PRE-RELEASE

Cylinder head

| Cylinder head |

(in car)

| To remove |

| Important | ||

|

The cylinder head may only be removed if the engine is at room temperature. |

||

|

||||||||||||||||||||||

| Important | ||

|

Be particulary observant regardning cleanliness when working on the fuel system. Loss of function may occur due to very small particles. Prevent dirt and grime from entering the fuel system by cleaning the connections and plugging pipes and lines during disassembly. Use 82 92 948 Plugs, A/C system assembly. Keep components free from contaminants during storage. |

||

| 1. |

Loosen the coolant expansion tank cap to release any pressure.

|

|

| 2. |

Remove the battery cover and disconnect the negative battery cable.

|

|

| 3. |

Remove the exhaust manifold stay.

|

|

| 4. |

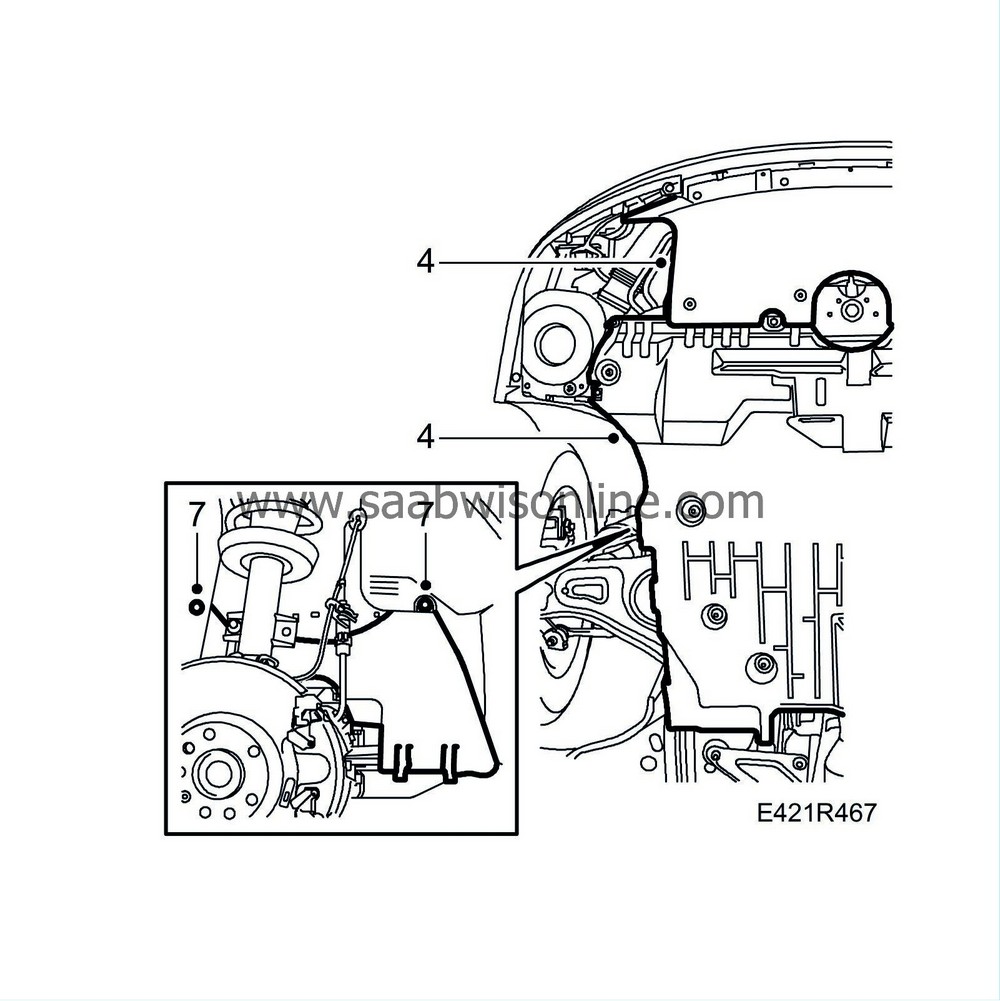

Raise the car and remove the lower engine cover and spoiler shield.

|

|

| 5. |

Place a receptacle under the car and drain the coolant.

|

|

| 6. |

Remove the right-hand front wheel.

|

|

| 7. |

Remove the belt circuit's cover.

|

|

| 8. |

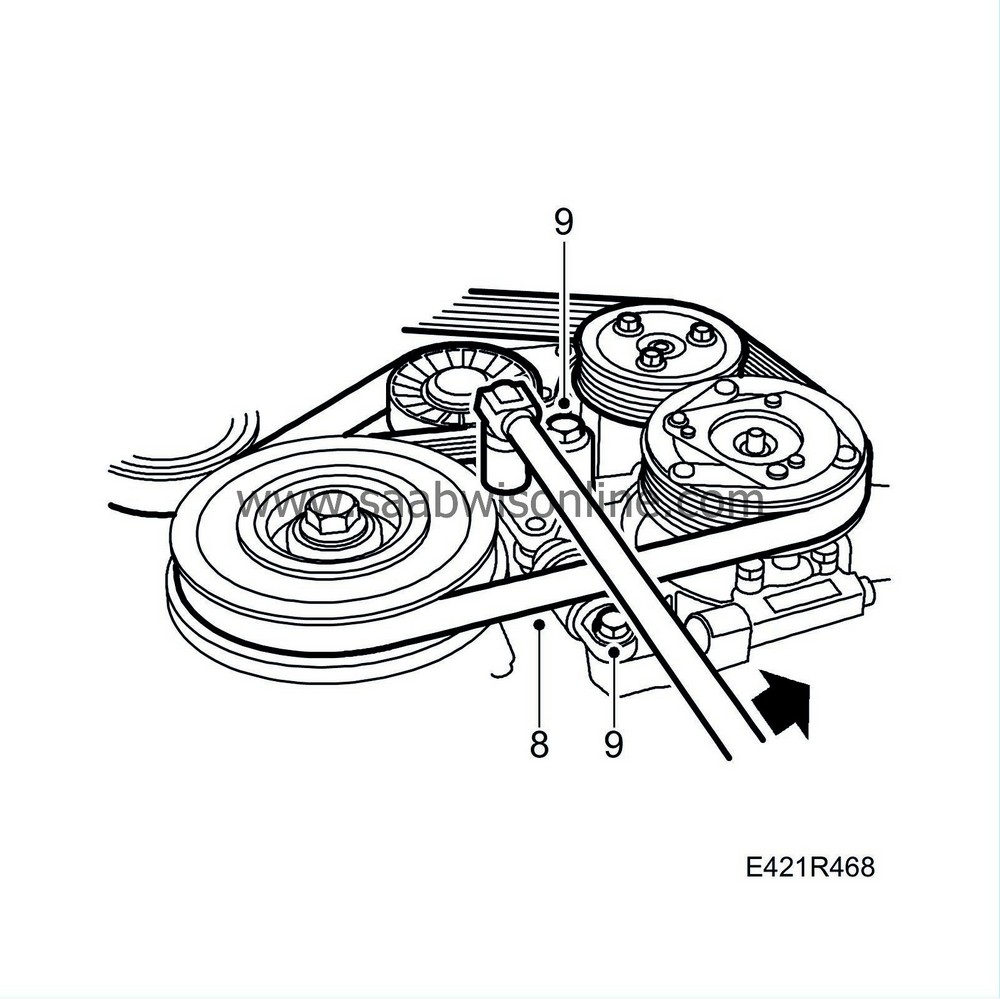

Mark the direction of rotation, take the tension off the multigroove belt and remove the belt.

|

|

| 9. |

Remove the belt tensioner.

|

|

| 10. |

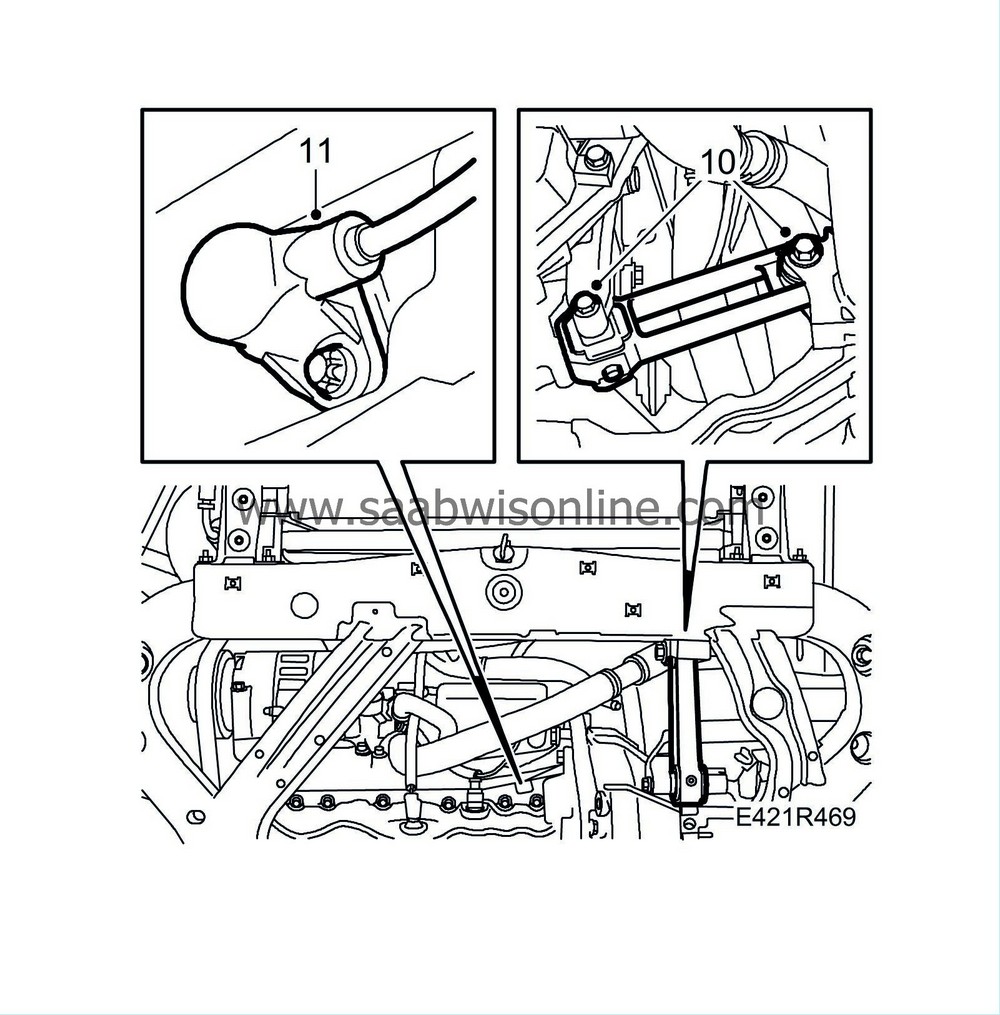

Remove the front bolt on the torque arm and undo the rear one. Secure the torque arm with a cable tie if necessary.

|

|

| 11. |

Remove the crankshaft position sensor.

