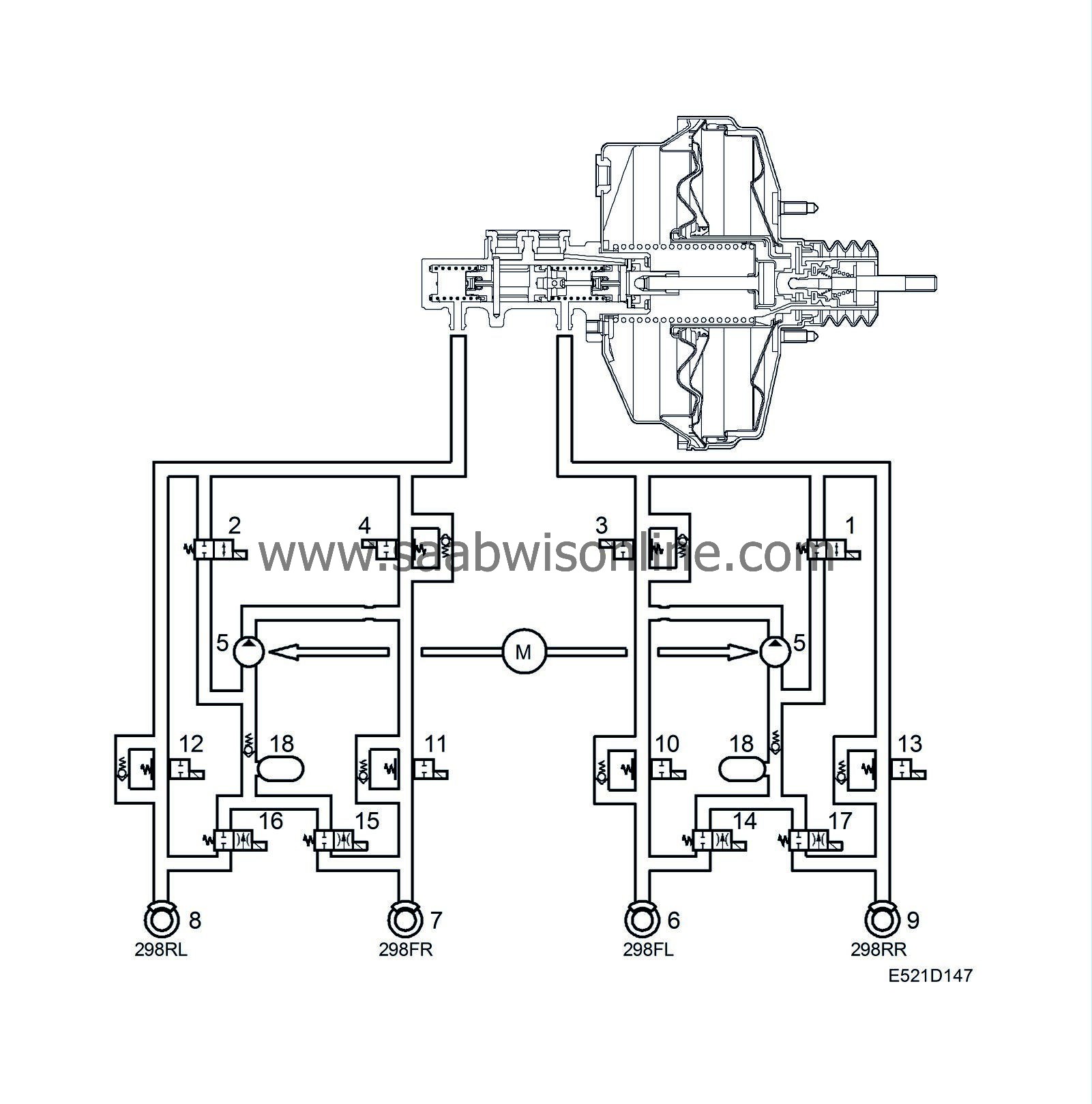

TCS modulation with braking

|

|

TCS modulation with braking

|

|

1.

