PRE-RELEASE

Timing cover

| Timing cover |

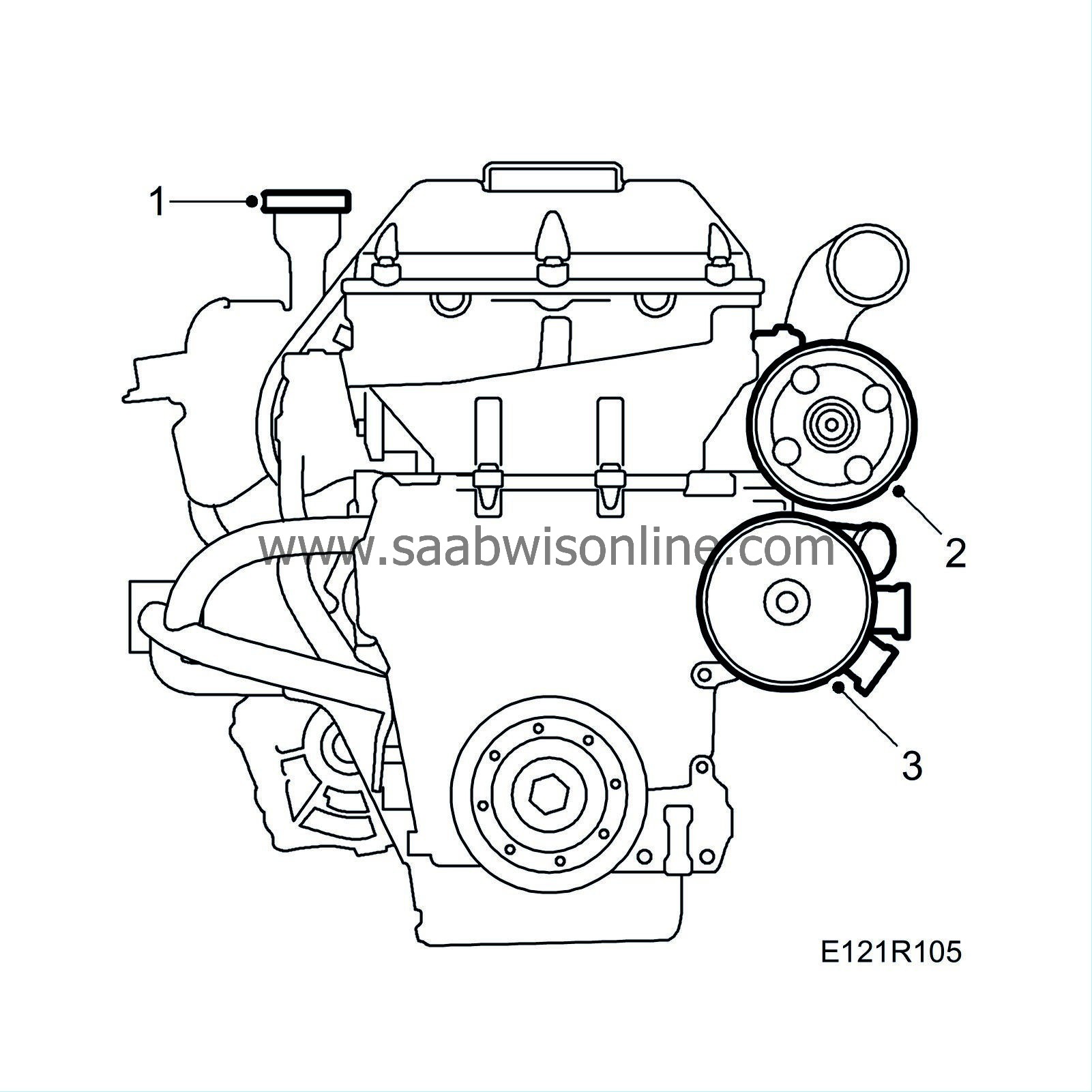

| 1. |

Remove the dipstick.

|

|

| 2. |

Remove power steering pump and bracket with lifting eye.

|

|

| 3. |

Remove water pump and sleeve with O-rings.

