| 7. |

Align any deformed sheet metal or panels.

|

|

| To fit |

| 1. |

Cut the replacement panel so that it fits against the cuts previously made.

|

|

| 2. |

Drill holes for plug welding where appropriate.

|

|

| 3. |

Grind clean the surfaces to be spot and plug welded.

|

|

| 4. |

Apply welding primer to the surfaces to be spot and plug welded. Use Teroson Zink Spray

|

|

| 5. |

Position the new spare part so that the joint can be but-welded.

|

|

| 6. |

Measure out the precise position of the spare part using the alignment jig measuring system and

Body dimensions, 4D, 5D

. Secure with a few welding clamps.

|

|

| 7. |

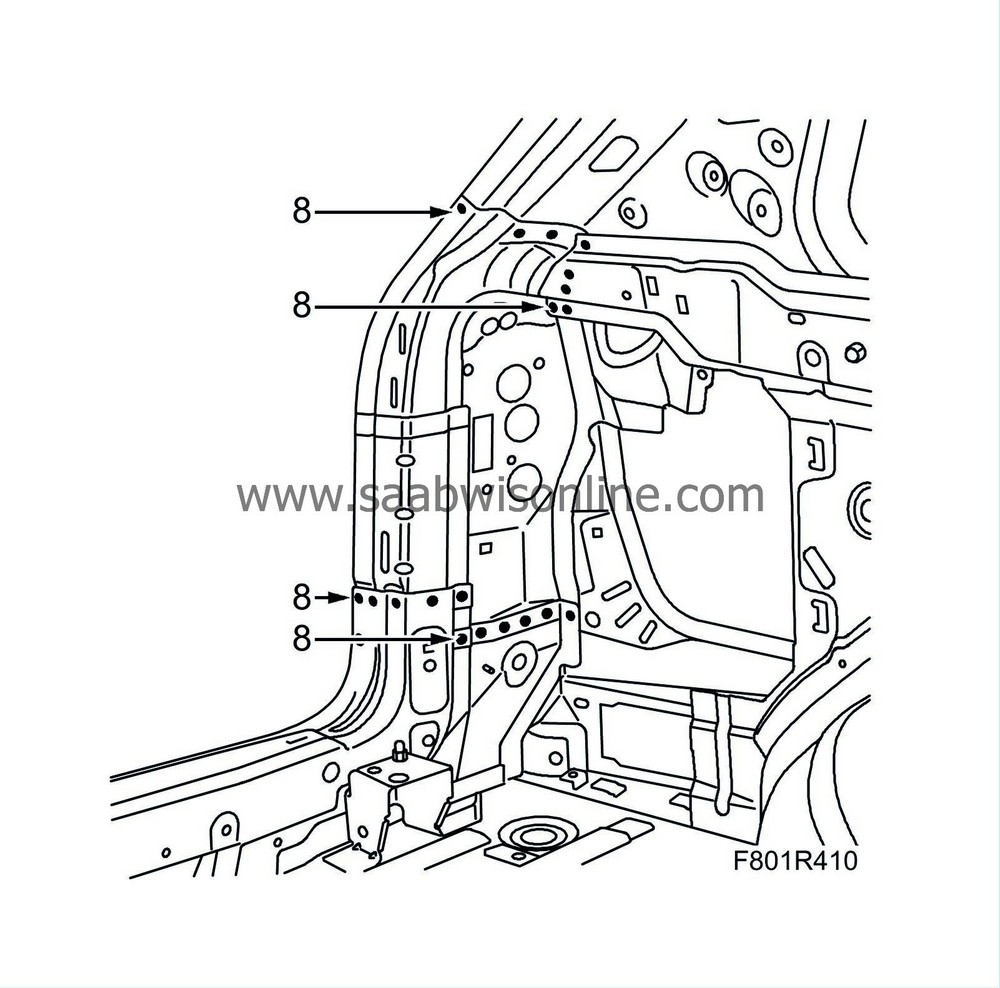

Spot and plug weld on the spare part.

|

|

| 8. |

Spot and plug weld on the spare part.

