PRE-RELEASE

Engine replacement (power train on subframe)

| Engine replacement (power train on subframe) |

| To remove |

| Note | ||

|

Drain the engine oil and transmission fluid. |

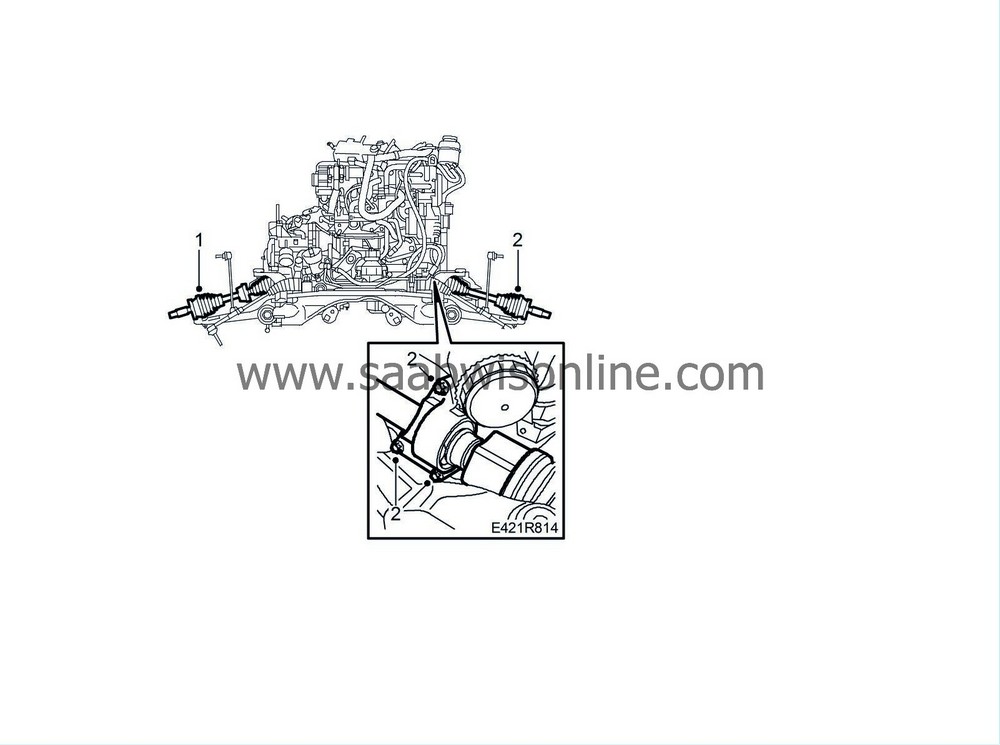

| 1. |

Use

87 92 616 Removal tool, drive shafts

to remove the left drive shaft and plug the gearbox with

87 92 665 Protective plug, drive shaft hole

.

|

|

| 2. |

Remove the left drive shaft with the intermediate shaft and bearing pedestal. Plug the gearbox with

87 92 665 Protective plug, drive shaft hole

.

