PRE-RELEASE

Body Lock Pillar Outer Panel Reinforcement Replacement

| Body Lock Pillar Outer Panel Reinforcement Replacement |

| Removal Procedure |

Refer to Approved Equipment for Collision Repair Warning .

Refer to Glass and Sheet Metal Handling Warning .

| 1. |

Disable the SIR system. Refer to

SIR Disabling and Enabling

.

|

|

| 2. |

Disconnect the negative battery cable. Refer to

Battery Negative Cable Disconnection and Connection

.

|

|

| 3. |

Visually inspect the damage. Repair as much of the damage as possible.

|

|

| 4. |

Remove the sealers and anti-corrosion materials from the repair area, as necessary. Refer to

Anti-Corrosion Treatment and Repair (Base)

Anti-Corrosion Treatment and Repair (Corrosion Protection)

.

|

|

| 5. |

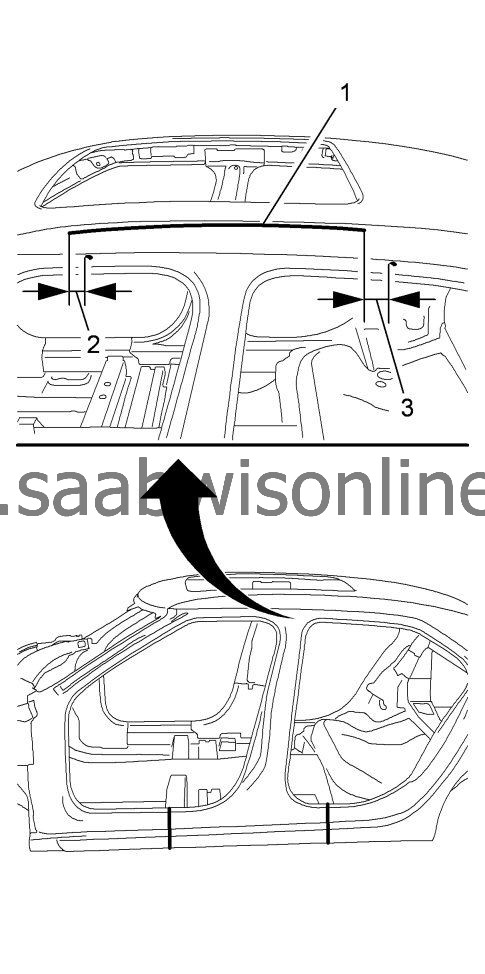

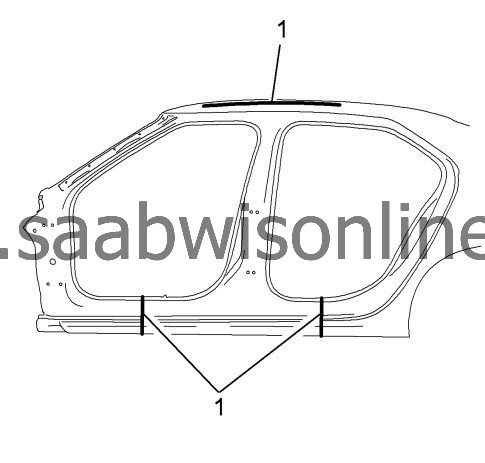

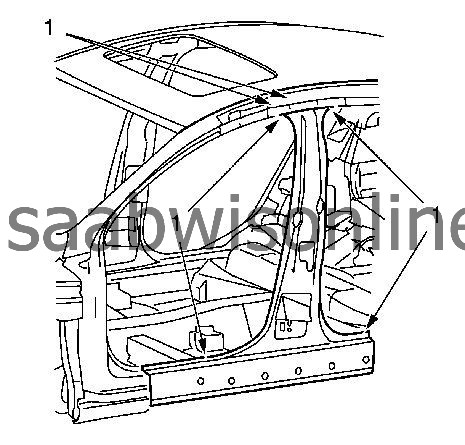

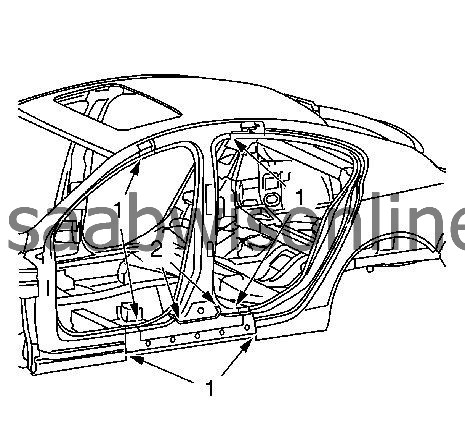

Create cut lines on the body lock pillar outer panel.

