PRE-RELEASE

Description of operation, function chains

| Description of operation, function chains |

| 1. Vehicle speed |

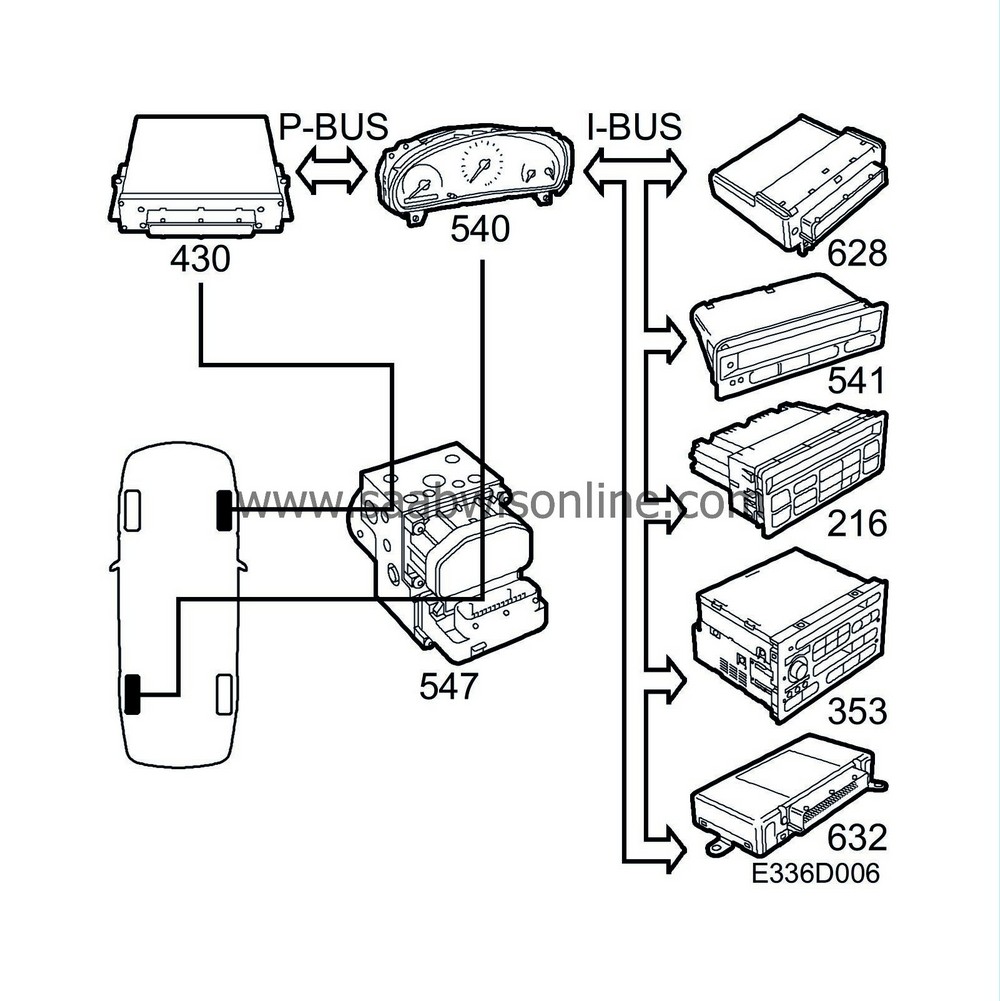

Cars with ABS

Vehicle speed is sensed by the ABS through an inductive sensor at each wheel. The sensor supplies the control module with alternating current, the amplitude and frequency of which increase with increasing wheel speed. The frequency is proportional to wheel speed, 29 Hz at a speed of one wheel revolution per second. The ABS control module uses the 4 wheel speeds to prevent wheel lock-up on braking.Several other systems in the car need to know vehicle speed. Cars with the ABS control module, which is not connected to the bus, have a control module output for each wheel speed. A transistor grounds each output 29 times per wheel revolution.

The main instrument panel is connected with a lead to the output for the LH rear wheel speed signal. The rear wheel is used to provide the most accurate measurement of distance from a non-driving wheel. In the main instrument panel, the frequency-modulated signal is converted to km/h. The main instrument panel makes a correction depending on programmed tyre type.