|

|

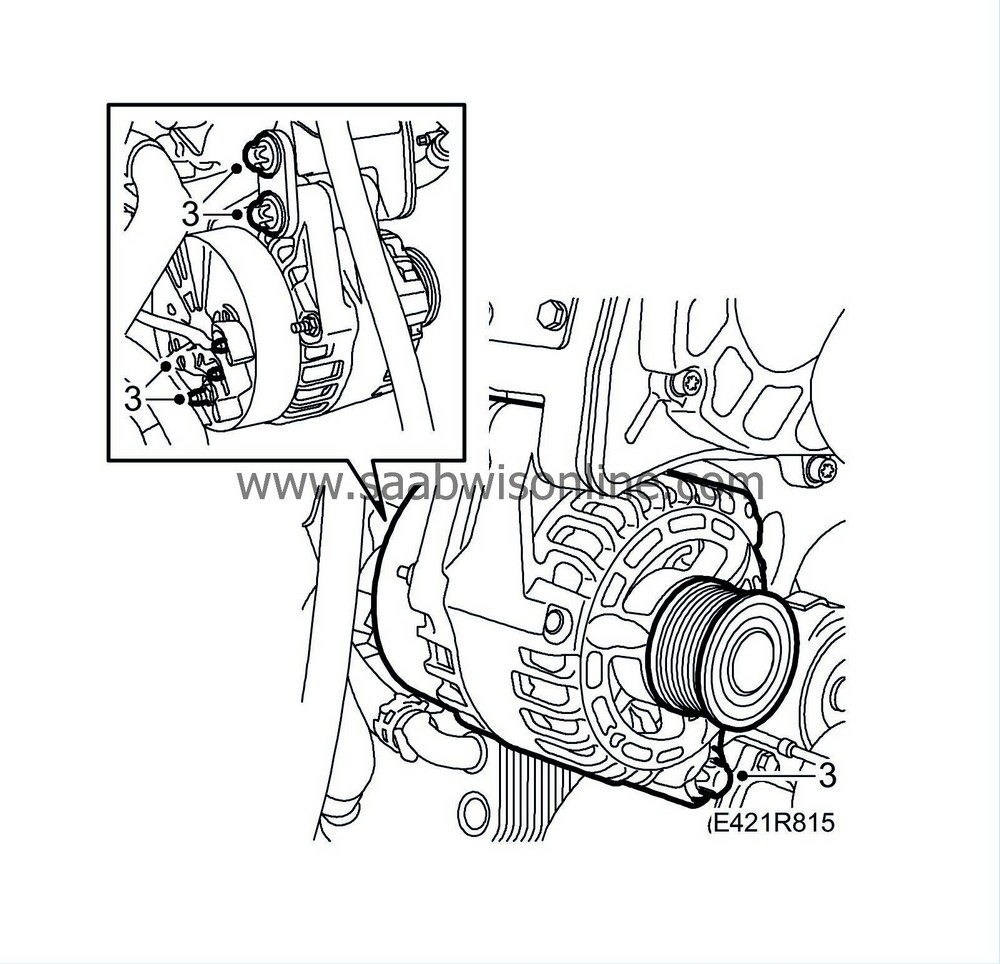

| 3. |

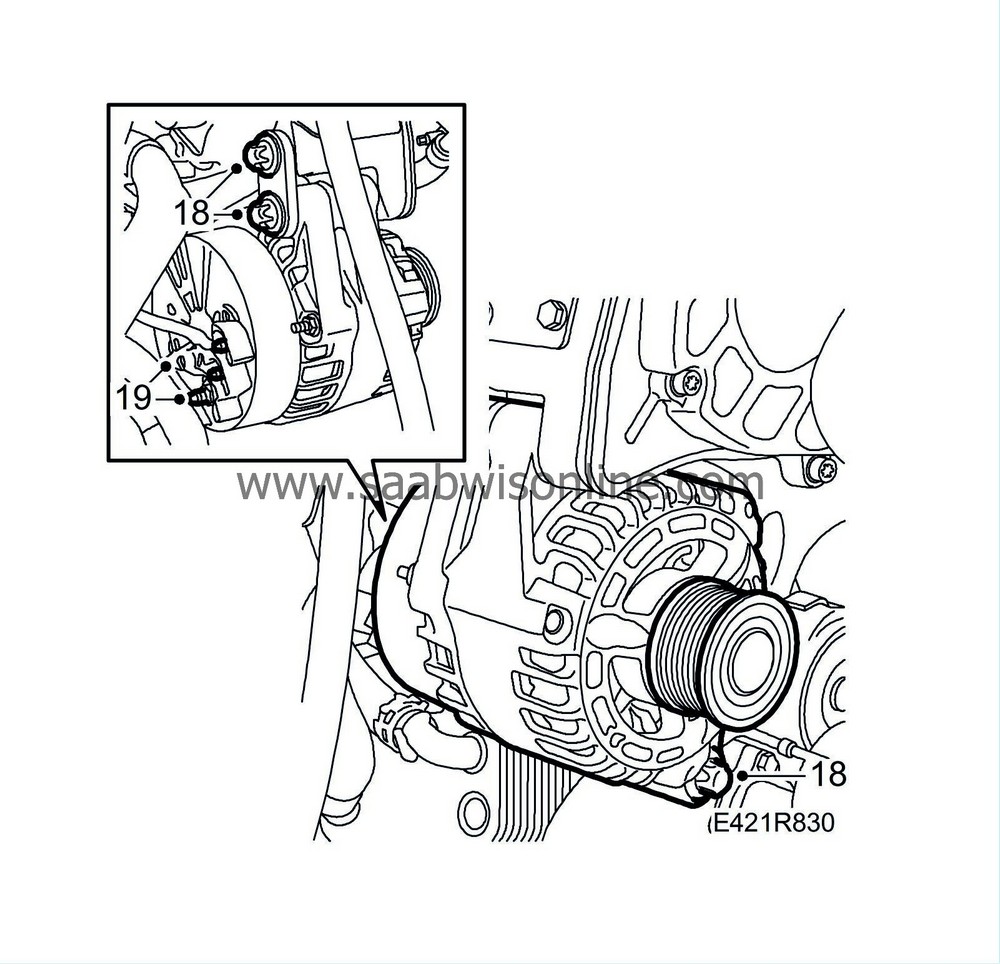

Detach the generator's electrical connections and remove the generator.

|

|

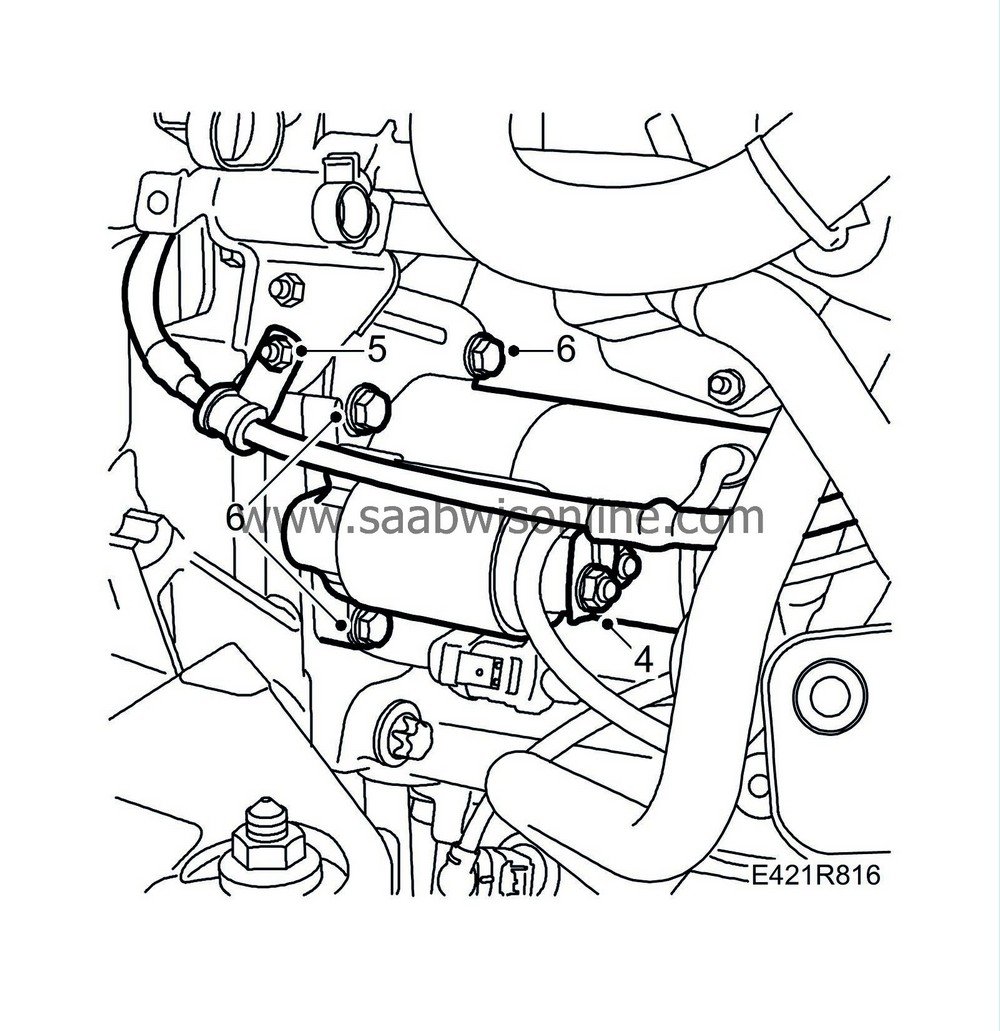

| 4. |

Detach the electrical connections from the starter motor.

|

|

| 5. |

Remove the positive cable's fixing and move the cable aside.

|

|

| 6. |

Remove the starter motor.

