PRE-RELEASE

Detailed description

| Detailed description |

Turbo control general

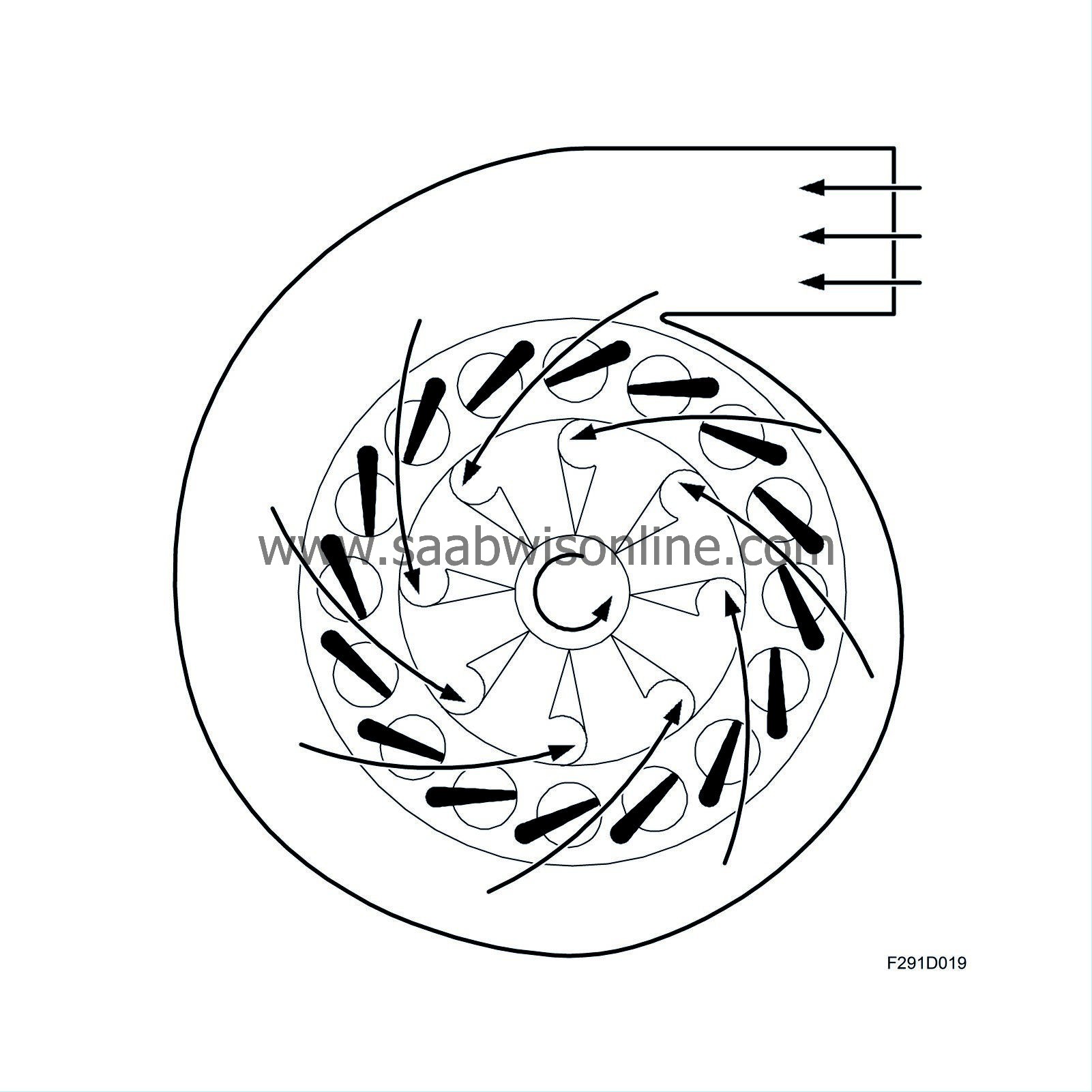

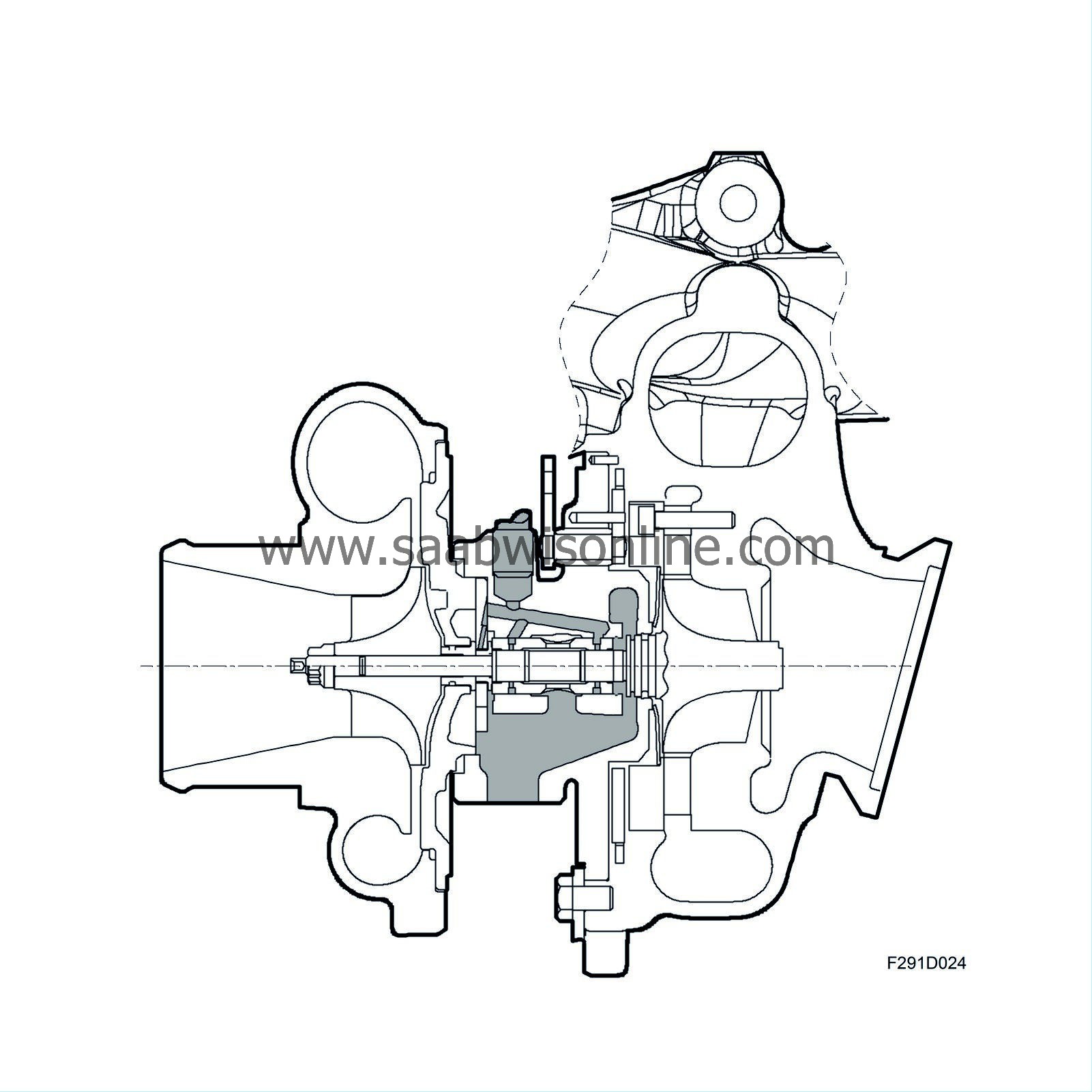

The engine is equipped with a VNT (Variable Nozzle Turbine) turbocharger, meaning that the turbine is regulated by controlling the position of a number of vanes positioned in the exhaust flow just prior to the turbine wheel. Thus, turbine speed can be regulated so that the turbocharger generates the desired amount of air mass for the engine to produce the desired torque with low emissions.When the amount of exhaust gas is little (light engine load/low engine speed) the vane opening is relatively little, which makes exhaust flow rate to the turbine wheel high so that turbine wheel speed remains relatively high. The turbocharger adds a relatively large addition, which means that a larger quantity of fuel is injected, producing high engine torque.

