PRE-RELEASE

Intermediate shaft, V6 diesel

| Intermediate shaft, V6 diesel |

| To remove |

| 1. |

Cover the wings and lift off the battery cover.

|

|

| 2. |

Remove the negative lead from the battery.

|

|

| 3. |

Remove the intake manifold.

|

|

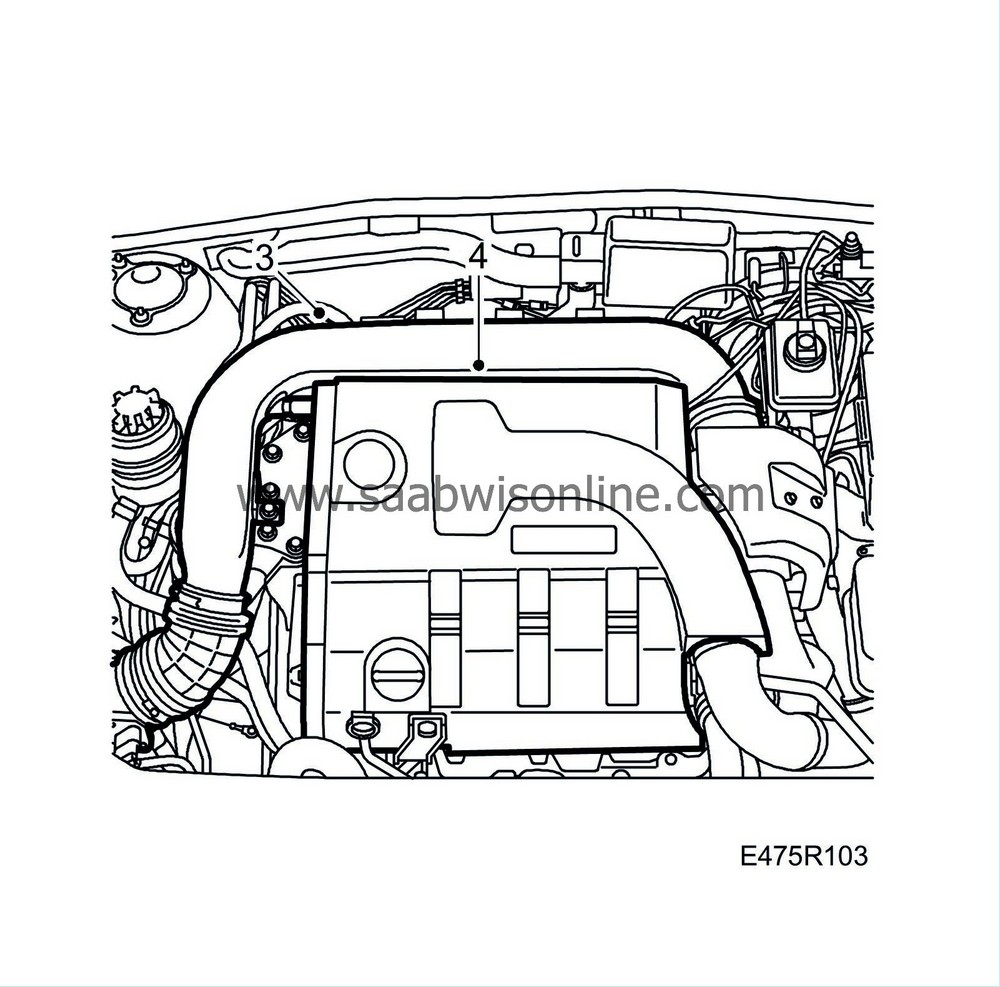

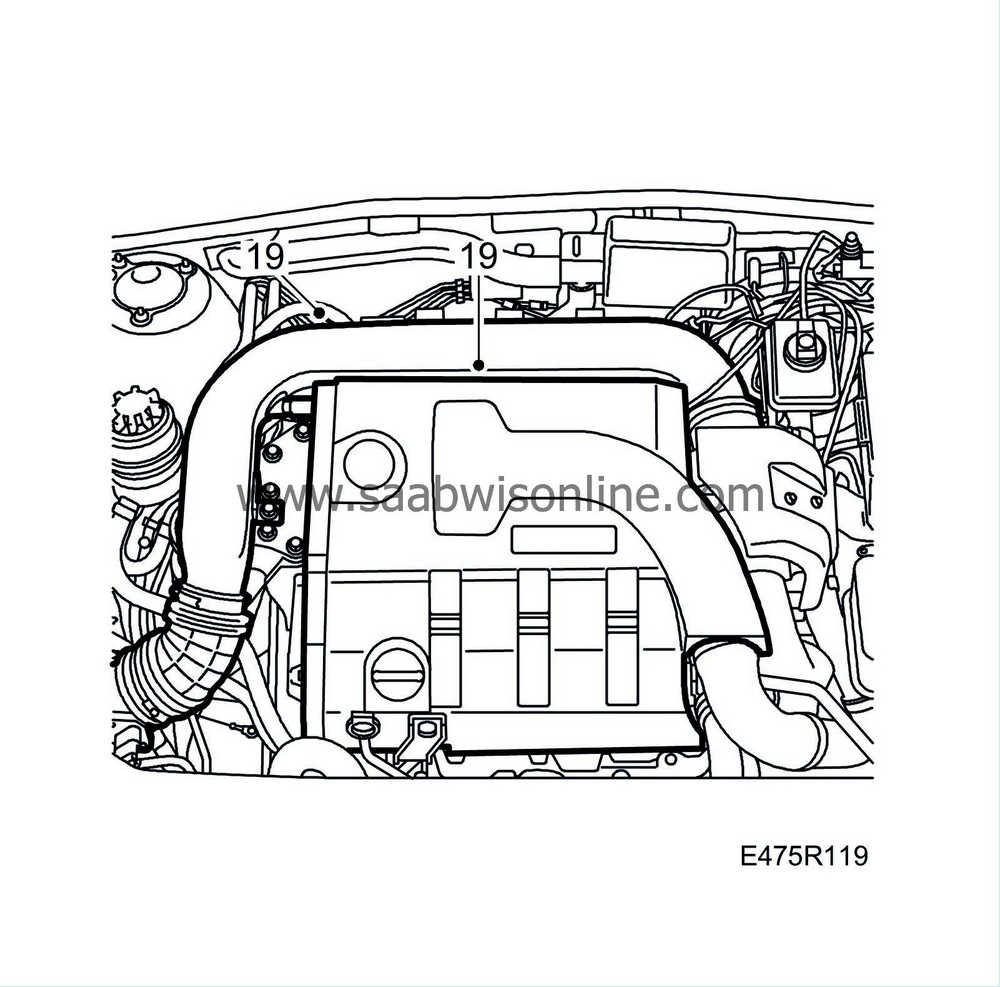

| 4. |

Remove the upper engine cover.