|

|

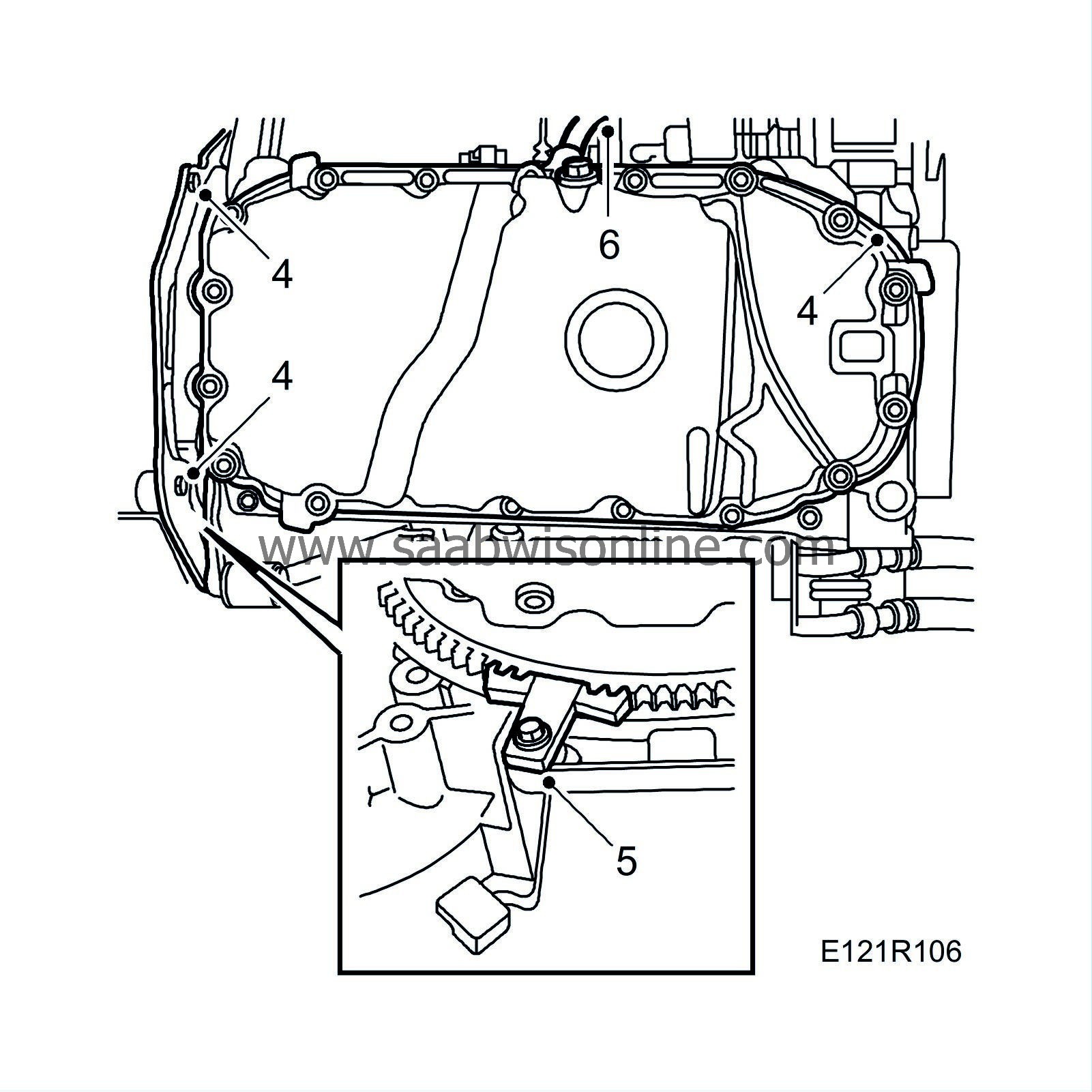

| 4. |

Remove guard plate and oil sump. Leave the guide sleeve in place in the cylinder block. Wipe clean from dripping oil.

