To assemble

| To assemble |

| General measures before assembly |

| • |

Parts and housing should be thoroughly washed before assembly.

|

|

| • |

Check the parts for wear. Change damaged or defective parts.

|

|

| • |

If there was a lot of swarf in the gearbox, all bearings should be replaced. Always change both bearings on one shaft, even if only one is damaged.

|

|

| • |

Change seals at the drive shafts.

|

|

| • |

All bearings and friction surfaces should be oiled before assembly with the same type of oil as in the gearbox. See Technical data.

List of lubricants and sealants

.

|

|

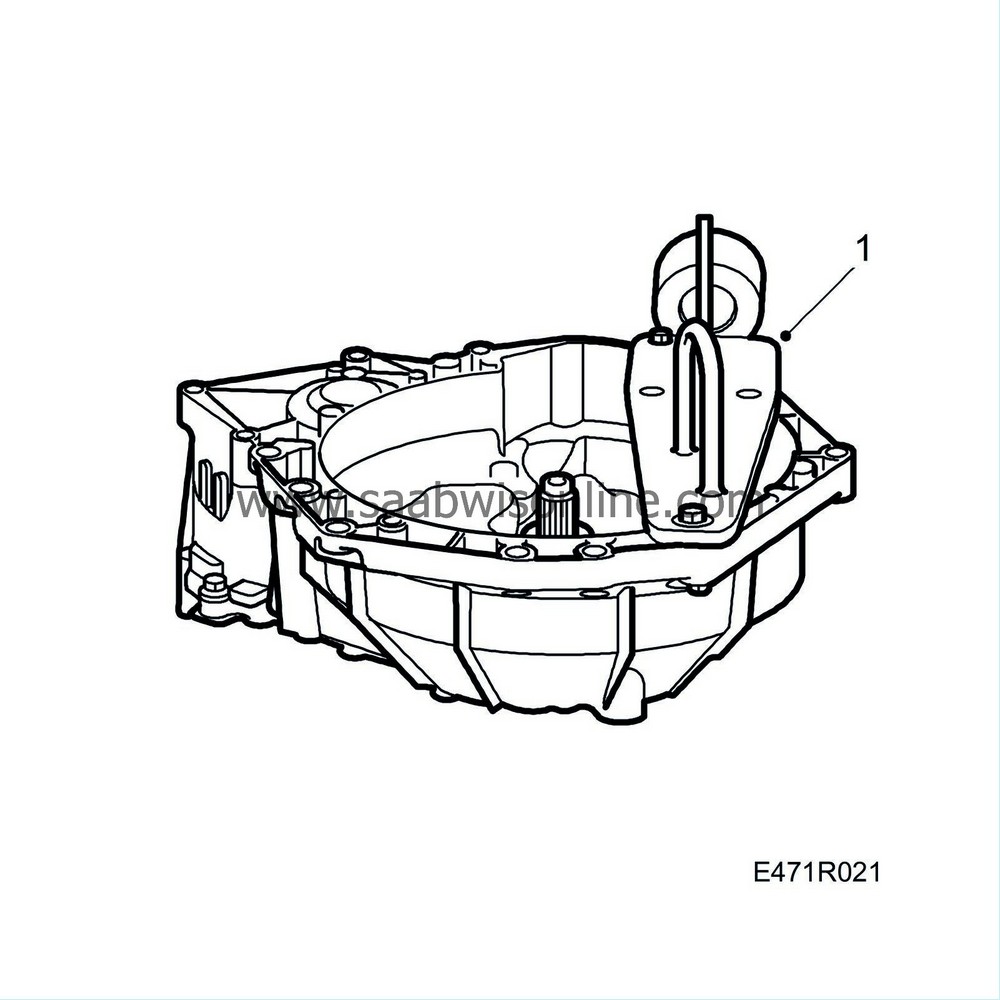

| 1. |

Position the clutch housing in the service stand using

87 92 228 Holder, transmission

.

|

|

| 2. |

Carefully scrape away old sealant residue from the mating face without damaging the sealing surfaces. Be sure to clean all sealant residue from the gearcase.

|

|

| 3. |

Fit the differential into the clutch housing and lubricate the bearing.

|

|

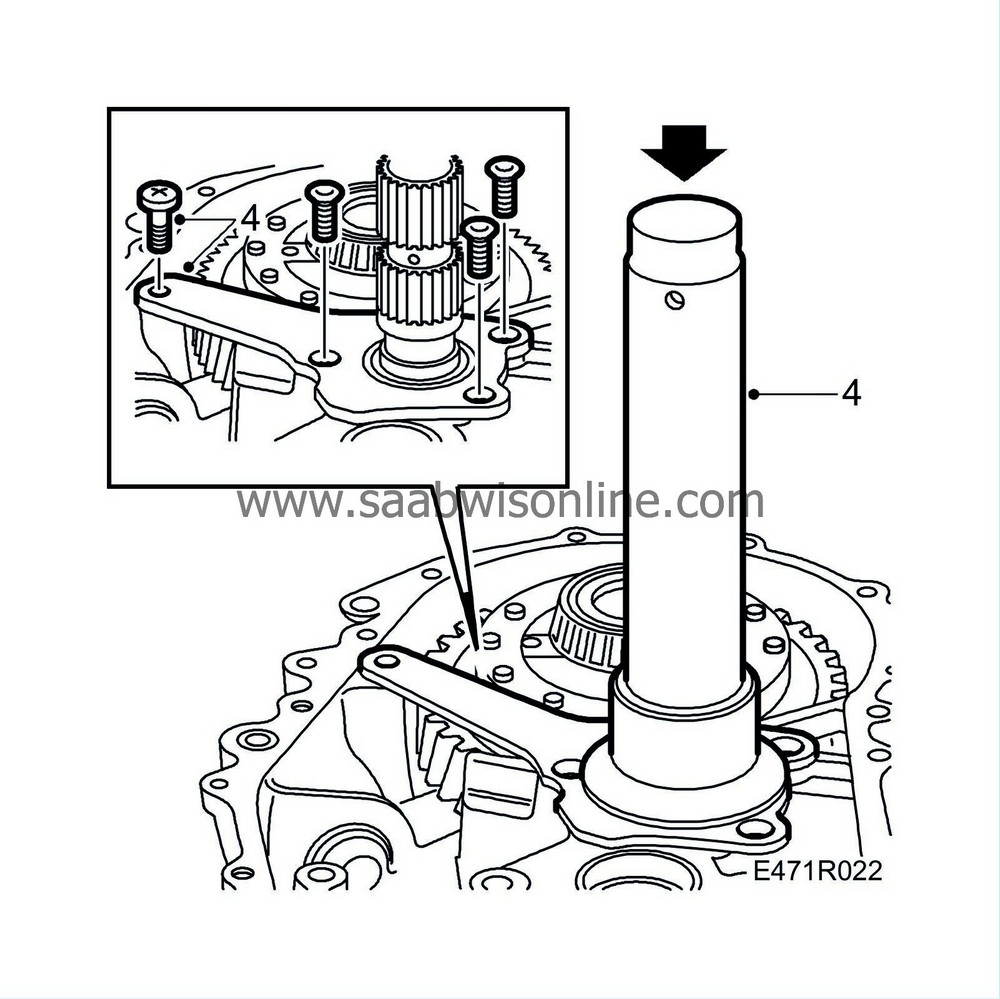

| 4. |

Place the output shaft in its seat, lubricate the bearing and mount the bearing race. Fit the bearing support and tap it down. Use

87 92 202 Sleeve

and

87 91 204 Sleeve, bearing race

. Use

Thread locking adhesive, Loctite 577

on all bolts and fit them. Tighten the 3 bolts in the middle alternately.

Tightening torque 45 Nm (33 lbf ft) The outer bolts should only be tightened to: Tightening torque 24 Nm (18 lbf ft) |

|

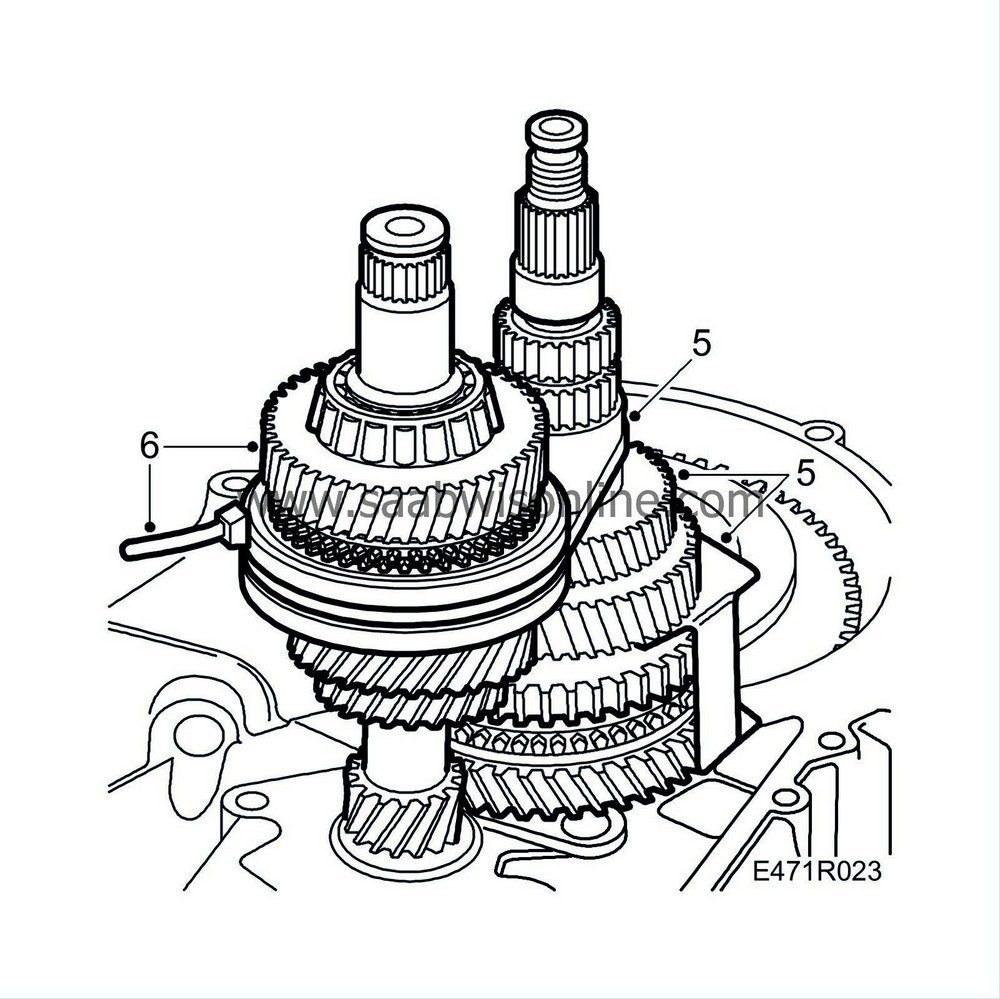

| 5. |

Fit 1st and 2nd gear wheels with synchromesh assembly on the output shaft with

87 92 103 Assembly fixture, 1

. Then fit the assembled parts on the output shaft. Fit 3rd gear wheel and spacer sleeve on the output shaft. Note that a used pinion must be turned the same way as previously. Do not let the fitted wheels go too far down on the shaft, save 15 mm. Otherwise the input shaft cannot be fitted.

|

|

| 6. |

Place the input shaft in the housing and lubricate the bearing. Fit a cable tie to keep the gears on the input and output shafts meshed.

|

|

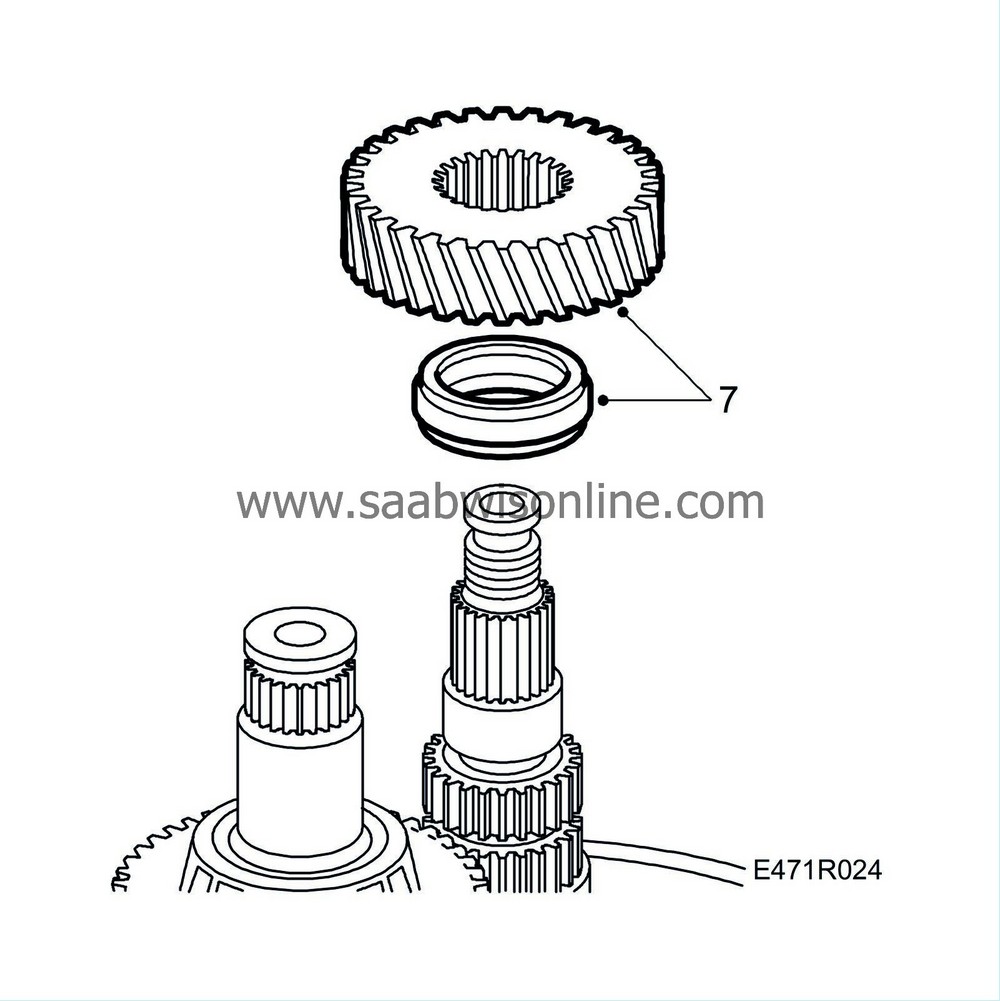

| 7. |

Press down the wheels on the output shaft towards the plane on the clutch housing. Carefully tap with a hammer,

87 91 204 Sleeve, bearing race

and

87 90 867 Assembly ring, input shaft bearing

until a

new clamping sleeve

and 4th gear wheel can be fitted. Mount 4th gear wheel with machined groove facing down.