The vane opening must be regulated to fit the existing operating conditions. As a rule, when exhaust gas quantity increases (high engine speed/high engine load), the vanes open. Otherwise, turbine speed would increase too much, resulting in damage to the turbocharger and/or engine as well as high boost pressure and high turbine pressure. The turbocharger's work must therefore be regulated to fit the needs of the engine at any given operating situation. The opening of the vanes is affected by a vacuum unit that is regulated by ECM via a solenoid valve.

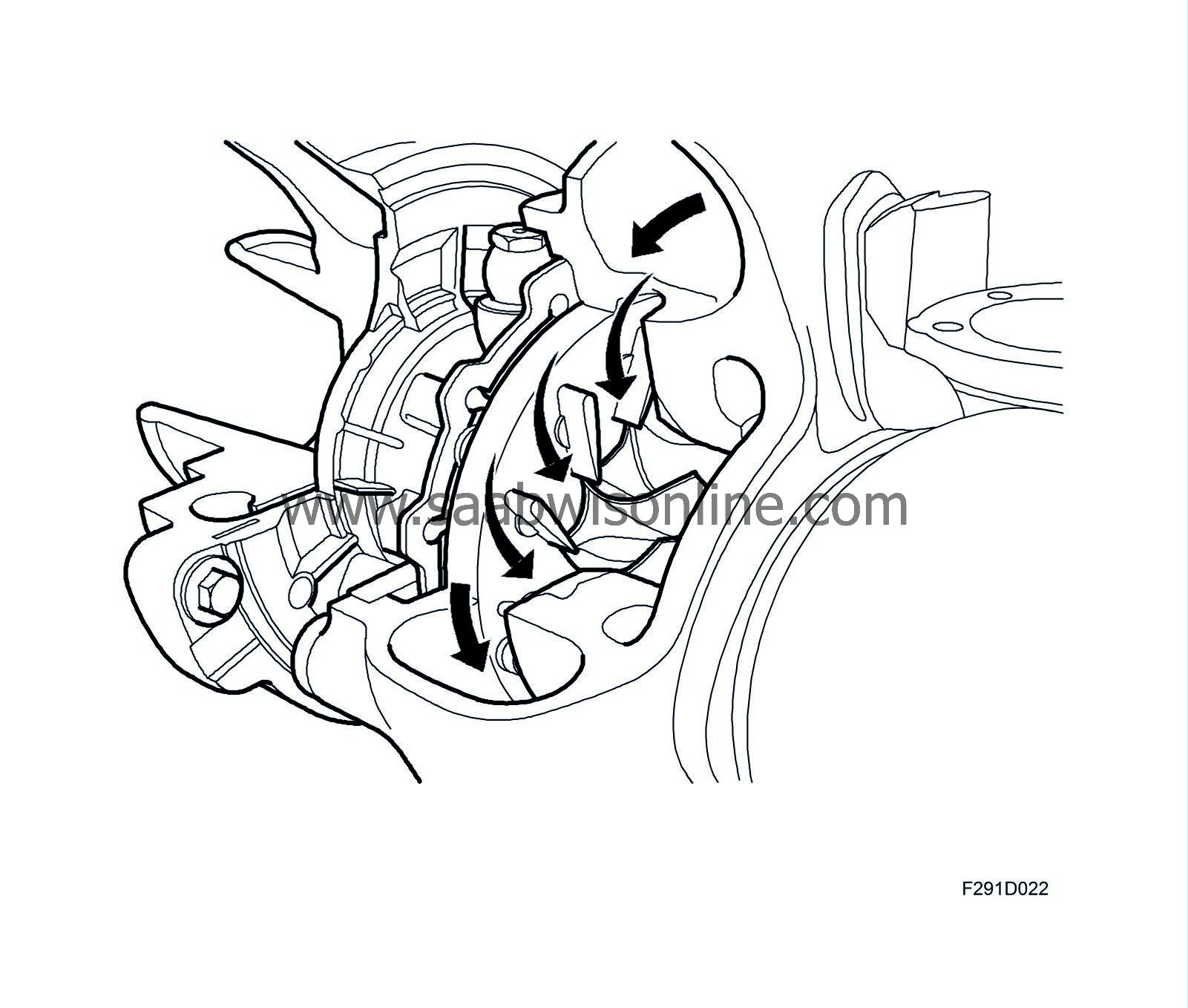

Vanes, closed position

When the amount of exhaust gas is little (light engine load/low engine speed) the vane opening is relatively little. The speed and angle of the exhaust gases when they reach the turbine wheel becomes such that turbine speed is high in relation to the amount of exhaust gases passing the turbine.