|

|

| 5. |

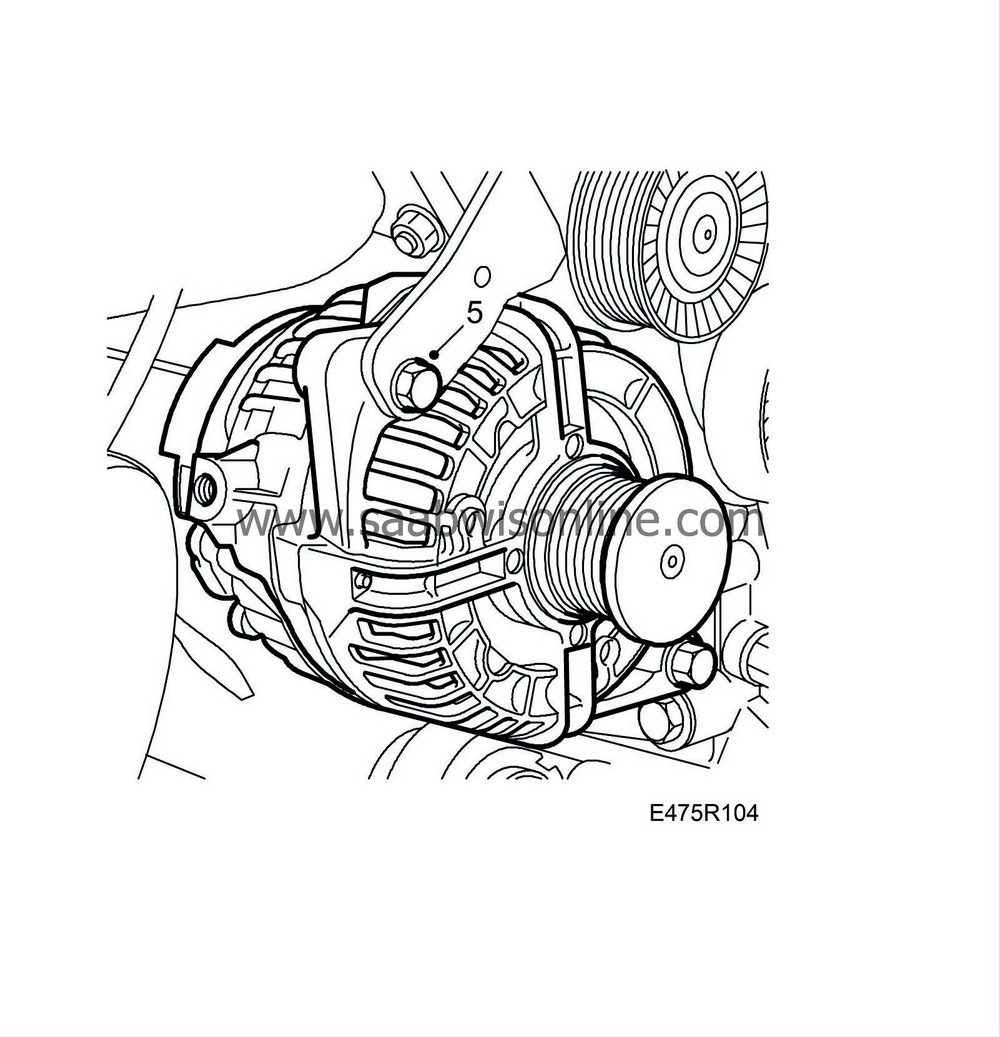

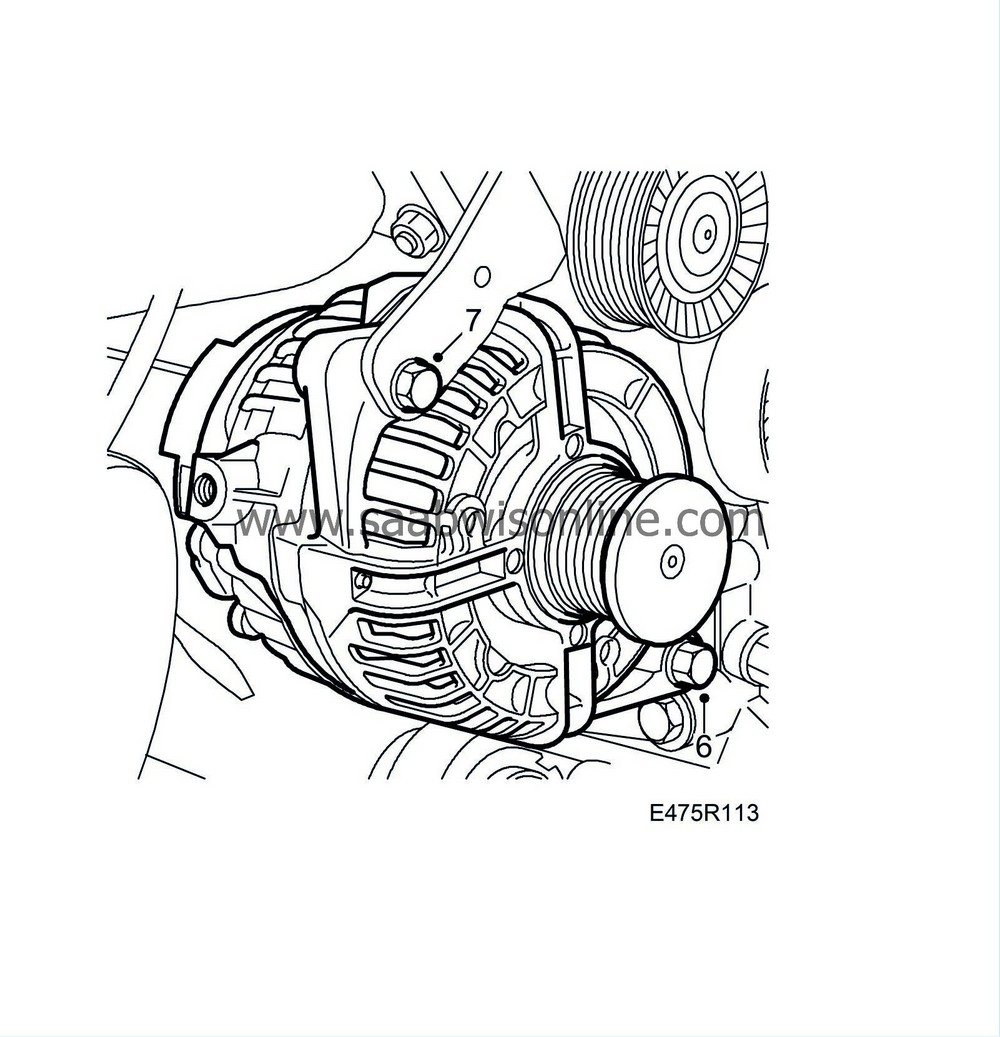

Remove the upper bolt from the generator.

|

|

| 6. |

Raise the car and remove the right-hand wheel.