|

|

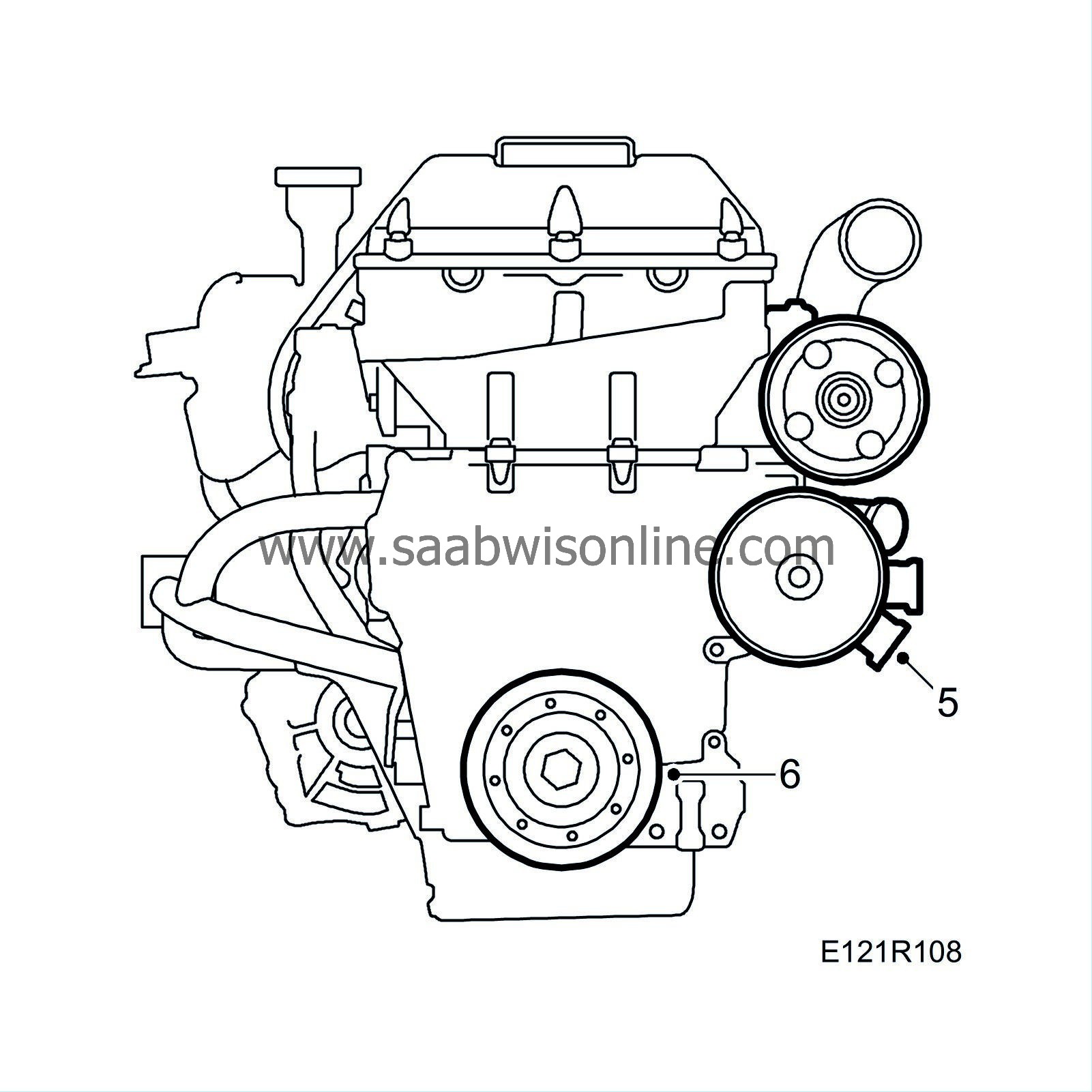

| 5. |

Use flywheel locking attachment 83 94 868

. Remove the crankshaft pulley.