|

|

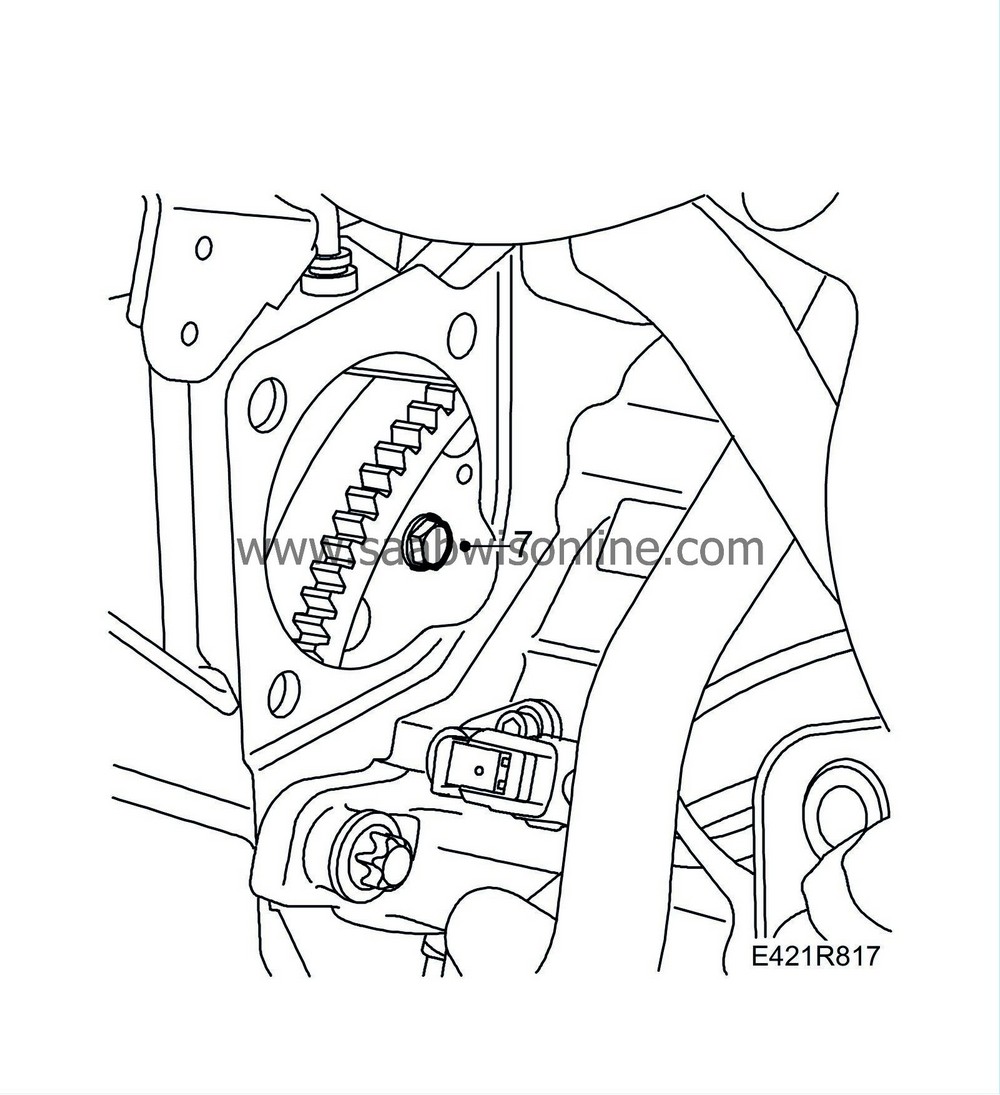

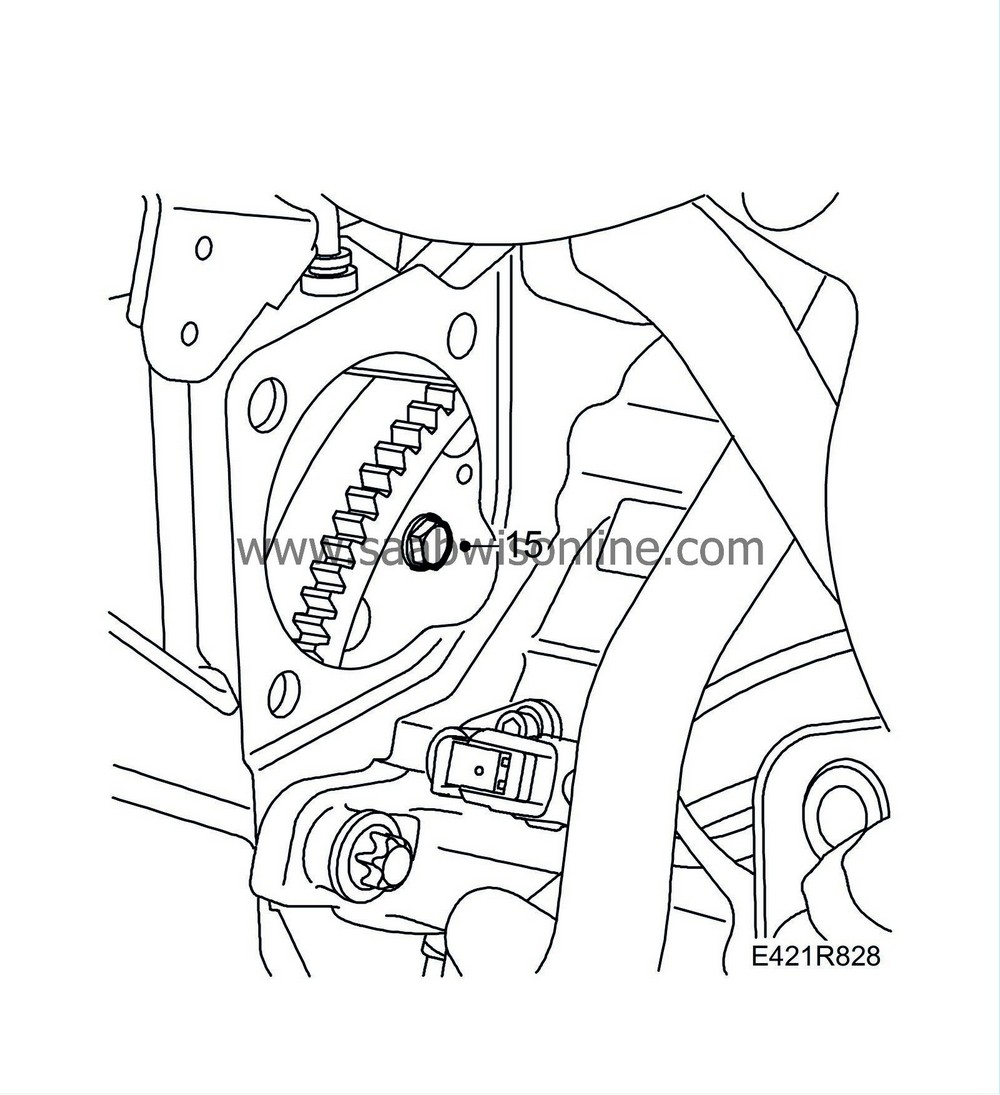

| 7. |

Aut:

Remove the bolts holding the torque converter in place. Rotate the engine on the crankshaft centre bolt.

|

|

| 8. |

Connect

83 92 409 Lifting yoke

to the engine and unload with an engine lift.

|

|

| 9. |

Remove the plastic wedges.