|

|

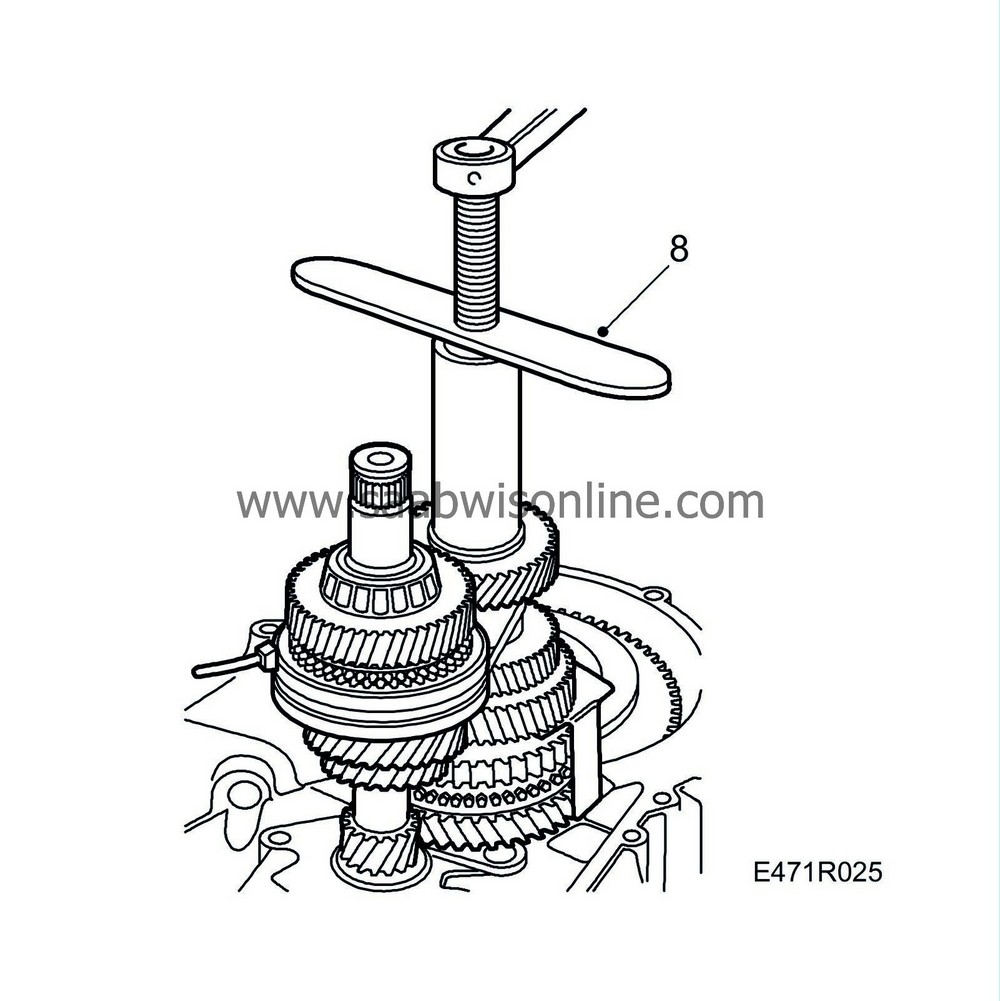

| 8. |

Fit

87 91 261 Puller, pinion

and pull down until the 4th gear pinion and wheel on the input and output shafts align with each other. Cut the cable ties and remove

87 92 103 Assembly fixture, 1

. Check that the 1st and 2nd gear pinions run smoothly on the output shaft.

|

|

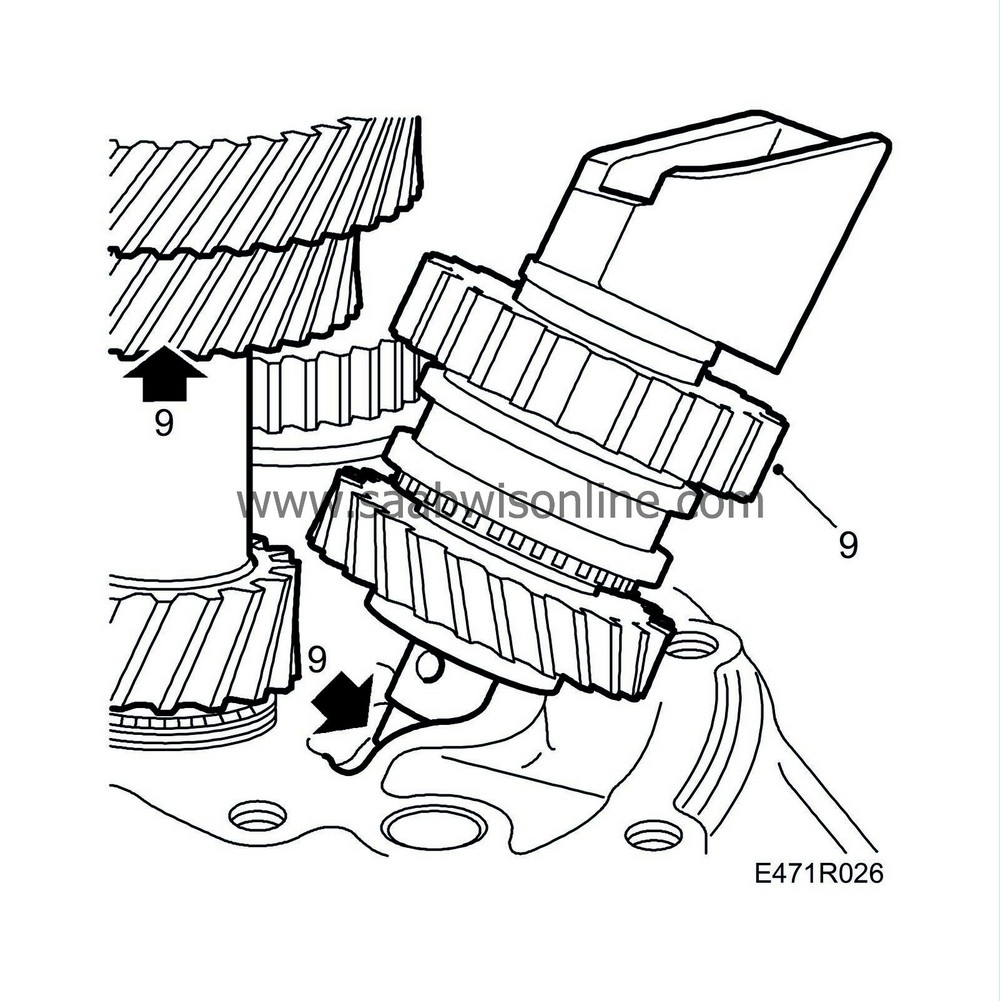

| 10. |

Fit the selector mechanism in the clutch housing. The forks should be in the neutral position. Press up the synchromesh sleeve against the 2nd gear position on the output shaft. Press up the synchromesh sleeve in 4th gear position on the input shaft

|

|

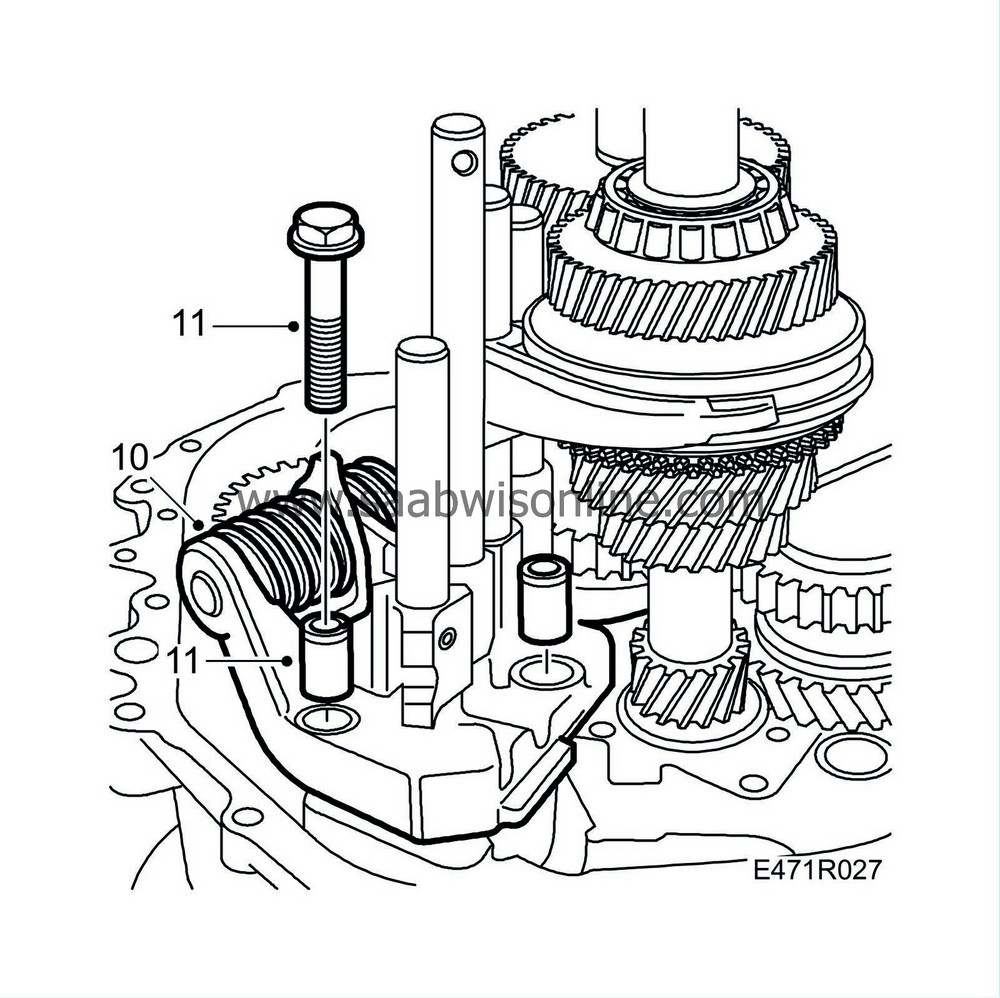

| 11. |

Place the 1st-2nd and 3rd-4th forks in the synchromesh sleeves and turn and push the mechanism into position. The synchromesh sleeves should be in the neutral position. Insert the locating sleeves and align the screws.

|

|

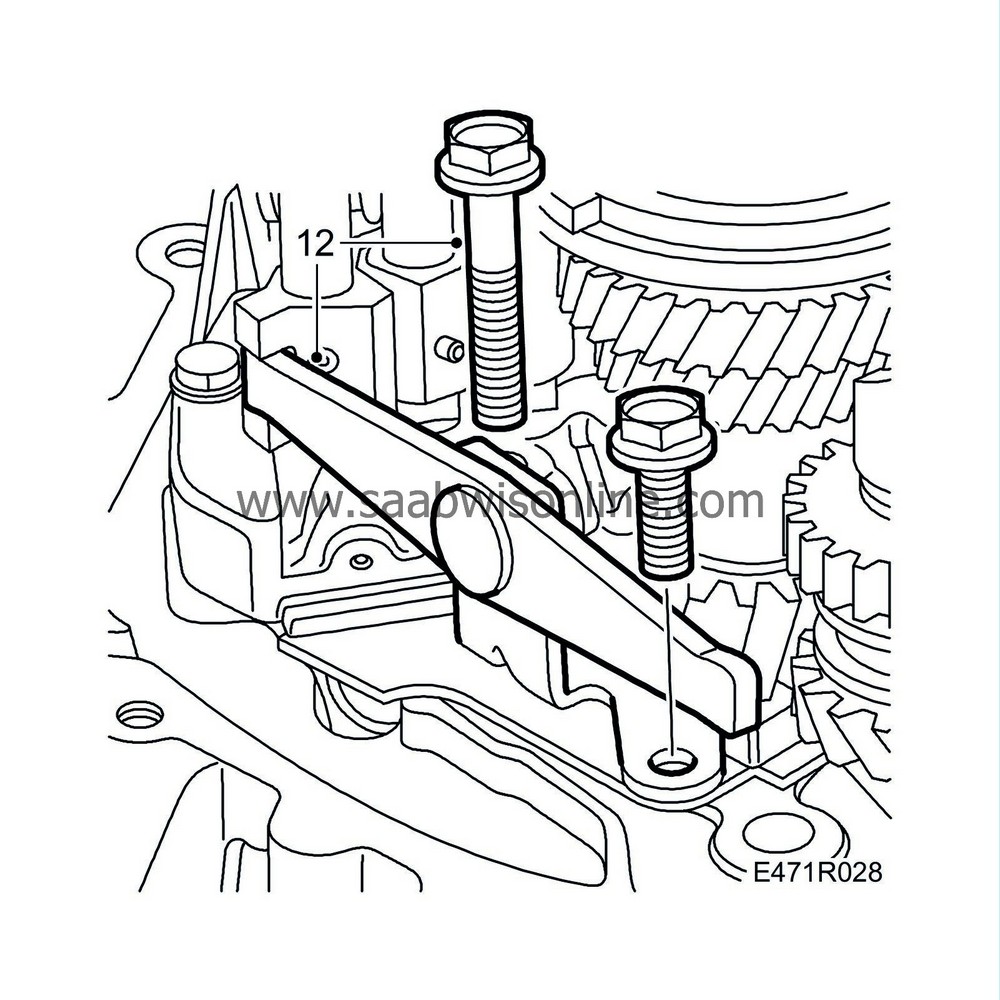

| 12. |

Fit the reverse gear selector fork with the two remaining bolts. Use

Thread locking adhesive, Loctite 577

on the short bolt. (The bolthole opens into the clutch housing and the thread adhesive will prevent oil leakage.) Tighten the 3 bolts.