|

|

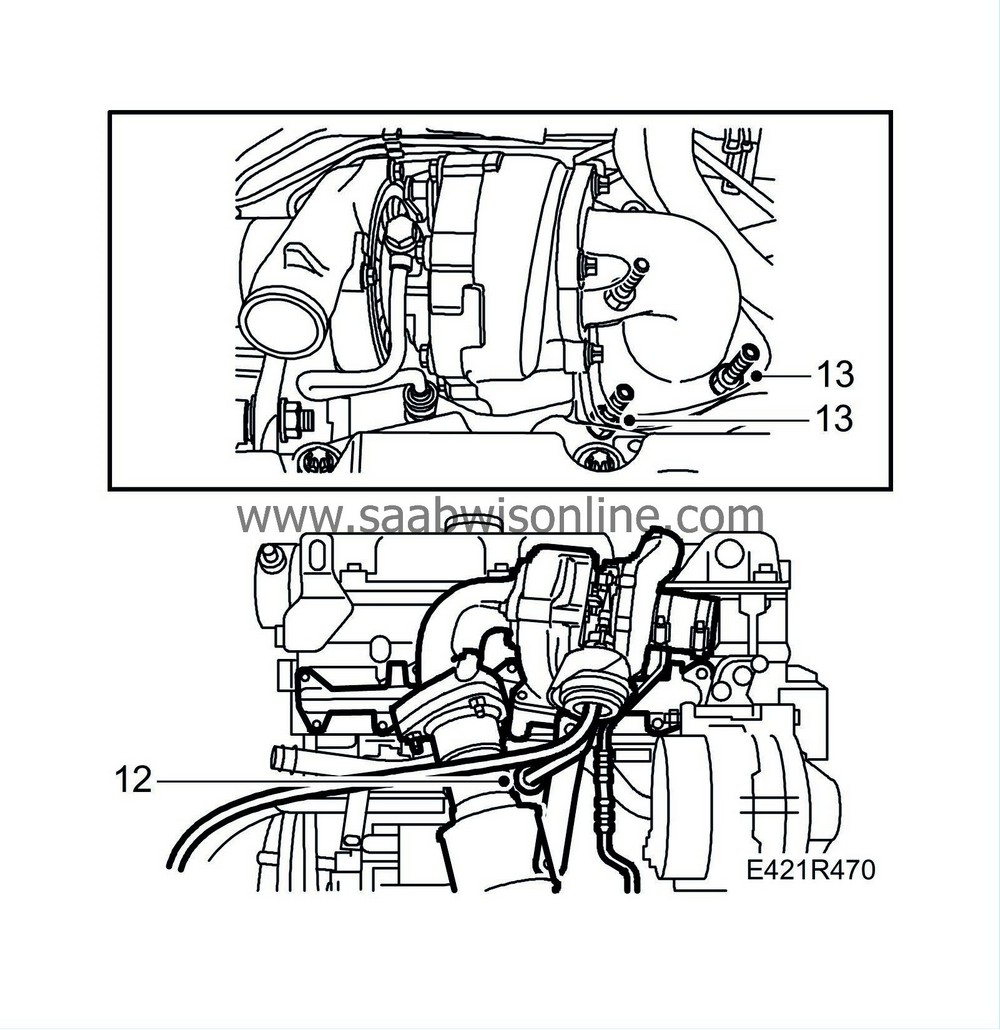

| 12. |

Detach the turbocharger return oil pipe from the engine block.

|

|

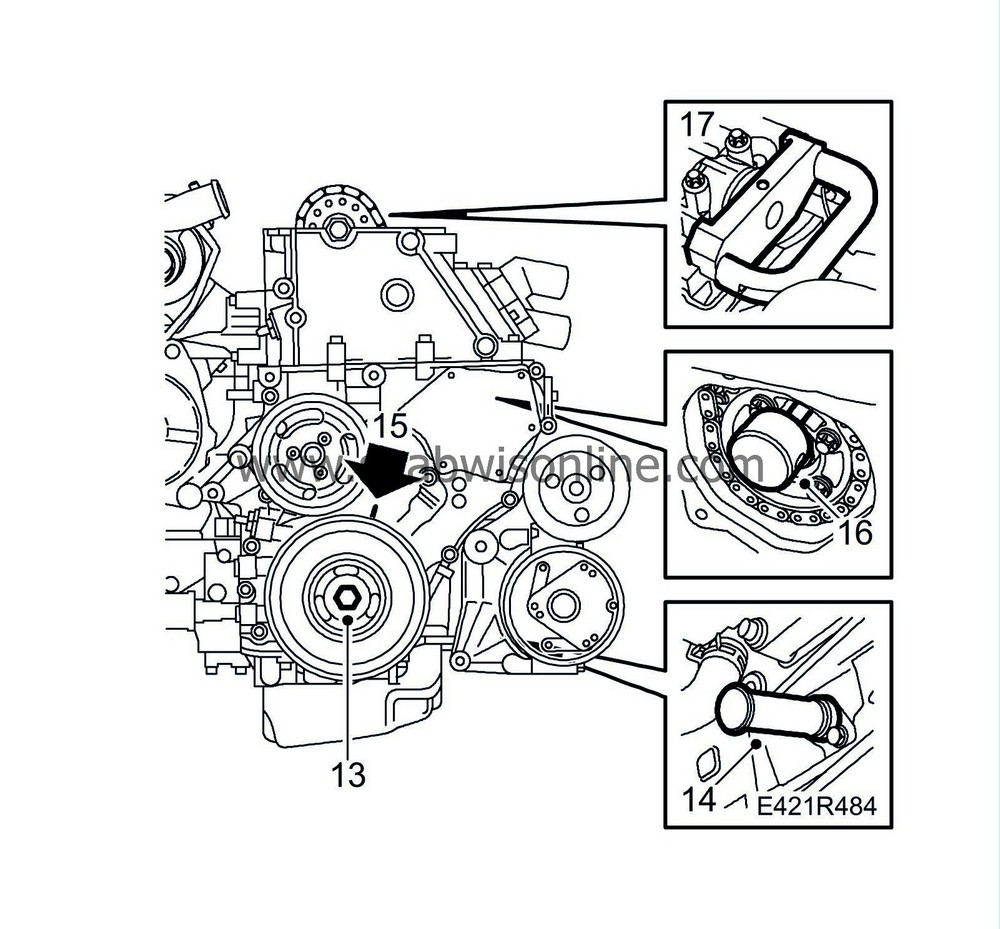

| 13. |

Remove the front two nuts between the front exhaust pipe and the turbo.

|

|

| 14. |

Lower the car and remove the upper engine cover.

|

|

| 15. |

Remove the intake manifold from the mass air flow sensor to the turbocharger and camshaft cover.

|

|

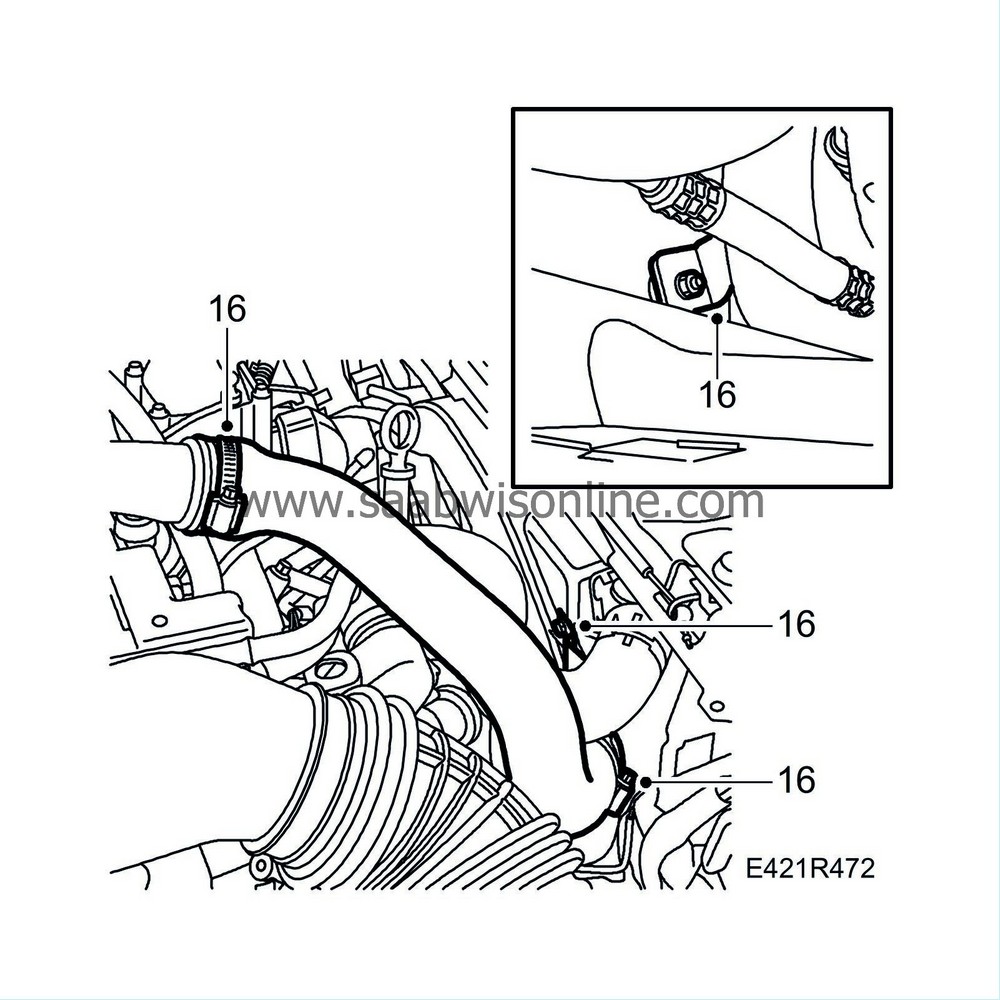

| 16. |

Remove the charge air hose with charge air pipe from the turbocharger and the charge air pipe on the fan cowling. Plug the connections.

|

|

| 17. |

Undo the rear cable harness mounting on the camshaft cover.

|

|

| 18. |

Undo the glow plug connections and move them out of the way.

|

|

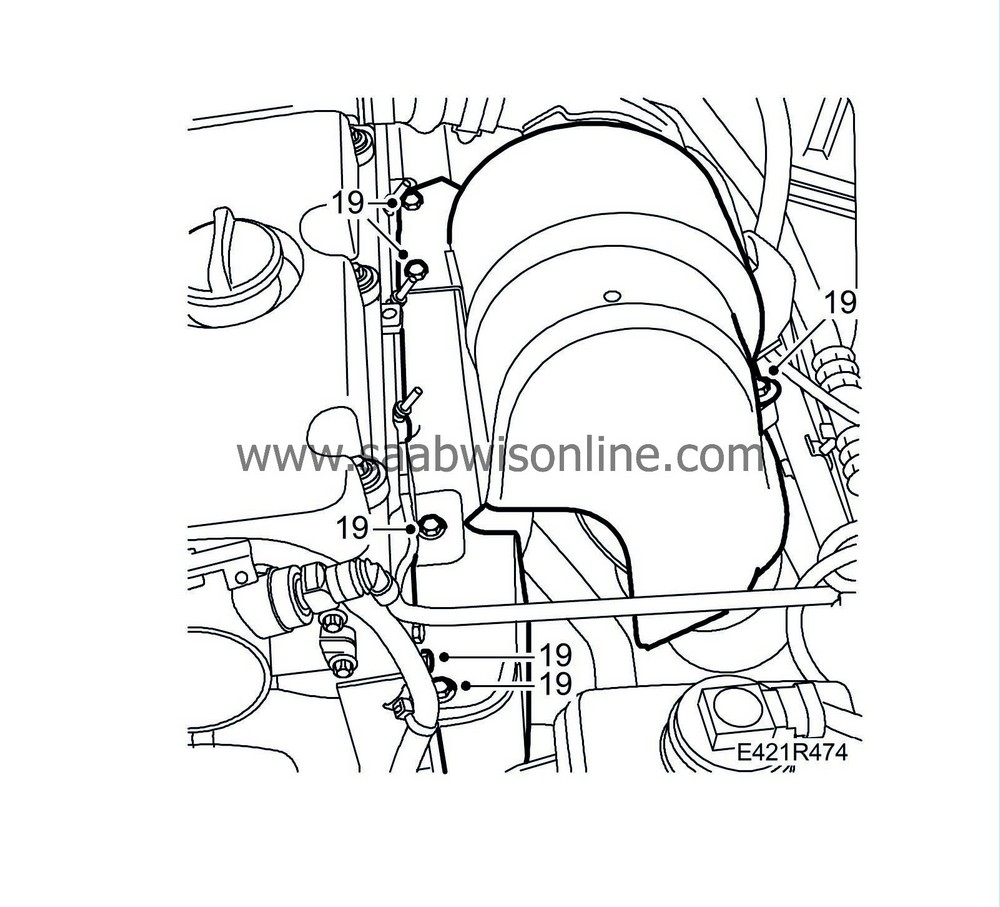

| 19. |

Remove the heat shields over the exhaust manifold and turbocharger and remove the lower bolt from the cable rail and the lifting eye bolt.

