Case Cover Assembly Assemble

|

|

Case Cover Assembly Assemble

|

|

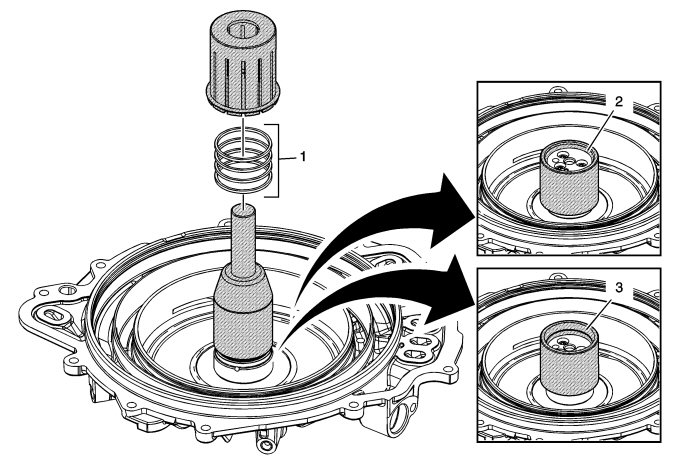

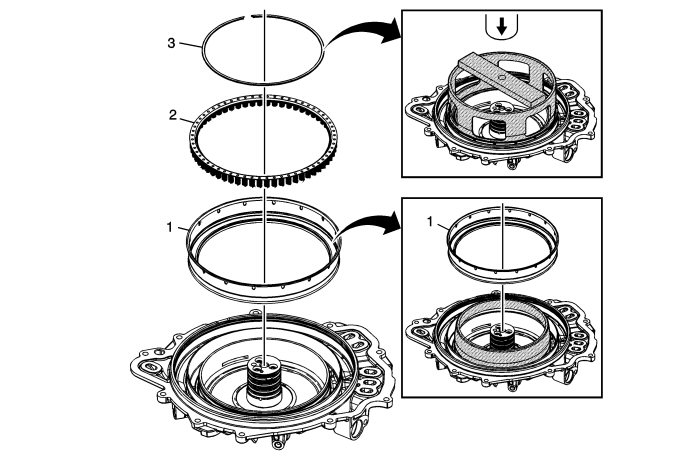

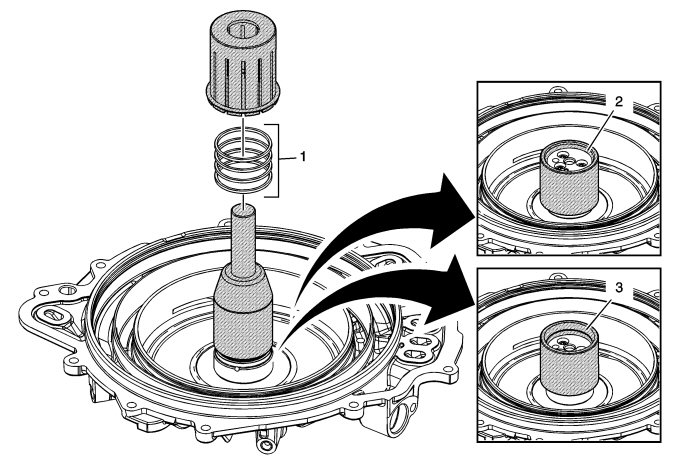

Fluid Seal Ring Installation

|

Fluid Seal Ring Installation

|

Callout

|

Component Name

|

|

1

|

3-5 Reverse and 4-5-6 Clutch Fluid Seal Ring

Procedure

|

1.

|

Place DT 46620-3 which is part of

DT-46620

seal installer over the case cover hub and adjust it so that only the bottom seal ring is exposed.

|

|

2.

|

Place a NEW fluid seal ring onto DT 46620-3 which is part of

DT-46620

seal installer.

|

|

3.

|

Use DT 46620-2 which is part of

DT-46620

seal installer to push the fluid seal ring down over DT 46620-3 which is part of

DT-46620

seal installer into the hub ring groove.