Tightening torque 24 Nm (18 lbf ft)

|

||||||||||

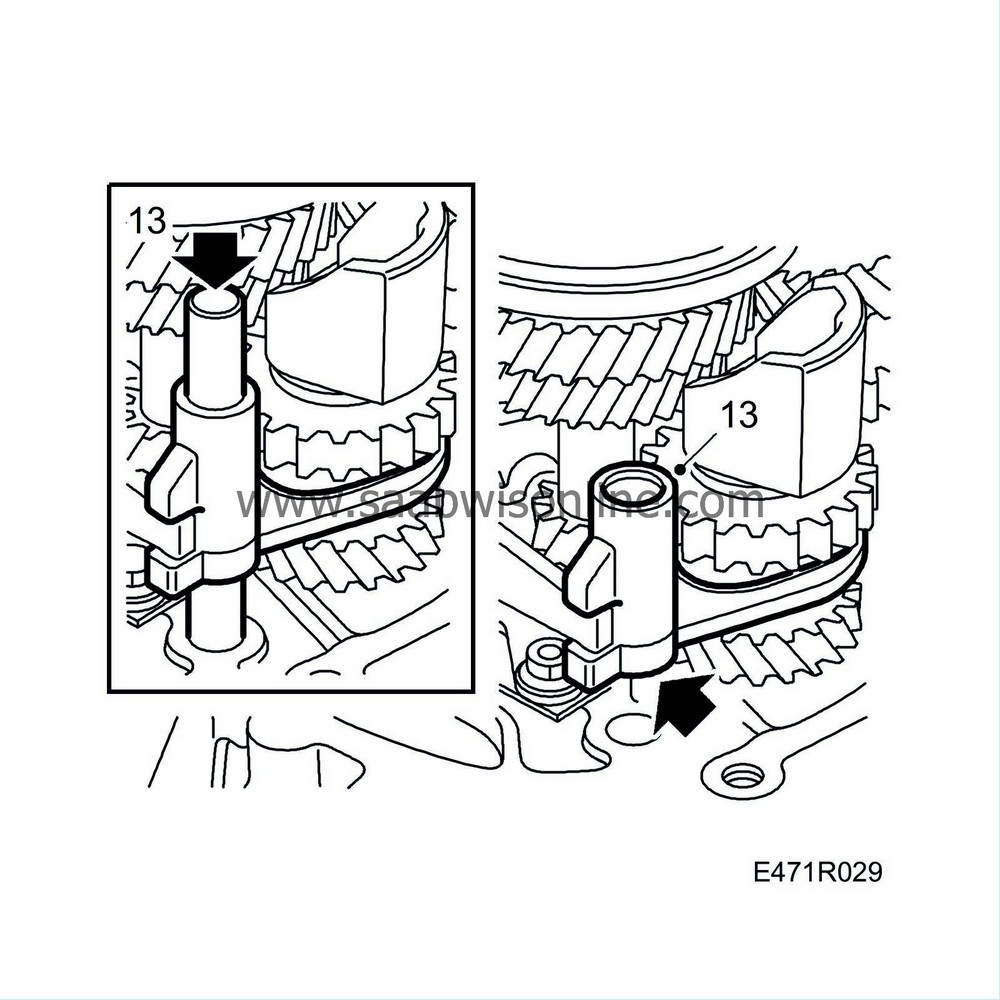

| 13. |

Fit the fork to the reverse synchromesh sleeve. Check that the reverse gear selector fork enters the groove on the reverse fork. Then push in the shaft. Engage reverse gear using the selector mechanism and check that it is fully engaged.

|

|

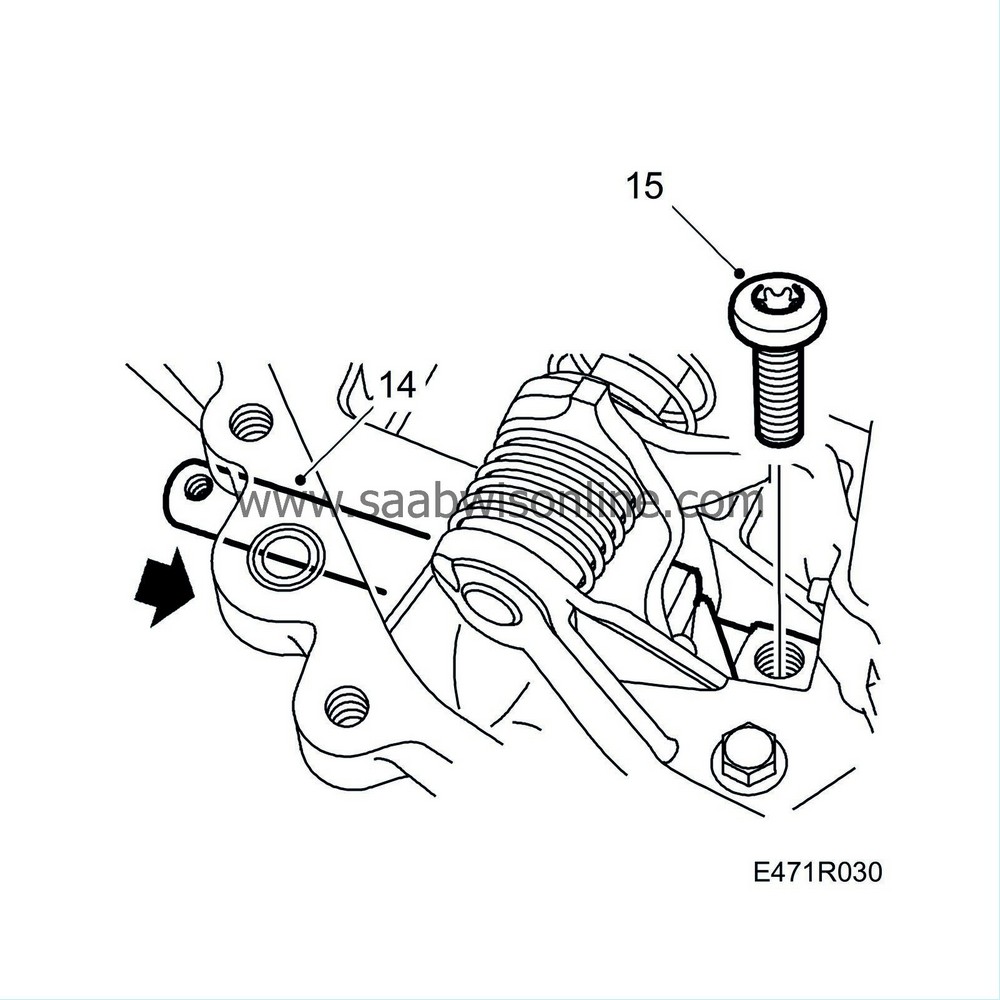

| 14. |

Position the gear selector rod, lightly smeared with transmission fluid in accordance with

List of lubricants and sealants

. Fit a new seal.

|

|

| 15. |

Thread in and mount the driver in position. Push in the gear selector rod and fit the screw.

Tightening torque 24 Nm (18 lbf ft) |

|

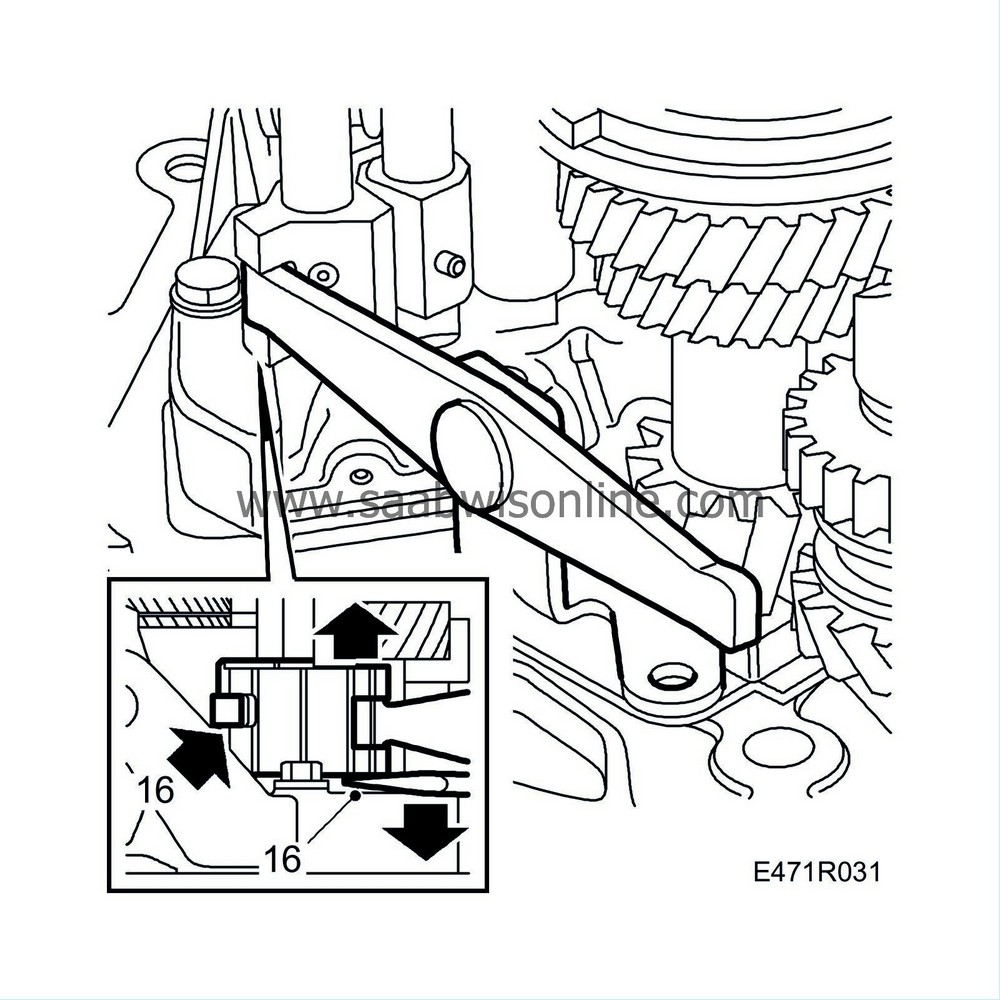

| 16. |

Check that all gears can be engaged. Also check the dual interlock feature by engaging 1st and then attempting to engage reverse by pushing in the reverse gear fork using a screwdriver. If reverse can be engaged, the locking pin in the selector mechanism must be checked.

|

|

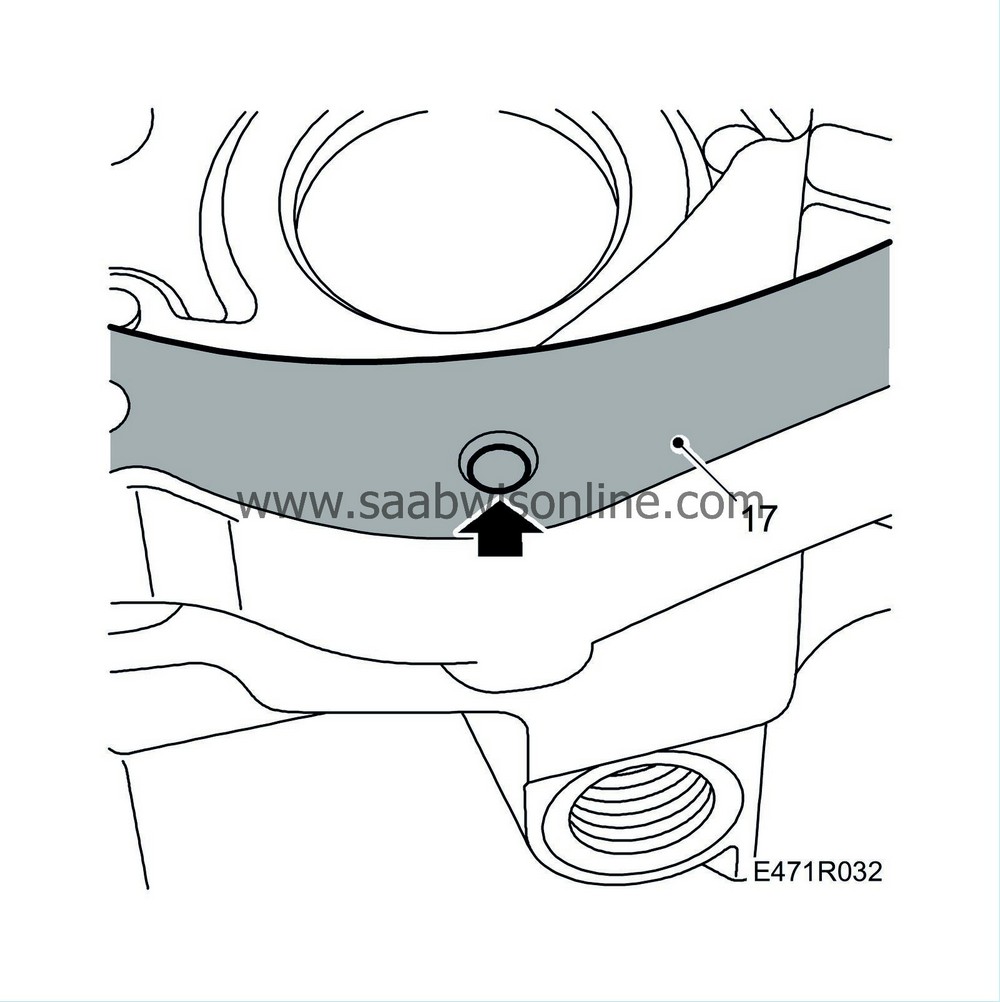

| 17. |

Clean the sealing surfaces thoroughly with

Cleaning agent, Loctite Super Clean 7063

. Apply

90 297 970 Flange sealant

sparingly to the contact surfaces on the gearcase and the clutch housing. Apply the Loctite and allow to dry for a couple of minutes.

|

||||||||||

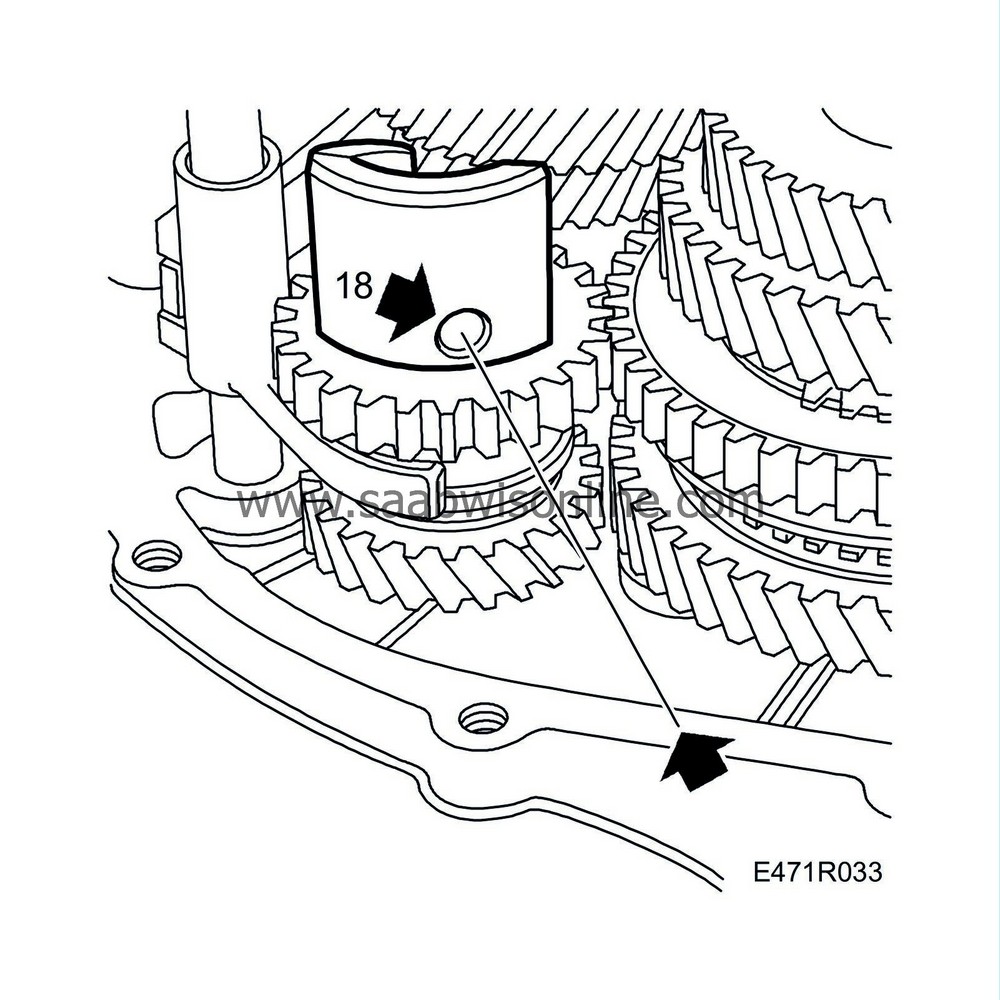

| 18. |

Check that the reverse shaft support is correctly positioned so that a new screw can be fitted after the gearcase fitted. Position the gearcase on the clutch housing.