. Remove the crankshaft pulley.

|

|

| 6. |

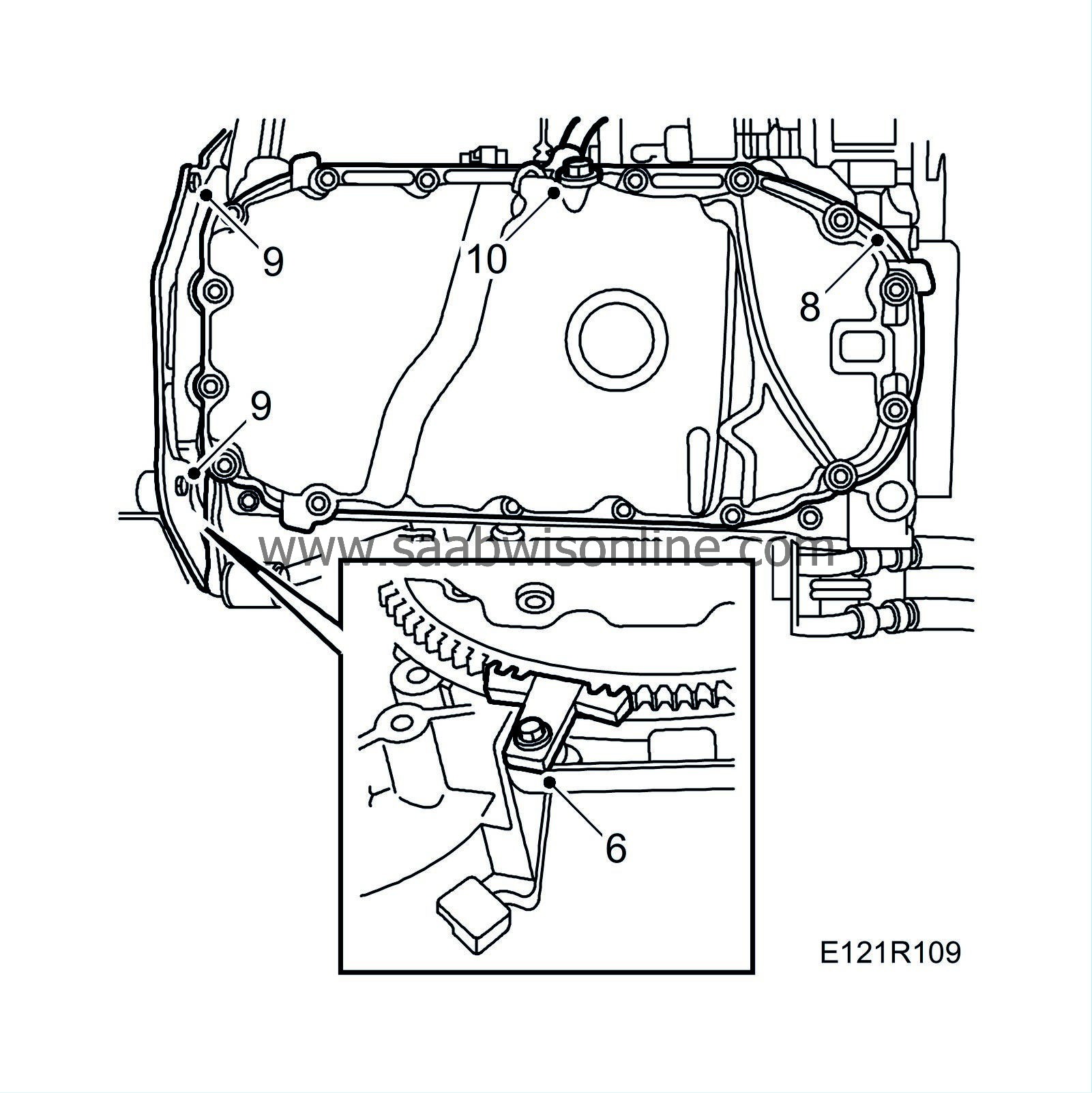

Disconnect the crankcase ventilation hose from the oil sump.