|

|

4.

|

Repeat the above steps to install all 4 seal rings, adjusting DT 46620-3 which is part of

DT-46620

seal installer to the appropriate ring groove.

|

Special Tools

DT 46620

Seal Installer

For equivalent regional tools, refer to

Special Tools

.

|

|

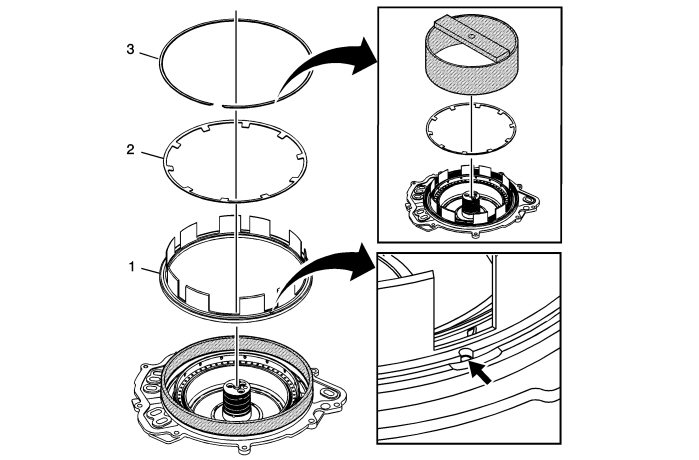

2

|

Small Chamfer Faces Up

Warning

Warning

|

|

Do not force the seal installer down over the seals as this will roll and damage the seals. The large chamfer is designed to fit over the over stretched seal. Use a hand to help shrink the seal if the seal installer is difficult to install over the seal rings.

|

|

|

|

|

|

Procedure

Install DT 46620-1 which is part of

DT-46620

seal installer with the large chamfer end down over the fluid seal rings and leave DT 46620-1 which is part of

DT-46620

seal installer on the seals for at least 60 seconds.

|

|

3

|

Large Chamfer Faces Up

Procedure

|

1.

|

Install DT 46620-1 which is part of

DT-46620

seal installer with the small chamfer end facing down for at least 60 seconds. This will properly size the bottom seal ring.

|

|

2.

|

Leaving DT 46620-1 which is part of

DT-46620

seal installer on the fluid seal rings for an extended period of time could cause a fluid leak on the initial clutch piston circuit until the seal rings warm up and expand to the proper dimension.