Cars with TC/ABS or ESP

On cars with Traction Control or ESP, the TC/ABS or ESP control module is connected to the P-bus. The TC/ABS or ESP control module sends out wheel speed for all four wheels, but the other systems only use information on the speed of the LH rear and RH front wheels.Wheel speed RL: The TC/ABS or ESP control module transmits the bus message “wheel speed rear left xxx km/h”. This message is used by MIU (internal). MIU sends “Vehicle speed” further along the P-bus and I-bus.

Wheel speed FR: The TC/ABS or EPS control module transmits the bus message “wheel speed front right xxx km/h”. This message is used by Trionic.

Since the main instrument panel is connected to a bus, all control modules connected to the bus are supplied with information on the speed of the left-hand rear wheel and the odometer reading.

The table of transmitted bus messages shows that MIU transmits the vehicle speed and that it is used by: Trionic, SID, ACC, Audio and TWICE. MIU also transmits the odometer reading, which is used by SID for the service indicator.

The various systems use the vehicle speed for the following functions:

| • |

Trionic has a separate lead from ABS for FR wheel speed. On cars with Traction Control or ESP, Trionic receives wheel speed information via the bus. The bus value is used as security for cruise control. Both values must exceed 40 km/h for this to work. The value is also used as a substitute value if the FR wheel speed should disappear.

|

|

| • |

DICE uses the value to activate the radiator fans for A/C on, high outside temperature and low speed.

|

|

| • |

SID uses the value for trip computer functions.

|

|

| • |

ACC uses the value for activating recirculation in connection with high outside temperature and low speed.

|

|

| • |

The Audio system uses the value for increasing the volume at high speeds.

|

|

| • |

TWICE uses the value for automatic locking of the doors when driving off (certain markets).

|

|

Diagnostics

ABS has extremely good diagnostics for its wheel sensors. This means that with a high degree of certainty the wheel speed signals will be present on the control module's four outputs if no diagnostic trouble codes have been generated in the system.Neither the main instrument panel nor any of the other bus systems have speed signal diagnostics for the LH rear wheel. If the speedometer is working, however, it is certain that speed information is present on the bus and consequently available to all systems connected to the bus.

If the speedometer is not working, the speed reading obtained on any bus system is always 0, and there are no diagnostic trouble codes in ABS, then the fault is probably in the lead between ABS and MIU.

Trionic has diagnostics on the speed signal for the RH front wheel, but it may require longer driving without a speed signal for a DTC to be set.

A readout of the two speed signals used in the car can be obtained from Trionic using the diagnostic tool.