|

|

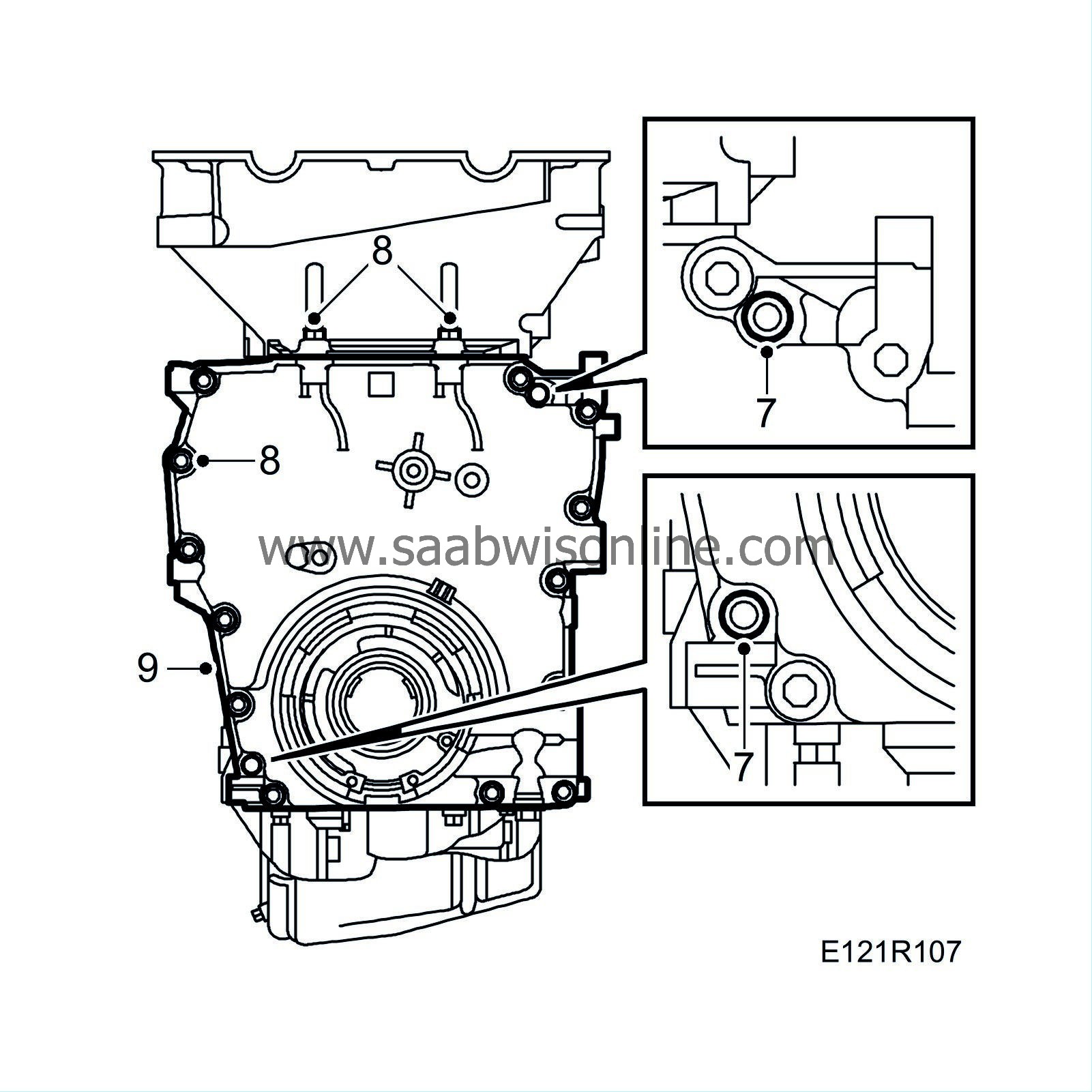

| 7. |

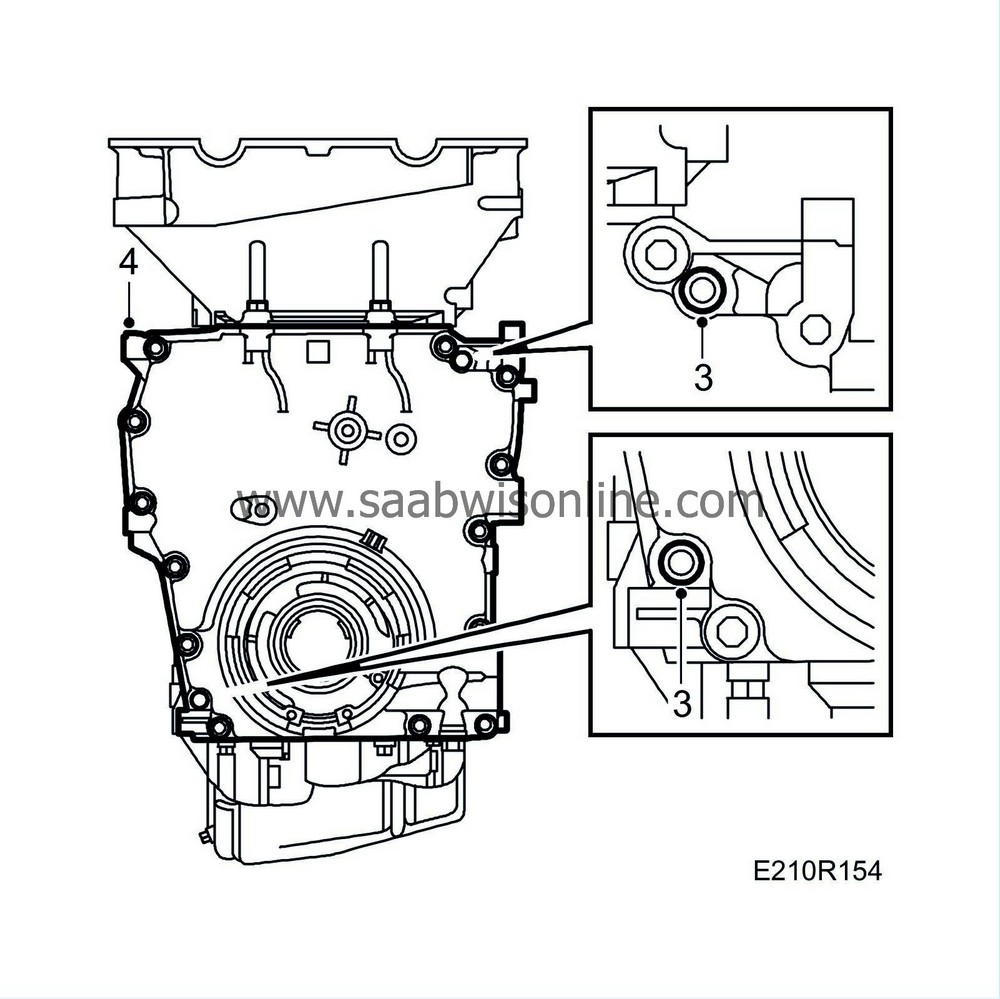

Remove guide pins from timing cover by cutting an internal thread with a 3/8” UNC screw tap and pull them out with sliding hammer 83 90 270

.

.

|

|

| 8. |

Remove all bolts from timing cover.

|

|

| 9. |

Pull the cover loose at the bottom first.

|

|

| 10. |

Then lift the cover out/down so that the gasket is not damaged on the cylinder head.

|

|

| To fit |

| 1. |

Thoroughly clean away all the sealant residue on all surfaces. Wash with benzine.

|

|

| 2. |

Apply Loctite 518 in a 1 mm thick bead onto sealing surfaces.

|

|

| 3. |

Fit the timing cover by carefully twisting it in place. Tighten retaining bolts loosely and knock in guide pins.

|

|

| 4. |

Torque tighten the timing cover.

Tightening torque 22 Nm (16 lbf ft) (up to and including engine no. 7006011) Tightening torque 19 Nm (14 lbf ft) (from and including engine no. 7006012) |

|

| 6. |

Fit the crankshaft pulley. Use flywheel locking attachment 83 94 868.

Tightening torque 175 Nm (130 lbf ft). |

|

| 7. |

Check that there are no impurities or other foreign matter in the sump and clean the sealing surfaces.

|

|

| 8. |

Apply an even bead of Loctite 518 on the oil sump's sealing surface and fit the oil sump in place.

Tightening torque 22 Nm (16 lbf ft). |

|

| 9. |

Fit the guard plate, plug in the oil level sensor and press the cable back into its clamps.

|

|

| 10. |

Check that the oil plug is tight and connect cables to oil pressure sensor, generator and starter motor.

Tightening torque 25 Nm (19 lbf ft). |

|