PRE-RELEASE

General on body alignment systems

| General on body alignment systems |

| • |

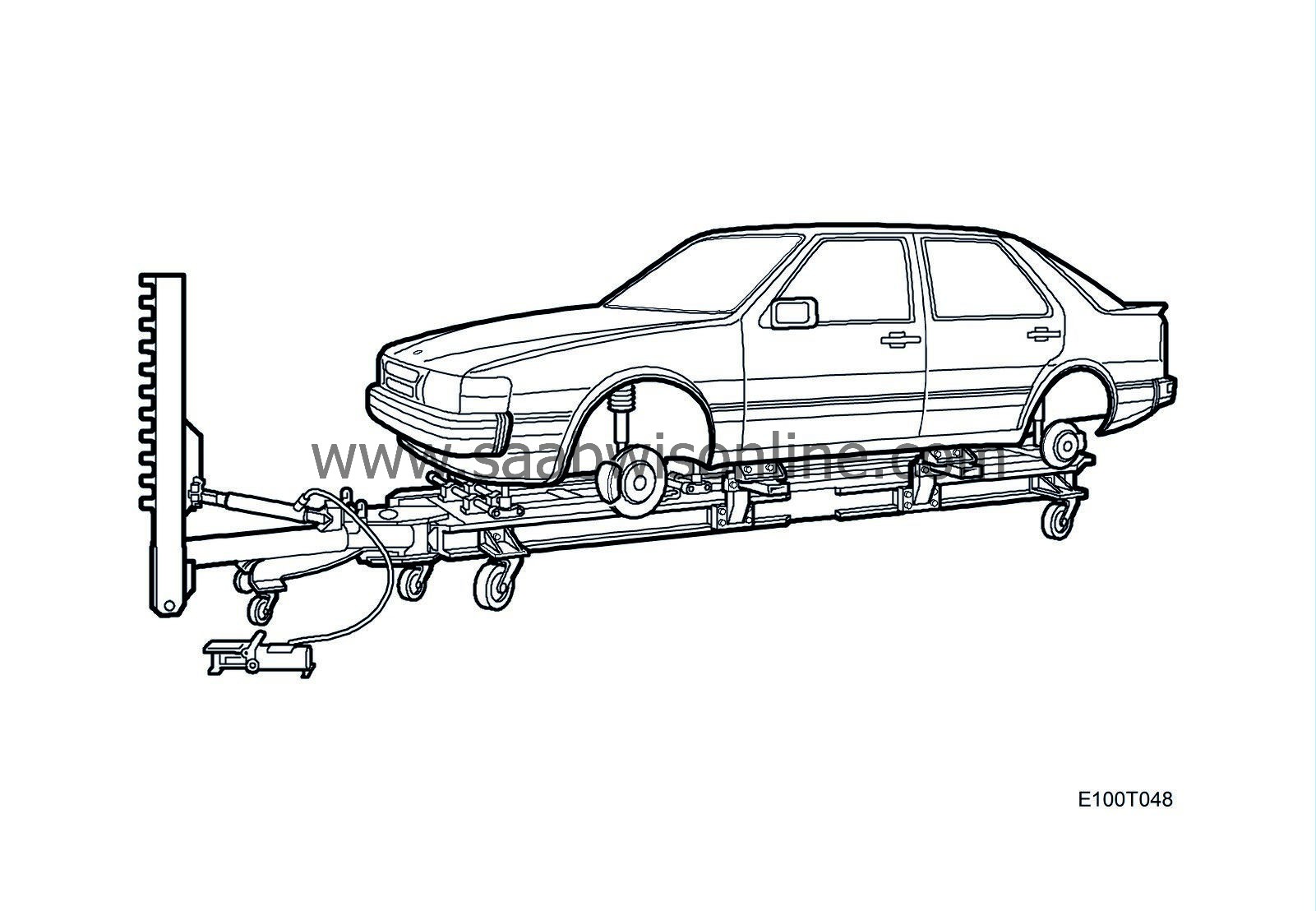

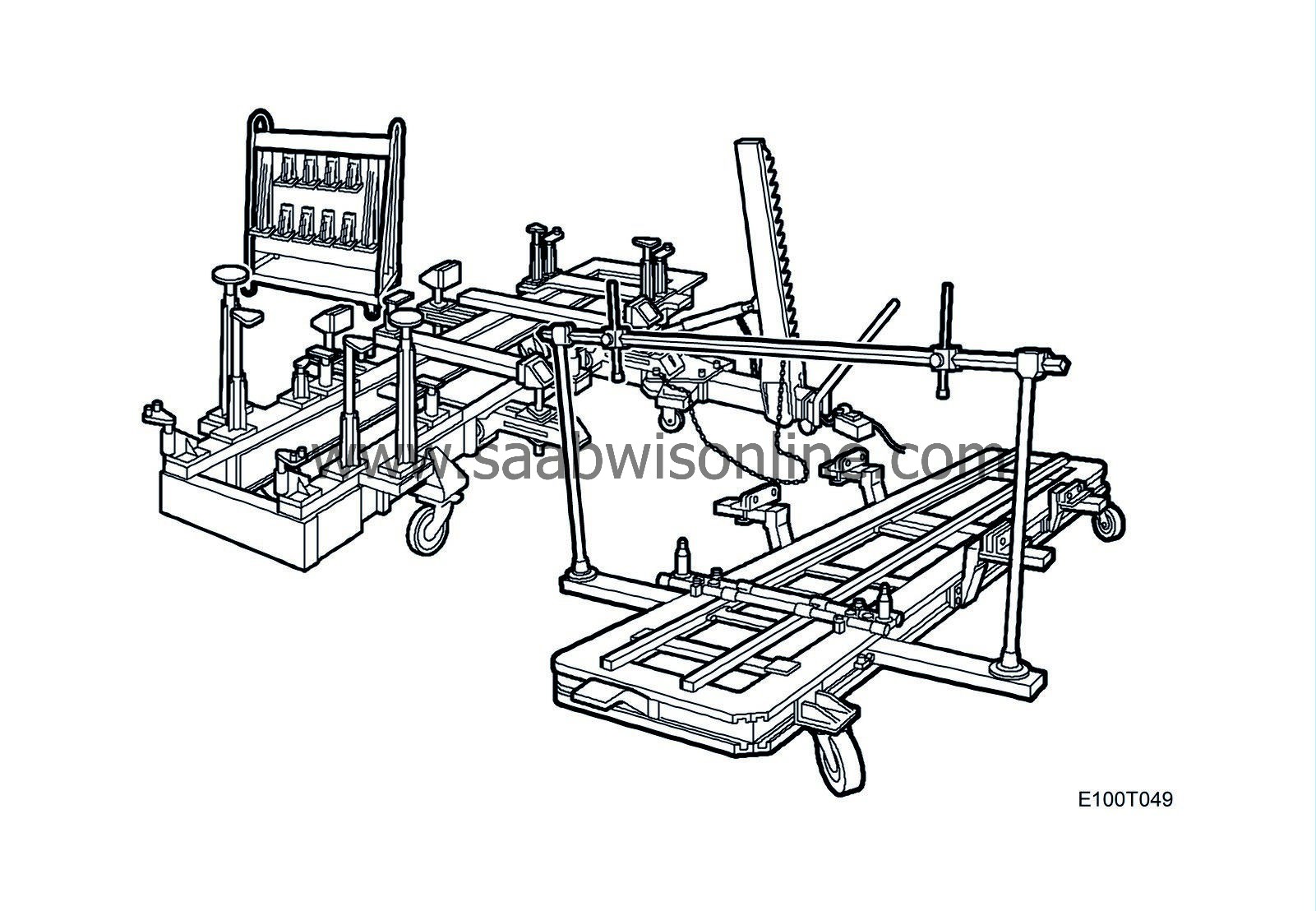

Equipment designed for this type of work

|

|

| • |

Employees well acquainted with use of the equipment and trained in body repair.

|

|

If these requirements are not fulfilled, there is little chance of a successful repair or meeting customer requirements.

It is therefore vital that the choice of alignment system is in harmony with employee desires and the damage types frequently dealt with. In the event of frequently recurring work, the choice is guided towards a rational solution with an easy-to-work jig.

Dataliner and Car-O-Liner are manufactured in Sweden and Celette, France. Saab has a good partnership with these manufacturers. This is reflected in the caliber of service that these companies offer both in the Swedish market and the export market.

| Fixed supports or measurement system? |

Our study shows that both fixed supports and universal measurement systems can meet the requirements set by Saab as the standard for a correctly adjusted body. It is therefore important to use your own conditions as a starting point when weighing the pros and cons of each system and choosing just the right solution.

The suppliers' basic kits are about the same price. In order to make the system a rational workplace, many supplement with special holders or pull clamps, which raises the price. You should thoroughly check the components of the system the supplier offers and work out a customised system based on your own needs.

Systems with multidraw, such as Dataliner, sometimes give greater chance of a rational alignment. For systems with draw aligner, an extra draw aligner must be acquired. The same also applies to the opportunity to straighten at roof height and then particularly upward pull.

A great advantage of universal measurement systems is the opportunity to measure and align several car models without great investments in fixed supports or the like. They are also significantly faster when straightening small and medium damage, where there is no need to remove the damaged component. With fixed supports, one point that has been pulled to the right measurement must be locked in place before work is continued at the next spot. It is also important that spare parts can be locked in the correct position during welding.

The following pages describe equipment intended for use as a reference when acquiring alignment equipment.