|

|

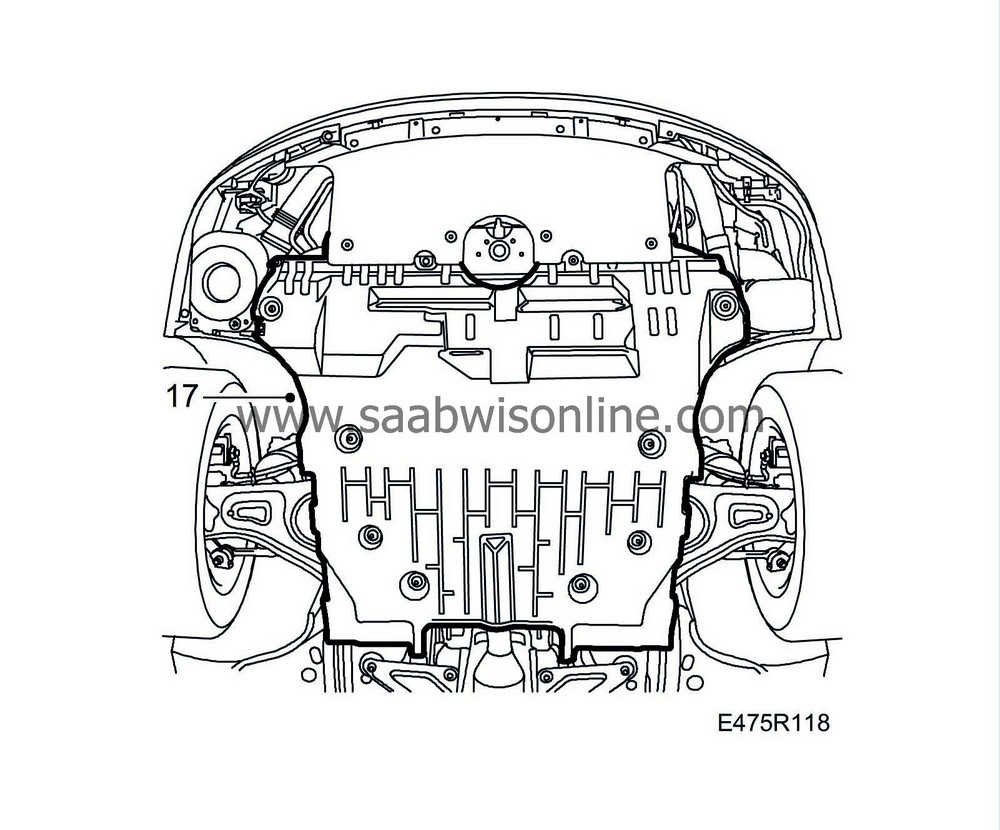

| 7. |

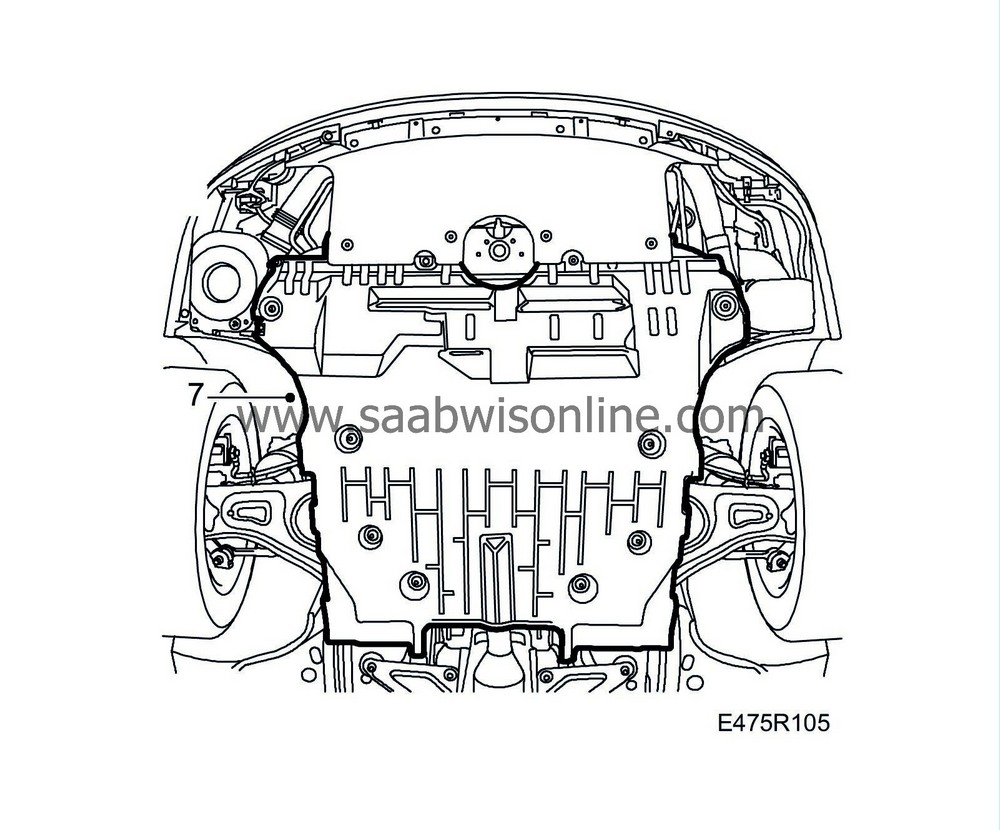

Remove the lower engine cover.

|

|

| 8. |

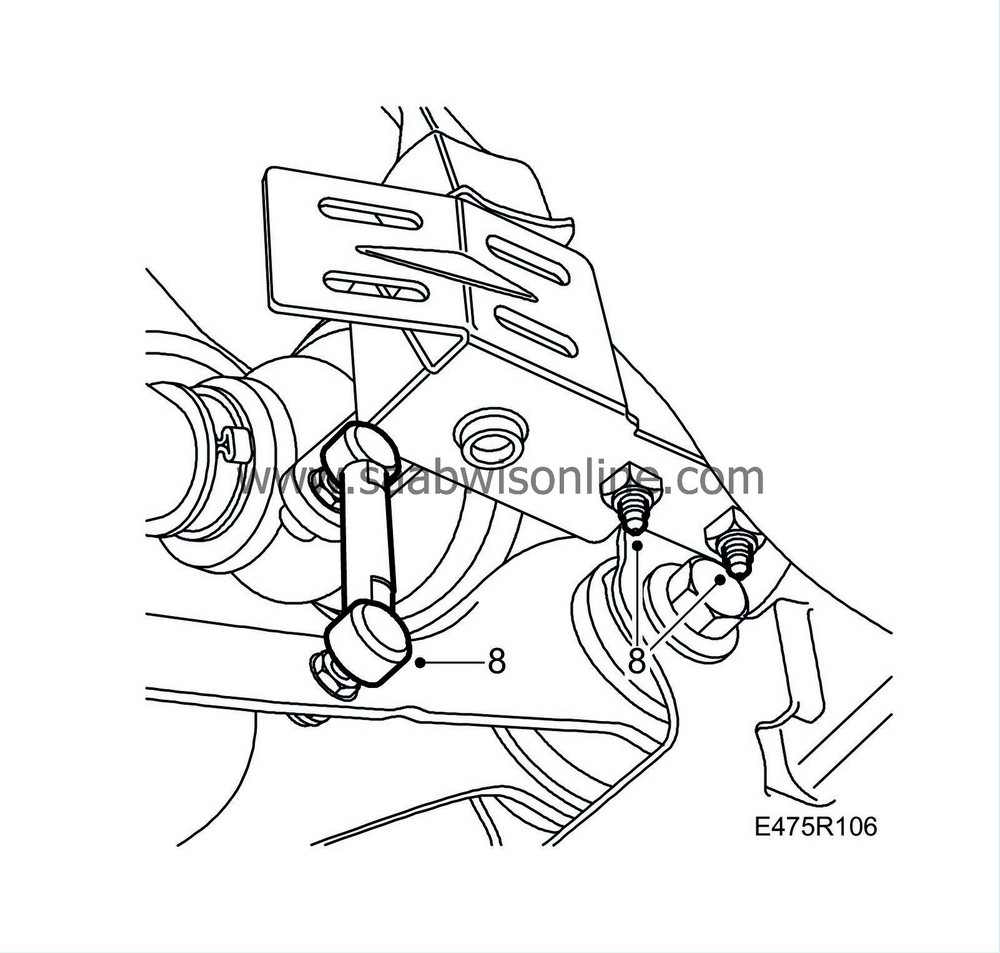

Remove any fasteners for the headlamp position sensor (option). Push the sensor to one side.