|

|

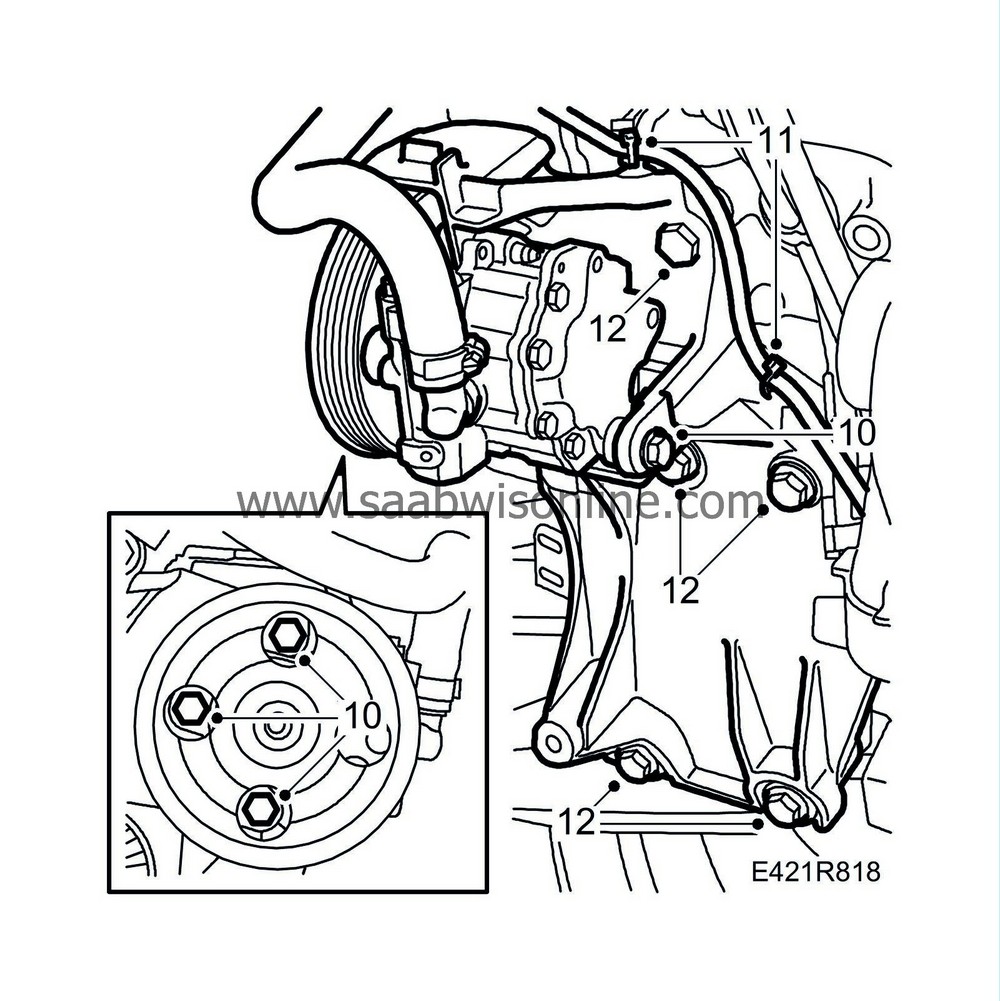

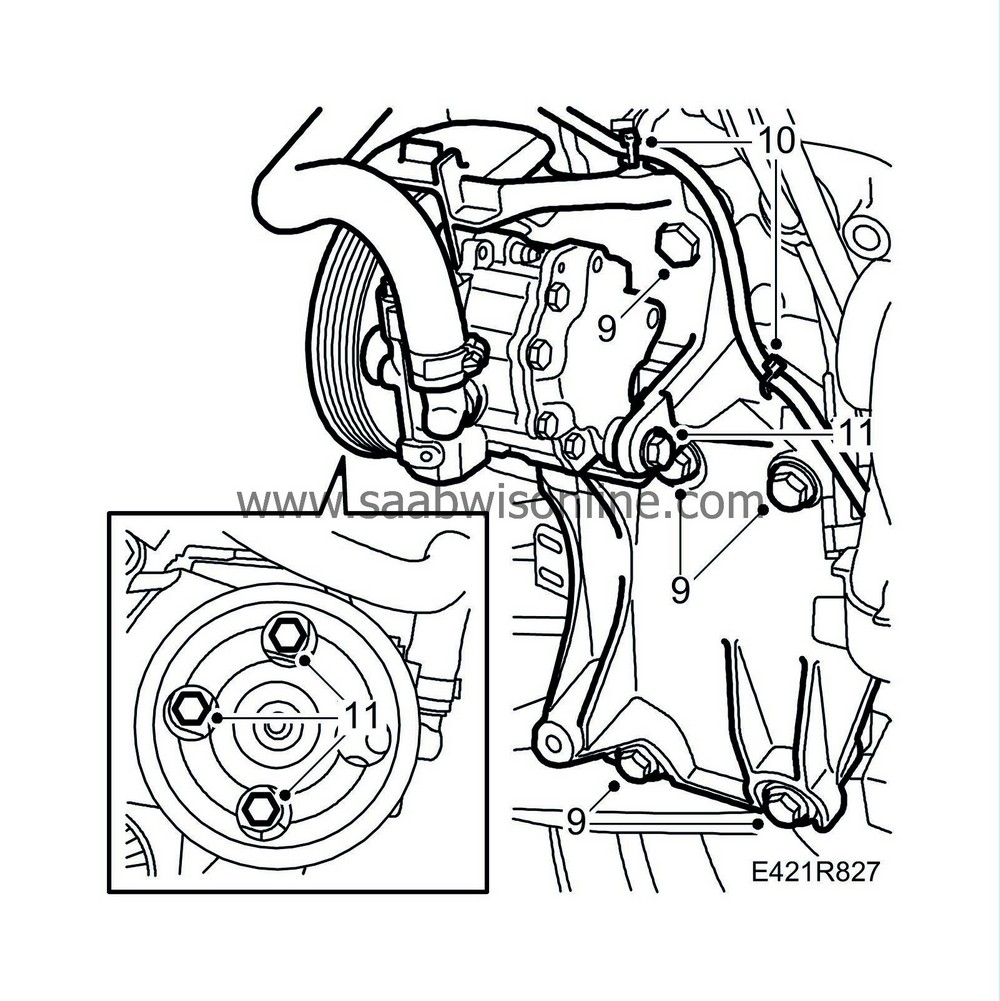

| 10. |

Remove the power steering pump. Leave the servo hoses in place on the pump.

|

|

| 11. |

Cut the cable tie holding the A/C compressor wiring harness in place.

|

|

| 12. |

Remove the bracket of the power steering pump.

|

|

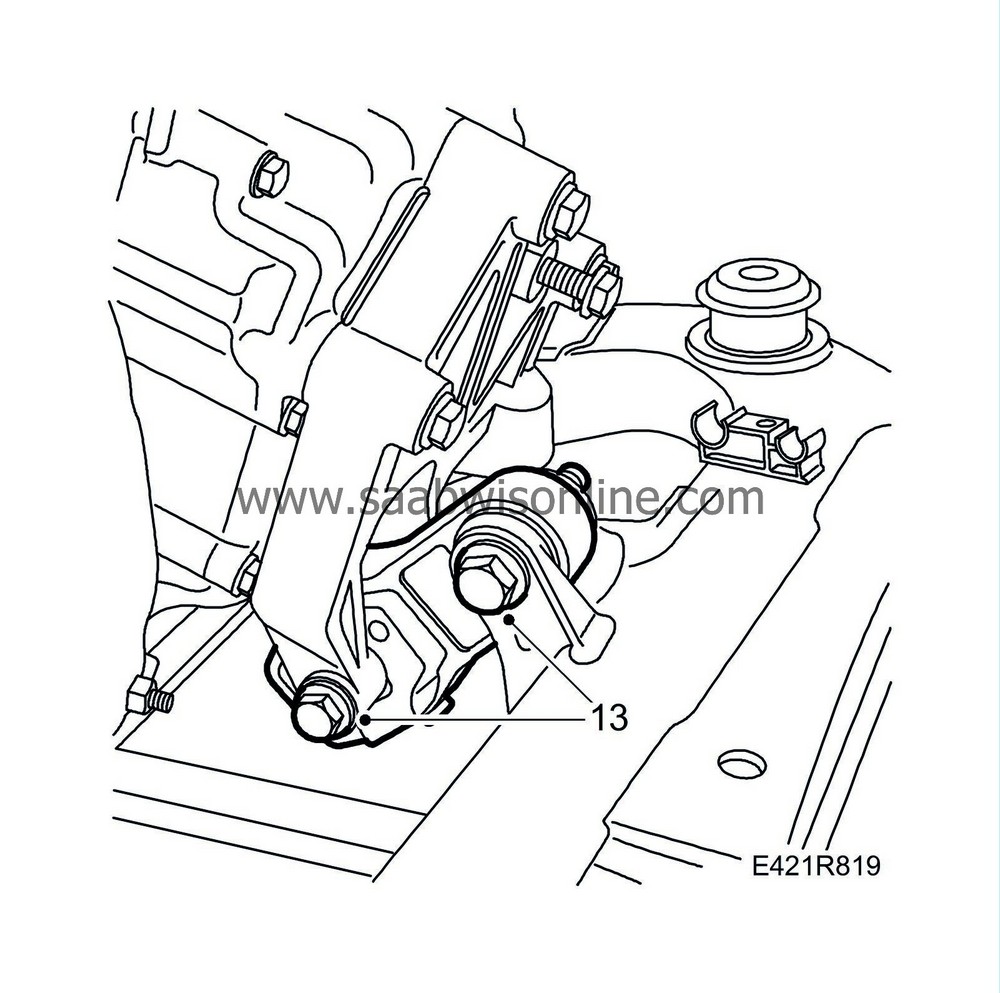

| 13. |

Remove the front torque arm from the subframe and gearbox.