|

|

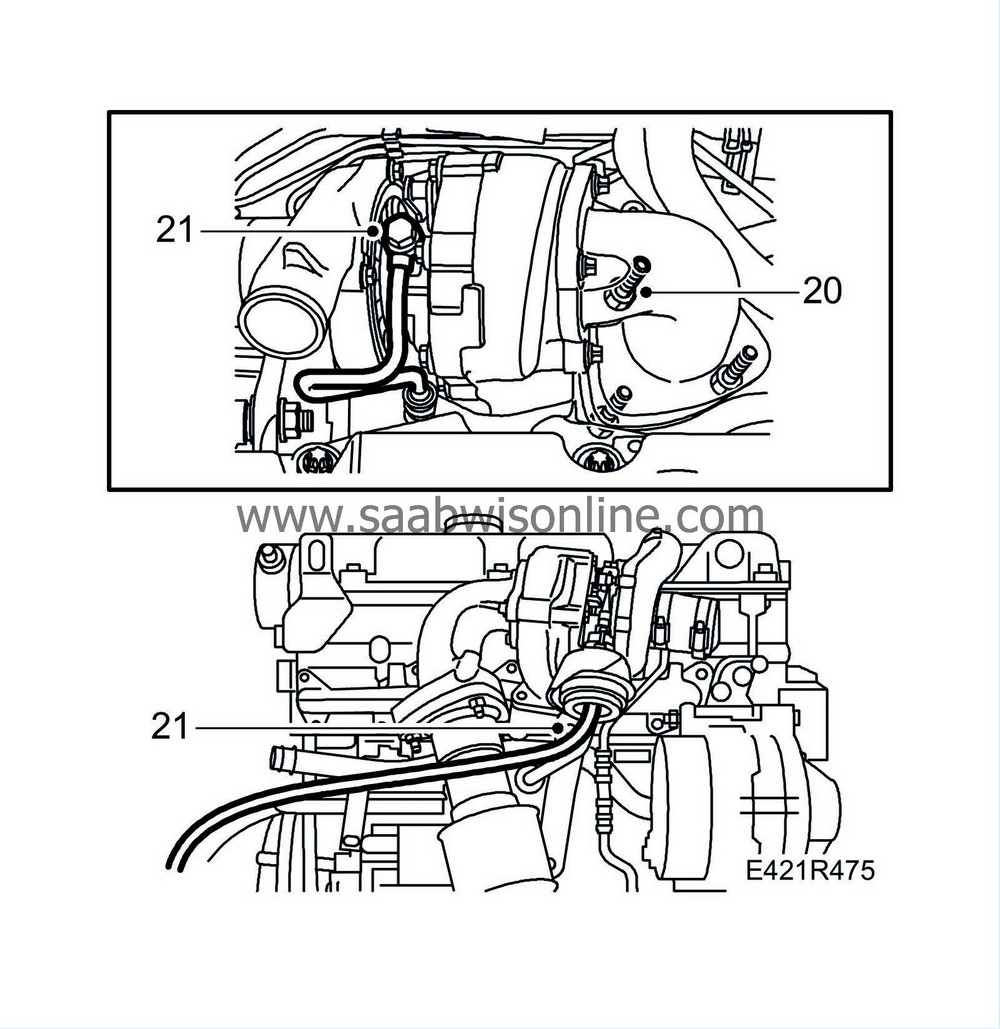

| 20. |

Remove the remaining nut between the front exhaust pipe and the turbo.

|

|

| 21. |

Undo the turbo oil delivery pipe from the turbo and the hose from the turbo vacuum unit.

|

|

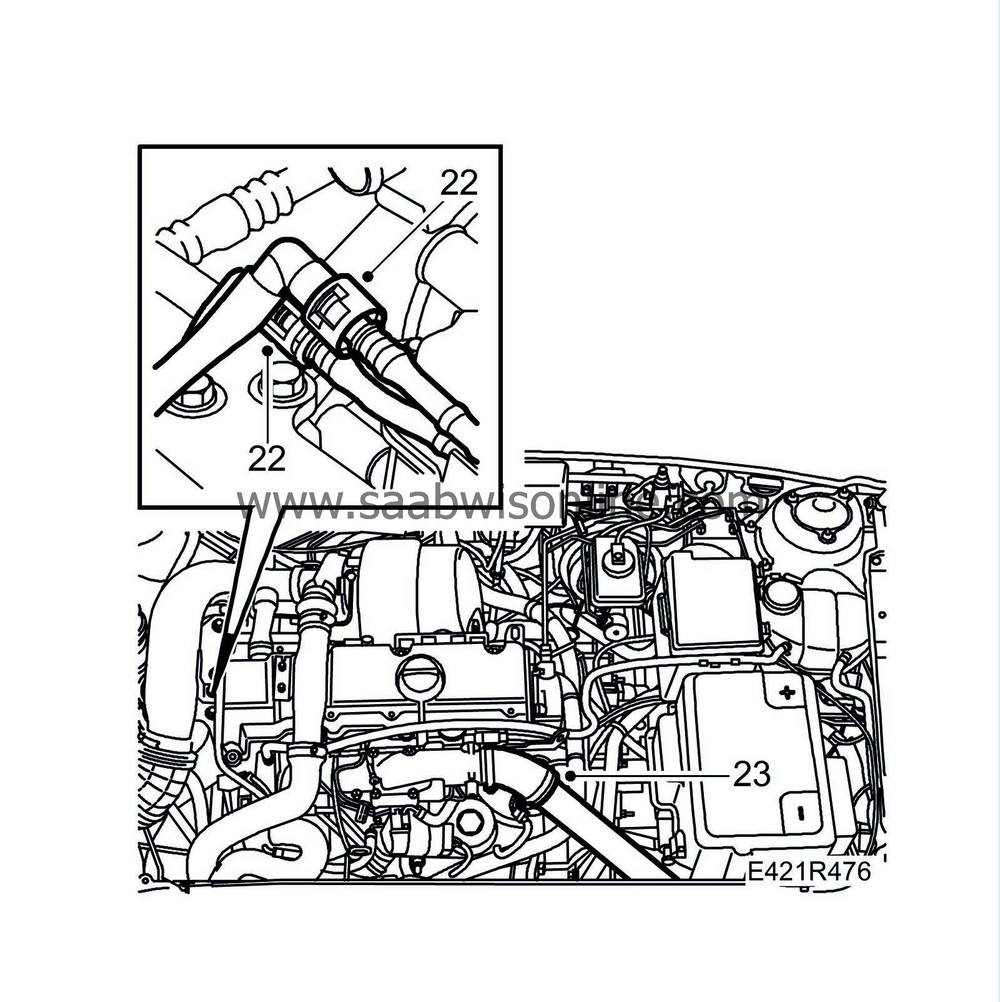

| 22. |

Separate the fuel hoses with

83 95 261 Tool, fuel line

and plug them. Use a rag to soak up any spilled fuel.

|

|

| 23. |

Remove the turbocharger delivery pipe with hose from the throttle body and move it out of the way.

|

|

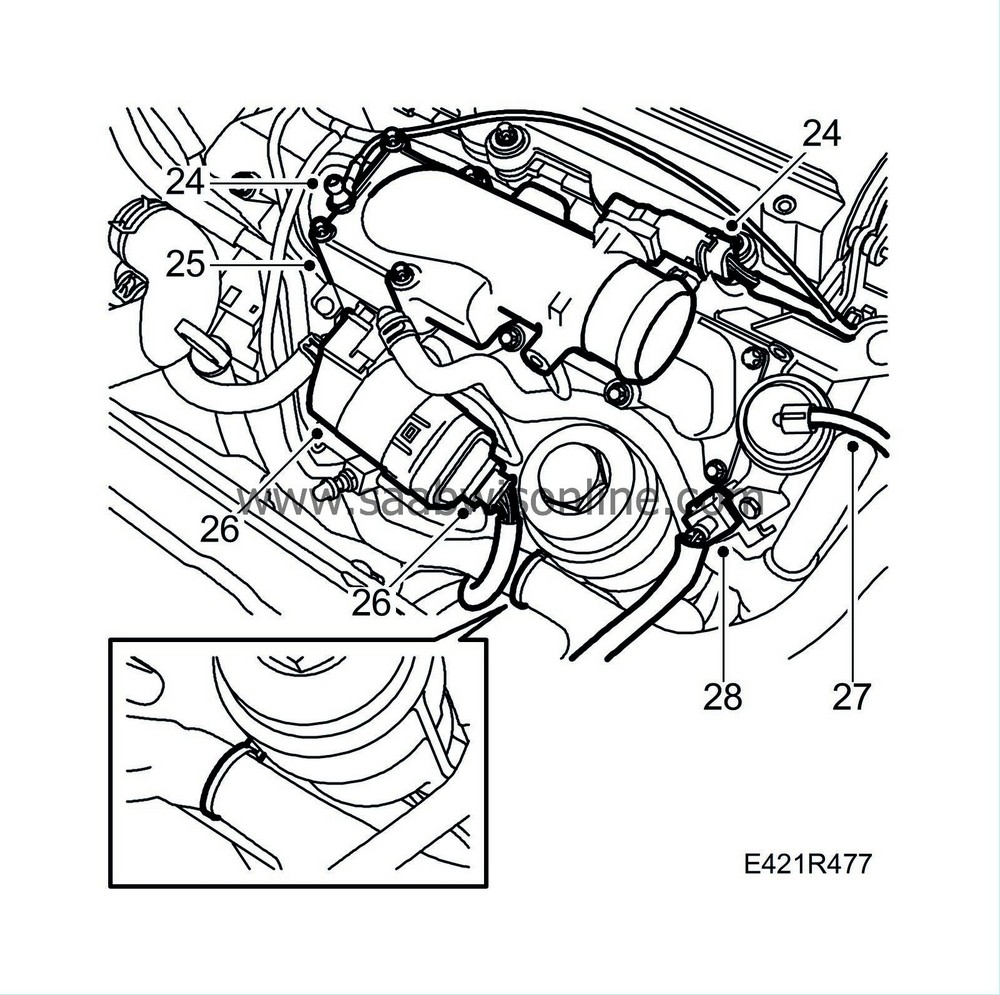

| 24. |

Unplug the pressure/temperature sensor and disconnect the ground cable.

|

|

| 25. |

Remove the throttle body.

|

|

| 26. |

Detach the connector and coolant hoses from the EGR valve. Remove the EGR valve.

|

|

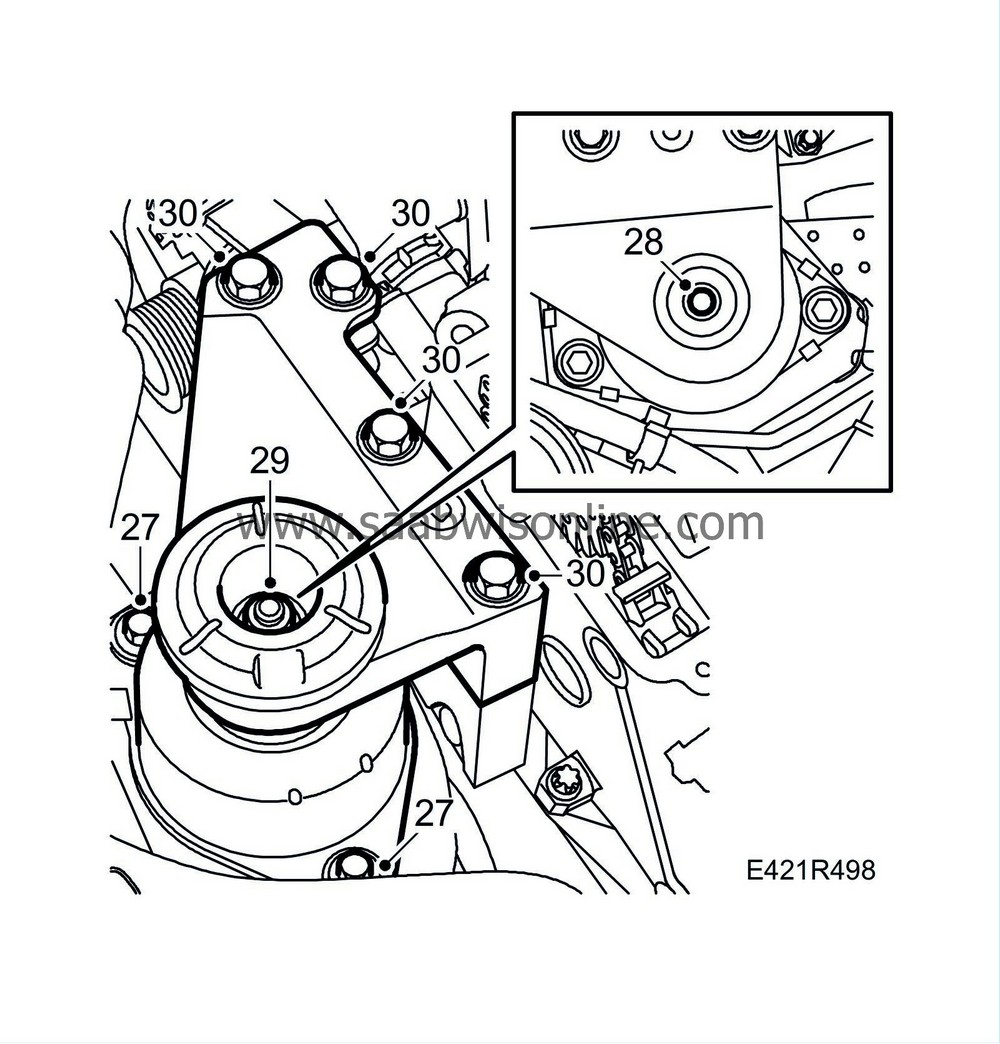

| 27. |

Detach the vacuum hose from the swirl throttle diaphragm unit.