|

|

| 9. |

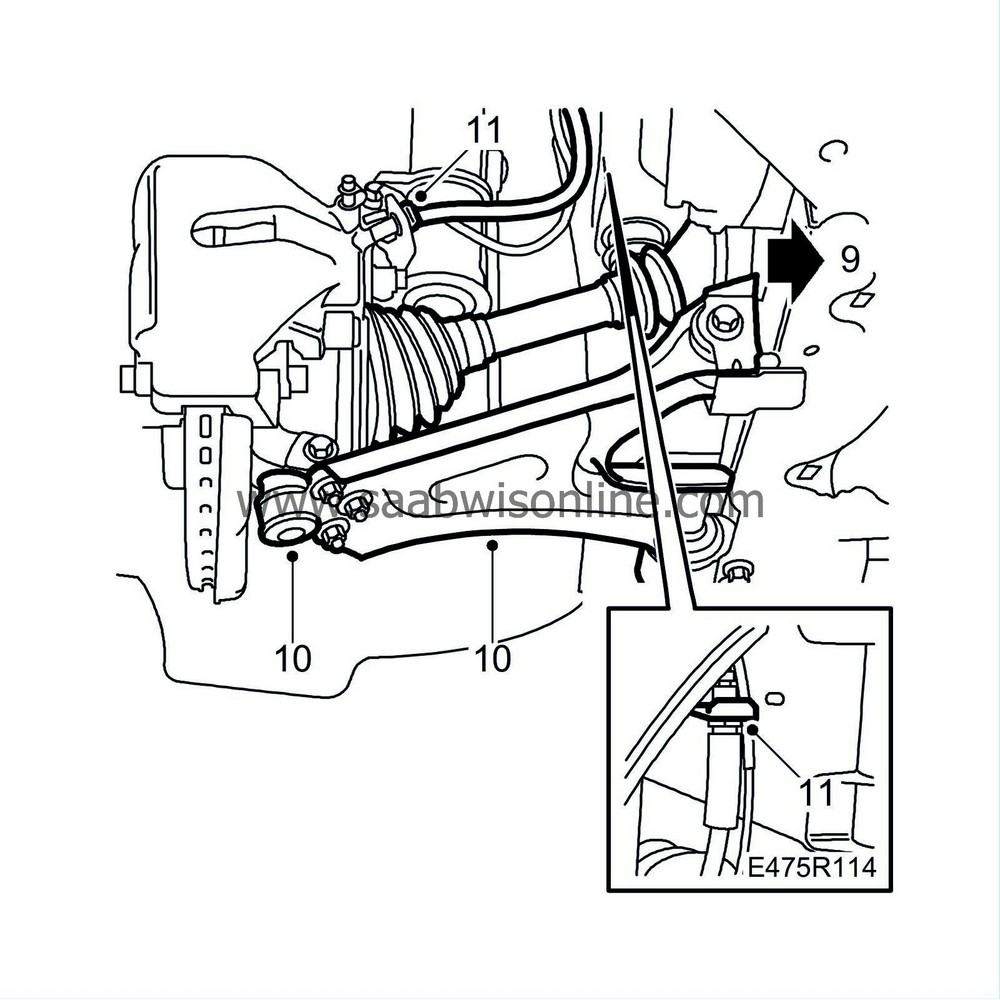

Remove the right-hand side cover.