| 2. Immobilization |

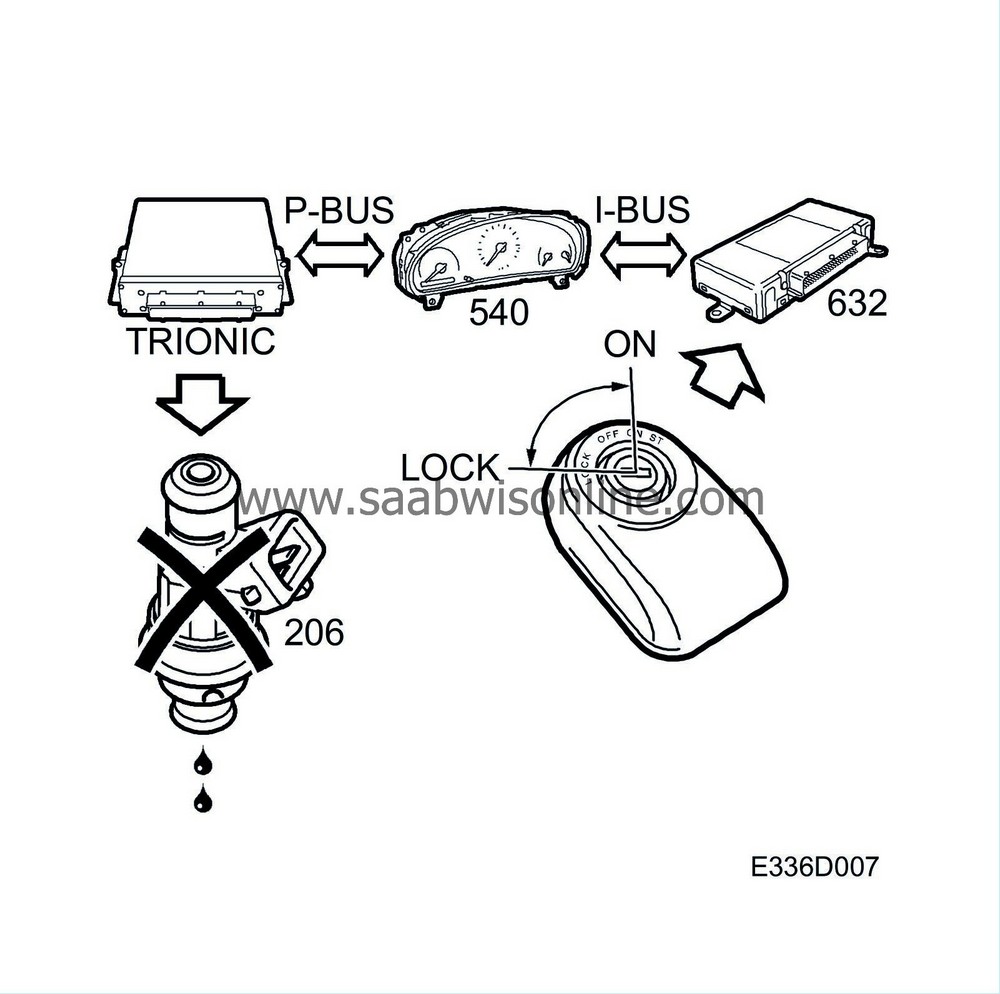

When the ignition is turned on. TWICE checks that the right key is inserted in the ignition switch. A circuit built into the remote control part of the key sends a code by means of inductance to a coil round the ignition switch under the centre console. The code is passed on to the control module which checks that it is correct. TWICE also checks that the right MIU is fitted in the car. MIU continuously sends out an ID number on the bus.

If the key and the MIU's ID number are OK, TWICE sends out the message ”Immobilization OFF” on the bus. This information is used by Trionic which cancels fuel shut-off, which is always activated every time the ignition is switched on.

Diagnostics

When TWICE, MIU or the Trionic control module is replaced, immobilization must be reprogrammed in TWICE. If this is not done, the engine cannot be started and DTC P1460 is set in Trionic.If immobilization is not reprogrammed in TWICE, the following DTCs are set in TWICE: DTC B1780 with replacement of Trionic, DTC B1782 with replacement of MIU.

If the diagnostic trouble code is generated even though programming was carried out, fault diagnosis will have to be carried out on the immobilization function in TWICE.

| 3. A/C |

A number of conditions must be met for the A/C relay to be grounded and the A/C compressor's electromagnetic clutch to pull.

In AUTO mode the ACC unit will request A/C engagement from DICE if:

| • |

Outside temperature (information via bus from SID) is above 0°C.

|

|

DICE then requests that the TRIONIC control module ground the A/C relay if the following conditions are fulfilled:

| 1. |

Coolant temperature (information via bus from the Trionic) is below 125°C.

|

|

| 2. |

Refrigerant pressure (own sensor) on the high-pressure side is between 2 and 27 bar.

|

|

| 3. |

The temperature in the evaporator (own sensor) must fulfil the following conditions:

|

|

| 3.a. |

If the temperature in the evaporator is above 3°C, DICE sends via the bus a request to the Trionic control module for A/C engagement.

|

| 3.b. |

If the temperature in the evaporator is below 0°C, the A/C compressor can only be engaged if the conditions in points 4 and 5 are satisfied.

|

| 4. |

The outside temperature (information via bus from SID) must be above 25°C.

|

|

| 5. |

One of the following conditions must also be met:

|

|

| 5.a. |

The engine must not have been running for more than 30 minutes (information via bus from the Trioinic control module).

|

| 5.b. |

Vehicle speed is below 5 km/h (information via bus from MIU).

|

The Trionic will then activate the compressor relay.

Diagnostics

In the event of a fault in any of the aforementioned sensors in the systems concerned, the A/C compressor will not work. The function chain clearly shows the importance of obtaining diagnostic trouble code readouts from all systems because several systems are involved in any given function.If there are no diagnostic trouble codes with the ”A/C not working” symptom description, all input values which can block the function must be checked methodically by means of the diagnostic tool's read value commands. The compressor relay is activated in the Trionic system. Then carry out fault diagnosis in the system which ”owns” the defective sensor or actuator.