|

|

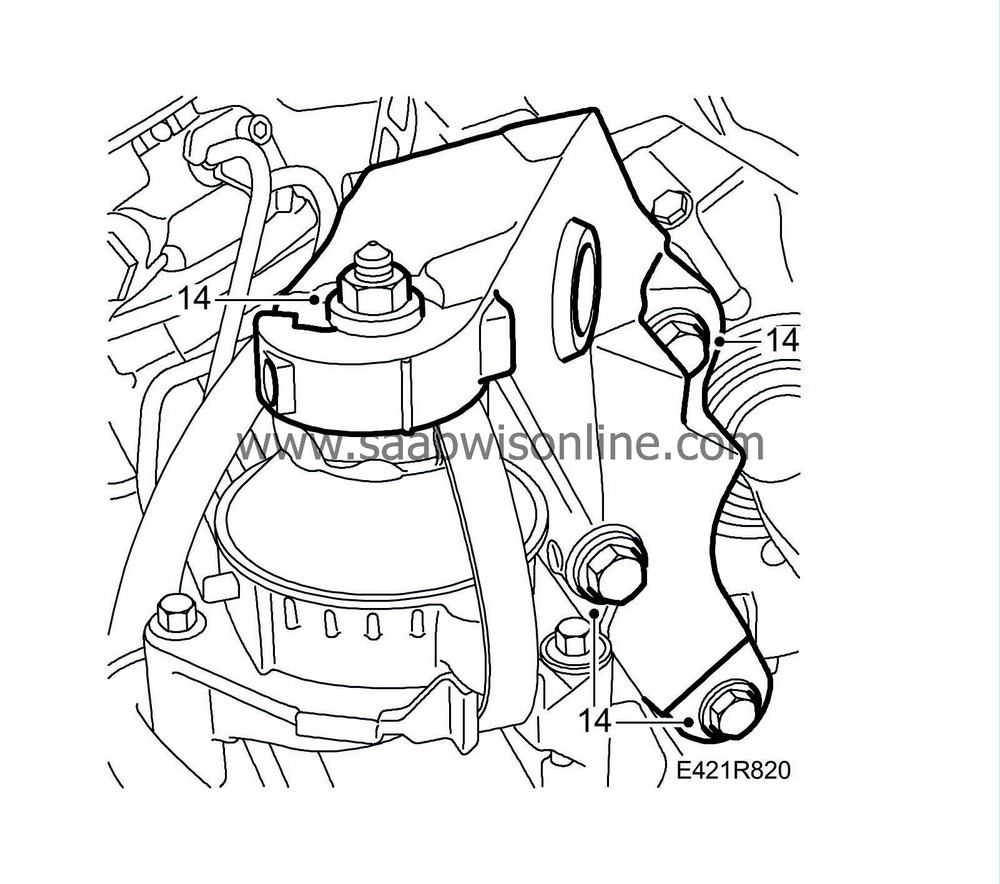

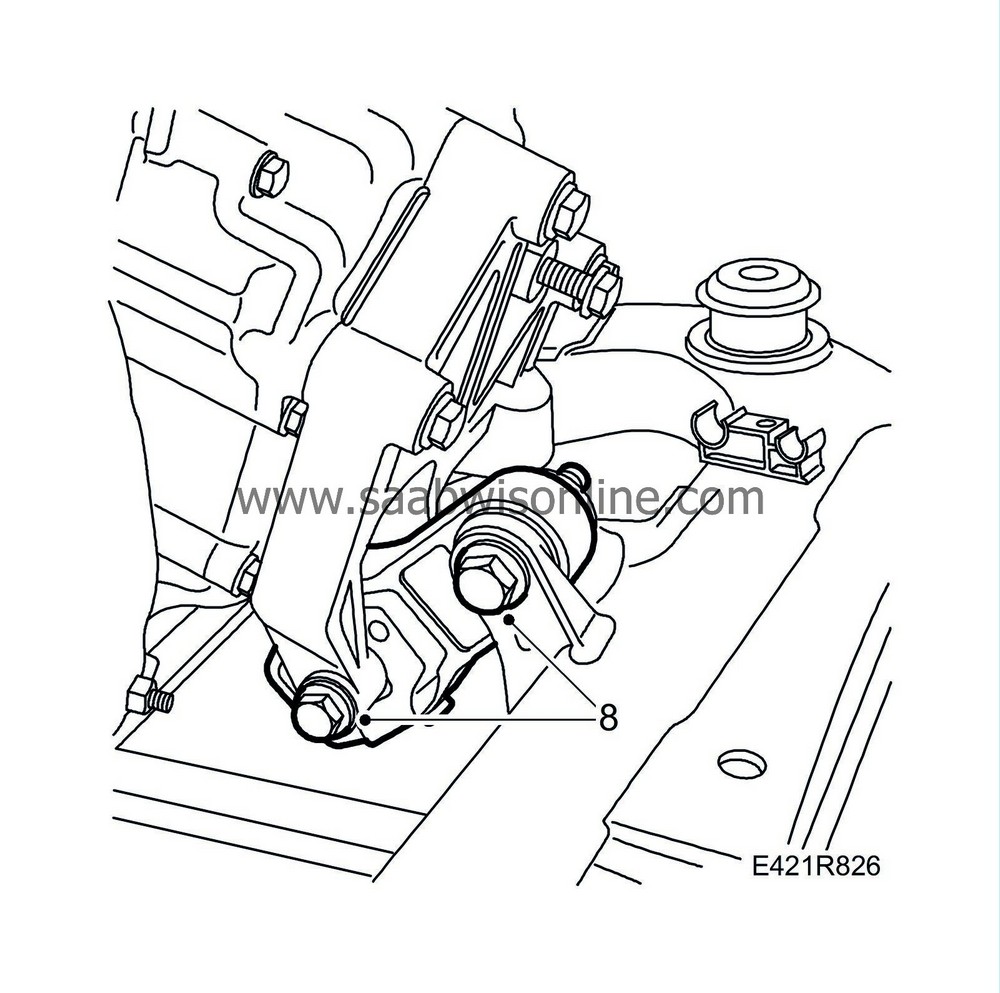

| 14. |

Slacken the nut and remove the bolts holding the engin bracket to the gearbox.

|

|

| 15. |

Raise the engine from the subframe.