|

|

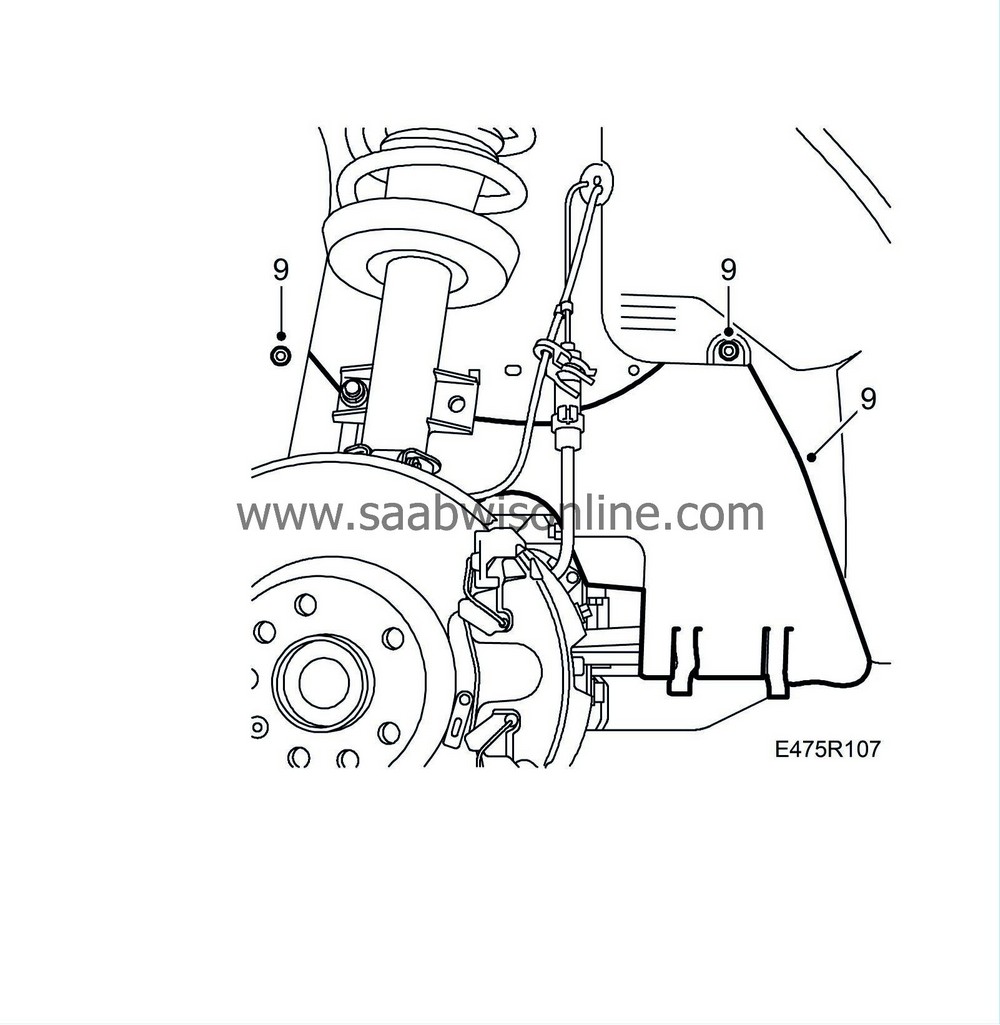

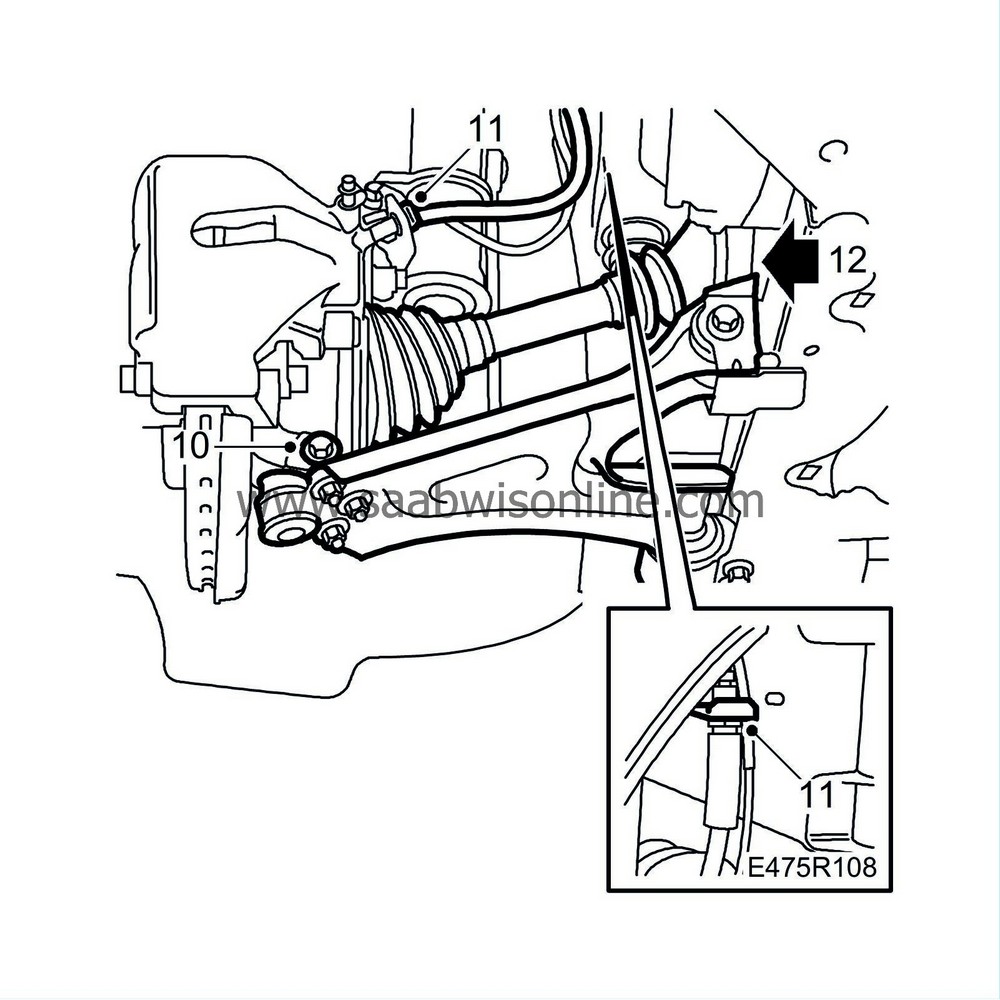

| 11. |

Remove the clip for the brake hose and the mountings for the ABS lead.

|

|

| 12. |

Tap out the drive shaft from the intermediate shaft using a brass drift and hammer. Pull out the shaft and move it to one side.