Vanes, open position

When the amount of exhaust gas is high (high engine speed/high engine load), the vane opening is large. The speed and angle of the exhaust gases when they reach the turbine wheel becomes such that turbine speed is low in relation to the amount of exhaust gases passing the turbine.

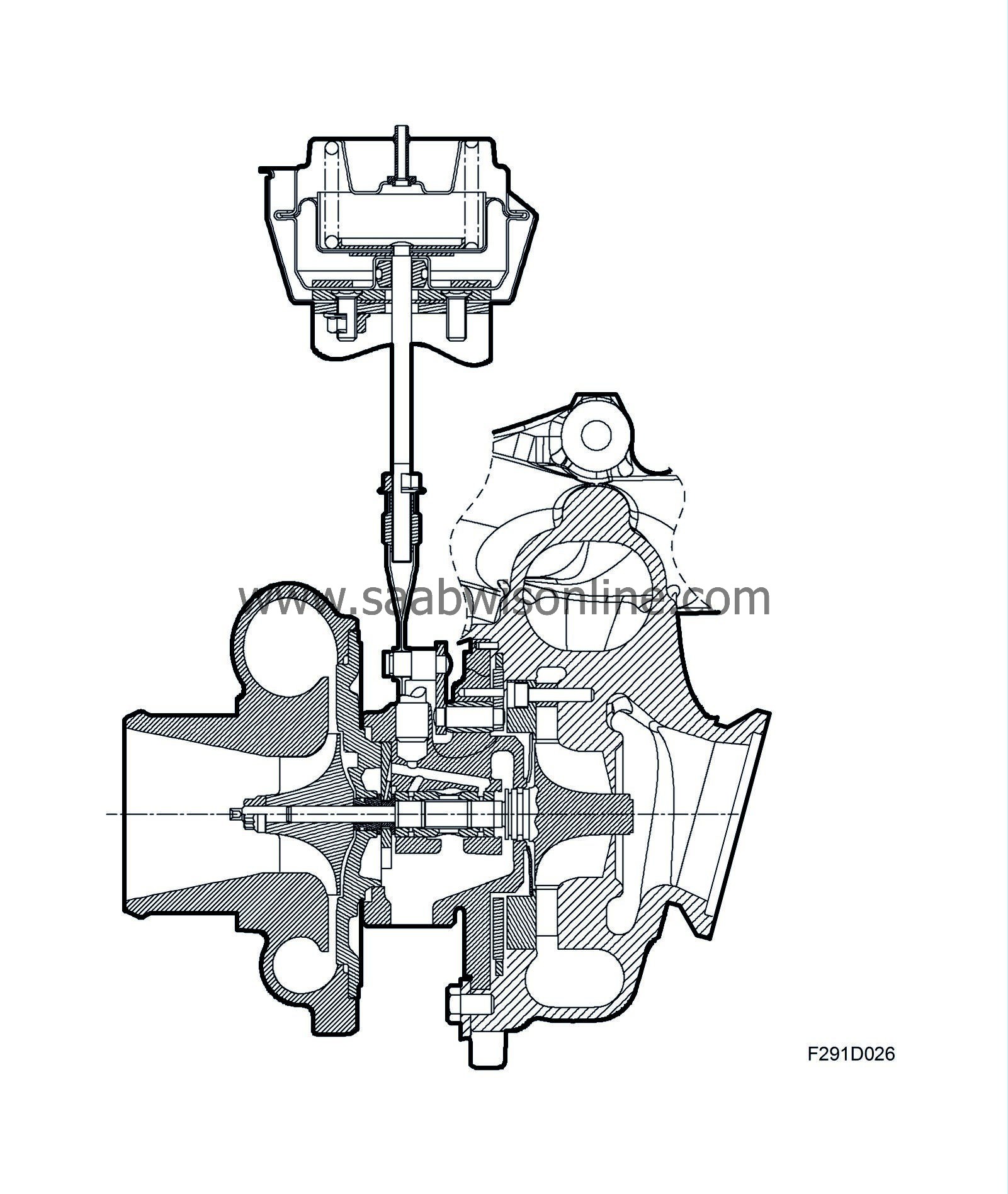

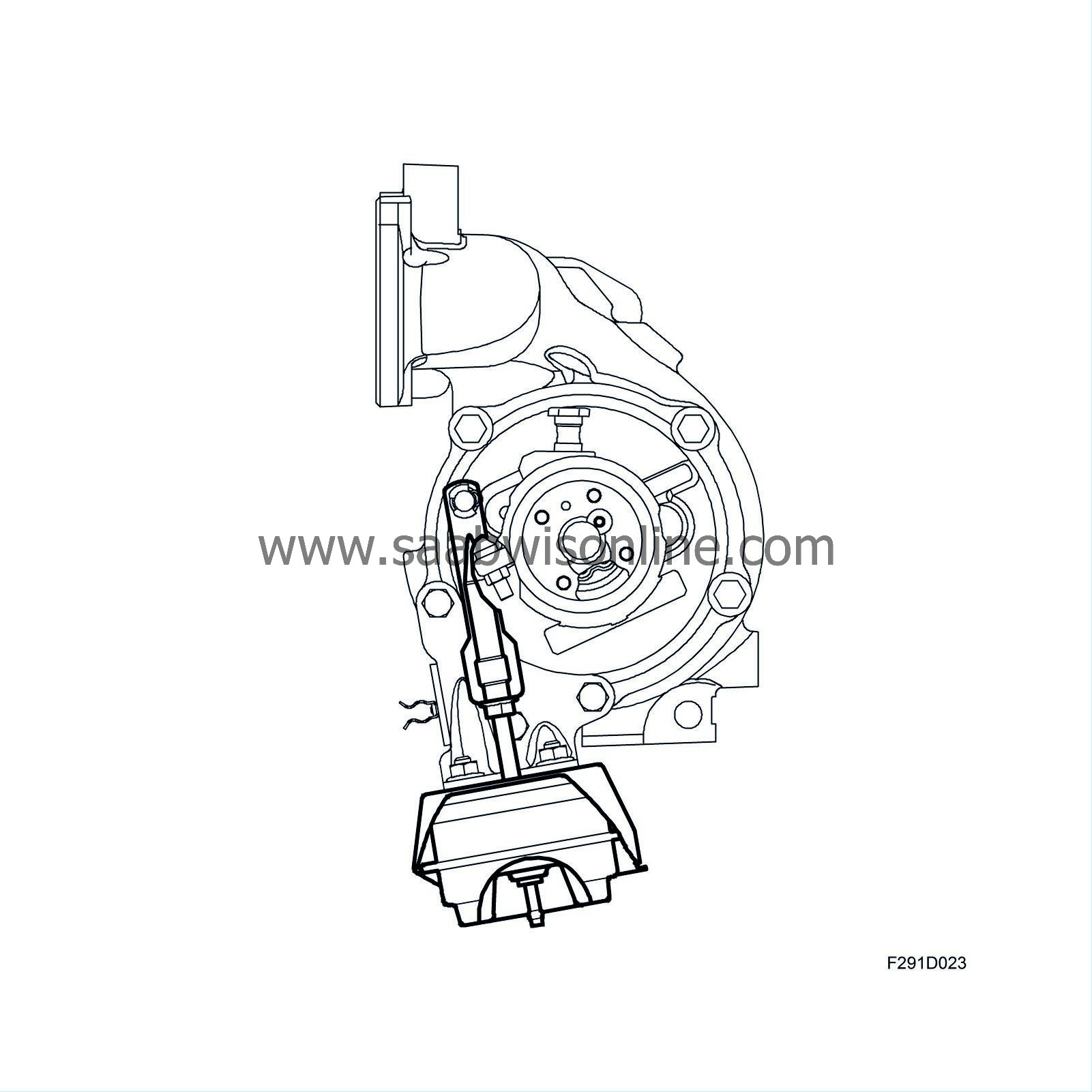

Diaphragm unit, VNT

The diaphragm unit manoeuvres the position of the vanes. It is regulated by a vacuum from a vacuum tank via a solenoid valve. A spiral spring in the diaphragm unit holds the vanes in the fully open position when the vacuum works in the opposite direction, i.e. closes the vanes. Vane position can be varied by regulated the vacuum to the diaphragm unit. This is done via a PWM-regulated solenoid valve that is regulated by ECM.