|

|

|

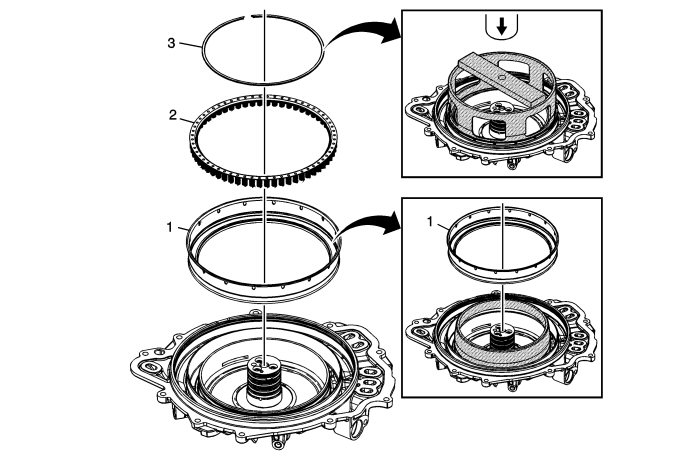

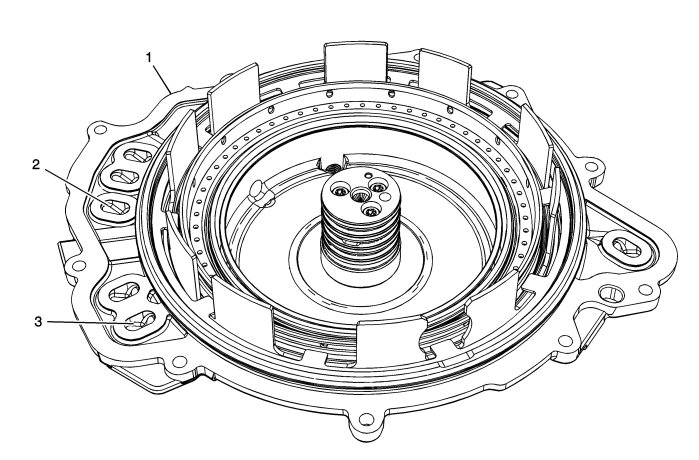

2-6 Clutch Piston Installation

|

2-6 Clutch Piston Installation

|

Callout

|

Component Name

|

|

1

|

2-6 Clutch Piston

Procedure

DT-46621

seal protector prevents the piston seal lip from damage over the retaining ring groove during installation. Apply a thin coat of ATF to the O.D. of

DT-46621

seal protector to ease the installation of the piston.

Special Tools

DT-46621

Seal Protector

For equivalent regional tools, refer to

Special Tools

.

|

|

2

|

2-6 Clutch Spring Assembly

|

|

3

|

2-6 Clutch Spring Assembly

Procedure

|

1.

|

Install the retaining ring with the opening positioned to the top of the case cover.

|

|

2.

|

Place the retainer ring inside

DT-46632

spring compressor prior to placing

DT-46632

spring compressor onto the spring.

|

Special Tools

DT-46632

Spring Compressor

For equivalent regional tools, refer to

Special Tools

.

|

|

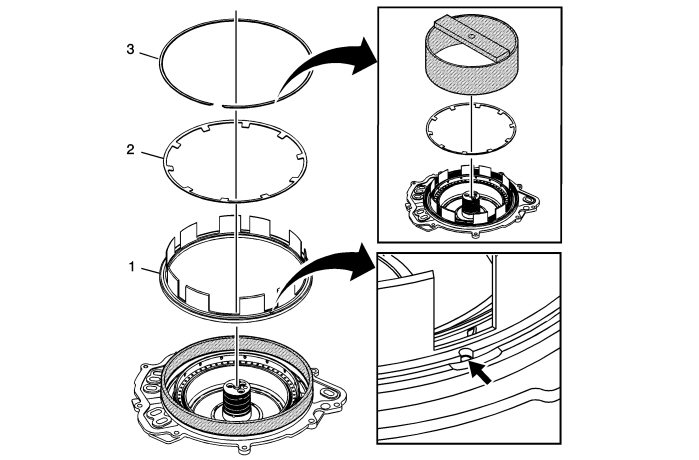

Low and Reverse Clutch Piston Installation

|

Low and Reverse Clutch Piston Installation

|

Callout

|

Component Name

|

|

1

|

Low and Reverse Clutch Piston Assembly

Procedure

|

1.

|

Install the L/R piston with the air bleed positioned at the alignment feature on the cover, using

DT-46628-1

seal protector. This will orient the piston fingers with the openings in the case.

|

|

2.

|

DT-46628-1

seal protector prevents the piston seal lip from damage during installation. Apply a thin coat of ATF to the I.D. of

DT-46628-1

seal protector to ease the installation of the piston.

|

Special Tools

DT-46628-1

Piston Seal Protector

For equivalent regional tools, refer to

Special Tools

.

|

|

2

|

Low and Reverse Clutch Spring

|

|

3

|

Low and Reverse Clutch Spring Retaining Ring

|

Note

|

|

Do not align the retainer opening with other retaining ring openings.

|

Special Tools

DT-46628-2

Spring Compressor

For equivalent regional tools, refer to

Special Tools

.