|

|||||||||

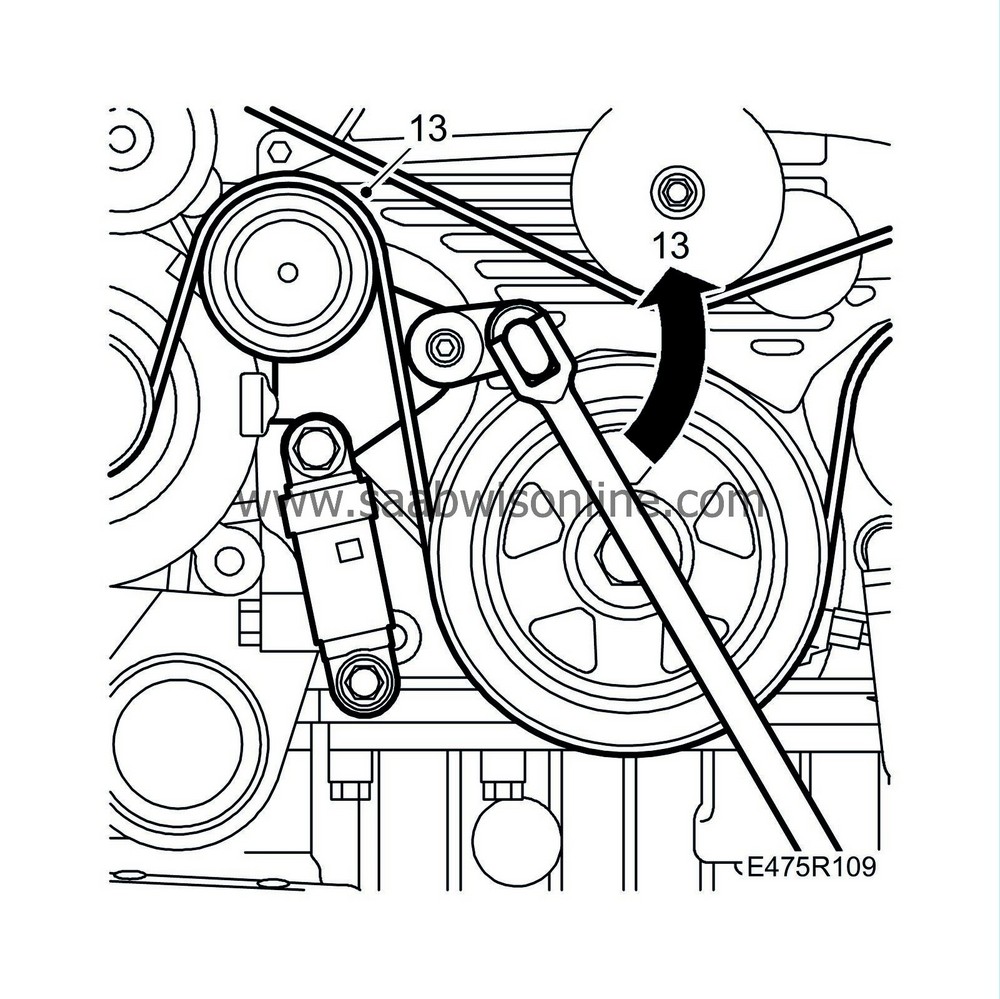

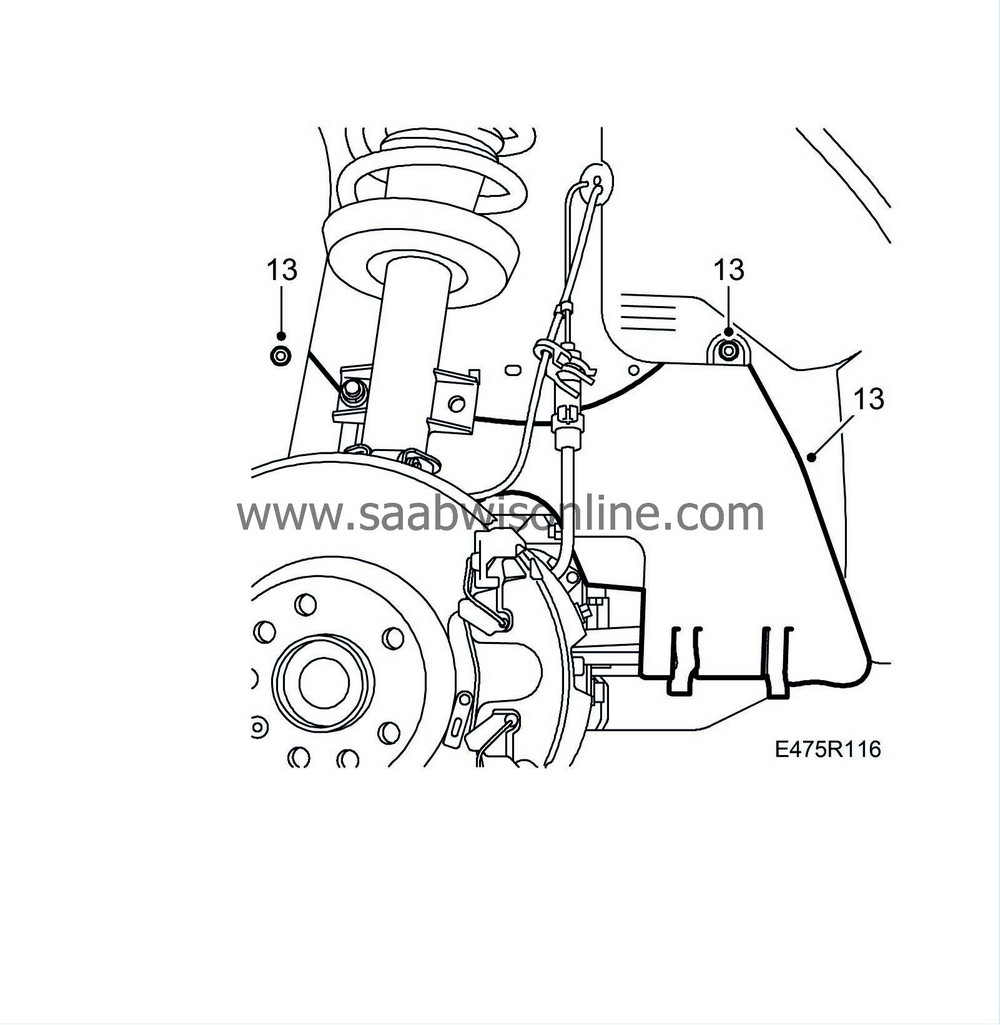

| 13. |

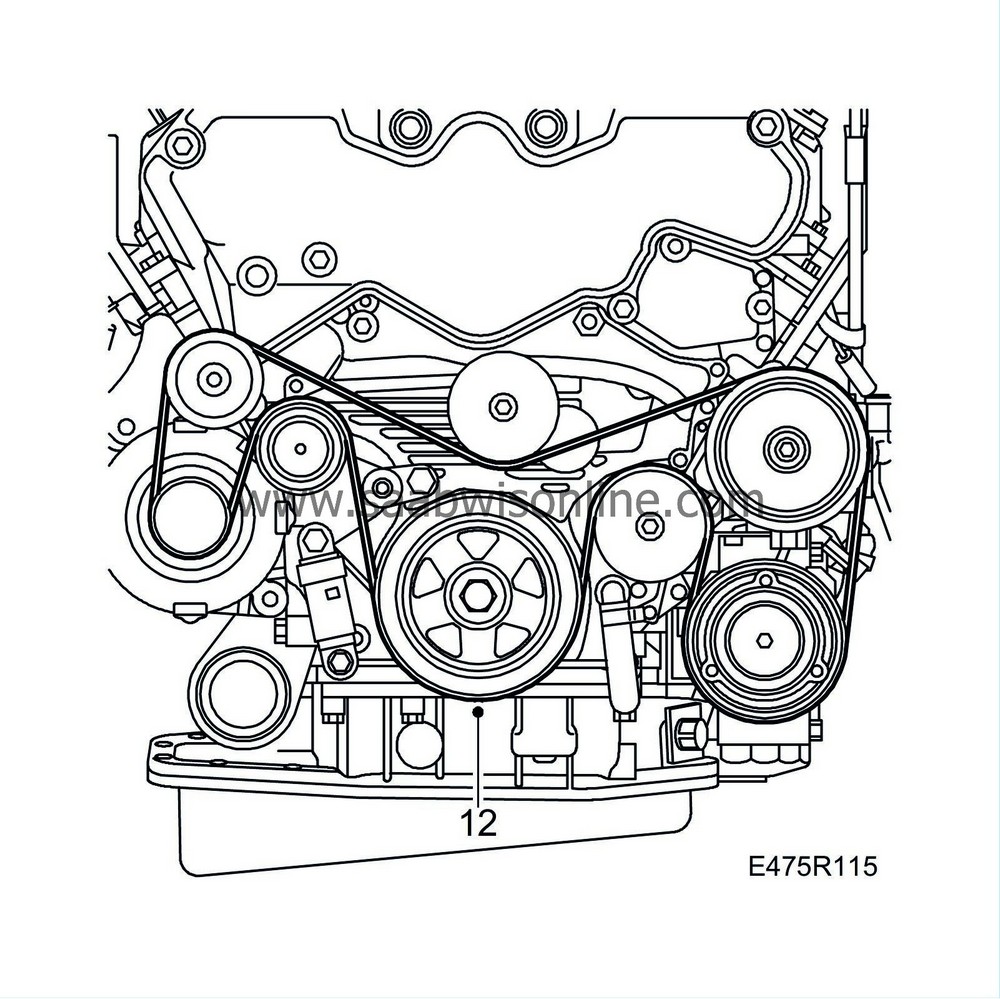

Relieve the belt tensioner with a 19 mm socket wrench and lift off the multigroove belt.