|

|

| 28. |

Detach the connector for the crankshaft position sensor from the bracket.

|

|

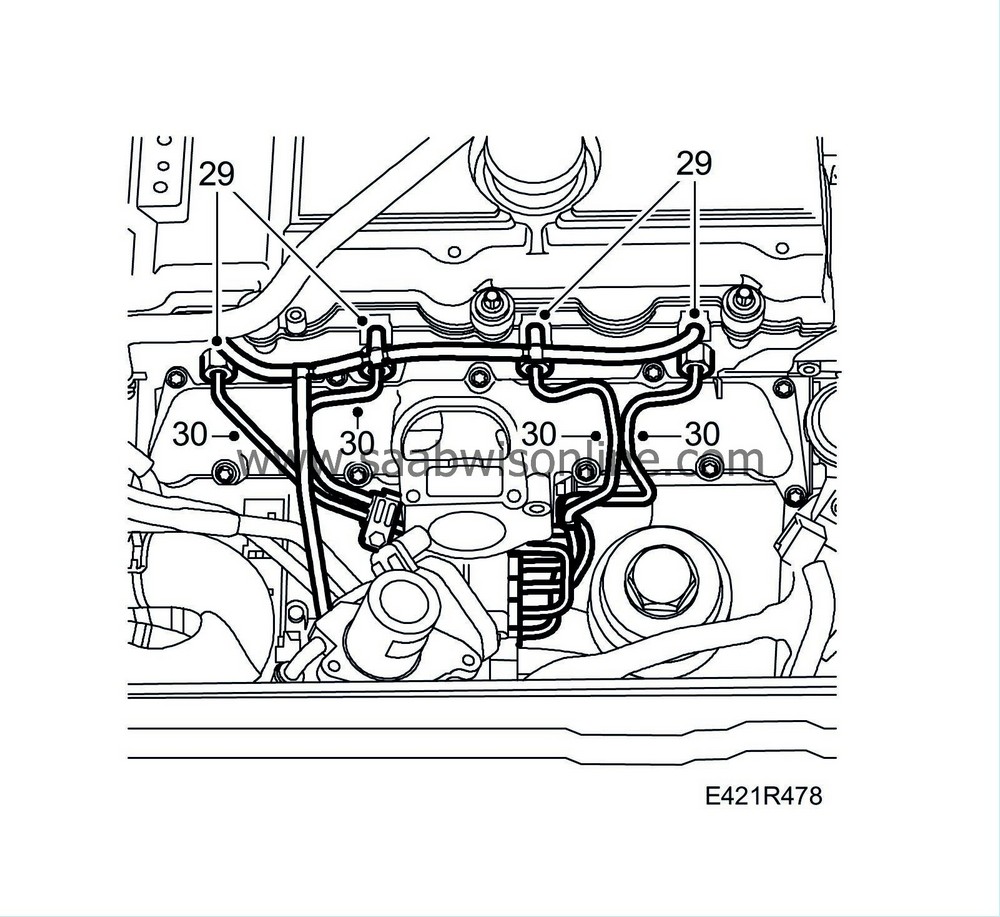

| 29. |

Detach the fuel return hoses from the fuel bridges. Place a receptacle under the car to collect any spilled fuel.

|

|

| 30. |

Detach the fuel rails with clips. Mark how the rails are fitted.

|

|

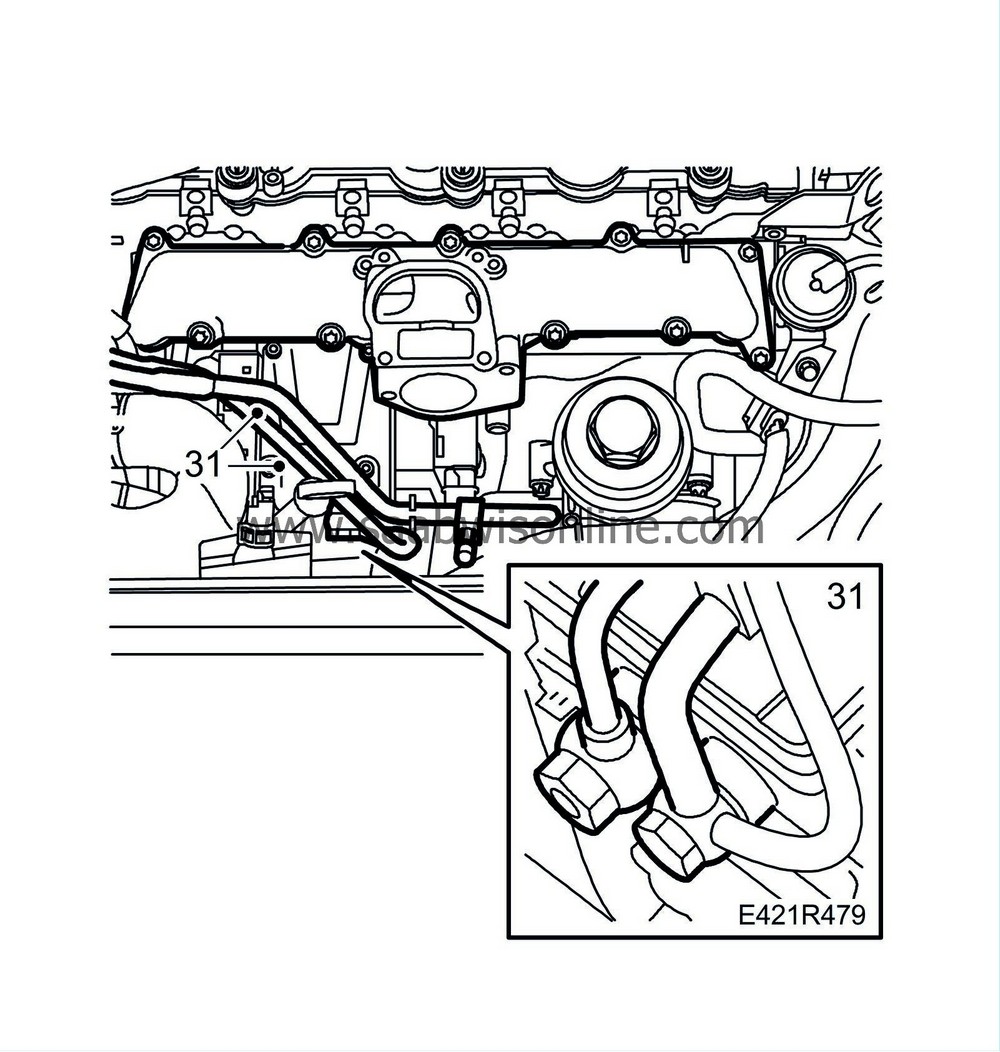

| 31. |

Detach the fuel inlet and return lines from the fuel distribution pump.

|

|

| 32. |

Undo the cable rail and move it aside.

|

|

| 33. |

Undo the vacuum hose to the brake servo and the vacuum hose connected to the bottom of the vacuum pump.

|

|

| 34. |

Remove the four vacuum pump retaining bolts and carefully lift off the vacuum pump and its adapter. Be prepared with a rag or similar to collect any spilled oil.