|

|||||||

| 6. |

Create cut line

10 mm (0.4 in)

on the upper front side panel (1).

|

|

| 7. |

Cut 80 mm in front of the luggage carrier side rail front support reinforcement and 150 mm in front of the luggage carrier side rail rear support reinforcement.

|

|

| 8. |

Cut out the body lock pillar outer panel roughly.

|

|

| 9. |

Locate and drill out all of the necessary factory welds.

|

|

| 10. |

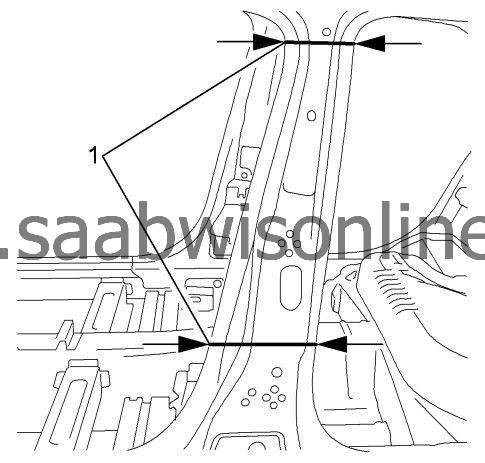

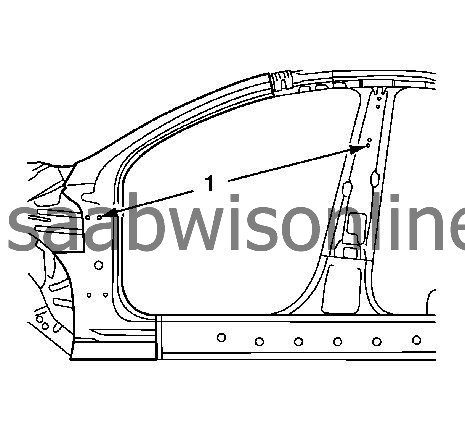

Create cut lines on the body lock pillar outer panel reinforcement (1).

|

|||||||

| 11. |

Cut out the body lock pillar outer panel reinforcement roughly.

|

|

| 12. |

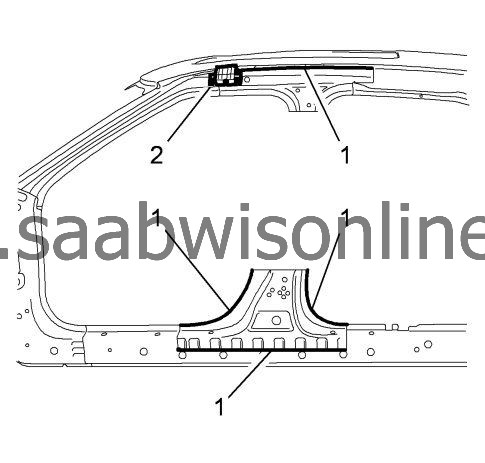

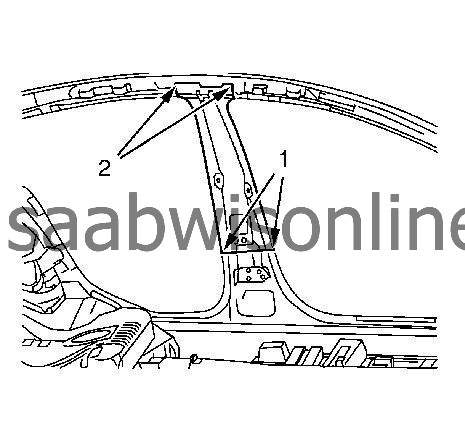

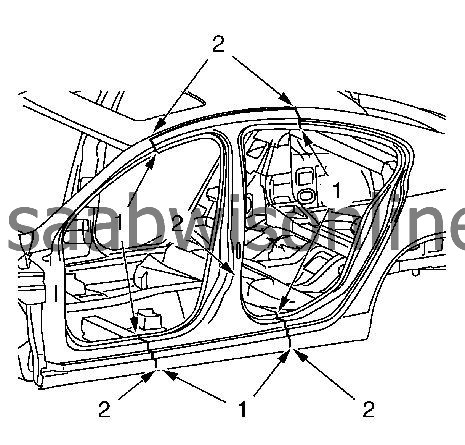

Drill out the necessary factory welds (1).