|

|

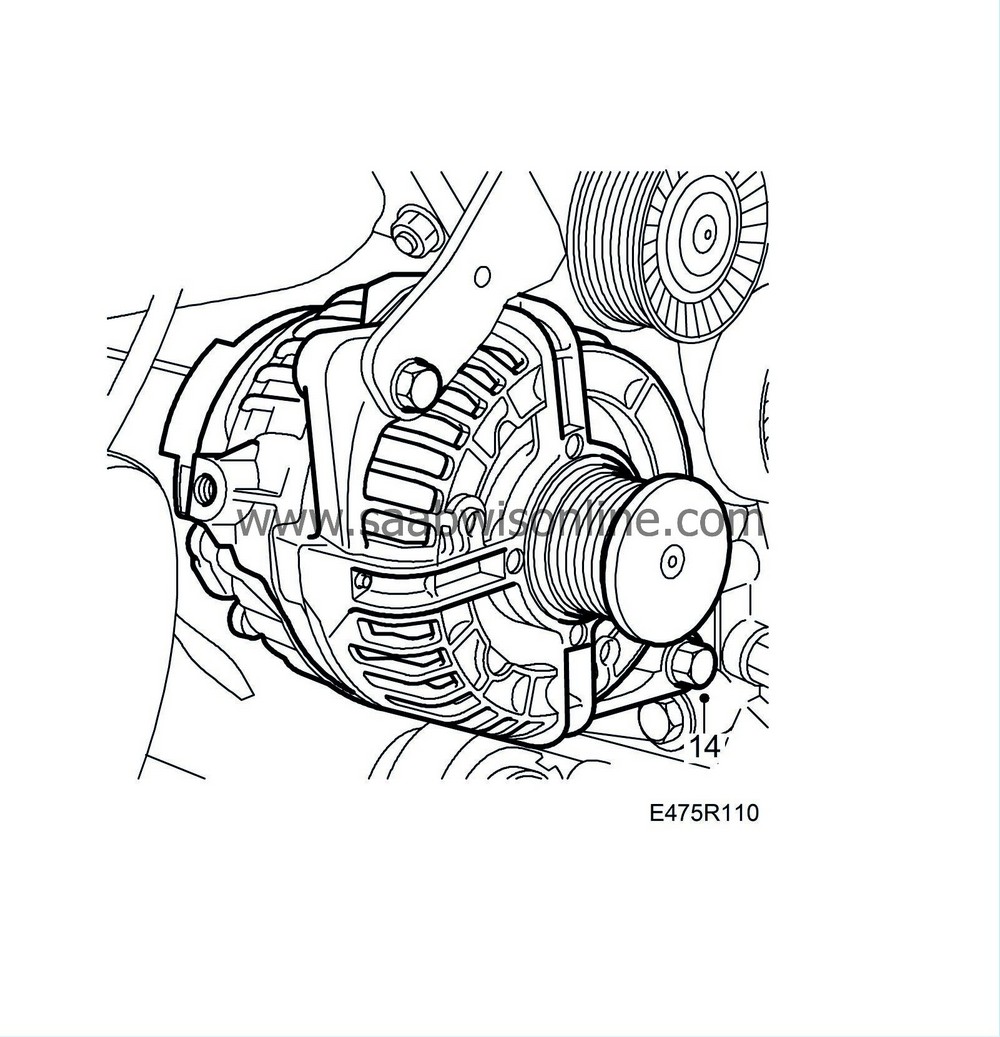

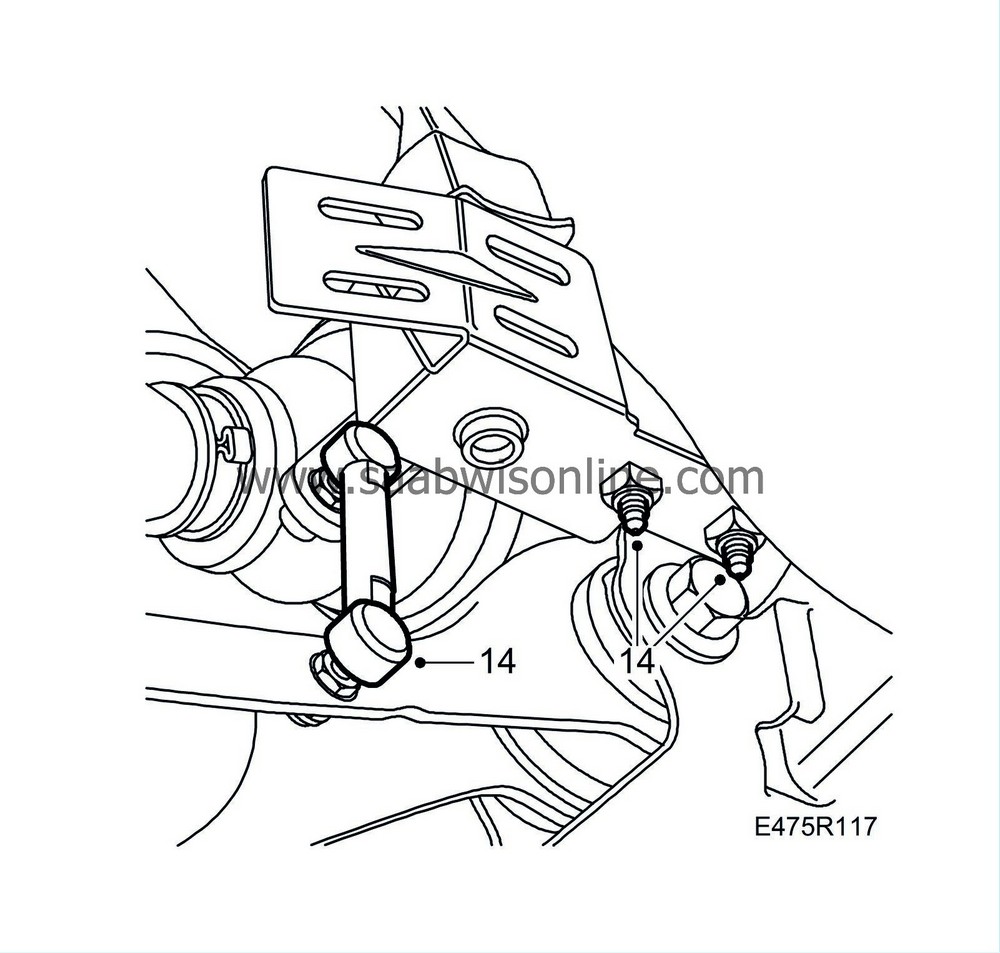

| 14. |

Remove the lower bolt from the generator and tilt the generator backwards.