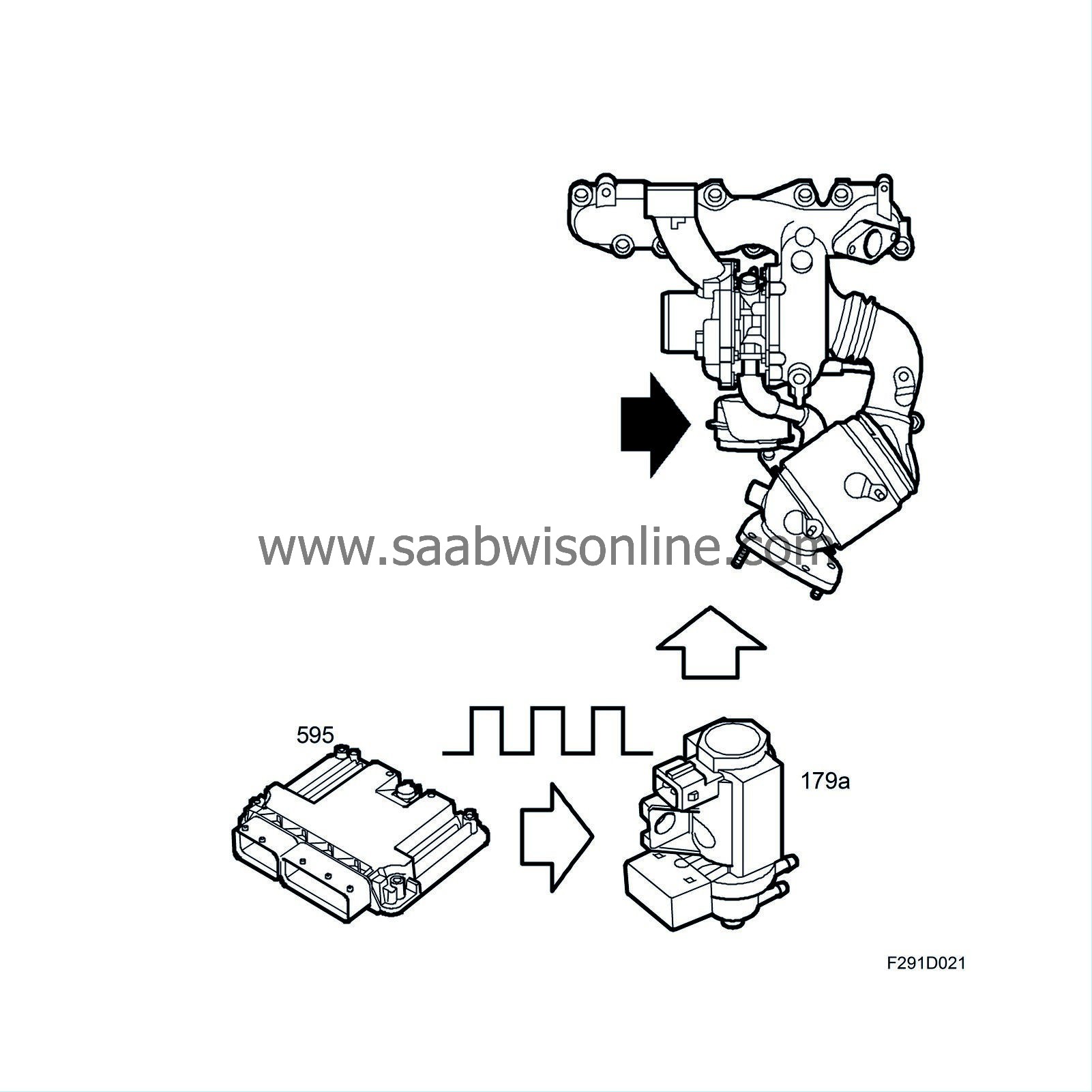

Solenoid valve, VNT

The solenoid valve is regulated by the engine control module via a PWM signal that opens the valve so that the desired negative pressure to the diaphragm unit is obtained. The vanes can be set to any position between open and closed by a combination of the spring force in the diaphragm unit and the negative pressure.

Lubrication

The turbine shaft that rotates at extremely high speed is carefully balanced together with the turbine and compressor impeller. The shaft is mounted in a fixed plain bearing bushing. This mounting requires a heavy flow of oil, which causes the shaft to float on an oil film during rotation. The oil is obtained from the engine lubricating system via a special oil line. The return oil is sent back to the engine oil sump. The seal between the shaft and bearing housing consists of rings (type - piston rings) that are positioned in the groove on the shaft.