|

|

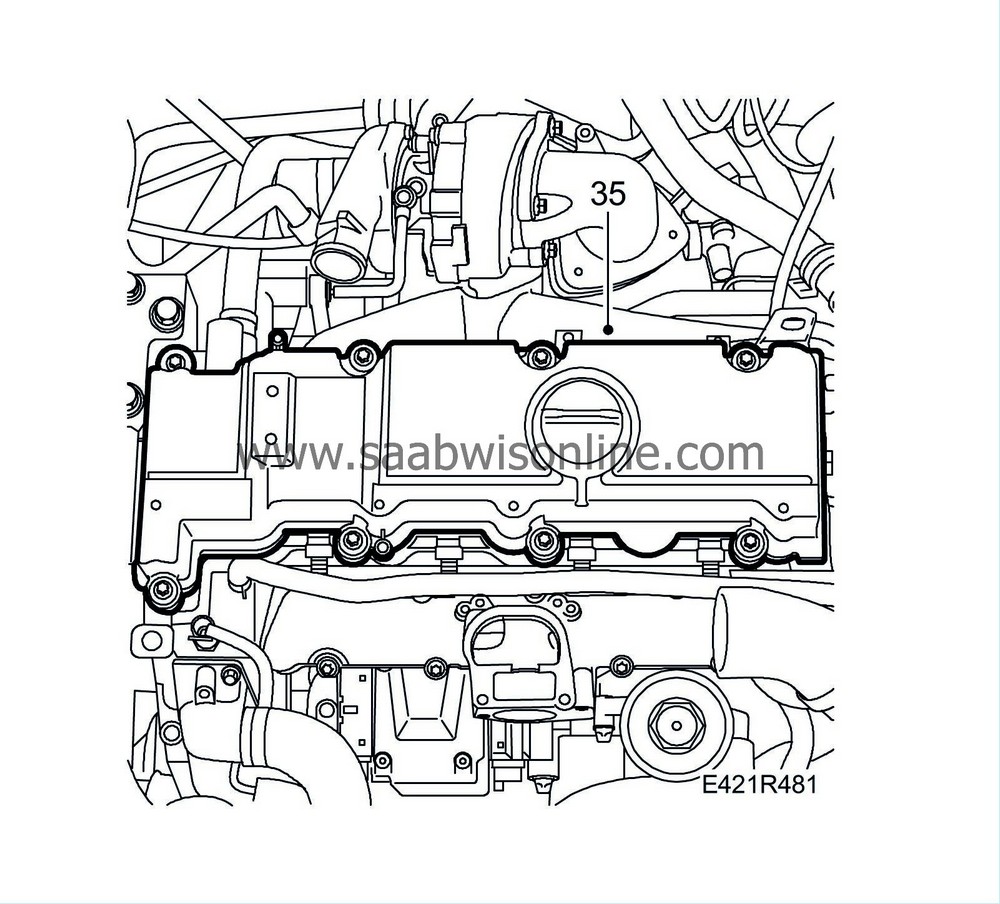

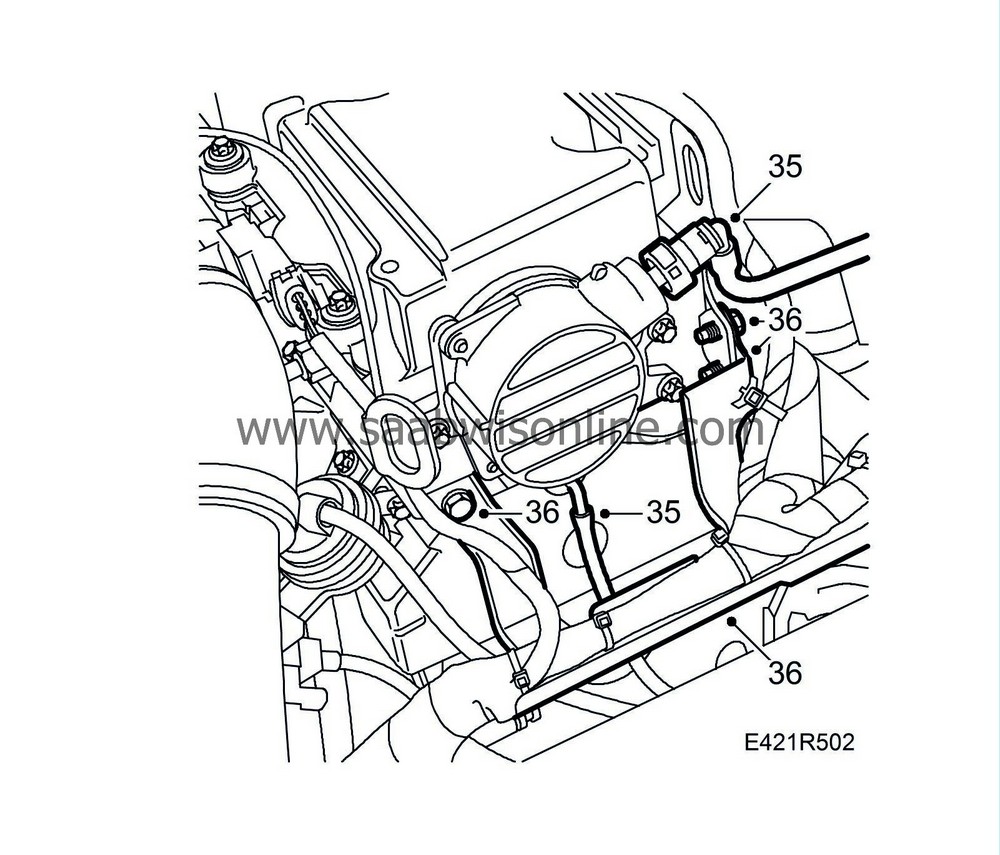

| 35. |

Remove the camshaft cover.

|

|

| 36. |

Turn the crankshaft to just before the mark for top dead centre in cylinder 1. Make sure both cam lobes for cylinder 1 are pointing up.

|

|

| 37. |

Insert

83 95 352 Setting tool, crankshaft

into the hole for the crankshaft position sensor. Push the tool somewhat inward at the same time as the crankshaft is turned to the zero point. The tool will then go into a recess in the crankshaft and lock it.

|

|

| 38. |

Position

83 95 386 Adjustment tool, camshaft

on the camshaft and cylinder head.

|

|

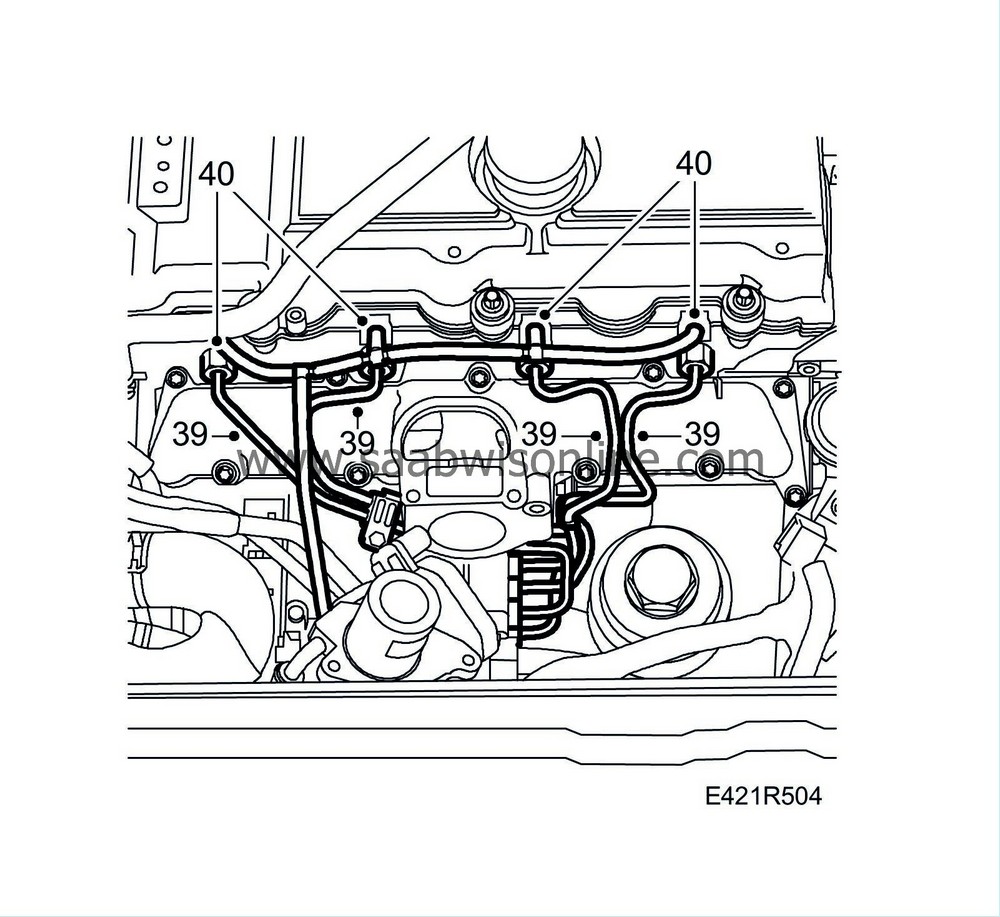

| 39. |

Remove the nut on the rear engine mounting.

|

|

| 40. |

Remove the nut and the vibration damper on the right-hand engine mounting.

|

|

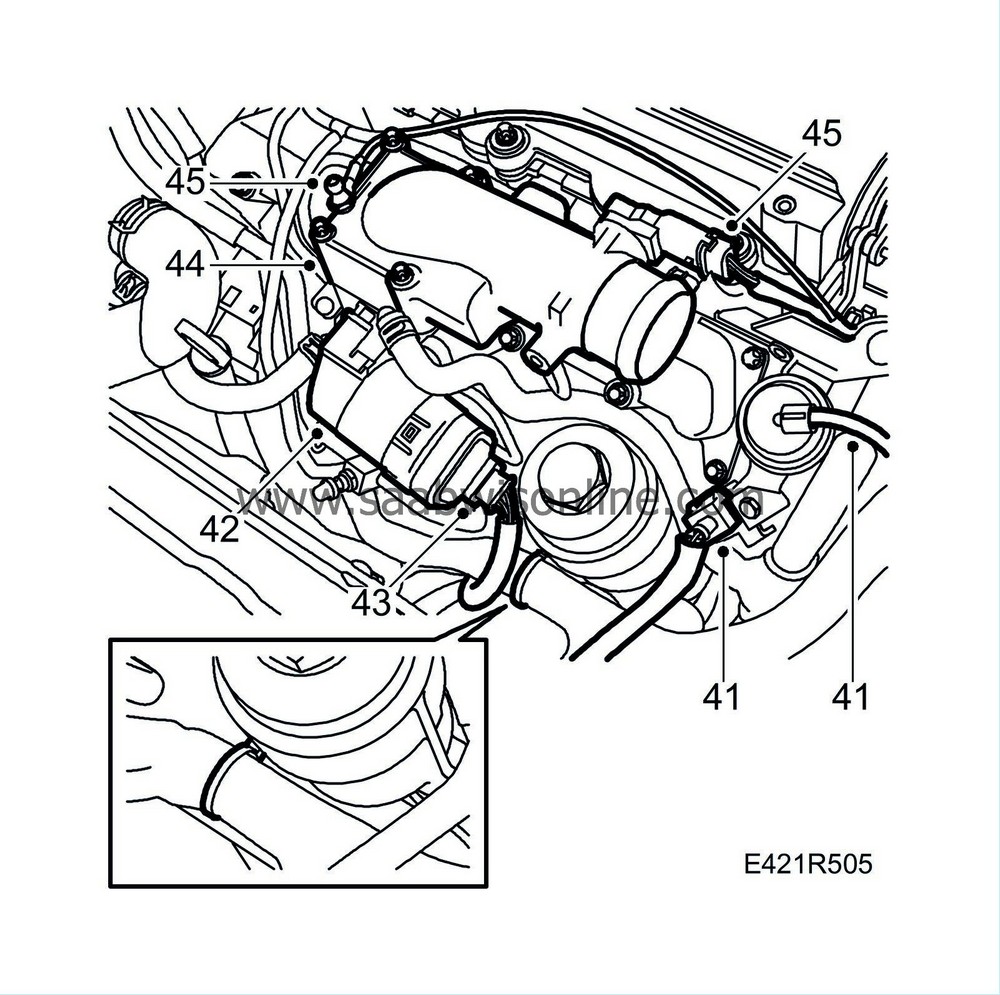

| 41. |

Take the weight of the engine with a jack.

|

|

| 42. |

Remove the upper engine bracket.

|

|

| 43. |

Dismantle the right-hand engine mounting.

|

|

| 44. |

Raise the engine with the jack and remove the lower bracket.

|

|

| 45. |

Remove the bolts on the timing cover plate, carefully insert a spatula behind the plate and prise it loose.

|

||||||||||

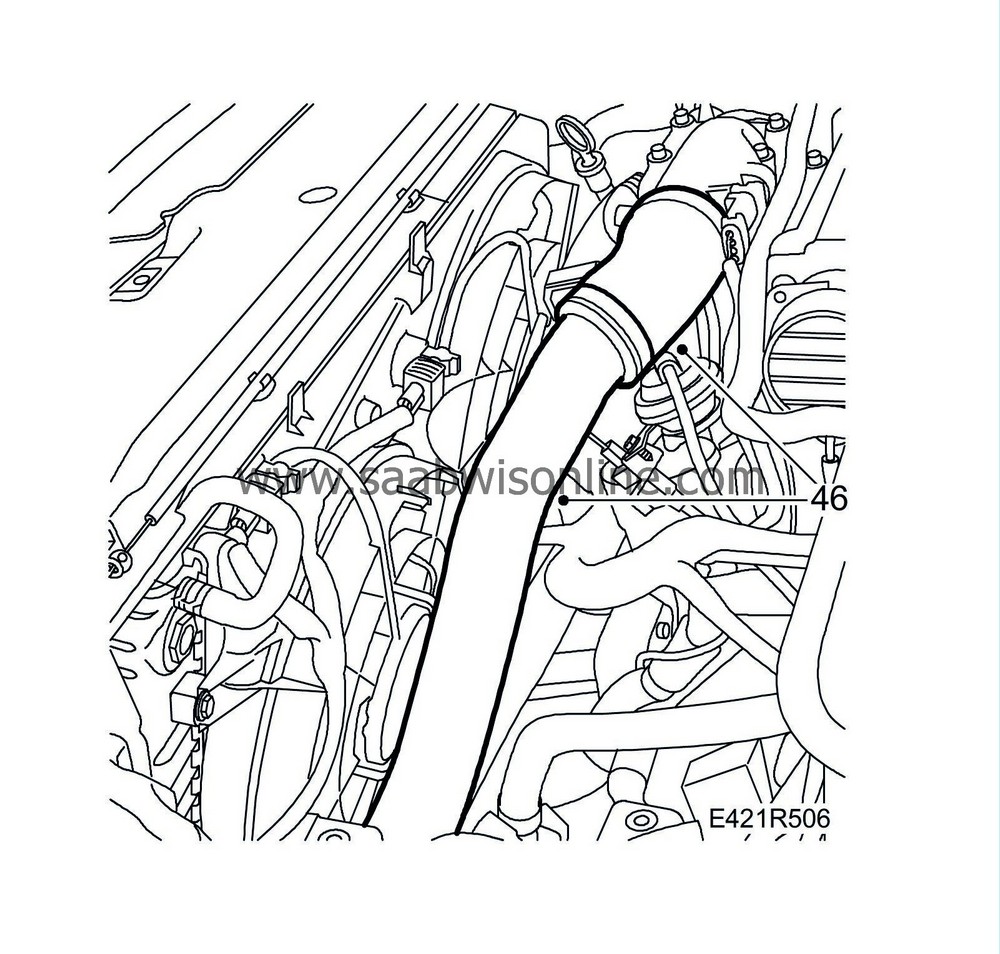

| 46. |

Position

83 95 337 Installation tool, fuel pump

in the fuel distribution pump recess.