|

|

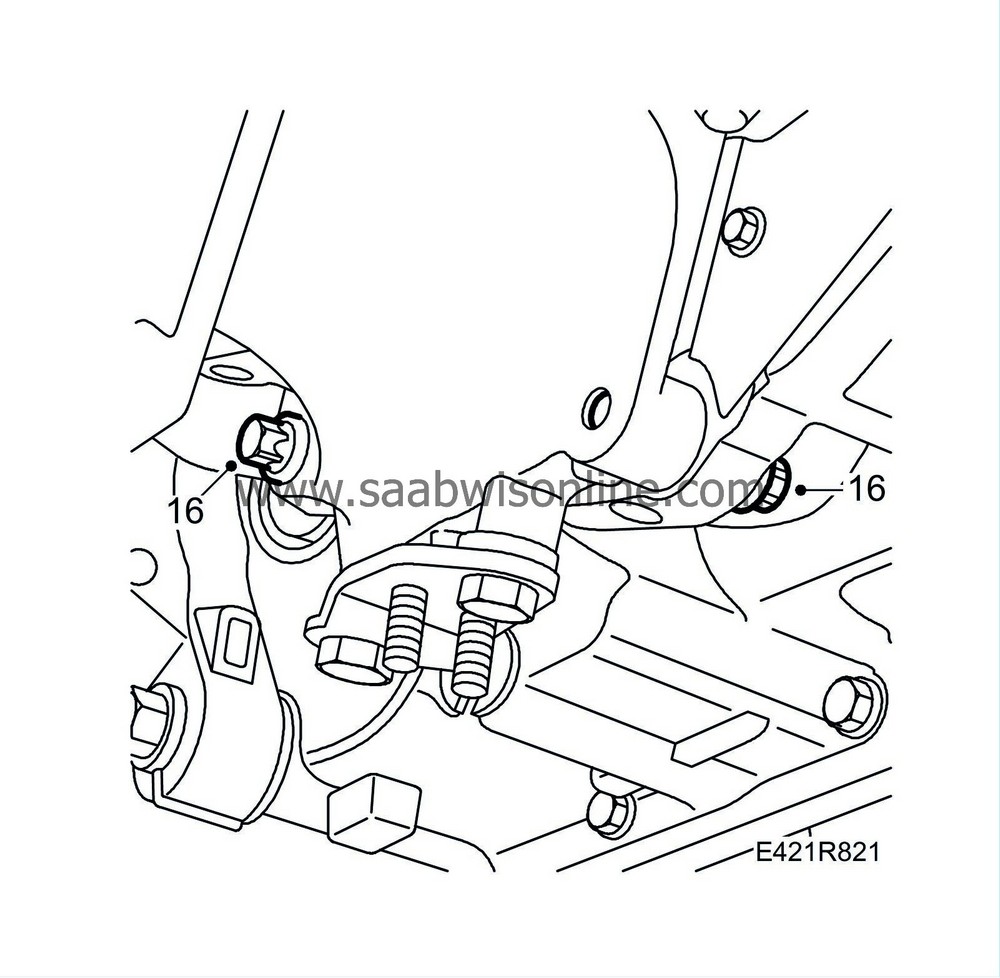

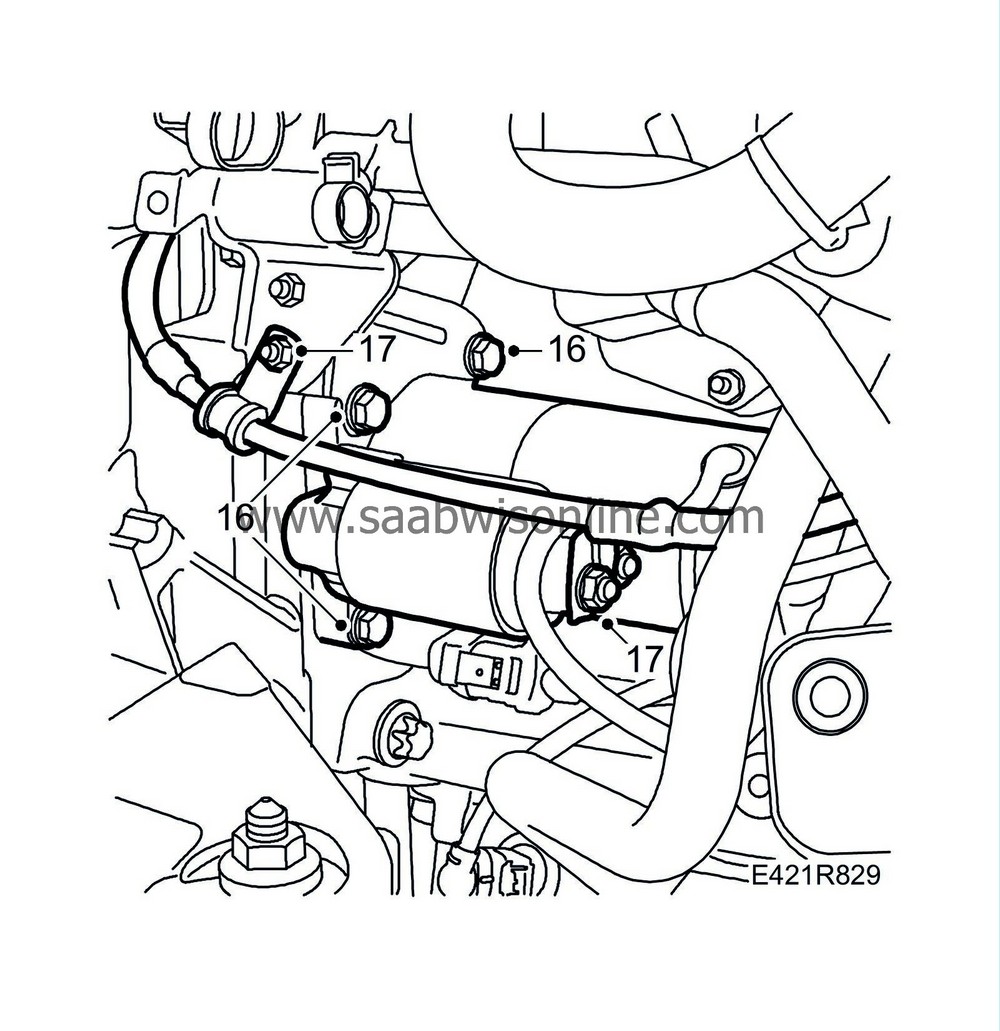

| 16. |

Remove the two lower bolts of the gearbox.

|

|

| 17. |

Place the engine on the floor.

|

|

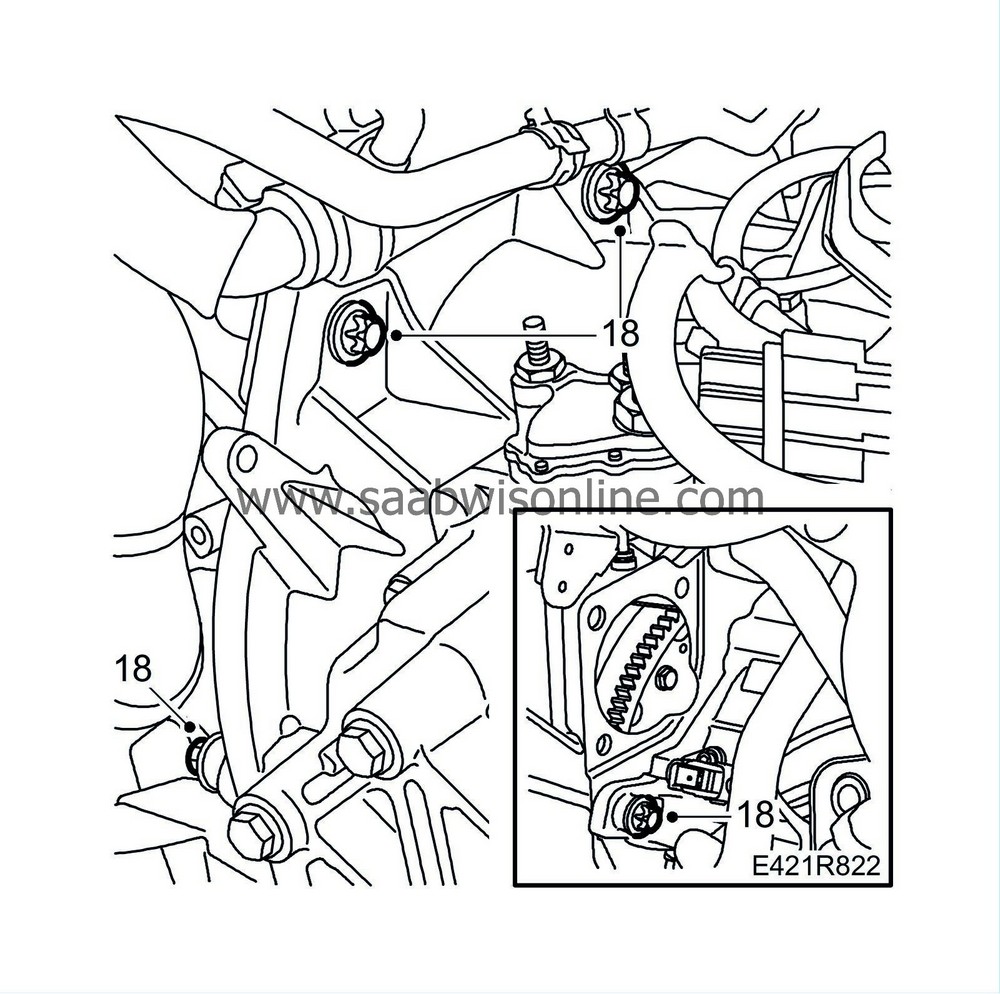

| 18. |

Remove the gearbox bolts and lift away the gearbox.