|

||||||||||

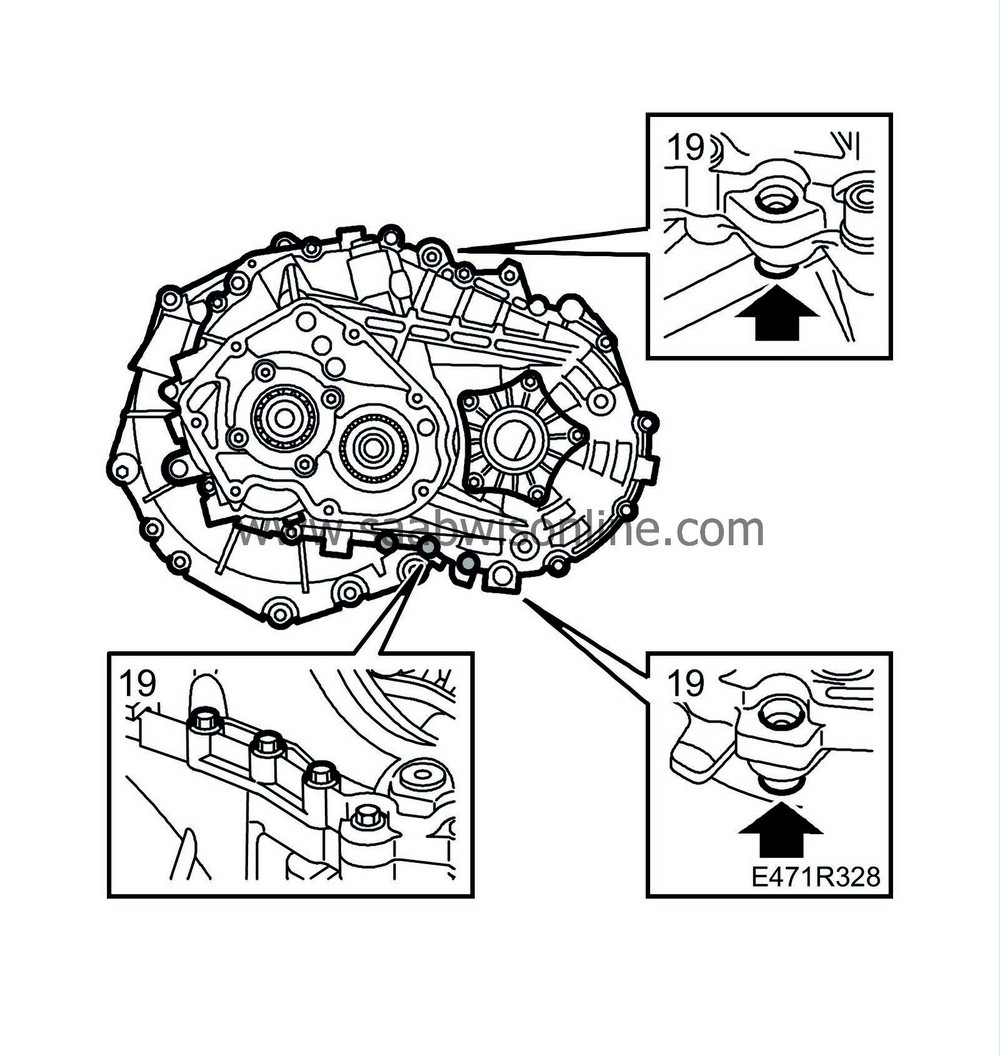

| 19. |

First lightly attach the clutch housing and gearcase using two bolts. Following which, tap up the locating sleeves. Loosely fit the bolt for the reverse shaft. If necessary, use a narrow screwdriver to guide the bolt hole up to the hole in the gearcase. Fit the remaining bolts. The three lower marked bolts should be replaced with quality 10.9.

Tightening torque 24 Nm (18 lbf ft) Tightening torque, lower marked bolts, quality 10.9, 31 Nm (23 lbf ft)

|

|

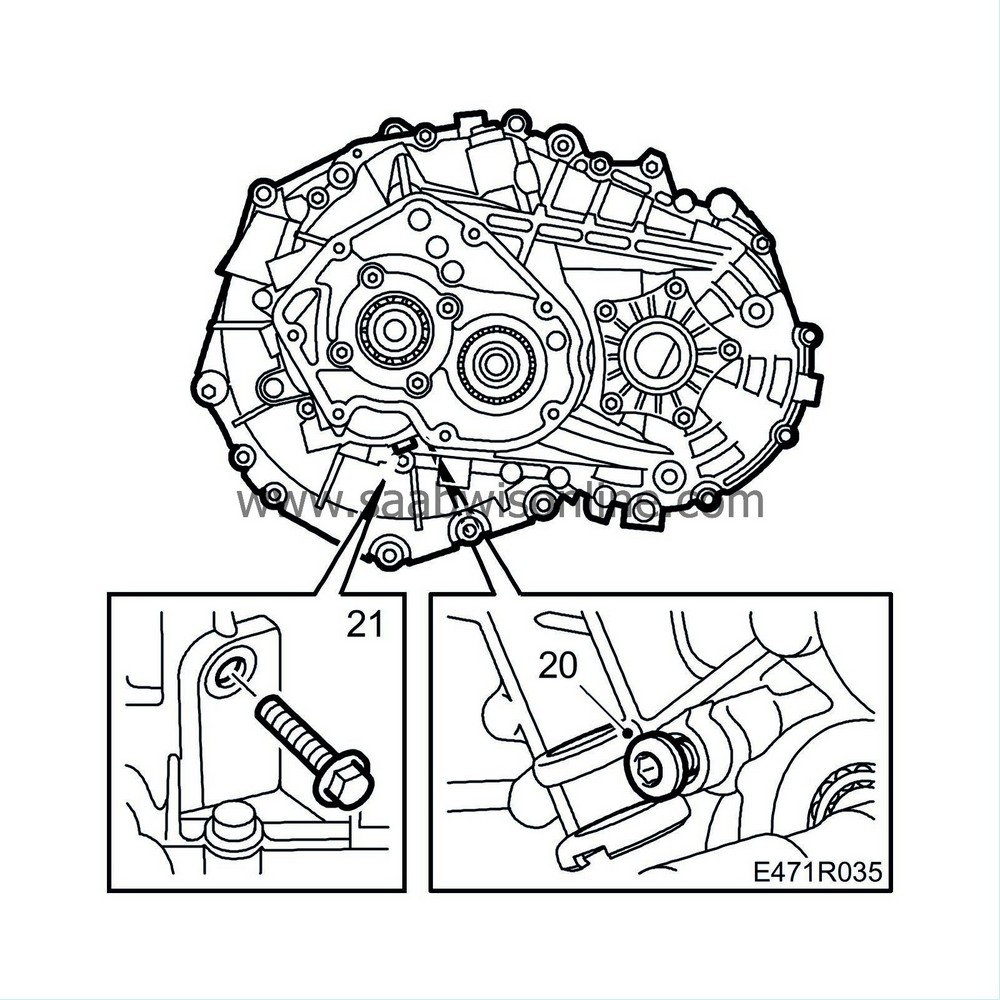

| 20. |

Tighten the screw for the reverse shaft. Note the O-ring!

Tightening torque 24 Nm (18 lbf ft) |

|

| 21. |

Tighten a new flange bolt (quality 10.9) to the reverse shaft support. If a 10.9 bolt was already used, this can be refitted. (The quality designation is stamped on the head.) The flange bolt specified above must not be fitted to gearboxes lacking a sufficiently large flange seat. The large flange has Ø = 21 mm, and the small Ø = 17 mm.

Tightening torque (quality 8.8), 20 Nm + 120° (15 lbf ft + 120°) Tightening torque (quality 10.9), 20 Nm + 45° (15 lbf ft + 45°) Tightening torque, bolt with small flange, 28 Nm (21 lbf ft) |

|

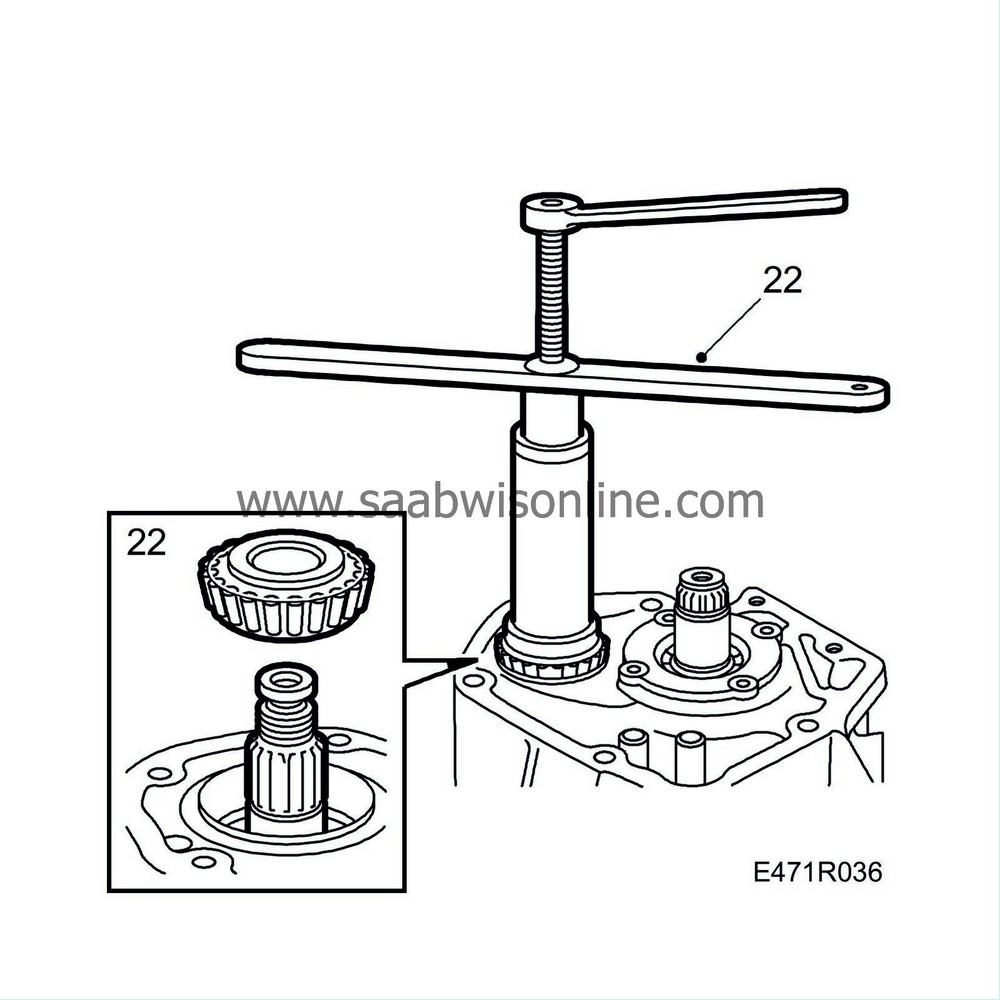

| 22. |

Fit the bearing to the output shaft, lubricate the bearing and tighten using

87 91 261 Puller, pinion

. Only pull to contact with the clamping sleeve.

|

|

| 23. |

Fit the 5th gear wheel to the output shaft. Tap down the 5th gear wheel slightly using a hammer and

78 41 067 Sleeve, inner driver bearing

. Fit

87 91 261 Puller, pinion

and use the puller to pull the wheel towards the bearing and fit a new nut.

|

||||||||||

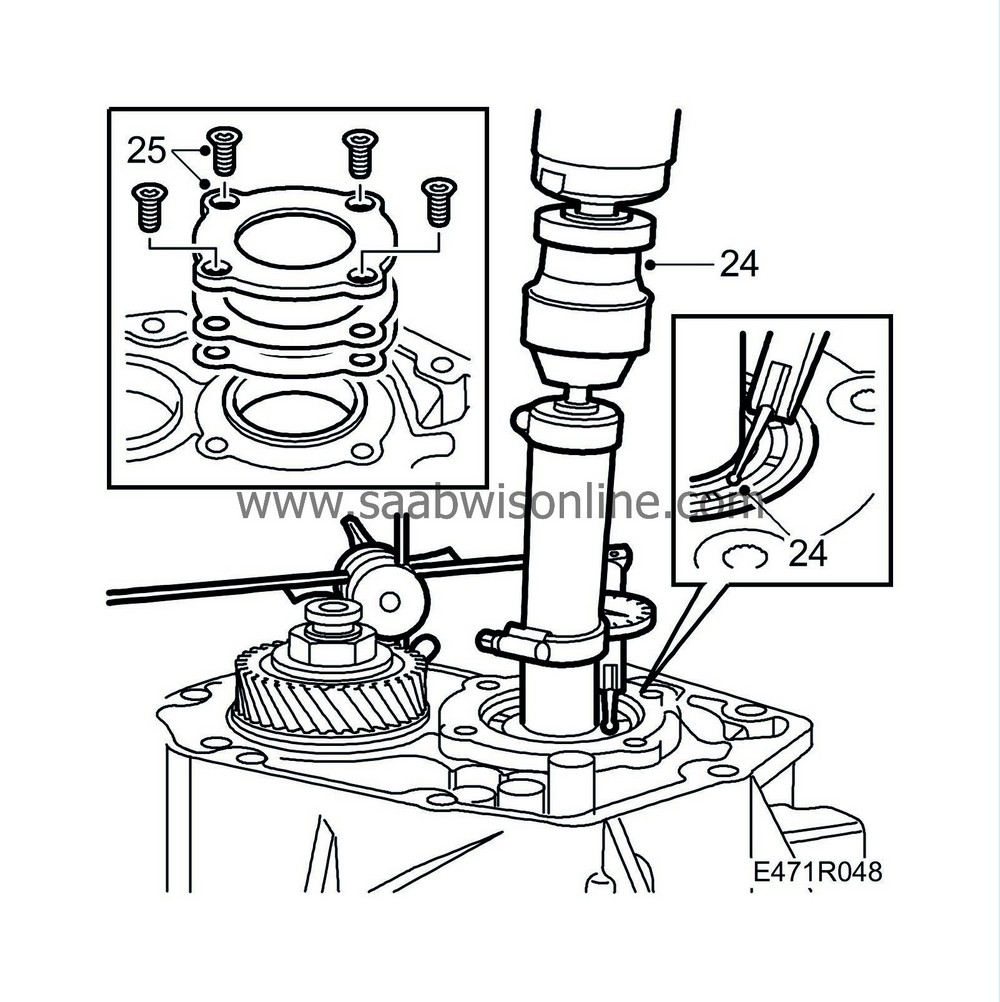

| 24. |

Fit

87 91 428 Driver

on the input shaft. Place the tip of the dial indicator on the input shaft bearing. Fit the drill onto the tool and "run" the gearbox so that the bearing "settles". Run and press simultaneously 20 rotations and then reset the dial indicator. Lift and run simultaneously an additional 20 rotations and read the value (or until the value has stabilised). Measure axial play. It should be 0.09-0.15 mm (Play is reduced to 0.04-0.11 mm when the output shaft bearing is adjusted to the correct preload). Adjust with shims under the bearing support as necessary. Shims are available in sizes 0.1, 0.15 and 0.30 mm.

|

|

| • |

Thicker shims=increase clearance

|

| • |

Thinner shims=decrease clearance

|

| • |

Shims are available in dimensions 0.10; 0.15; 0.30 mm.

|

||||||||||

| 25. |

When adjusting axial play on input shaft:

Undo and remove the 4 screws from the bearing support. Refit the bearing support together with the correct package of shims and tighten alternately. Tightening torque 38 Nm (28 lbf ft)Check play again. Remove the three tools. |

|

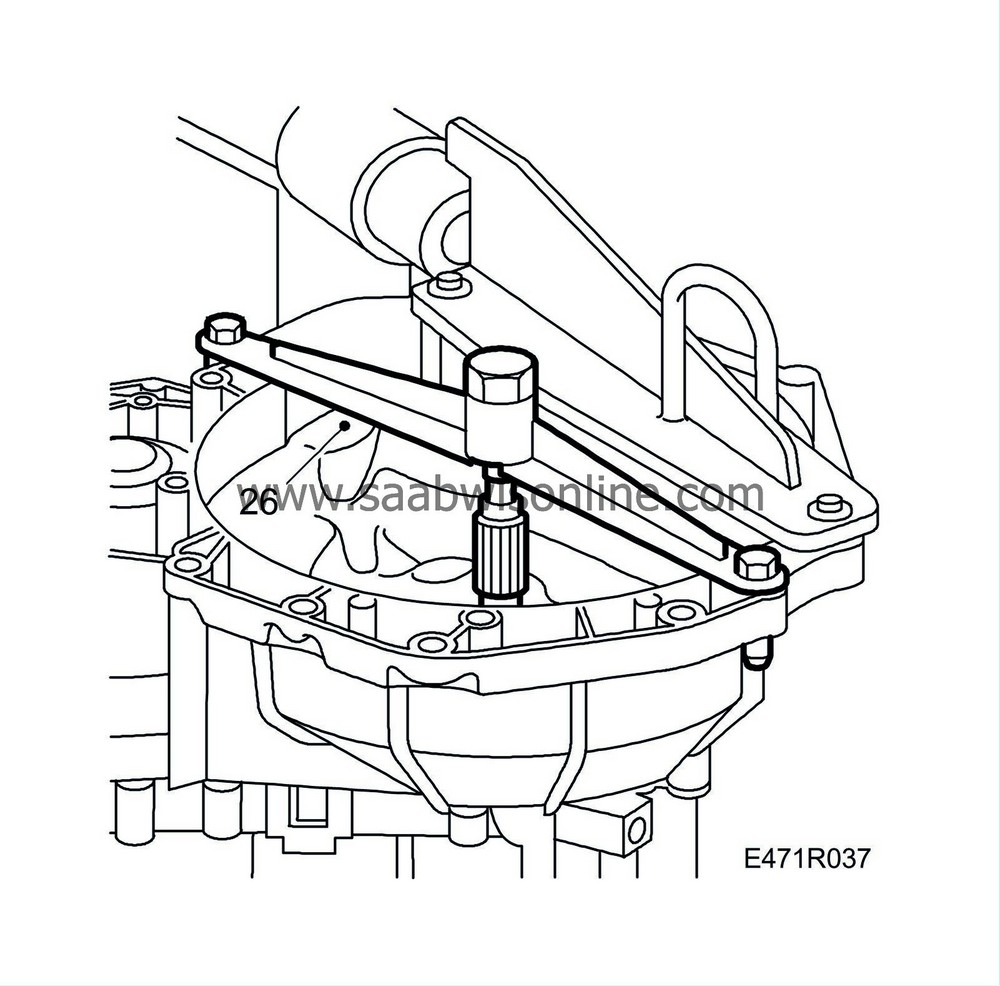

| 26. |

Fit

87 92 517 Holding tool, input shaft

to the input shaft as a counterstay when the 5th gear synchromesh hub is tapped down.

|

|

| 27. |

Fit the 5th pinion with needle bearing. Lubricate the bearing.

|

|

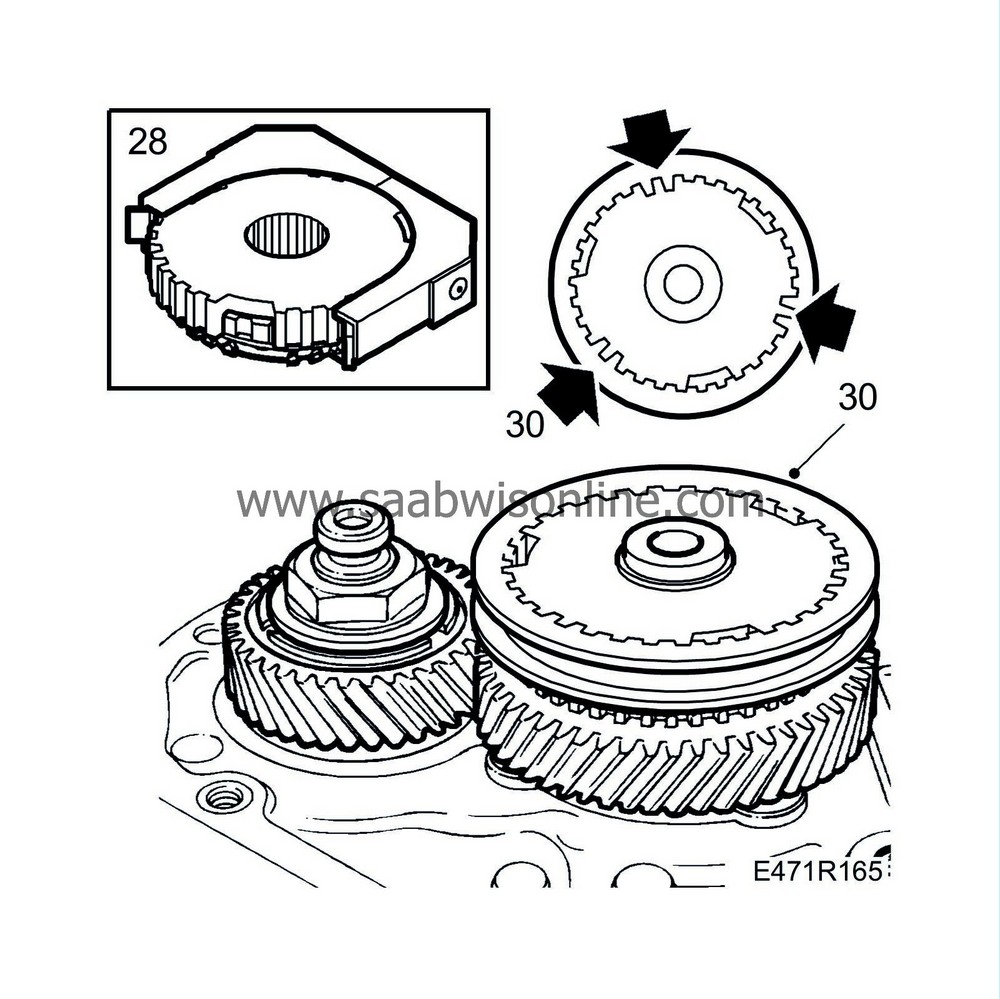

| 28. |

Assemble the wire ring, the 3 leaf springs, the synchronisation ring and the hub using

87 92 582 Fixture, 5

2. The hub is tapped down using

78 41 067 Sleeve, inner driver bearing

on the input shaft splines.

The synchromesh stop lugs must align directly with the deep teeth spaces on the synchromesh hub . |

|

| 29. |

Remove

87 92 582 Fixture, 5

.

|

|

| 30. |

Fit the 5th synchromesh sleeve with the tip angles down.

|

|

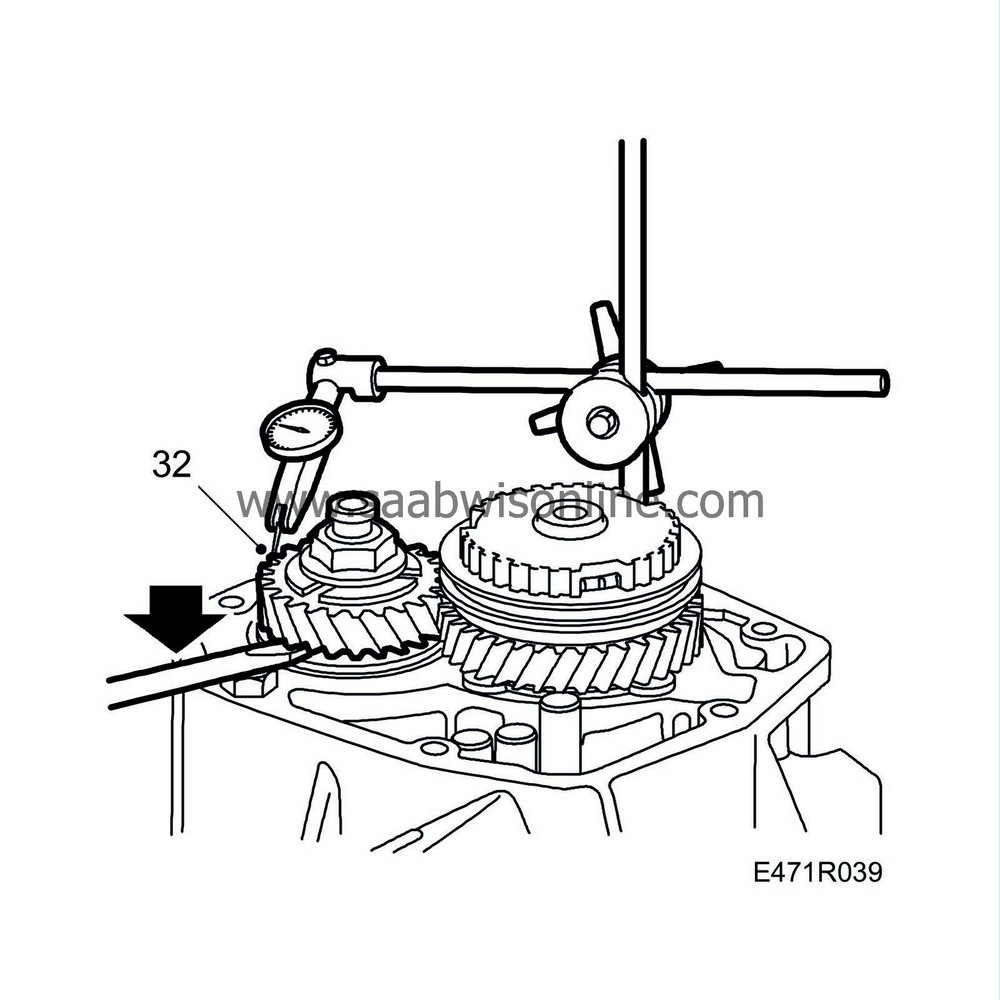

| 31. |

Fit

87 92 194 Dial gauge kit

towards the gear wheel using

87 90 727 Bracket, dial gauge

.

|

|

| 32. |

Engage 1st gear and press down the 5th gear synchromesh sleeve so that the gearbox is "locked". Tighten the nut and measure alternately with the dial indicator until the axial play of the output shaft is 0.06 ±0.05 mm. Use a short M8 screw in the sealing plane as break point. Disengage 1st and 5th gears.

|

||||||||||

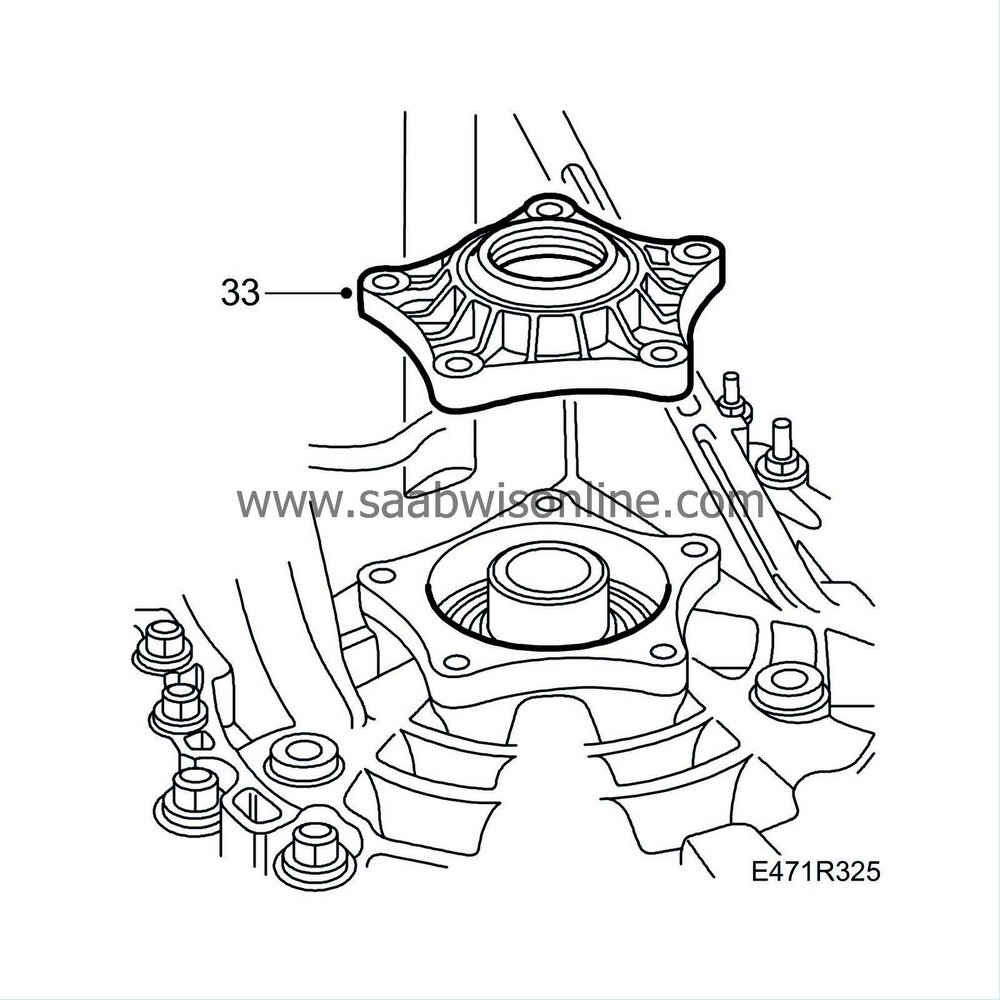

| 33. |

Check and adjust the preload of the differential as follows:

Thread in the bearing race, but not all the way. Fit the bearing support without O-ring, shaft seal and shims. Tighten 4 screws. Tightening torque 24 Nm (18 lbf ft) |

|

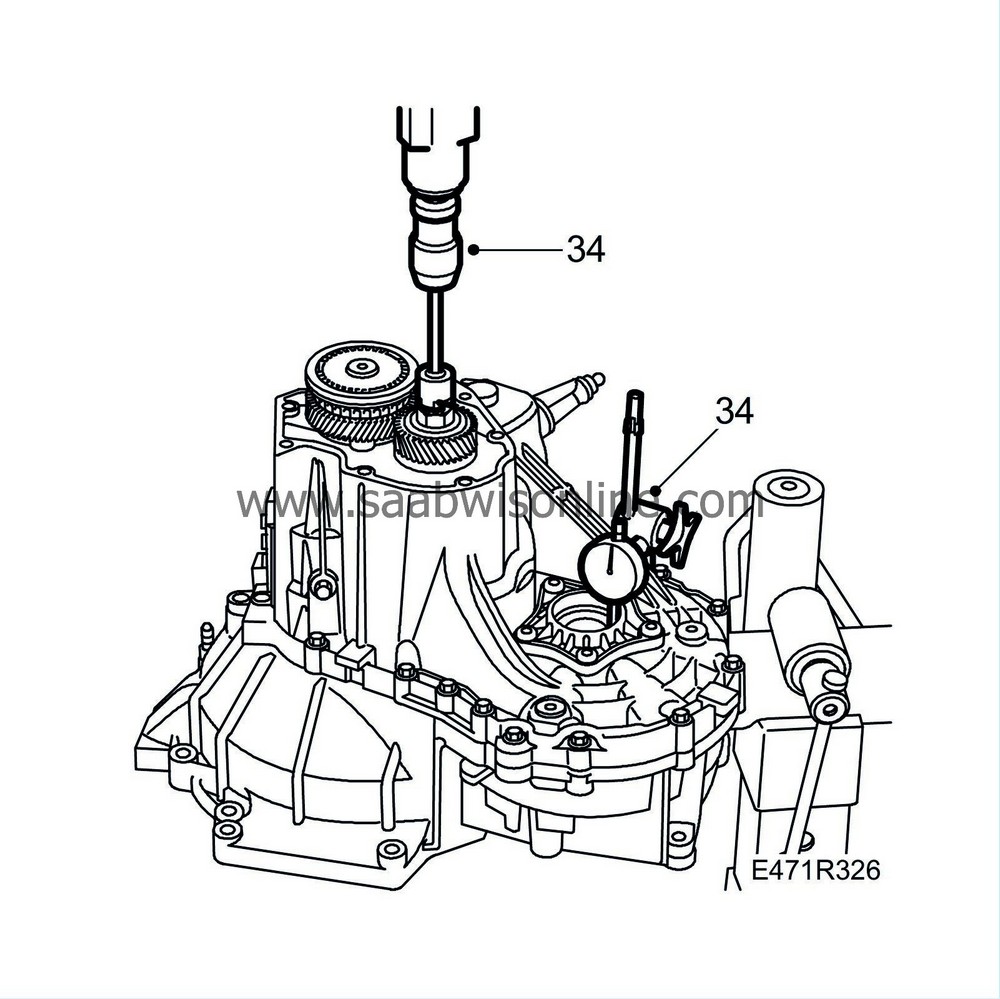

| 34. |

Fit

87 90 727 Bracket, dial gauge

using

87 92 194 Dial gauge kit

in the available hole. Set the tip at the differential housing. Run the output shaft using a drill and

87 92 053 Driver

until the value on the dial gauge has stabilised. Reset the dial gauge.

|

|||||||||

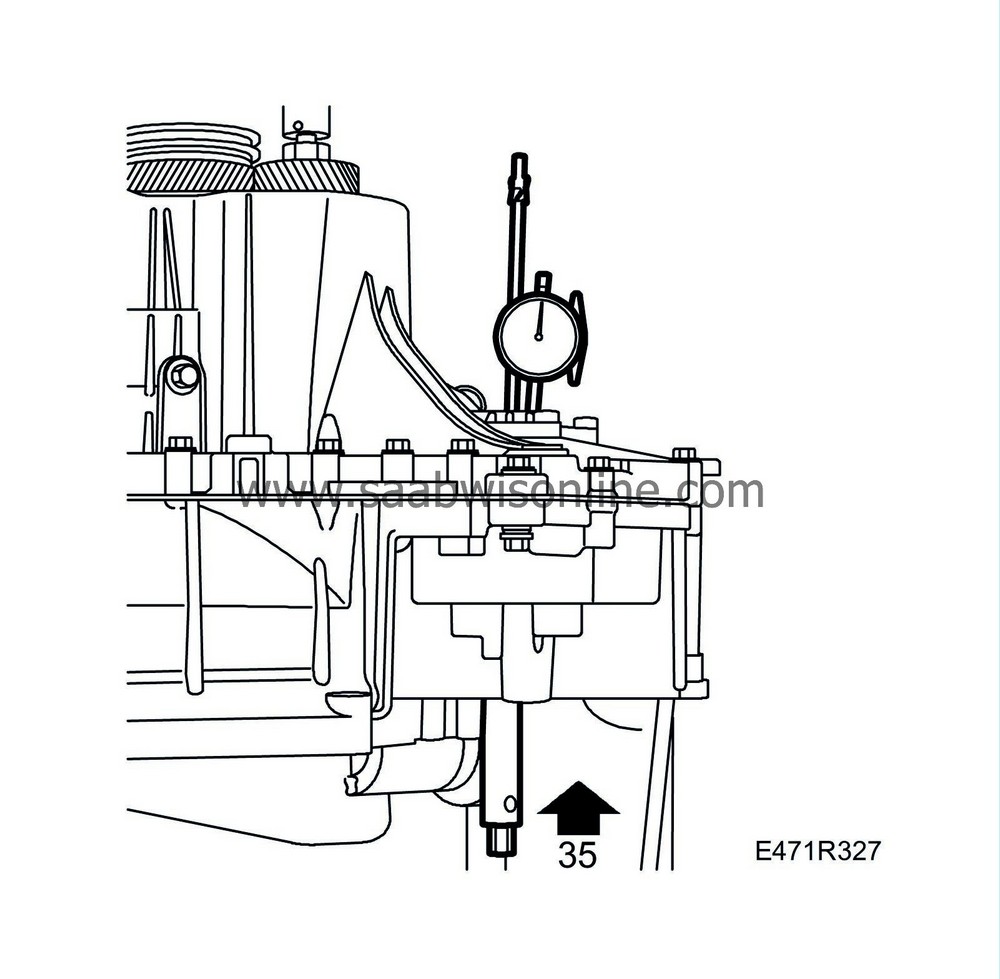

| 35. |

Lift the differential using

87 91 337 Driver, measuring differential bearing torque

and read the value on the dial gauge. The correct shim thickness is: measured value plus the value from the table.

|

|||||||||

| • |

Thicker shims=increase preload

|

| • |

Thinner shims=reduce preload

|

| • |

Shims for the differential are available in sizes 0.10, 0.15, 0.30, 0.50 mm

|

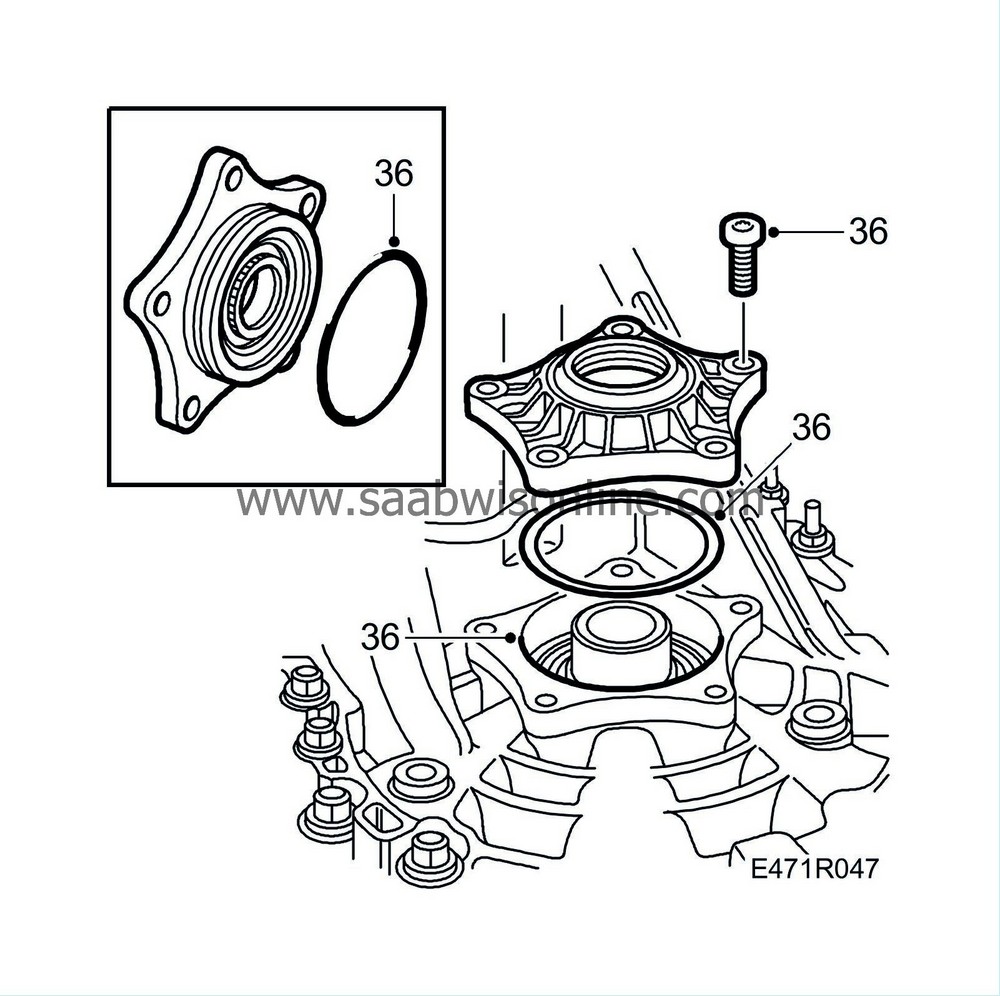

| 36. |

Remove the dial gauge, stand and bearing support. Fit and grease the O-ring on the bearing support. Fit the bearing support with the measured shims. Pull down the bearing support until it reaches "measured nominal value +0.15 mm".

|

||||||||||

| 37. |

Turn the gearbox so that it is in the same position as it would be in the car, i.e. horizontal.

|

|

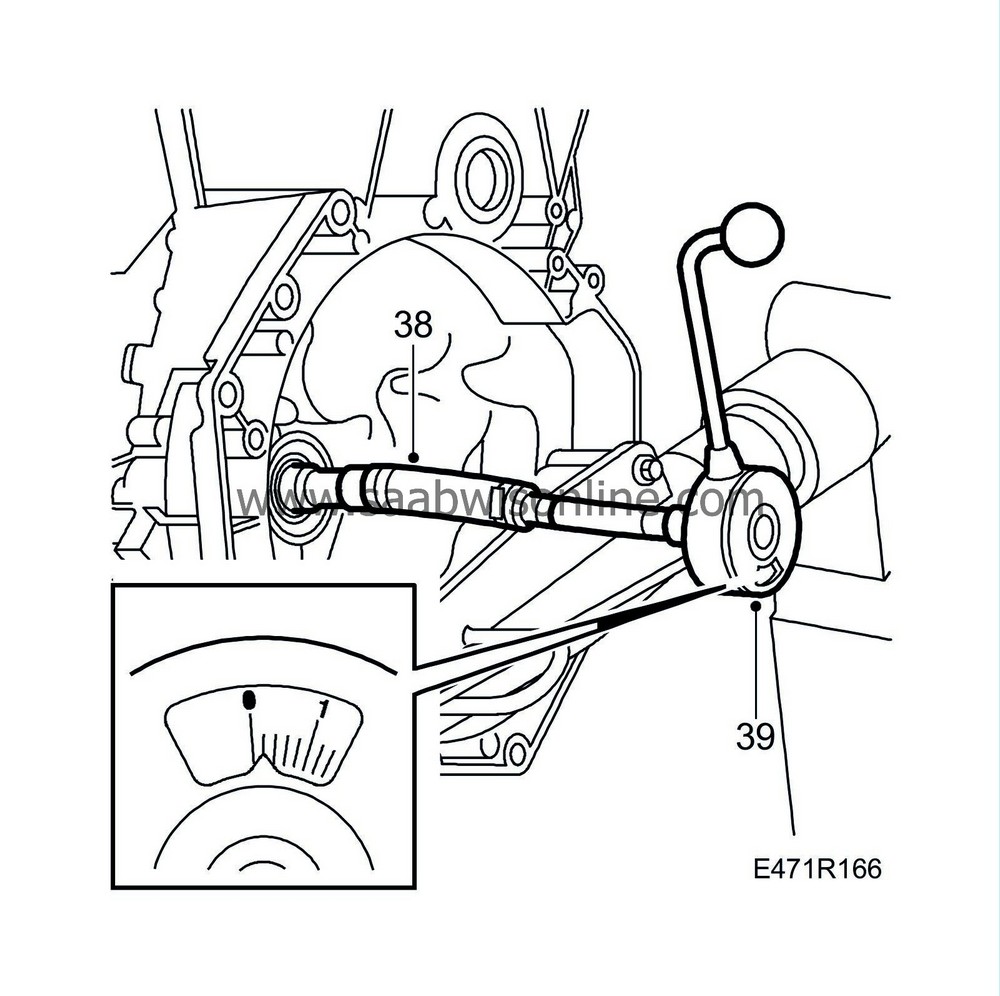

| 38. |

Fit the M8 fuel hose (approx. 100 mm long) between

87 91 428 Driver

and hexagon socket (M8 with 1/2" drive). Check that no gear is engaged.

|

||||||||||

| 39. |

Connect the torque wrench (graduated in Nm) and rotate the wrench clockwise several revolutions at even speed. Read off the average value while rotating, normally 0.10-0.30 Nm.

If the value is greater than 0.30 Nm or if it varies greatly while rotating, either the baulk rings or dirt and cuttings in the bearing are slowing it down. Dismantle the gearbox and investigate the cause. Rotating the shaft backwards and forwards under axial load may help. The bearings must be oiled in later, however. |

|

| 40. |

Turn the gearbox back around.

|

|

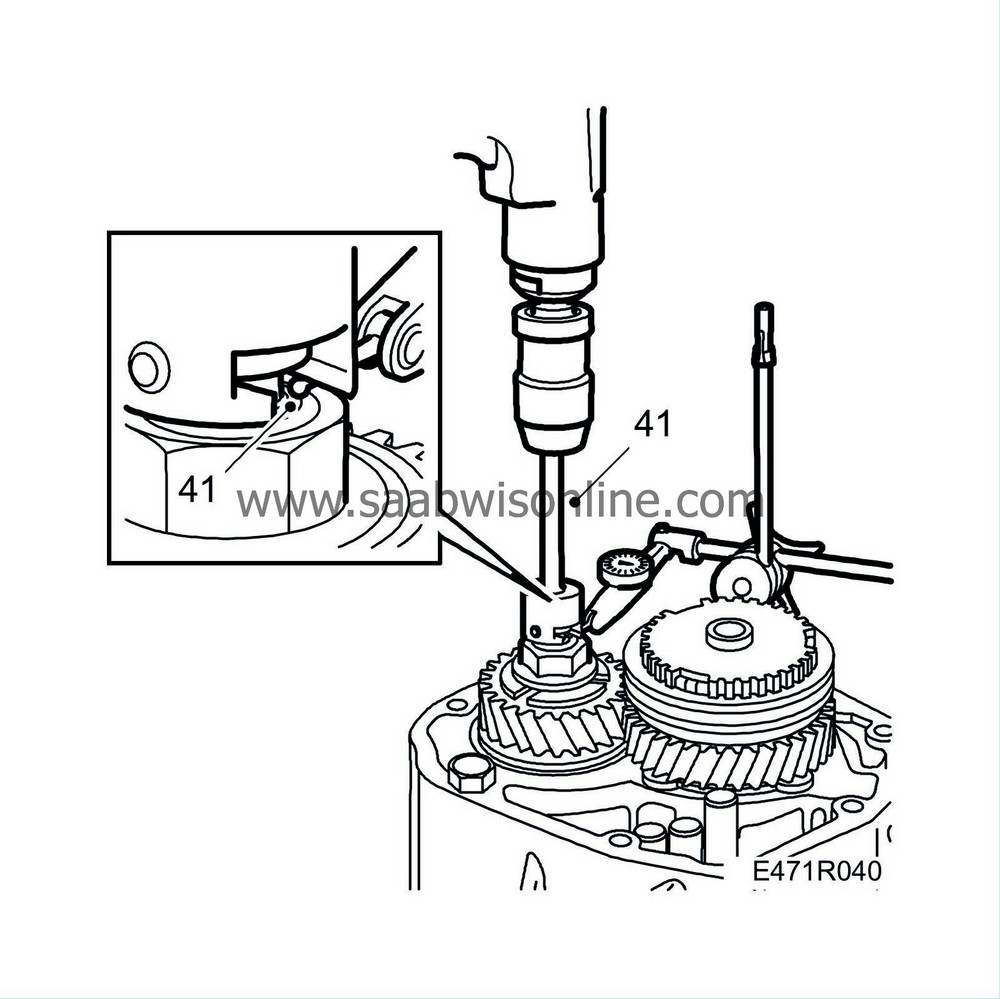

| 41. |

Position the dial indicator tip on the shaft as illustrated. Fit

87 92 053 Driver

on the output shaft and "run" the gearbox with a drill so that the bearing "settles". Run and press simultaneously 20 rotations and then reset the dial indicator. Lift and run simultaneously an additional 20 rotations and read the value (or until the value has stabilised). Remove the tool.