|

|

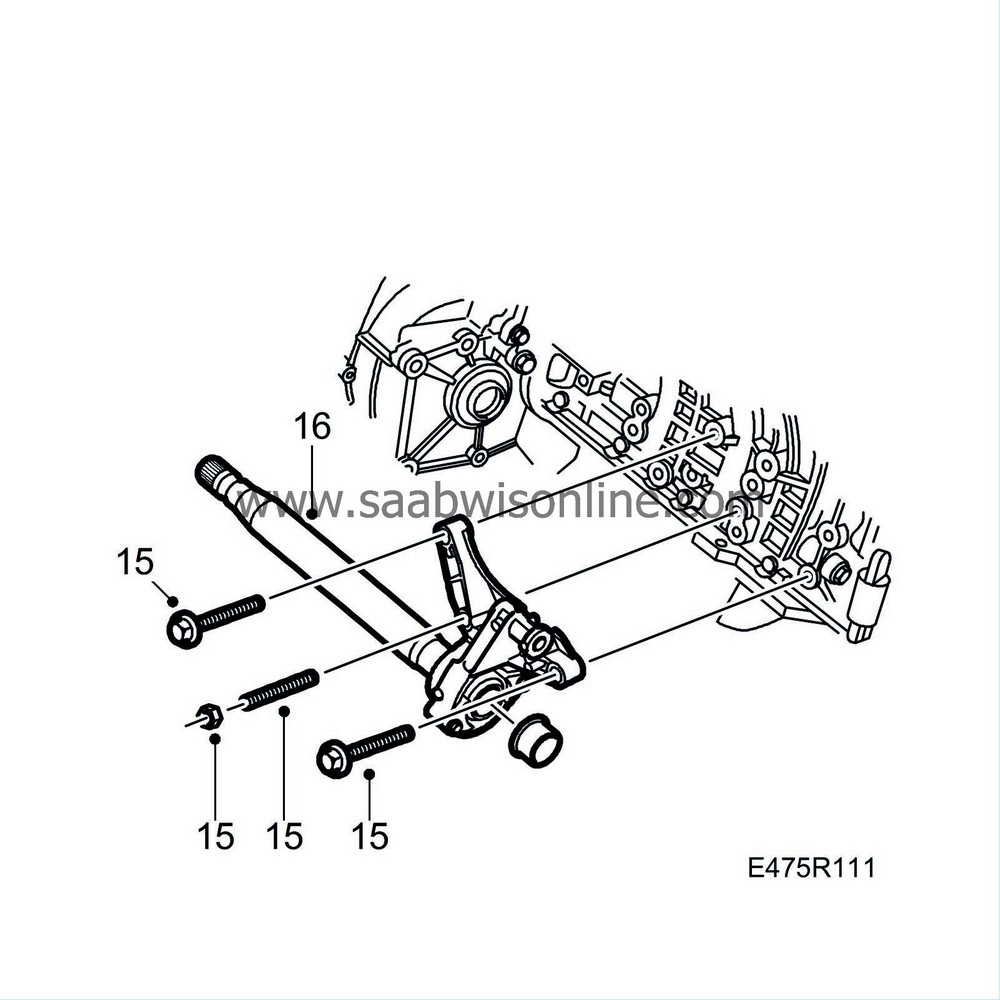

| 15. |

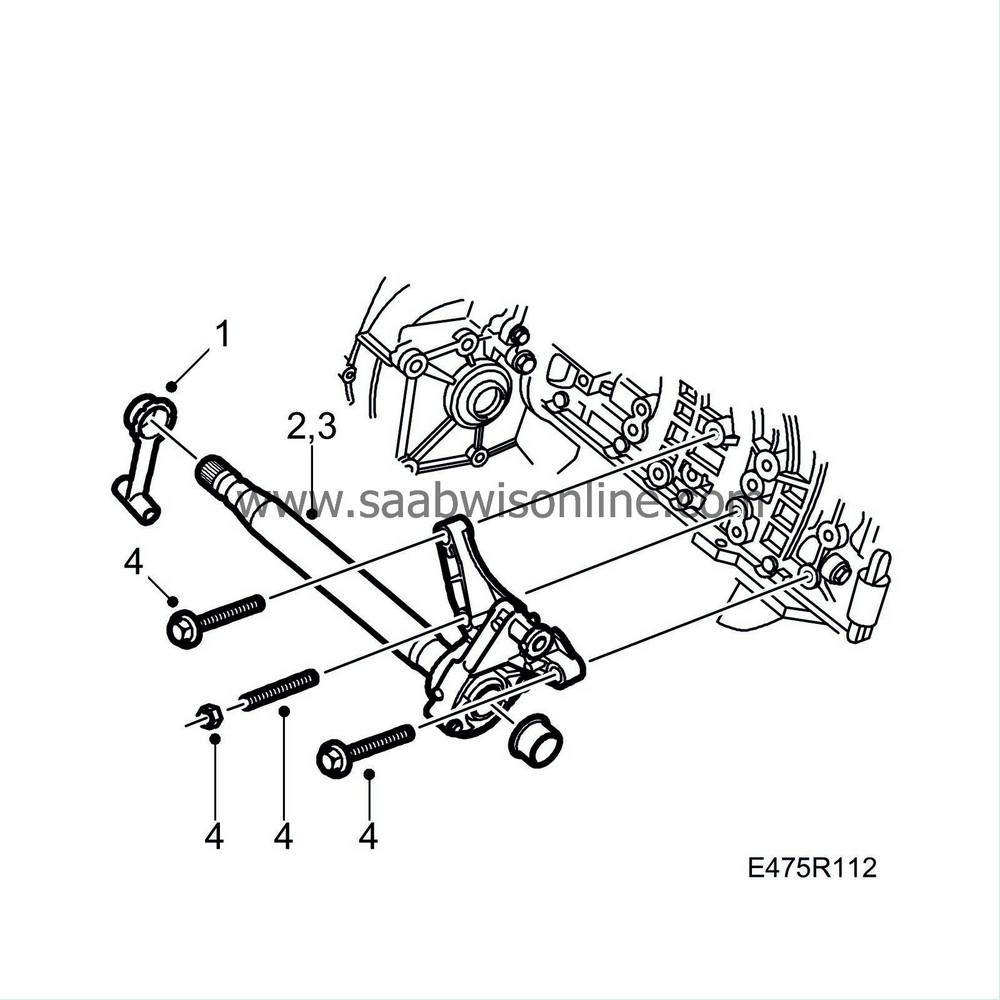

Remove the bolts securing the intermediate shaft bearing bracket. The stud must also be removed. Use an Allen key if necessary.

|

|

| 16. |

Place a receptacle under the gearbox and carefully withdraw the intermediate shaft.

|

|

| To fit |

| 1. |

Fit

83 95 162 Protective collar, drive shafts

into the sealing ring.

|

||||||||||

| 2. |

Make sure that the intermediate shaft is clean and then insert the intermediate shaft into the protective sleeve.

|

||||||||||

| 3. |

Push in the rest of the shaft.

|

|

| 4. |

Fit the bearing bracket bolts. Make sure that the stud reaches the end of its hole. Use an Allen key if necessary.

Tightening torque 50 Nm (37 lbf ft) |

|

| 5. |

Ensure the adjuster sleeve on the generator is protruding about 1 mm to facilitate fitting.

|

|

| 6. |

Position the generator and fit the lower bolt.

|

|

| 7. |

Lower the car and fit the upper bolt to the generator.

Tightening torque 28 Nm (21 lbf ft) |

|

| 8. |

Raise the car and tighten the lower bolt on the generator.

Tightening torque 58 Nm (43 lbf ft) |

|

| 9. |

Lubricate the drive shaft splines with

90 513 210 Universal paste

and insert the drive shaft into the intermediate shaft. Make sure the dust cover is correctly seated on the drive shaft. Check that the circlip snaps into place in the intermediate shaft.

|

|

| 10. |

Fit the ball joint to the steering swivel member and tighten.

Tightening torque 50 Nm (37 lbf ft)

|

|||||||||

| 11. |

Secure the brake hose in the mounting on the steering swivel member and fit the clips. Fit the ABS cable mountings.

|

|

| 12. |

Relieve the tension of the belt tensioner and fit the multigroove belt.

|

|

| 13. |

Fit the right-hand side cover.

|

|

| 14. |

Fit the headlamp level sensor (option) if applicable.

|

|

| 15. |

Fit the wheel and tighten the wheel bolts. See

Wheels

Tightening torque 110 Nm (80 lbf ft)

|

||||||||||

| 16. |

Fill up with automatic transmission fluid to the correct level. See

Topping up with fluid

.

|

|

| 17. |

Fit the lower engine cover.

|

|

| 18. |

Lower the car, connect the battery and fit the battery cover.

|

|

| 19. |

Fit the upper engine cover and the intake manifold.

|

|

| 20. |

Set the clock and radio code if applicable.

|

|

Warning

Warning