Aut:

Press the torque converter toward the gearbox.

|

|

| 19. |

Aut:

Fit

87 92 574 Holder

to hold the torque converter in place.

|

|

| To fit |

| 1. |

Aut:

Turn the torque converter so that the bolt holes align with the holes on the driver plate and turn the engine so that the oval hole in the driver is centred at the starter motor opening. Fit

87 92 574 Holder

to hold the torque converter in place during installation. Grease the torque converter guide pin.

|

|

| 2. |

Check that the two guide sleeves sit on the engine. Grease the guide sleeves.

|

|

| 3. |

Mount the gearbox on the engine.

Aut:

Remove

87 92 574

just before the gearbox is in place.

|

|

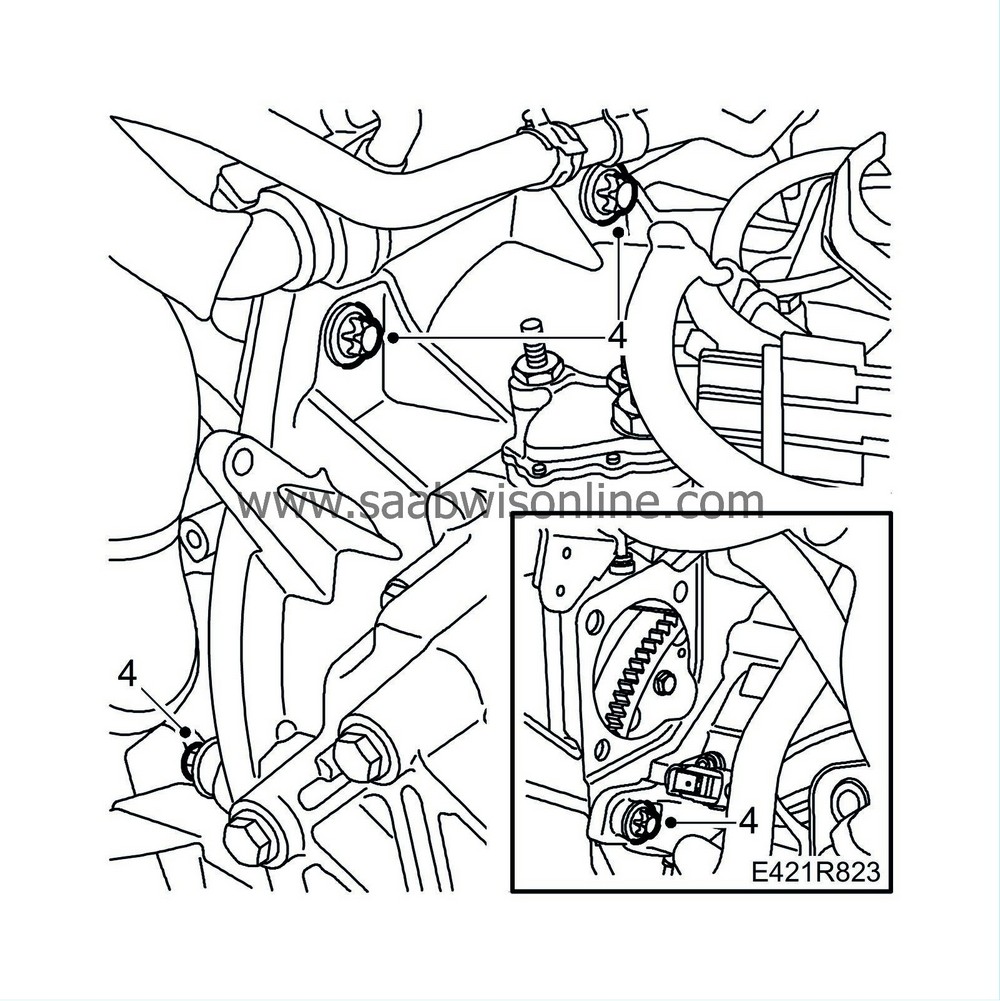

| 4. |

Fit the accessible bolts of the gearbox.

Tightening torque: M12 60 Nm (44 lbf ft) Tightening torque: M10 40 Nm (30 lbf ft)

|

|

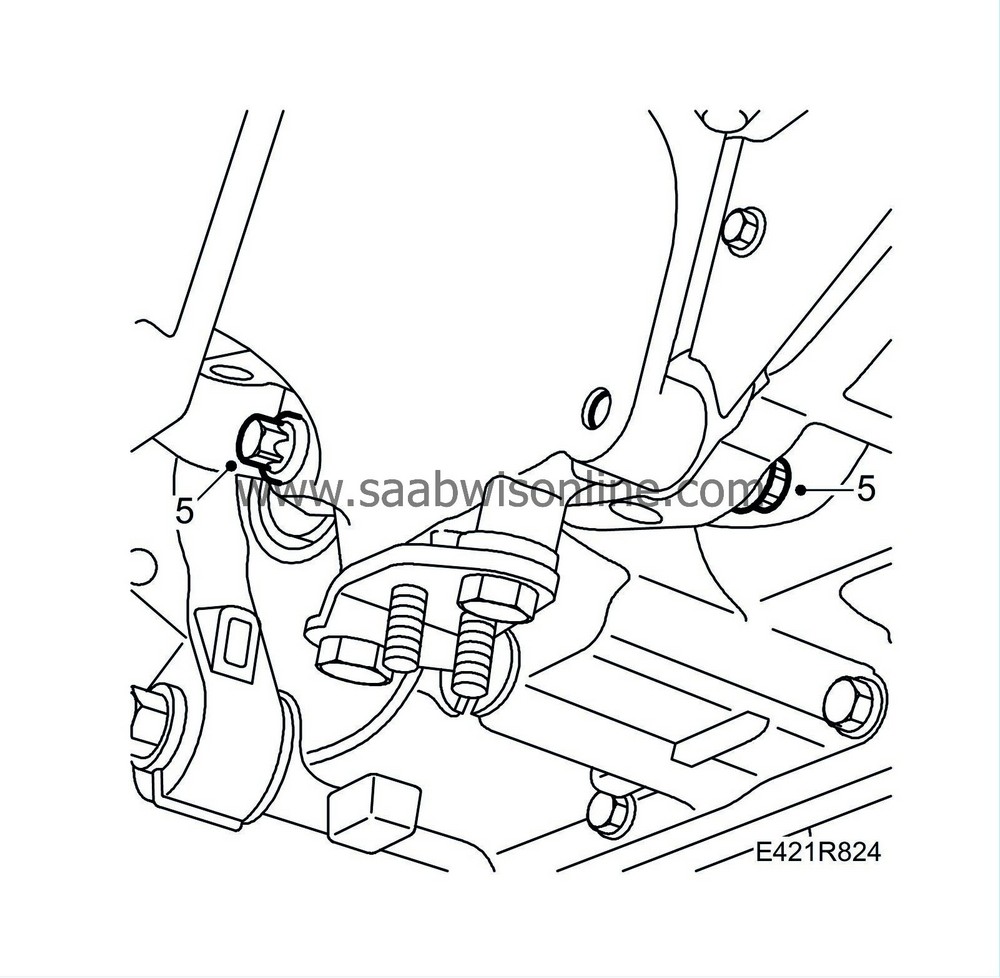

| 5. |

Raise the engine with an engine lift and fit the 2 lower bolts.