Note the measured value for axial play and then add it to the nominal value

. Remove the dial indicator.

|

|||||||||

| 42. |

Engage 5th gear by pushing down the synchromesh sleeve. Engage 1st gear.

|

|

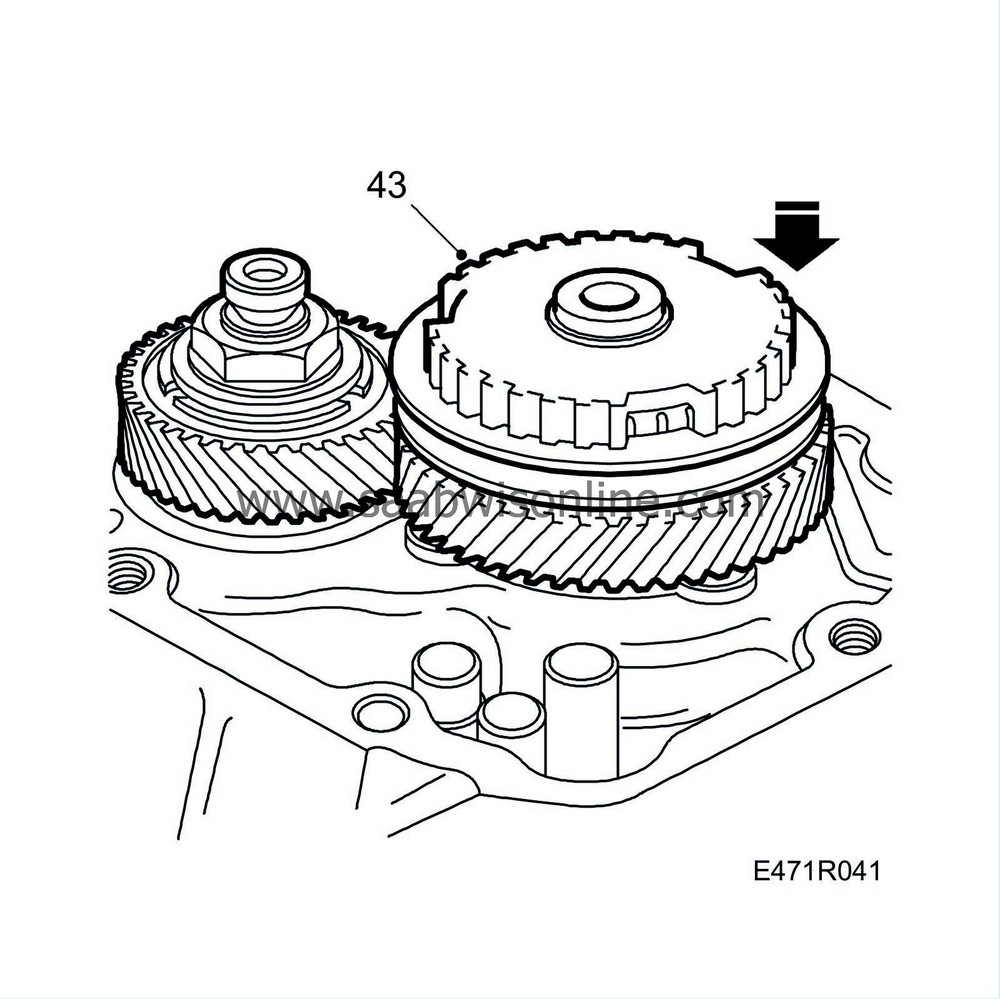

| 43. |

Remove

87 92 053 Driver

from the output shaft.

|

|

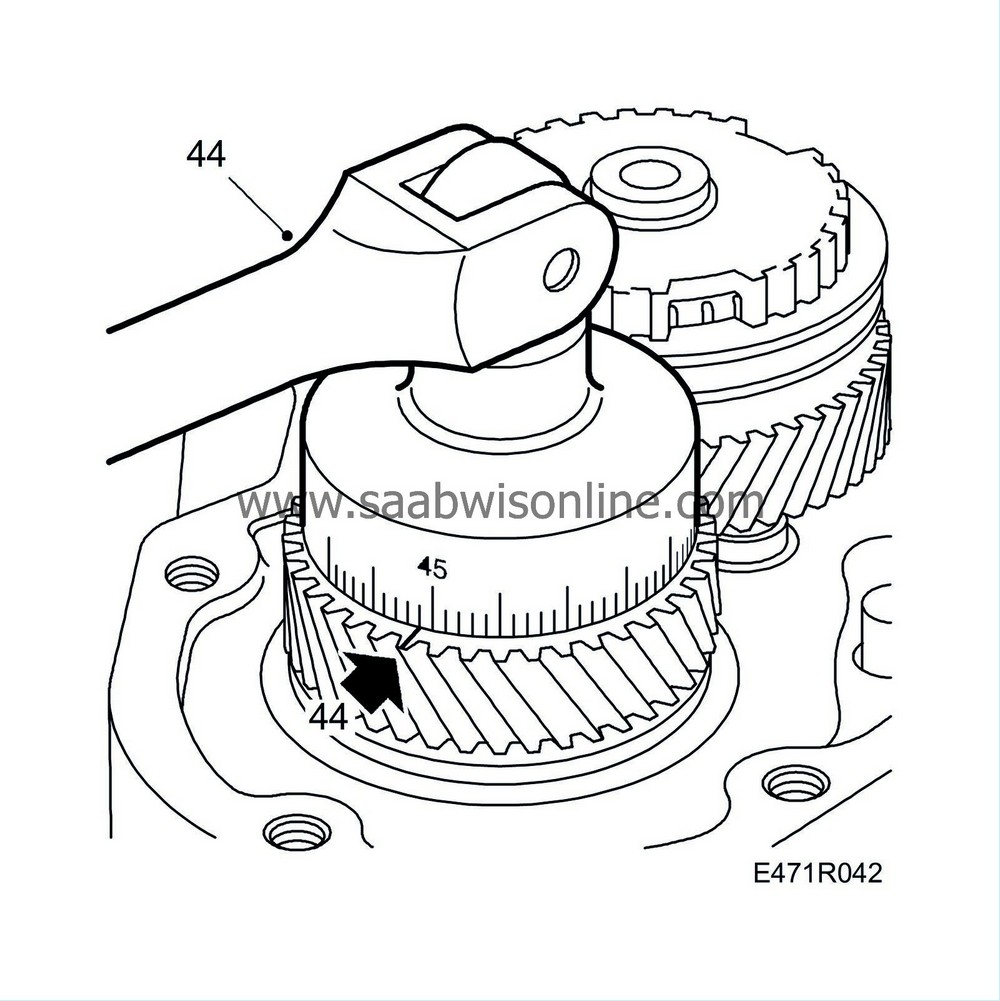

| 44. |

Fit

87 92 061 Millimetre wheel, 27 mm

on the output shaft nut. Set the tool (mm disc) graduation to the calculated value (measured + nominal, see example). Use a felt tipped pen or the like to mark a tooth on the gear wheel. Each dash corresponds to 0.01 mm.

Example: Measured value 0.43 + 0.03 (nominal value, over 5000 km) = 0.46 mm Check the rolling torque on new bearings only |

|||||||

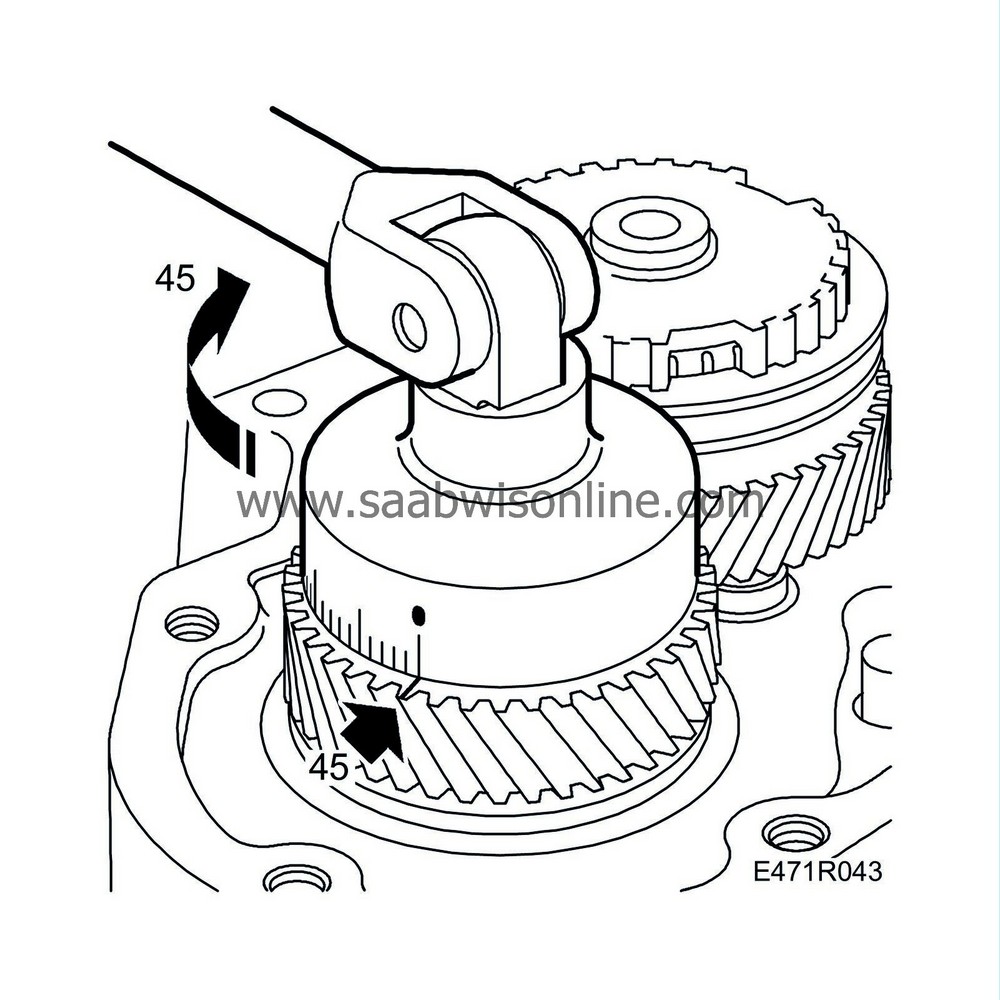

| 45. |

Pull in 2-3 stages until the zero graduation (0) of the tool (mm disc) is at the marked tooth. Measure axial play again as indicated in pt 41-45 to make sure the amount of preload is correct. Remove the tool and sleeve.

If an old bearing is fitted on the output shaft, lock the nut and continue to pt 52. If a new bearing is fitted, do not lock the nut and continue with the next point.

|

|

| 46. |

Before taking a more precise measurement of the output shaft bearing preload, the following must be complied with:

Input shaft bearing (axial play 0.09 - 0.15 mm) Differential, bearing support fitted but not tightened (axial play 0.10 - 0.20 mm) All bearings oiled |

|

| 47. |

Turn the gearbox so that it is in the same position as it would be in the car, i.e. horizontal. Disengage 1st gear and lift off the 5th synchromesh sleeve.

|

|

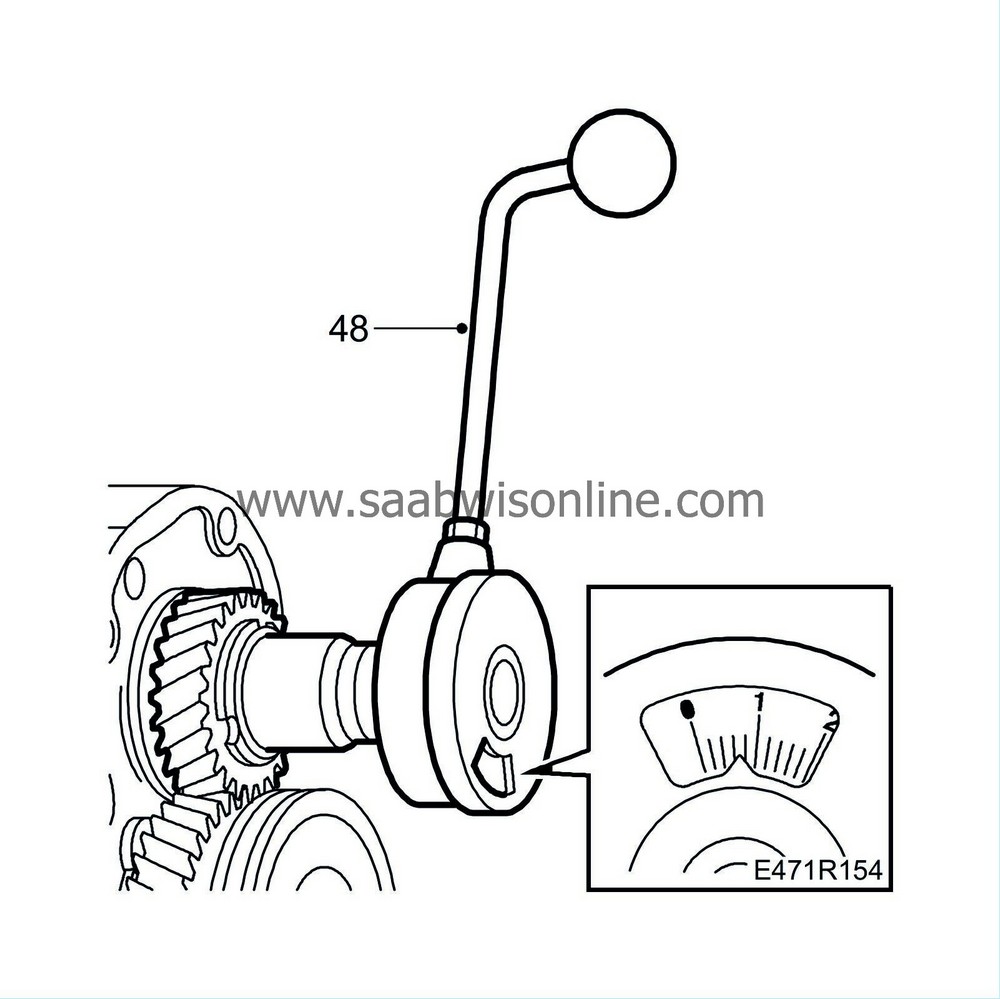

| 48. |

Place the torque wrench at the 5th gear nut output shaft. No gear must be engaged. Rotate the torque wrench several turns clockwise at an even speed. Read the average value from the display during rotation.

|

|

| 49. |

The read value should be 0.5 - 1.0 Nm.