|

|

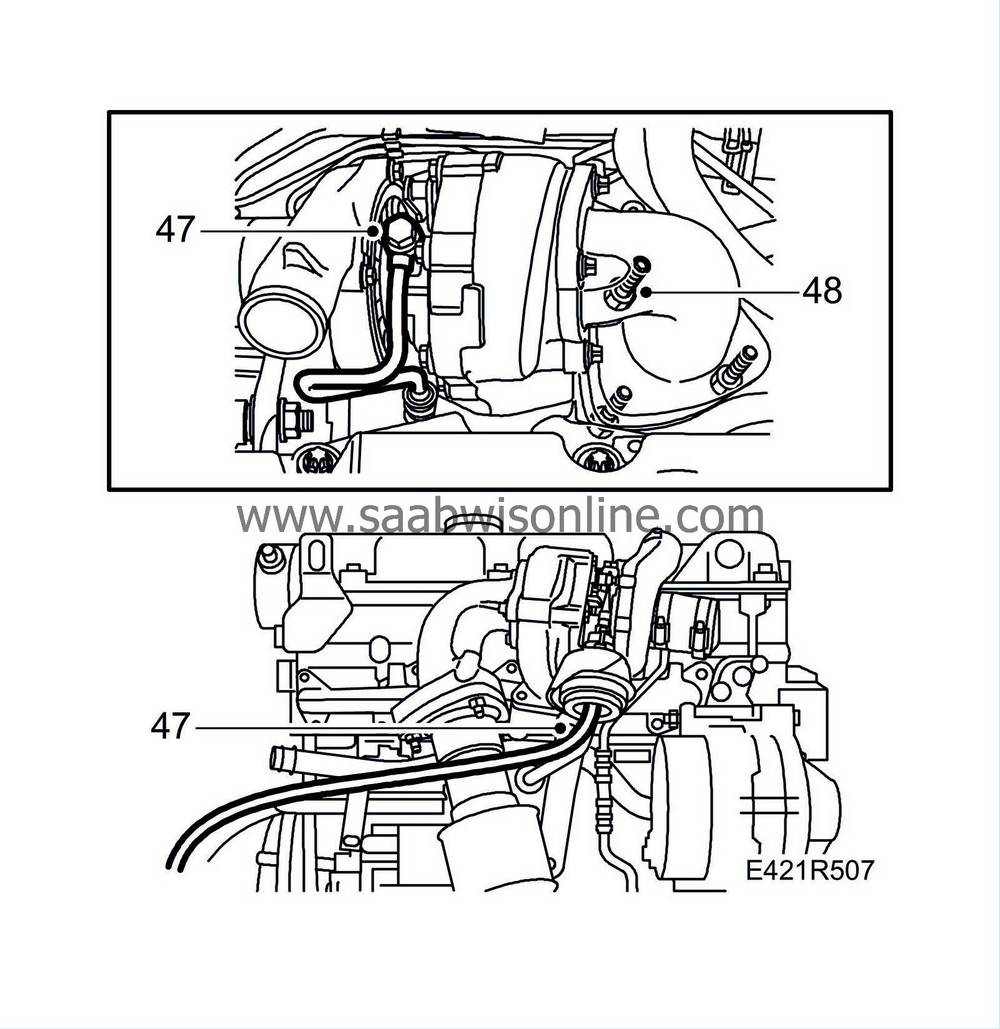

| 47. |

Remove the upper timing chain tensioner.

|

|

| 48. |

Remove

83 95 337 Setting tool, fuel pump

from the fuel pump recess.

|

|

| 49. |

Place a receptacle under the car. Undo the drain nipple on the fuel distribution pump with an 8mm Allen key. Connect a hose in the engine block nipple. Drain the coolant.

|

|

| 50. |

Detach the coolant hoses from the thermostat housing and the radiator connection.

|

|

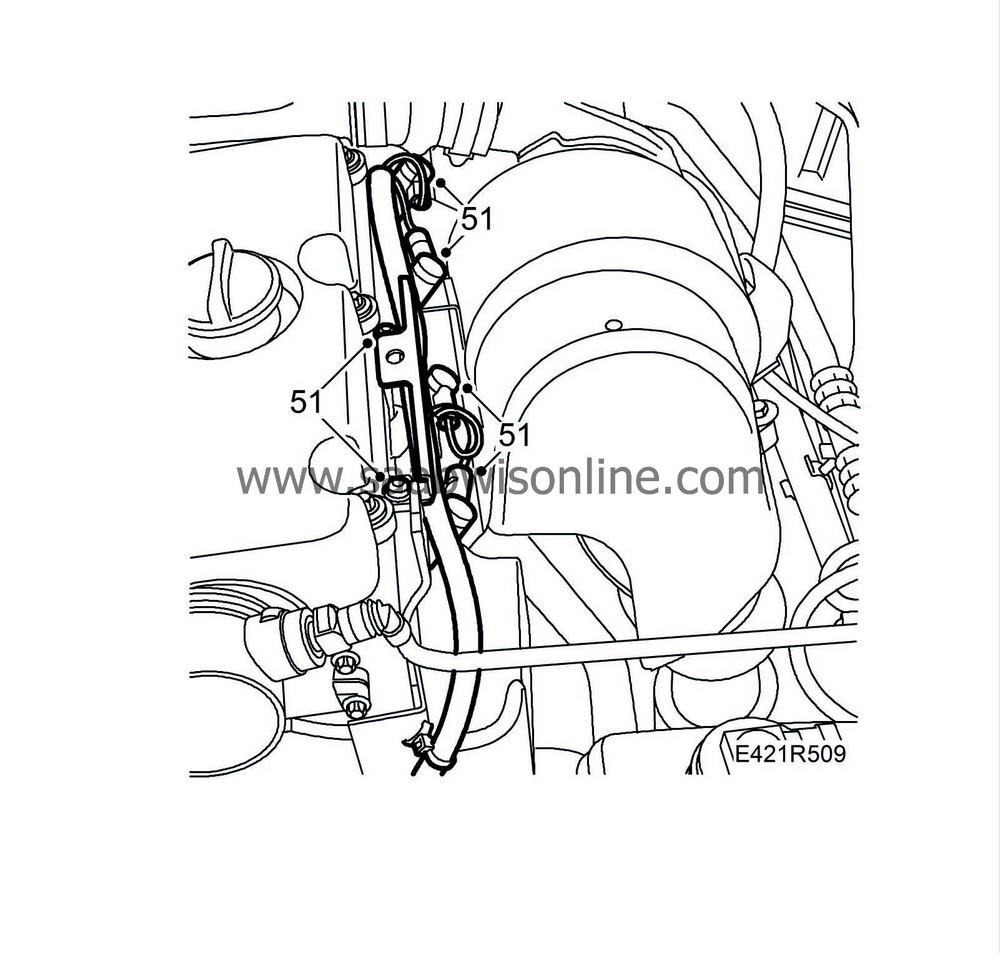

| 51. |

Remove the ventilation hose to the coolant expansion tank.

|

|

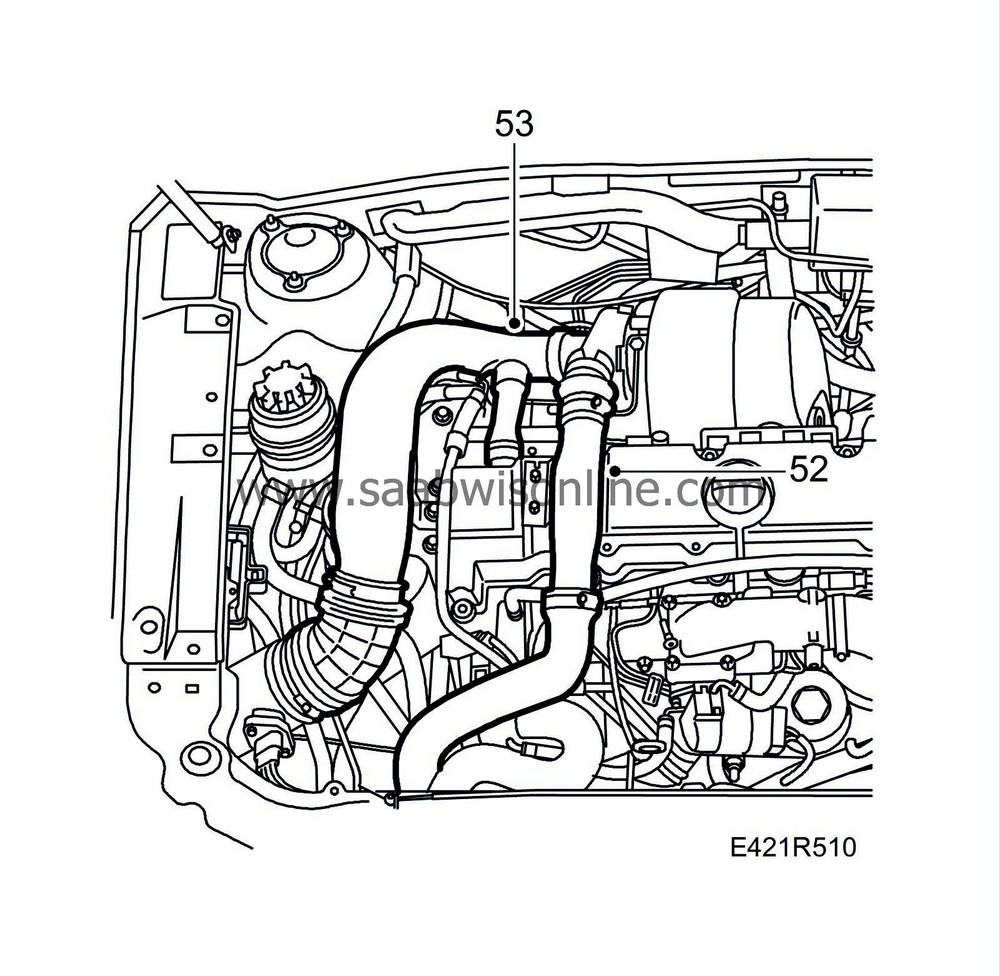

| 52. |

Unplug the coolant temperature sensor connector.

|

|

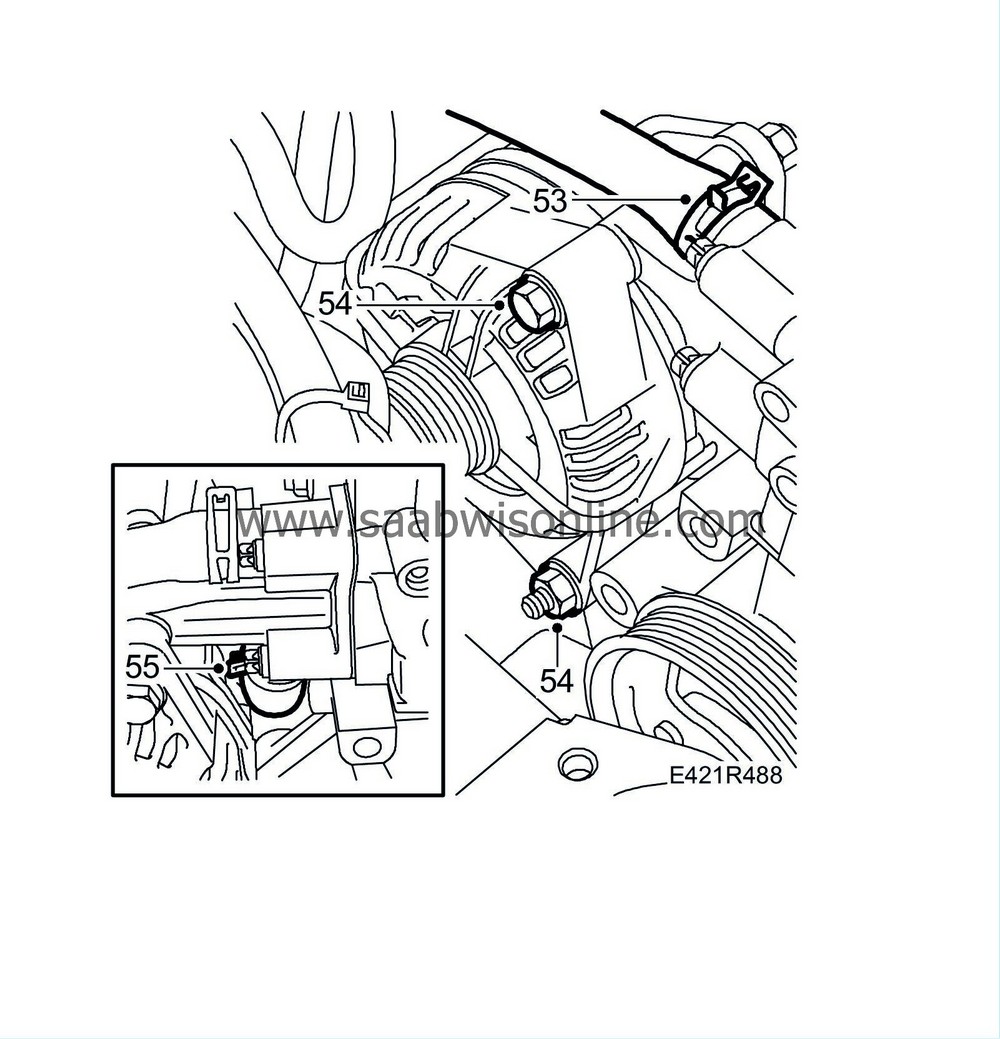

| 53. |

Cover the generator to protect it against any spilled coolant and remove the hose from the generator bracket.