|

|||||||

| 13. |

Remove the luggage carrier side rail front support reinforcement (2). Refer to

Luggage Carrier Side Rail Front Support Reinforcement Replacement

.

|

|||||||

| 14. |

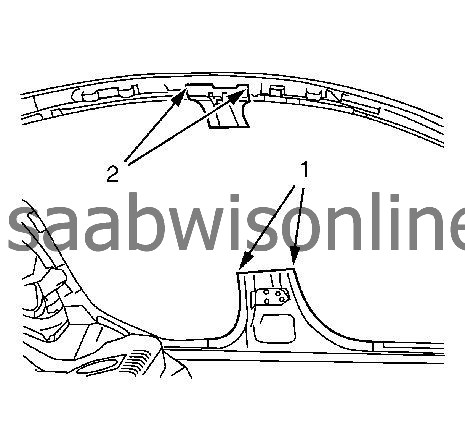

Drill out the necessary factory welds (1) on the center pillar inner panel lower reinforcement.

|

|

| 15. |

Drill out the necessary factory welds (2) on the center pillar inner panel.

|

|

| 16. |

Remove the damaged body lock pillar outer panel reinforcement.

|

|

| Installation Procedure |

| 1. |

Create cut lines on the body lock pillar outer panel (1).

|

|||||||

| 2. |

Cut the body lock pillar outer panel in corresponding locations to fit the original panel. The sectioning joint should be trimmed to allow min. 1 times the metal thickness at the sectioning joint.

|

|

| 3. |

Prepare new body lock pillar outer panel in the area (1).

1 x slots (5 x 18 mm / 0.2 x 0.7 in) |

|

| 4. |

Prepare new body center pillar inner panel in the area (1).

14 x slots (8 x 24 mm / 0.3 x 0.9 in)

|

|

| 5. |

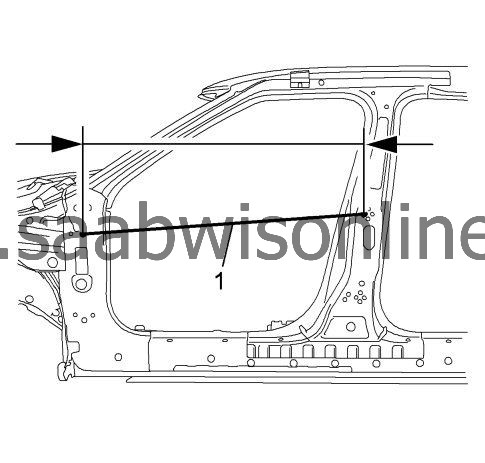

Position and measure (1) from the front hinge pillar body to the center pillar inner panel

1191 mm (48.9 in)

on to the vehicle.

|

|

| 6. |

Verify the fit of the center pillar inner panel.

|

|

| 7. |

Clamp the center pillar inner panel into position.

|

|

| 8. |

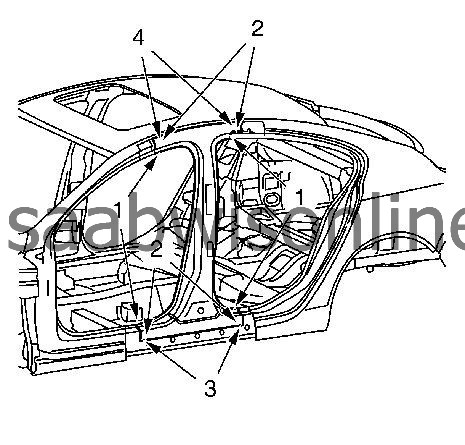

Spot weld the center pillar inner panel (1) accordingly.

|

|||||||

| 9. |

MIG-braze the center pillar inner panel (2).

|

|

| 10. |

Grind MIG brazed seams.

|

|

| 11. |

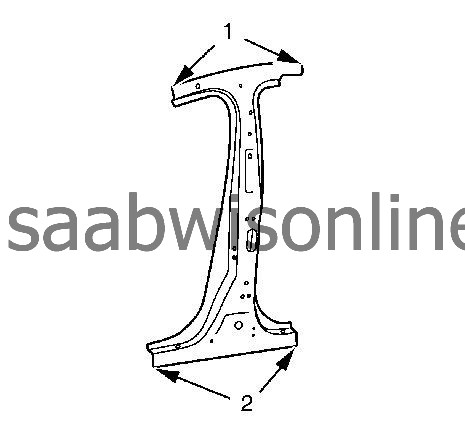

Prepare new body lock pillar outer panel reinforcement in the area (1).