Tighten the nut on the output shaft (5th and 1st engaged) two dashes on the millimetre marking at a time, on 87 92 061Millimetre wheel, 27 mm 1 until the correct rolling torque (0.5 - 1.0 Nm) is obtained. Average torque varies greatly : Cause: Retarding baulk rings, swarf or dirt in the bearings. Action: Dismantle the gearbox. Average torque higher than 1.0 Nm: Cause: Same as above or bearings too tight Action: Dismantle the gearbox and change clamping sleeve. The bearings should then be preloaded and checked. |

|

| 50. |

Lock the nut

|

|

| 51. |

Turn the gearbox back around.

|

|

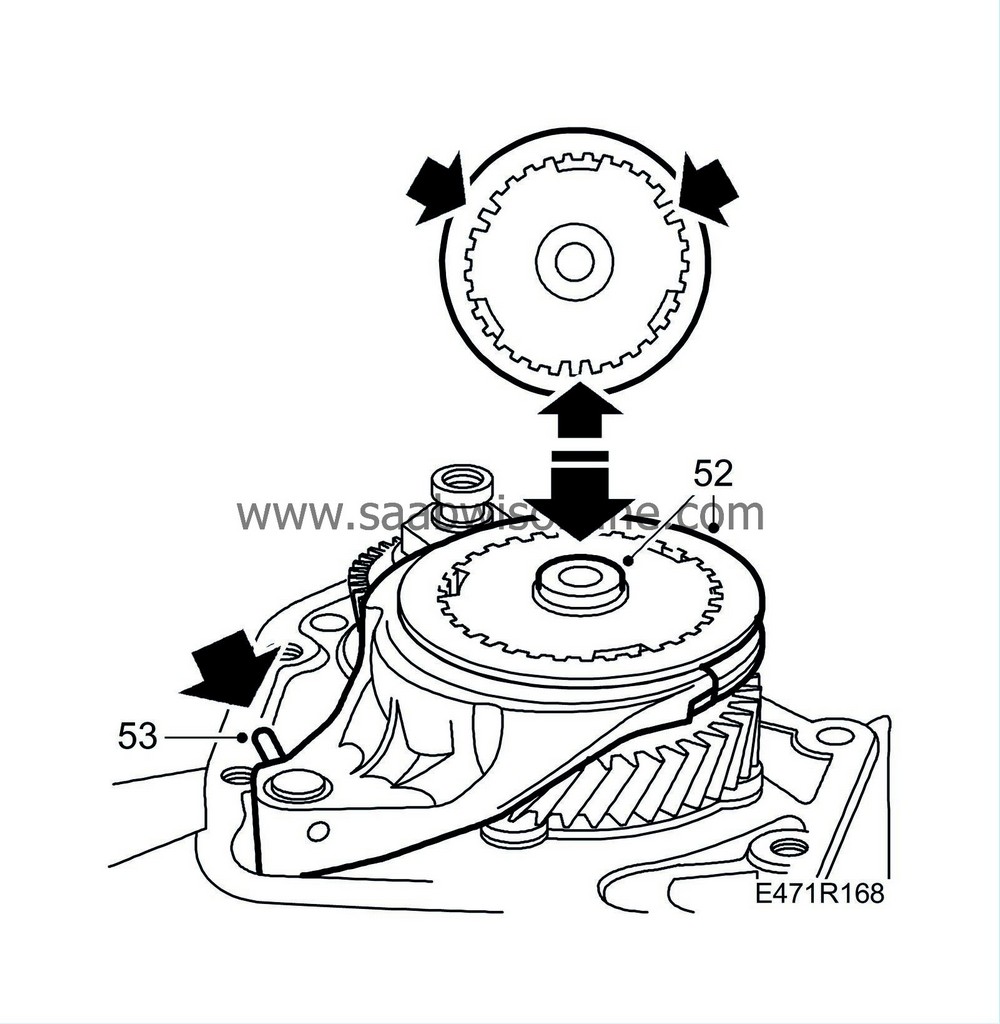

| 52. |

Lift off the 5th synchromesh sleeve and fit the 5th fork to the 5th synchromesh sleeve. Fit the fork and sleeve to the shaft.

|

||||||||||

| 53. |

Tap the retention pin into the selector shaft.

|

|

| 54. |

Fit a new circlip.

|

|

| 55. |

Tighten the screws for the differential bearing support.

Tightening torque 24 Nm (18 lbf ft) |

|

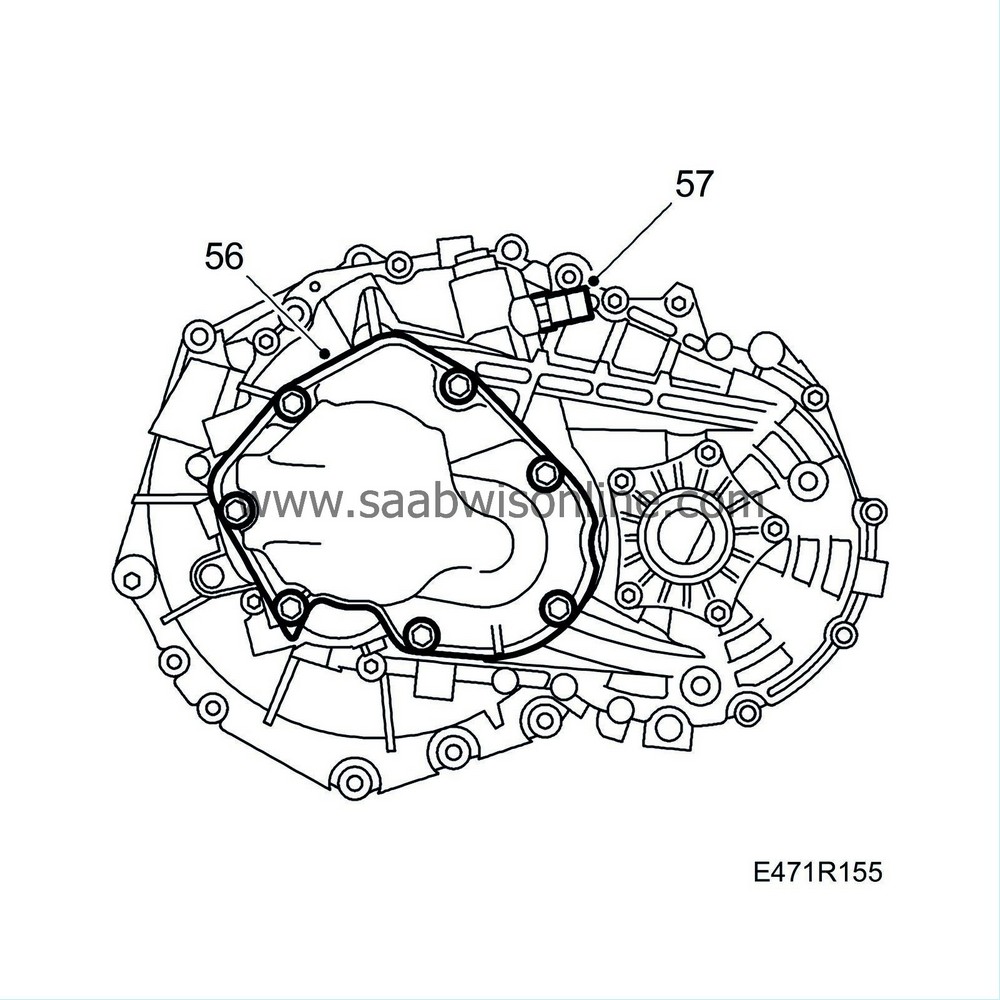

| 56. |

Remove the cover from the hole in the gearcase and fit a new gasket and the end plate.

Tightening torque 24 Nm (18 lbf ft) |

|

| 57. |

Refit the reversing light switch using a new gasket if it was removed.

Tightening torque 24 Nm (18 lbf ft) |

|

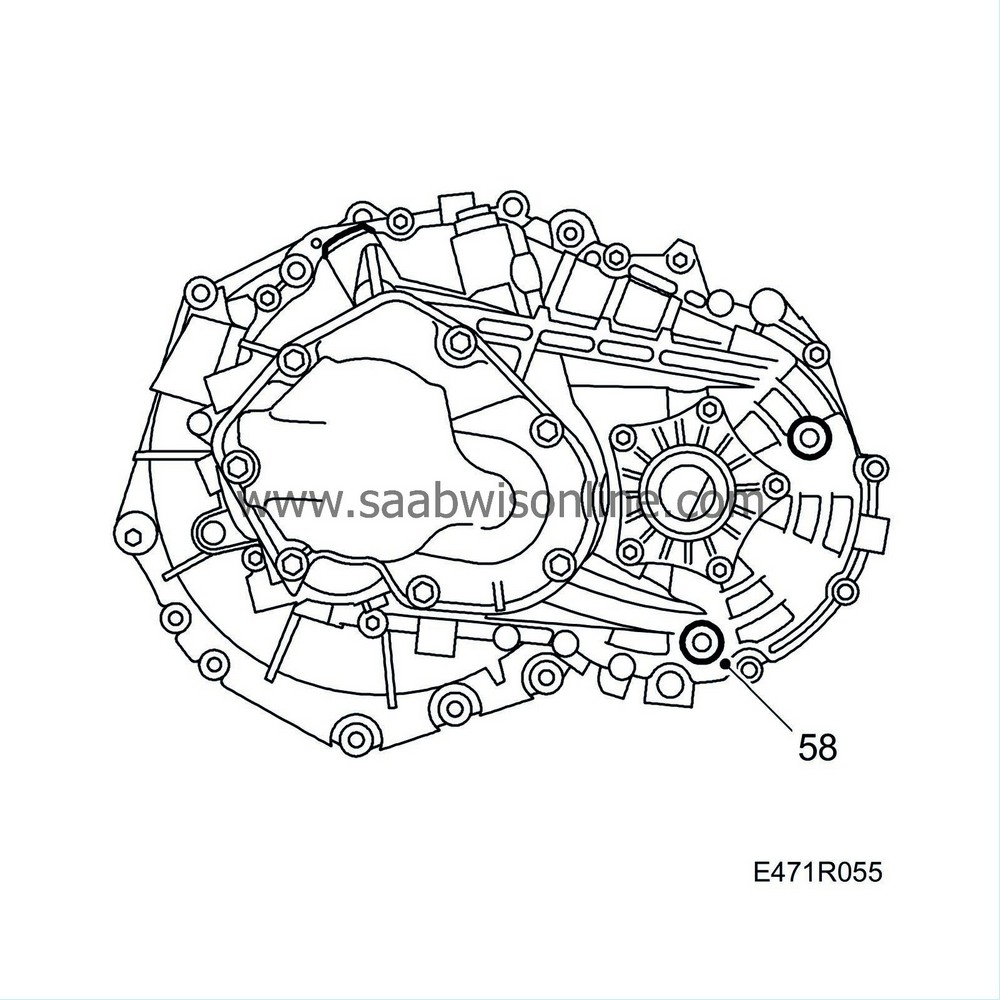

| 58. |

Check that the magnet is in position in the oil drain plug. Fit the plug.

Tightening torque 50 Nm (37 lbf ft) |

|

| 59. |

Lubricate the seal rings for input shaft and drive shafts.

|

|

| 60. |

Fluid is not added until the drive shafts are fitted on the gearbox and the gearbox is fitted in the vehicle. Quantity: 1.9 litre; see Technical data

List of lubricants and sealants

.

|

|

| 61. |

Fit the slave cylinder, using

74 96 284 Thread locking adhesive

on the screws.

Tightening torque 10 Nm (7 lbf ft) |

|

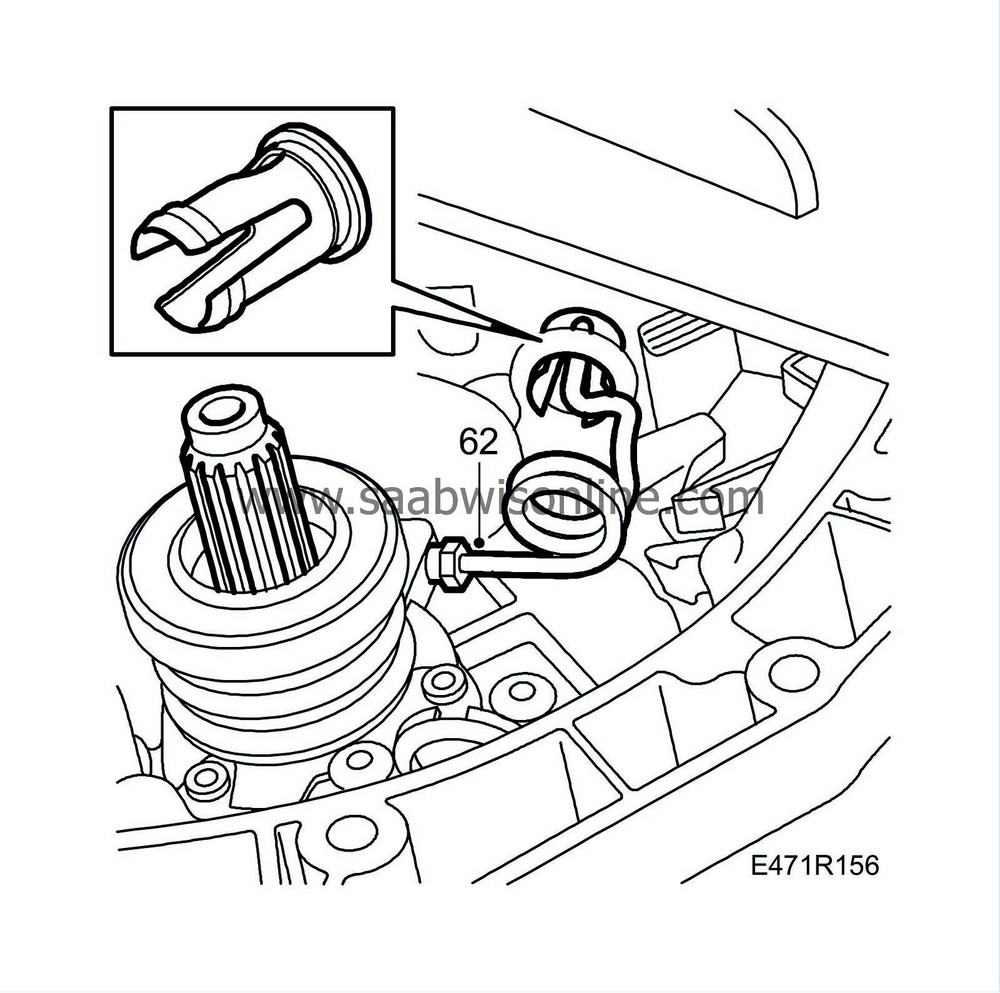

| 62. |

Fit delivery pipe in place and fit the bush.

|

|

| 63. |

Bleed the slave cylinder before the gearbox is fitted.

Bleeding the slave cylinder

.

|

|

Warning

Warning