|

Pressure Increase Valve Front Left

|

|

2.

|

Pressure Increase Valve Front Right

|

|

3.

|

Pressure Relief Valve Front Left

|

|

4.

|

Pressure Relief Valve Front Right

|

|

10.

|

Front left inlet valve

|

|

11.

|

Front right inlet valve

|

|

12.

|

Rear left inlet valve

|

|

13.

|

Rear right inlet valve

|

|

14.

|

Front left outlet valve

|

|

15.

|

Front right outlet valve

|

|

16.

|

Rear left outlet valve

|

|

17.

|

Rear right outlet valve

|

Since TCS modulation braking occurs without depression of the brake pedal, the hydraulic unit must build up and modulate the pressure to the driven wheel which is to be braked if it develops wheelspin in excess of the permitted limit.

The ESP control module actuates TCS modulation using the brakes when the following criteria are fulfilled:

|

•

|

One of the driven wheels is spinning more than the permissible limit.

|

|

•

|

The driver does not depress the brake pedal, the brake lights switch input is not active.

|

|

•

|

Road speed is below 100 km/h.

|

When TCS modulation with braking occurs, the vacuum servo, primary piston and secondary piston are in their rest positions. In the valve block the inlet and outlet valves are in their rest positions, that is to say the inlet valves are open and the outlet valves are closed.

The ESP control module starts the return pump. At the same time, the pressure relief valve is shut to allow a build-up of pressure. The pressure increase valve is opened to supply the pump with brake fluid and increase the pressure. The control module closes the pressure increase valve when a preset pressure is reached. The pressure is then modulated by the control module: it opens the pressure increase valve for an increase in pressure; keeps the pressure increase valve and pressure relief valve closed for pressure holding; and opens the pressure relief valve for a drop in pressure. The excess brake fluid that arises when the pressure relief valve is opened is returned to the master cylinder.

When TCS modulation starts, a "filling pulse" is generated, which means that a small (same for both wheels) amount of pressure is built up in the wheel cylinders of both drive wheels, irrespective of which wheel is to be modulated with braking. Pressure will be maintained on the front wheel which is not to be braked, i.e. both the pressure increase and pressure relief valves will be closed. This is in order to prepare for an application of the brakes if it should prove necessary.

The pressure increase valve on the wheel which is spinning will open. This causes an increase in the pressure to the wheel cylinder and the wheel is braked.

Modulation continues until:

|

•

|

The friction between wheels and road surface changes so that wheelspin does not exceed the limit.

|

|

•

|

The driver brakes (brake lights switch input active).

|

|

•

|

The ESP control module halts regulation due to a risk of the brakes overheating.

|

When modulation is interrupted, the ESP control module stops the return pump, closes the pressure increase valve and opens the pressure relief valve, i.e. the valves and the return pump return to their inactivated positions.

If TCS modulation is interrupted by the driver braking, TCS modulation with braking will be disengaged and the braking function will be chosen instead. Any delay that may then arise will not affect the braking function since the brake fluid can flow through the check valve which is mounted parallel with the pressure relief valve.

The ESP control module continuously records the total duration of TCS modulation with braking over a certain period of time. This prevents the risk of the brakes overheating due to TCS modulation with braking (modulation is interrupted).

The time is compared with a preprogrammed maximum value and modulation with braking is disengaged when this is exceeded.

Phase 1 Pressure build-up on both front wheels (filling pulse)

The return pump starts, the pressure increase valve opens (fixed time), the pressure relief valve closes.

Phase 2 Pressure increase in the circuit with wheelspin.

Pressure increase valve open, pressure relief valve closed, return pump running.

Phase 3 Pressure reduction in the circuit with wheelspin.

Pressure relief valve open, pressure increase valve closed, return pump running.

Phase 4 Release

Braking function selected. Pressure increase valve closes, pressure relief valve opens, both valves return to rest position, return pump stops.