Tightening torque: M12 60 Nm (44 lbf ft) Tightening torque: M10 40 Nm (30 lbf ft)

|

|

| 6. |

Position the engine on the subframe.

|

|

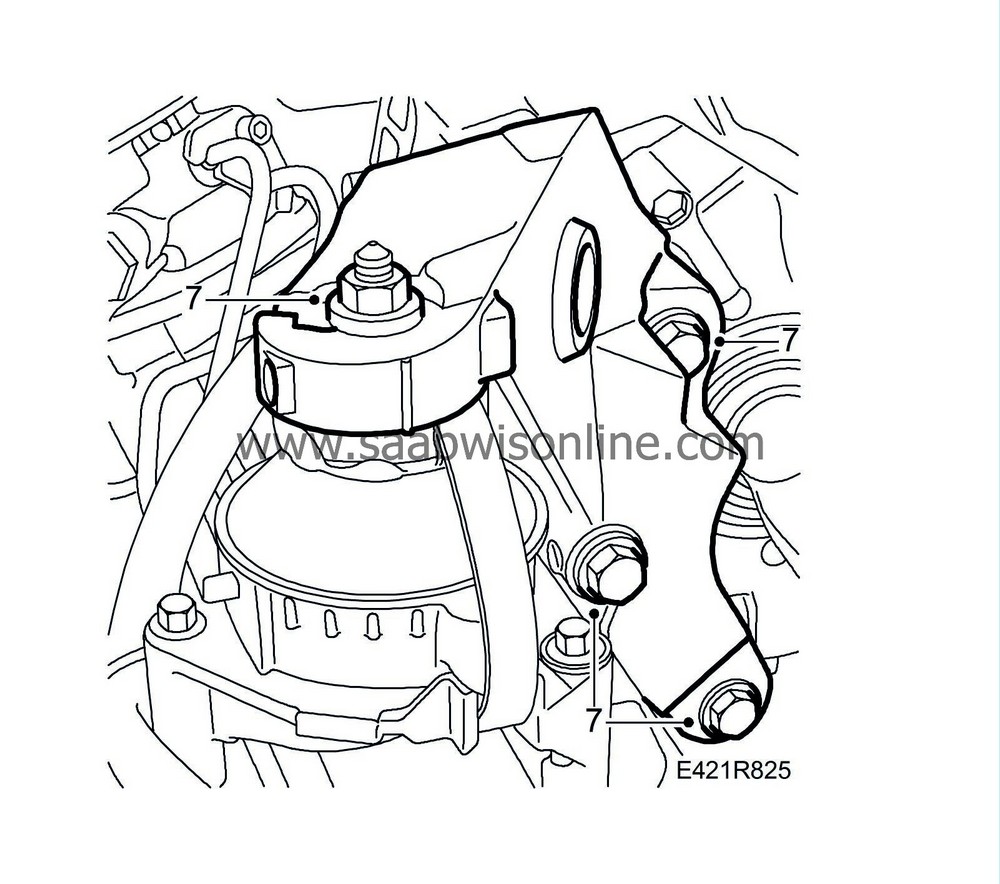

| 7. |

Fit the bolts that hold the engine bracket to the gearbox. Tighten the nut.

Tightening torque, bolts: 60 Nm +60 °(44 lbf ft +60°)

|

|

| 8. |

Fit the front torque arm to the subframe and gearbox.

Tightening torque: Nm ( lbf ft)

|

|

| 9. |

Fit power steering pump bracket.

Tightening torque: 47 Nm (35 lbf ft)

|

|

| 10. |

Secure the A/C compressor wiring harness.

|

|

| 11. |

Fit the power steering pump.

Tightening torque: 24 Nm (18 lbf ft) |

|

| 12. |

Position plastic wedges between the gearbox and subframe and between the A/C compressor bracket and subframe.

|

|

| 13. |

Lower the engine on the plastic wedges and remove the engine lift and lifting yoke.

|

|

| 14. |

Aut:

Apply

Thread locking adhesive, Lotite 242

to the bolts that hold the torque converter to the driver plate.

|

|||||||

| 15. |

Turn the crankshaft at its centre bolt and tighten when all the bolts are in place.

Tightening torque: 20 Nm +45 ° (15 lbf ft +45°)

|

|

| 16. |

Fit the starter motor.

Tightening torque: 24 Nm (18 lbf ft)

|

|

| 17. |

Secure the positive cable and fit the starter motor electrical connections.

|

|

| 18. |

Fit the generator.

Tightening torque: 60 Nm (44 lbf ft)

|

|

| 19. |

Fit the generator's electrical connections.

|

|

| 20. |

Remove the plastic plug from the gearbox.

|

|

| 21. |

Fit the right driveshaft with intermediate shaft as follows: Fit

83 95 162 Protective collar, drive shafts

in the seal ring.

|

||||||||||

| 22. |

Make sure that the intermediate shaft is clean before inserting it in the tool. Lubricate the shaft with transmission fluid.

|

||||||||||

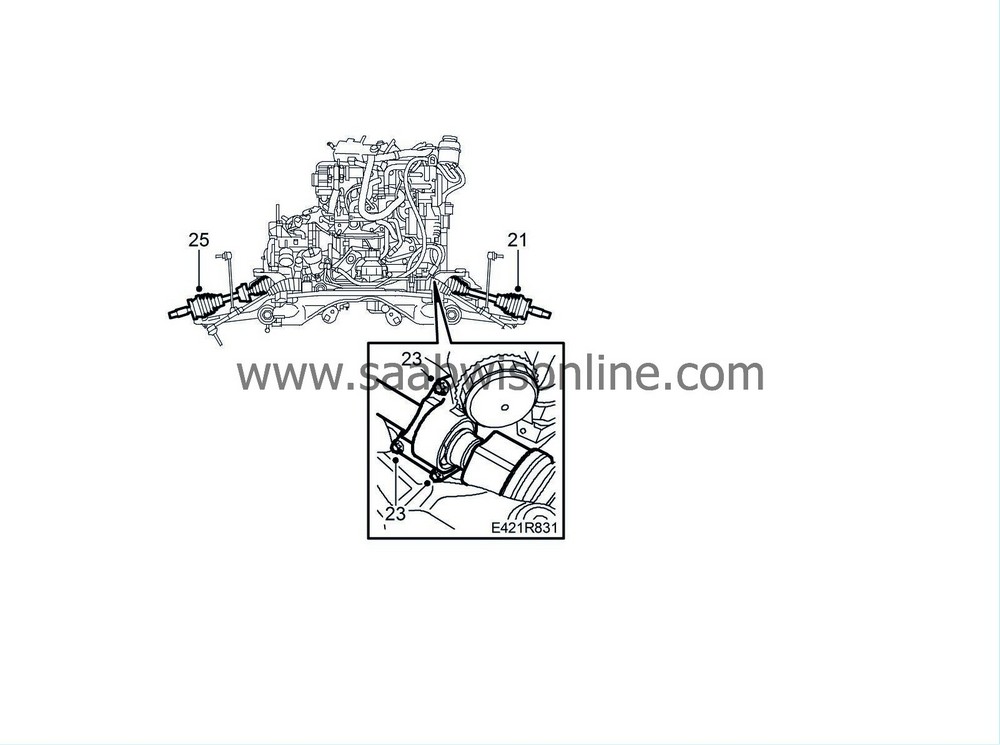

| 23. |

Insert the rest of the shaft and fit the bearing pedestal bolts.

Tightening torque: 50 Nm (37 lbf ft) |

|

| 24. |

Remove the plastic plug from the gearbox.

|

|

| 25. |

Fit

83 95 162 Protective collar, drive shafts

in the drive shaft seal ring.

|

|

| 26. |

Make sure that the drive shaft is clean before inserting it in the protective sleeve. Lubricate the shaft with transmission fluid.

|

|

| 27. |

Insert the rest of the shaft until the circlip engages.

|

|