|

|

| 54. |

Lower the engine slightly, remove the upper bolt on the generator bracket and loosen the lower bolt so that the generator can be tilted down.

|

|

| 55. |

Detach the lower hose from the generator bracket.

|

|

| 56. |

Fit a long cable tie to the timing chain to be used as a handle.

|

|

| 57. |

Remove the camshaft sprocket using an open spanner for support in the hexagonal recess on the camshaft.

|

|

| 58. |

Place the chain carefully to one side.

|

|

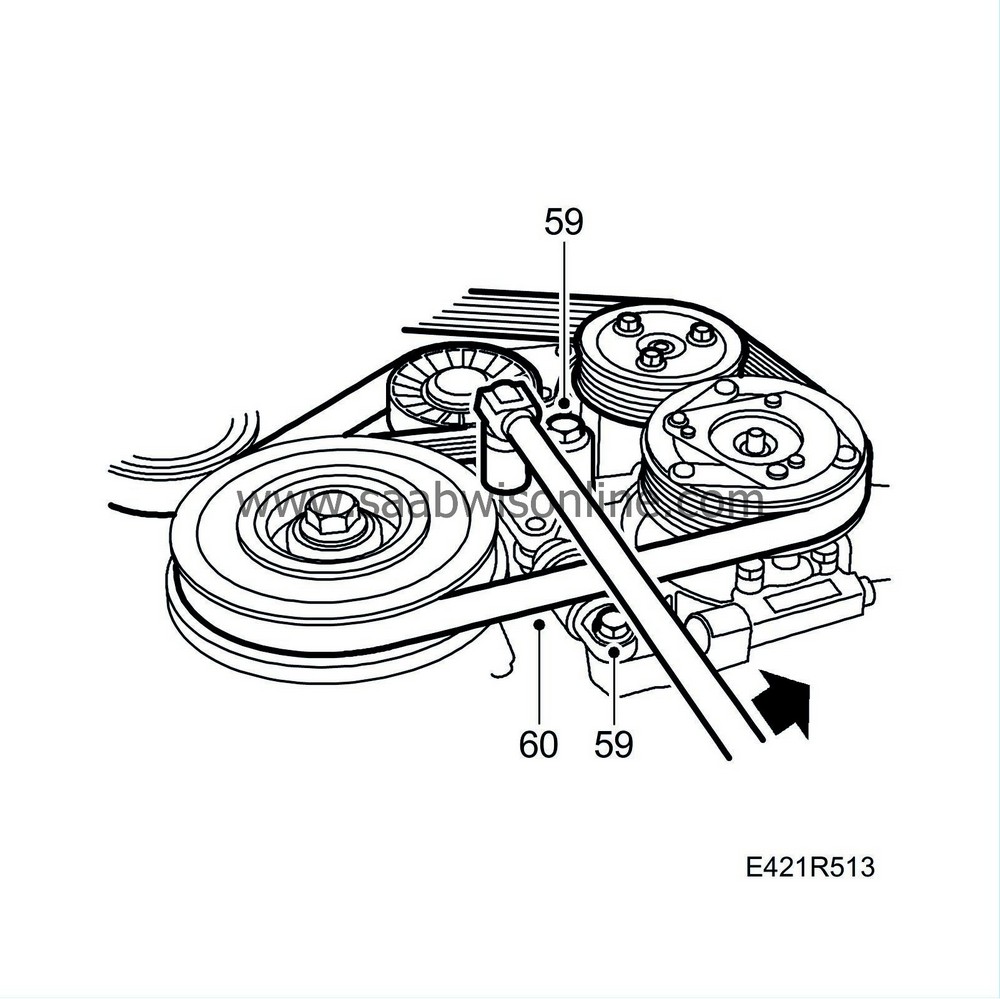

| 59. |

Remove the four bolts securing the cylinder head to the timing cover.

|

||||||||||

| 60. |

Remove the cylinder head by undoing the bolts in the order illustrated. Lift the cylinder head straight up and lay it down in such a way that the fuel injector nozzles, glow plugs or valves are not damaged.

|

|

| To fit |

| 1. |

Blow clean the bolt holes in the cylinder block with compressed air.

|

|

| 2. |

Clean the cylinder bore, cylinder head and cylinder block sealing surfaces from any remnants of gasket. Use a steel rule to check that the cylinder head and cylinder block are flat and none of the sealing surfaces are damaged.

|

|

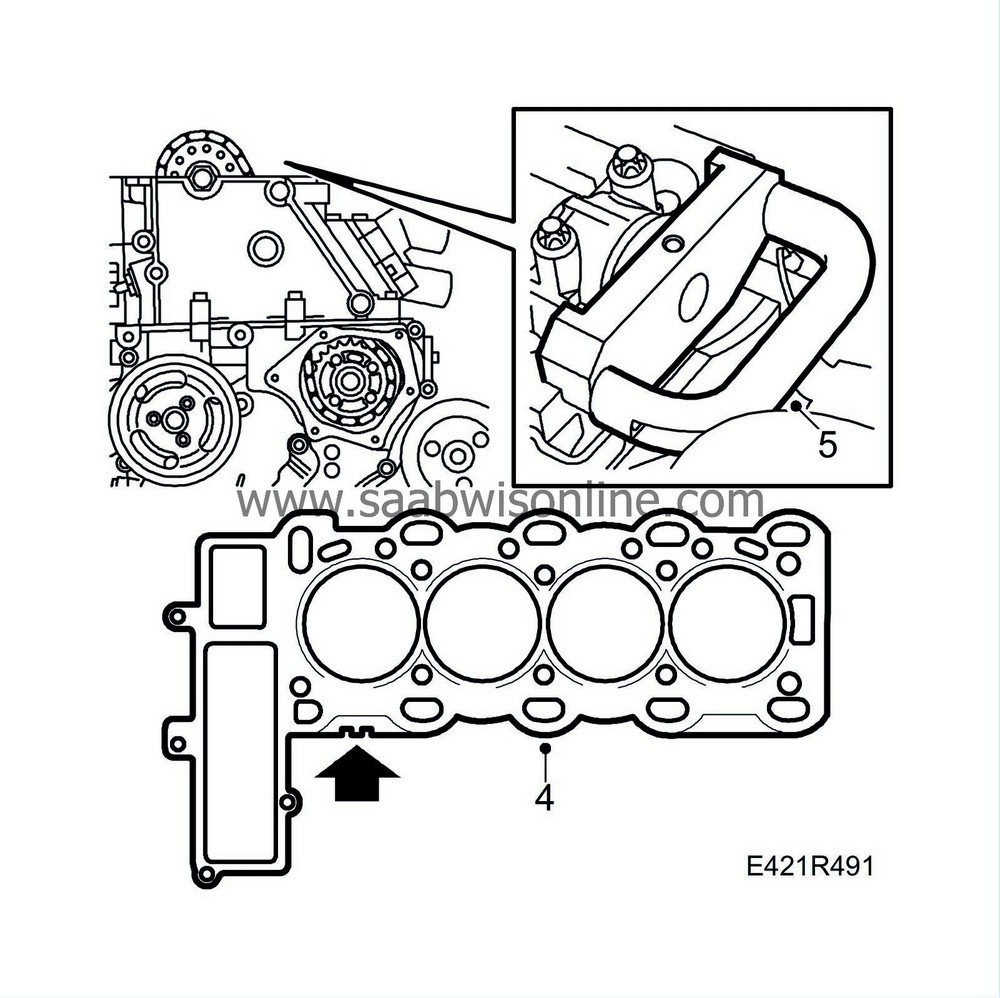

| 3. |

Apply

87 81 841 Silicon flange sealant

sparingly to the places shown in the illustration.

|

|

| 5. |

Position

83 95 386 Setting tool, camshaft

on the camshaft and cylinder head. The camshaft can be turned slightly using an open spanner in the hexagonal recess on the camshaft while positioning the tool correctly.

|

|

| 6. |

Position the cylinder head onto the cylinder block while pulling the timing chain up to the correct position.

|

|

| 7. |

Fit the cylinder head with new bolts in the order shown in the illustration. Follow the illustrated order for each step.

Tightening torques Step I: 25 Nm (18 lbf ft) Step II: 65° Step III: 65° Step IV: 65° Step V: 65° |

|

| 8. |

Fit the bolts in the timing cover in the same position as previously.

Tightening torque: 20 Nm (15 lbf ft)

|

|

| 9. |

Lift up the timing chain and position the camshaft sprocket so that it runs easily on the camshaft. Tighten it by hand with a new bolt.

|

|

| 10. |

Position

83 95 337 Setting tool, fuel pump

in the fuel distribution pump recess. Fix the adapter in position on the camshaft sprocket by turning it lightly anticlockwise with a ratchet handle. Tighten the adjusting screw on the tool.

|

||||||||||

| 11. |

Tighten the bolt on the camshaft sprocket. Use an open spanner in the hexagon recess on the camshaft for support.

Tightening torque: 90 Nm + 60° (67 lbf ft + 60°) |

|

| 12. |

Replace the chain tensioner for the upper timing chain using a new gasket.

Tightening torque: 60 Nm (44 lbf ft) |

|

| 13. |

Remove all the tools and gauges. Turn the crankshaft two revolutions until just before the mark for top dead centre in cylinder 1. Make sure both cam lobes for cylinder 1 are pointing up.

|

|

| 14. |

Insert

83 95 352 Setting tool, crankshaft

into the hole for the crankshaft position sensor. Push the tool somewhat inward at the same time as the crankshaft is turned to the zero point. The tool will then go into a recess in the crankshaft and lock it.

|

|

| 15. |

Make sure the markings on the crankshaft pulley and the timing cover are in line. The arrow on the single timing chain pulley on the fuel distribution pump must also be in line with the recess in the pump.

|

|

| 16. |

Insert

83 95 337 Installation tool, fuel pump

in the fuel distribution pump recess. The valve timing must be adjusted if the gauge does not fit, see

Setting valve timing

.

|

|

| 17. |

Position

83 95 386 Setting tool, camshaft

on the camshaft and cylinder head. The valve timing must be adjusted if the gauge does not fit, see

Setting valve timing

. Remove all the setting tools.