|

|

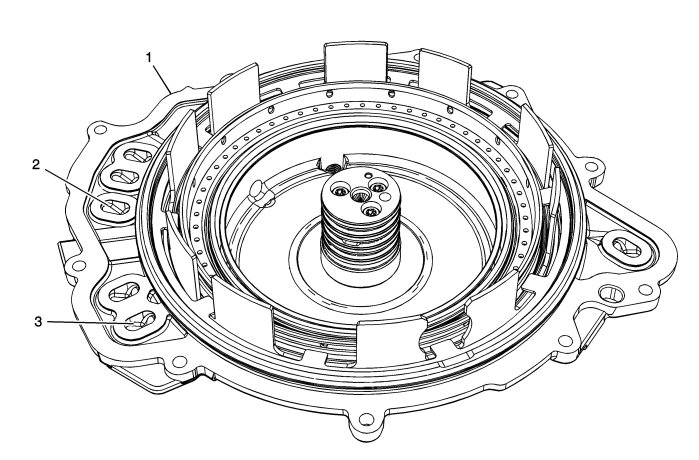

2-6 and Low-Reverse Piston Function Inspection

|

2-6 and Low-Reverse Piston Function Inspection

|

Callout

|

Component Name

|

|

1

|

Case Cover Assembly

|

Note

|

|

The fluid seal rings should be in place and not damaged.

|

|

|

2

|

2-6 Clutch Feed Passage

Warning

Warning

|

|

Regulate the air pressure to 40 psi maximum. High pressure could cause the piston to over travel and damage the piston seals.

|

|

|

|

|

|

Procedure

Apply shop air to the 2-6 clutch feed. Observe the 2-6 piston movement.

|

Note

|

|

Minimal piston movement and excessive air leaking could indicate damage to the 2-6 piston seals or improper assembly.

|

|

|

3

|

Low and Reverse Clutch Feed Passage

Warning

Warning

|

|

Regulate the air pressure to 40 psi maximum. High pressure could cause the piston to over travel and damage the piston seals.

|

|

|

|

|

|

Procedure

Apply shop air to the Low and Reverse clutch feed. Observe the Low and Reverse piston movement.

|

Note

|

|

Minimal piston movement and excessive air leaking could indicate damage to the Low and Reverse piston seals or improper assembly.