Drill out the necessary slots. 9 x slots (8 x 24 mm / 0.3 x 0.9 in)

|

|

| 12. |

Prepare new body lock pillar outer panel reinforcement in the area (2).

9 x slots (8 x 24 mm / 0.3 x 0.9 in) |

|

| 13. |

Clean and prepare the attaching surfaces for welding.

|

|

| 14. |

Apply bodywork repair through structural adhesive to body (1). Refer to

Structural Adhesive Body Repairs

.

|

|

| 15. |

Position and measure (1) from the front hinge pillar body to the rear hinge pillar body

1090 mm (43 in)

on to the vehicle.

|

|

| 16. |

Verify the fit of the body lock pillar outer panel reinforcement.

|

|

| 17. |

Clamp the body lock pillar outer panel reinforcement into position.

|

|

| 18. |

Spot tack-weld the body lock pillar outer panel reinforcement (1).

|

|||||||

| 19. |

MIG-braze the body lock pillar outer panel reinforcement (2).

|

|

| 20. |

MIG-braze full seam interrupted 9 times

30 mm (1.2 in)

the body lock pillar outer panel reinforcement (3).

|

|

| 21. |

MIG-braze full seam interrupted 5 times

30 mm (1.2 in)

the body lock pillar outer panel reinforcement (4).

|

|

| 22. |

Grind MIG-brazed seams.

|

|

| 23. |

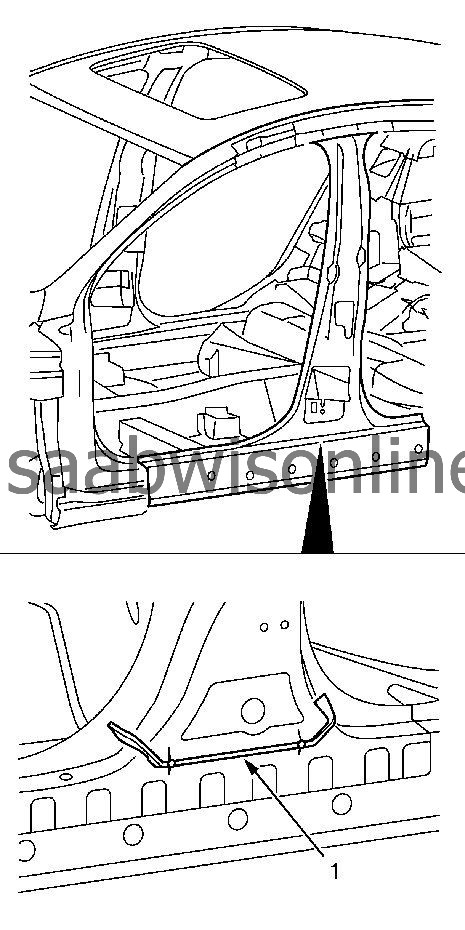

Install the sound deadener (1).

|

|

| 24. |

Install the luggage carrier side rail front support reinforcement. Refer to

Luggage Carrier Side Rail Front Support Reinforcement Replacement

.

|

|

| 25. |

Clean and prepare the attaching surfaces for welding.

|

|

| 26. |

Apply bodywork repair through structural adhesive to body (1). Refer to

Structural Adhesive Body Repairs

.

|

|

| 27. |

Apply 1K-Adhesive bead on the sound deadener (2). Refer to

Chemical Products

.

|

|

| 28. |

Position the body lock pillar outer panel on the vehicle.

|

|

| 29. |

Verify the fit of the roof outer panel.

|

|

| 30. |

Clamp the body lock pillar outer panel into position.

|

|

| 31. |

Spot weld the body lock pillar outer panel (1) accordingly.

|

|||||||

| 32. |

MIG-braze the body lock pillar outer panel (2).

|

|

| 33. |

Grind MIG brazed seams.

|

|

| 34. |

Apply the sealers and anti-corrosion materials to the repair area, as necessary. Refer to

Anti-Corrosion Treatment and Repair (Base)

Anti-Corrosion Treatment and Repair (Corrosion Protection)

.

|

|

| 35. |

Connect the negative battery cable. Refer to

Battery Negative Cable Disconnection and Connection

.

|

|

| 36. |

Enable the SIR system. Refer to

SIR Disabling and Enabling

.

|

|