|

|

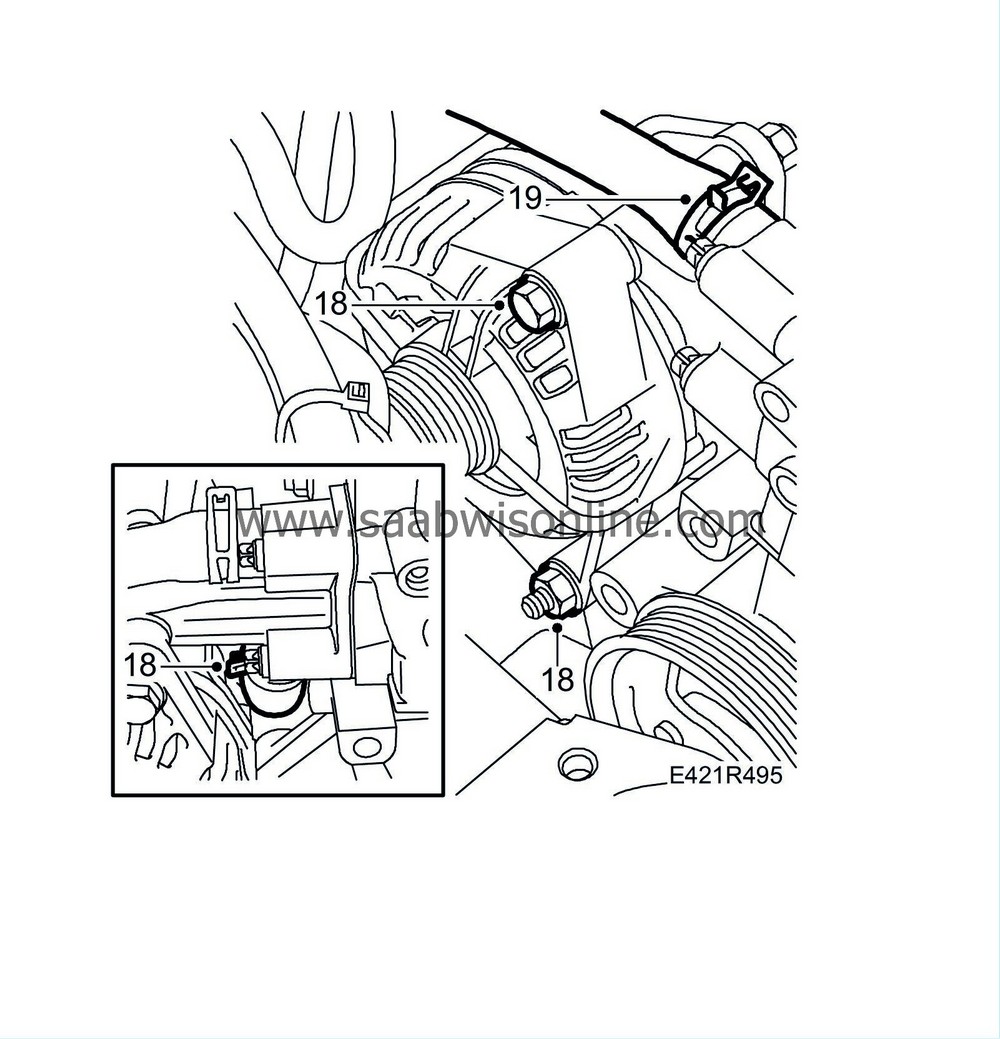

| 18. |

Fit the lower hose from the generator bracket. Rotate the generator forward, fit the upper bracket bolt and tighten the lower one.

Tightening torque: 47 Nm (35 lbf ft)

|

|

| 19. |

Fit the upper hose to the generator bracket.

|

|

| 20. |

Plug in the coolant temperature sensor connector.

|

|

| 21. |

Fit the ventilation hose to the coolant expansion tank.

|

|

| 22. |

Fit the coolant hoses from the thermostat housing and the radiator connection.

|

|

| 23. |

Fit the engine block drain plug with a new O-ring.

|

|

| 24. |

Cover the opening in the timing cover with a lint-free rag clean the sealing surface from any remnants of gasket. Clean the sealing surface on the cover plate as well.

|

|

| 25. |

Apply a bead of

87 81 841 Silicon flange sealant

about 2 mm thick on the cover plate, remove the rag from the timing cover and fit the cover plate.

Tightening torque: 6 Nm (5 lbf ft).

|

|

| 26. |

Fit the lower engine bracket.

Tightening torque: 47 Nm (35 lbf ft) |

|

| 27. |

Fit the right-hand engine mounting.

Tightening torque: 40 Nm + 30°(30 lbf ft + 30°)

|

|

| 28. |

Fit the upper bracket but do not tighten the bolts. Lower the jack until the upper bracket comes in contact with the engine mounting. Adjust the position of the upper bracket so that the engine mounting stud is situated as close as possible to the middle of the upper bracket hole.

|

|

| 29. |

Fit the engine mounting vibration damper and nut and tighten the upper bracket retaining bolts.

Tightening torque: 40 Nm + 60° (30 lbf ft + 60°) |

|

| 30. |

Lower the car completely and remove the jack· Tighten the nut to the right of the engine mounting.

Tightening torque 105 Nm (77 lbf ft) |

|

| 31. |

Fit the nut of the rear engine pad.

Tightening torque: 47 Nm (35 lbf ft)

|

|

| 32. |

Clean the cylinder head sealing surfaces from any gasket remnants. Place a new gasket on the camshaft cover. The bolts where the gasket is fitted have sleeves. Apply

87 81 841 Silicon flange sealant

on the sealing surface, see illustration.

|

|

| 33. |

Position the camshaft cover on the cylinder head and tighten the bolts.

Tightening torque: 8 Nm (6 lbf ft) |

|

| 34. |

Clean the sealing surfaces on the vacuum pump and cylinder head. Place a new gasket on the vacuum pump, apply sealant

87 81 841 Silicon flange sealant

as illustrated and fit the pump together with the adapter.

Tightening torque: 8 Nm (6 lbf ft)

|

|

| 35. |

Connect the hoses to the vacuum pump.

|

|

| 36. |

Fit the upper cable rail screws.

|

|

| 37. |

Fit the fuel inlet and return lines to the fuel pump with new seals but do not tighten the connections yet.

|

|

| 39. |

Inspect the tapered fuel rail connections and change the pipe if any of them are damaged. Fit the fuel rails.

Tightening torque: 25 Nm (19 lbf ft)

|

|

| 40. |

Fit new fuel return hoses to the fuel bridges.

|

|

| 41. |

Plug in the connectors to the crankshaft position sensor.

|

|

| 42. |

Fit the EGR valve with a new O-ring.

Tightening torque: 10 Nm (7 lbf ft) |

|

| 43. |

Plug in the EGR valve connector and connect its coolant hoses.

|

|

| 44. |

Fit the throttle body with a new gasket.

Tightening torque: 10 Nm (7 lbf ft) |

|

| 45. |

Fit the ground cable and the pressure/temperature sensor connector on the throttle body.

|

|

| 46. |

Connect the turbocharger delivery pipe with hose to the throttle body.

|

|

| 47. |

Fit the turbocharger oil delivery pipe with new seals and the hose to the turbocharger vacuum unit.

Tightening torque: 12 Nm (9 lbf ft)

|

|

| 48. |

Fit the rear nut on the front exhaust pipe and the turbo. Lubricate studs with

90 513 210 Universal paste

.

Tightening torque: 25 Nm (19 lbf ft) |

|

| 49. |

Fit the lower screw for the cable rail and the lifting eye bolt.

|

|

| 50. |

Fit the heat shields over the exhaust manifold and turbocharger.

|

|

| 51. |

Connect the glow plug electric connections and fit the rear wiring harness mounting to the camshaft cover.

|

|

| 52. |

Remove the plugs, connect and fit the turbocharger delivery pipe with hose to the turbocharger, camshaft cover and turbocharger delivery pipe on the fan cowling.

|

|

| 53. |

Fit the intake manifold from the mass air flow sensor to the turbo and the hose for the crankcase ventilation.

Tightening torque, mass air flow sensor: 3.5 Nm (2.5 lbf ft) |

|

| 54. |

Raise the car and fit the two front nuts on the exhaust pipe and turbocharger.

Tightening torque: 25 Nm (19 lbf ft)

|

|

| 55. |

Fit the turbocharger oil return pipe to the cylinder block.

|

|

| 56. |

Fit the exhaust manifold stay and insert the bolt.

|

|

| 57. |

Fit the crankshaft position sensor with a new O-ring.

Tightening torque: 8 Nm (6 lbf ft)

|

|

| 58. |

Cut off the cable tie, fit the front bolt on the torque arm stay and tighten the rear one.

Tightening torque, front bolt 90 Nm + 90° (66 lbf ft + 90°) Tightening torque, rear bolt 50 Nm + 120° (37 lbf ft + 120°) |

|

| 59. |

Fit the belt tensioner and tighten the upper bolt first.

Tightening torque, upper bolt 42 Nm (31 lbf ft). Tightening torque, lower bolt 23 Nm (17 lbf ft).

|

|

| 60. |

Fit the multigroove belt and make sure it is positioned correctly over the belt pulleys.

|

|

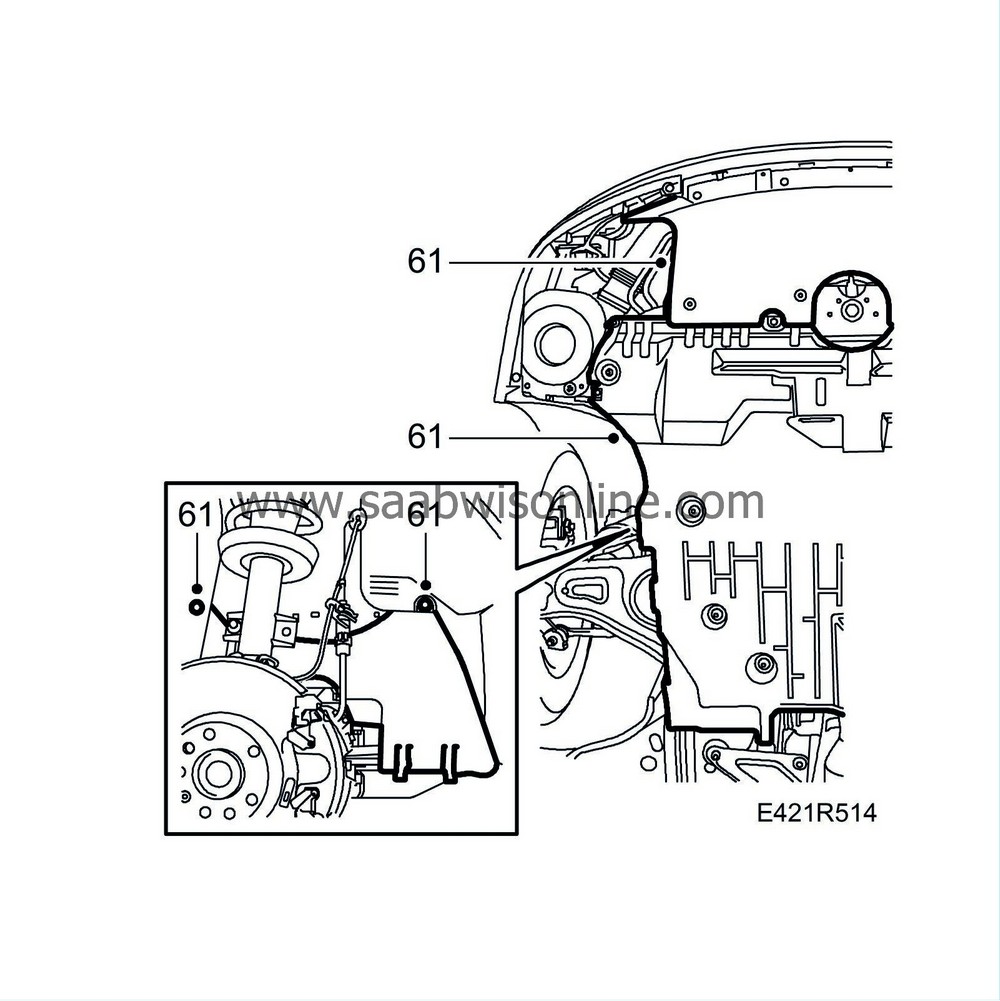

| 61. |

Fit the spoiler shield and the lower engine cover. Fit the drive belt cover.

|

|

| 62. |

Fit the wheel, see

Wheels

|

|

| 63. |

Lower the car, fit the upper bolt on the exhaust manifold stay and tighten the lower one.

|

|

| 64. |

Connect the negative battery cable and fit the battery cover.

|

|

| 65. |

Bleed the fuel system, see

Bleeding the fuel line, 4-cyl

.

|

|

| 66. |

Add coolant to around 20 mm above the mark on the expansion tank. See

Coolant

|

|

| 67. |

Replace the upper engine cover.

|

|

| 68. |

Adjust the clock, SID and calibrate AC/ACC.

|

|

Warning

Warning