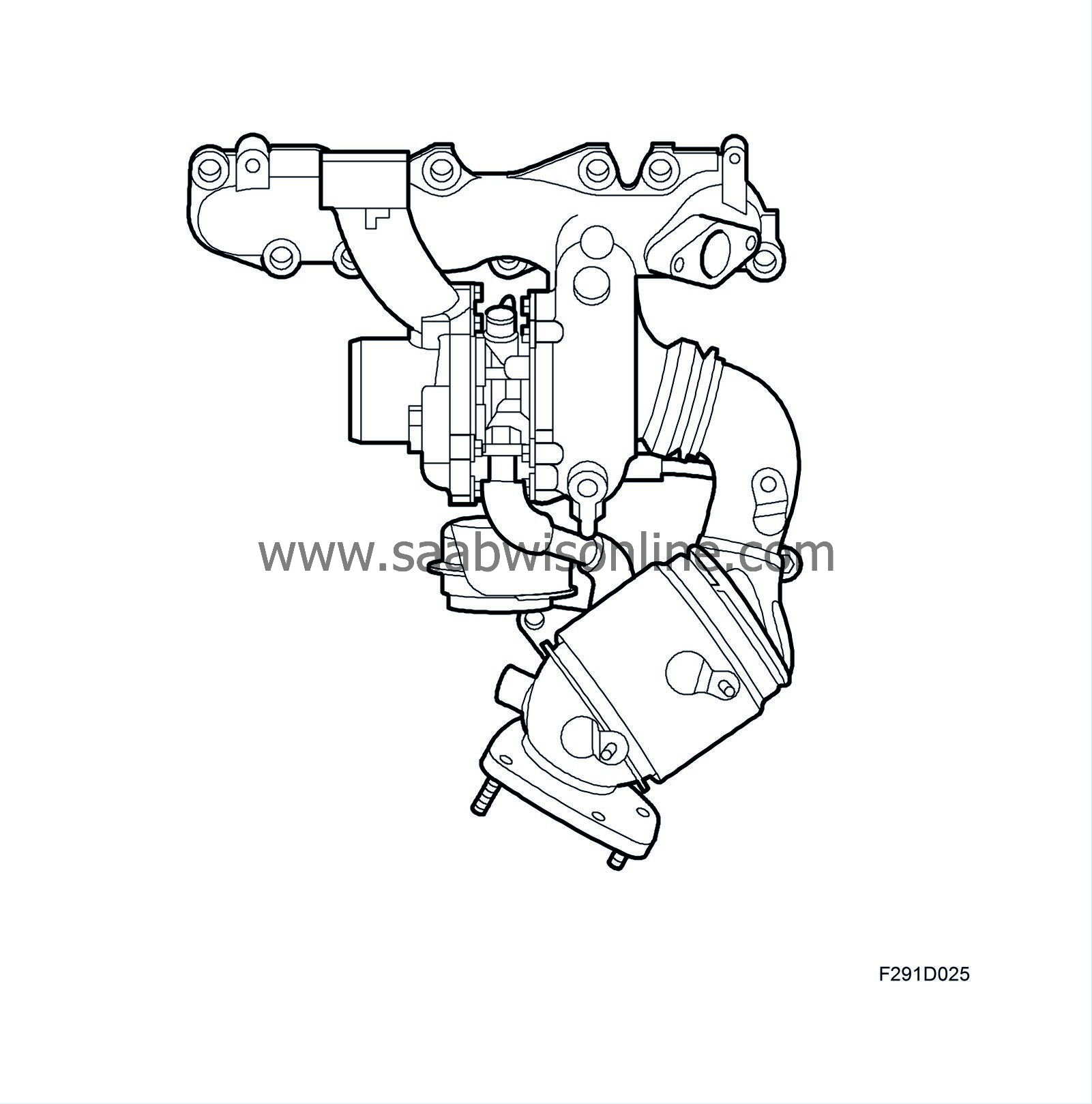

Exhaust manifold

The exhaust manifold is integrated with the turbine housing into a single unit. The exhaust manifold has a connection for EGR.