|

|

|

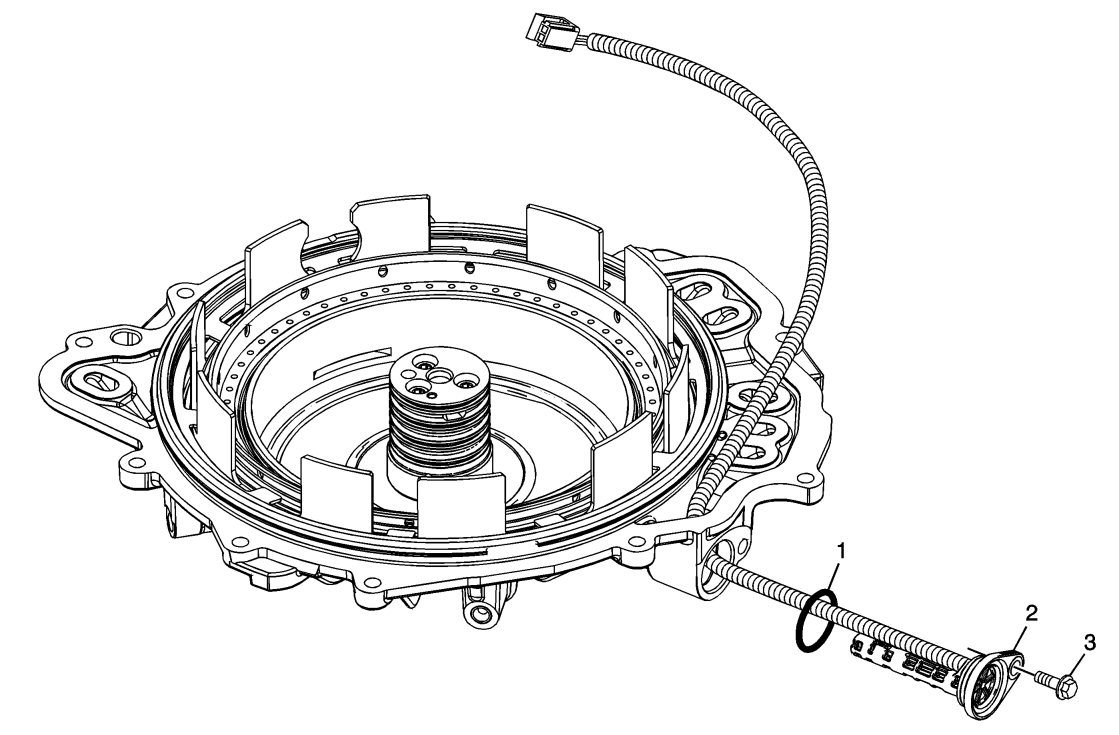

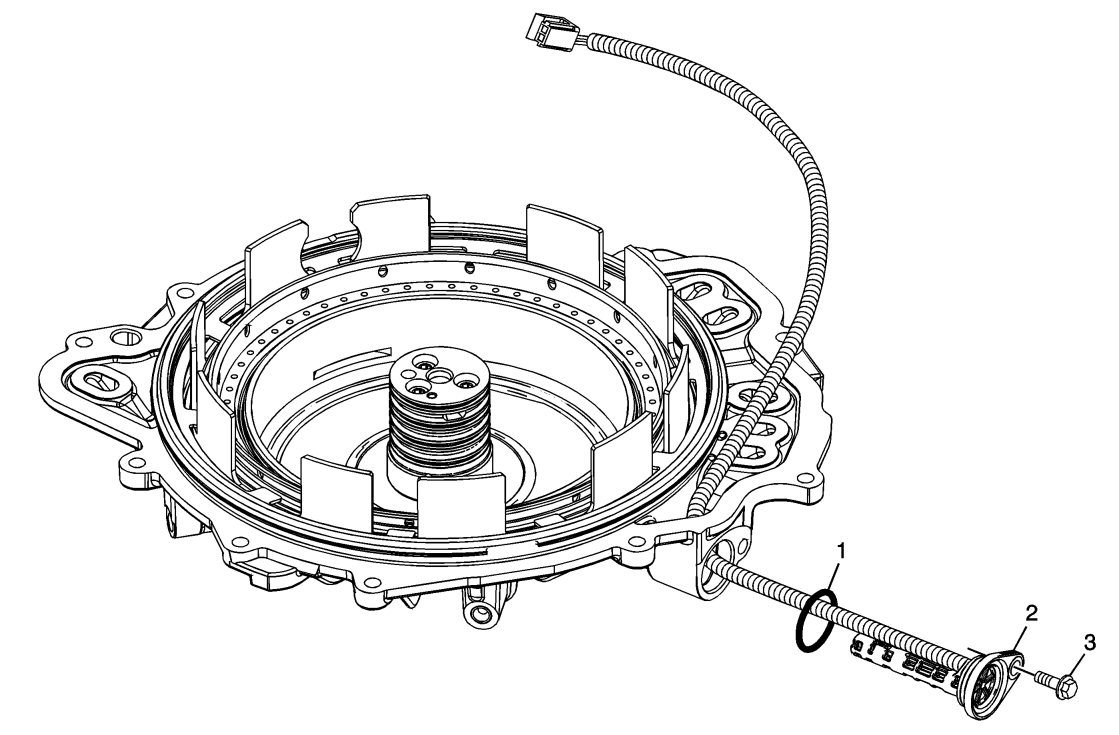

Input Speed Sensor Installation

|

Input Speed Sensor Installation

|

Callout

|

Component Name

|

|

1

|

Input Speed Sensor Seal

|

|

2

|

A/Trans Input Speed Sensor Assembly

|

|

3

|

A/Trans Input Speed Sensor Bolt M6 x 25

Refer to

Fastener Caution

.

Procedure

Apply threadlocker or equivalent to the input speed sensor bolt. Refer to

Adhesives, Fluids, Lubricants, and Sealers

.

|

Note

|

|

The seal is coated with a dry lubricant. If the coating is missing, lubricate the seal with automatic transmission fluid prior to installation.

|

Tighten

9 Nm (7 lb ft)

|

Warning

Warning