|

|

| 9. |

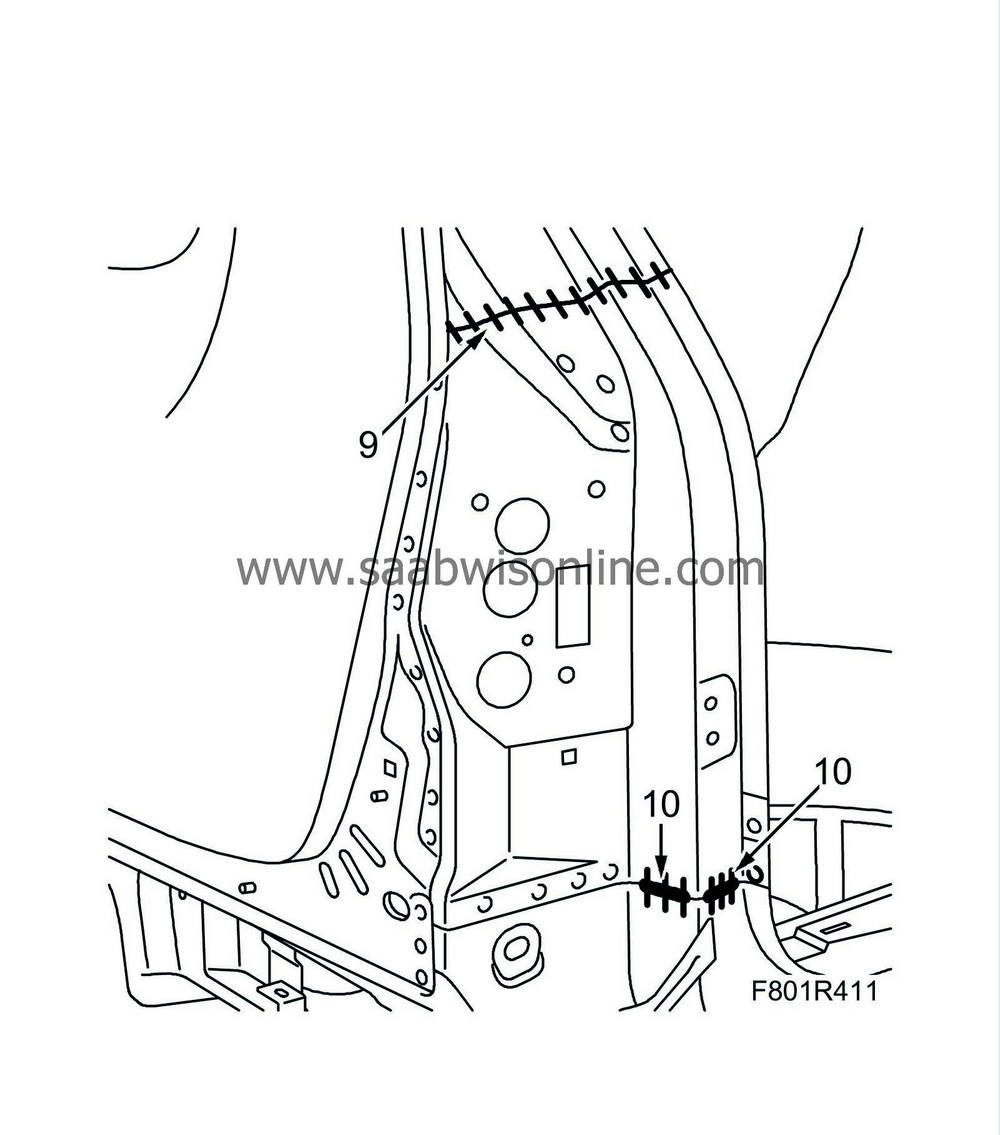

Seam weld the joint.

|

|||||||||

| 10. |

Seam weld with MIG brazing.

|

|

| 11. |

Grind the welds.

|

|

| 12. |

Wash away surplus welding primer. Welding primer reduces the adhesion of paint, filler and sealant.

|

|

| 13. |

Apply primer to all bare metal surfaces.

|

|

| 14. |

Seal joints and seams with sealant.

|

|

| 15. |

Apply anti-corrosion agent after painting. Use Terotex HV 400 or Mercasol 1.

|

|

Warning

Warning