Poor performance

Symptom of fault

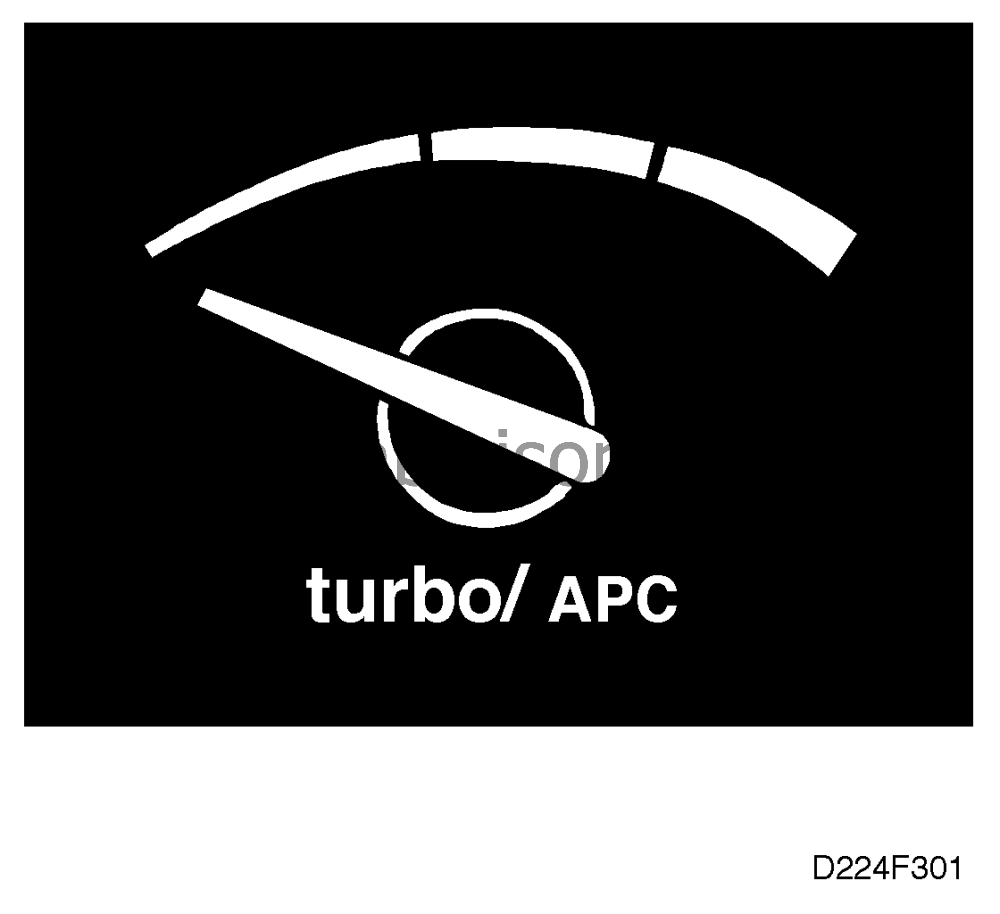

Weak engine. The turbo/APC gauge gives a low reading.

Conditions

No diagnostic trouble codes.

Diagnostic help

|

Note

|

|

Boost pressure on cars with a manual gearbox is limited in reverse, 1st and 2nd gears.

|

|

-

|

If necessary, carry out adjustment

in MIU 2 (main instrument display panel 2) by means of an ISAT scan

tool.

|

The APC valve can be activated with the ISAT scan tool.

|

-

|

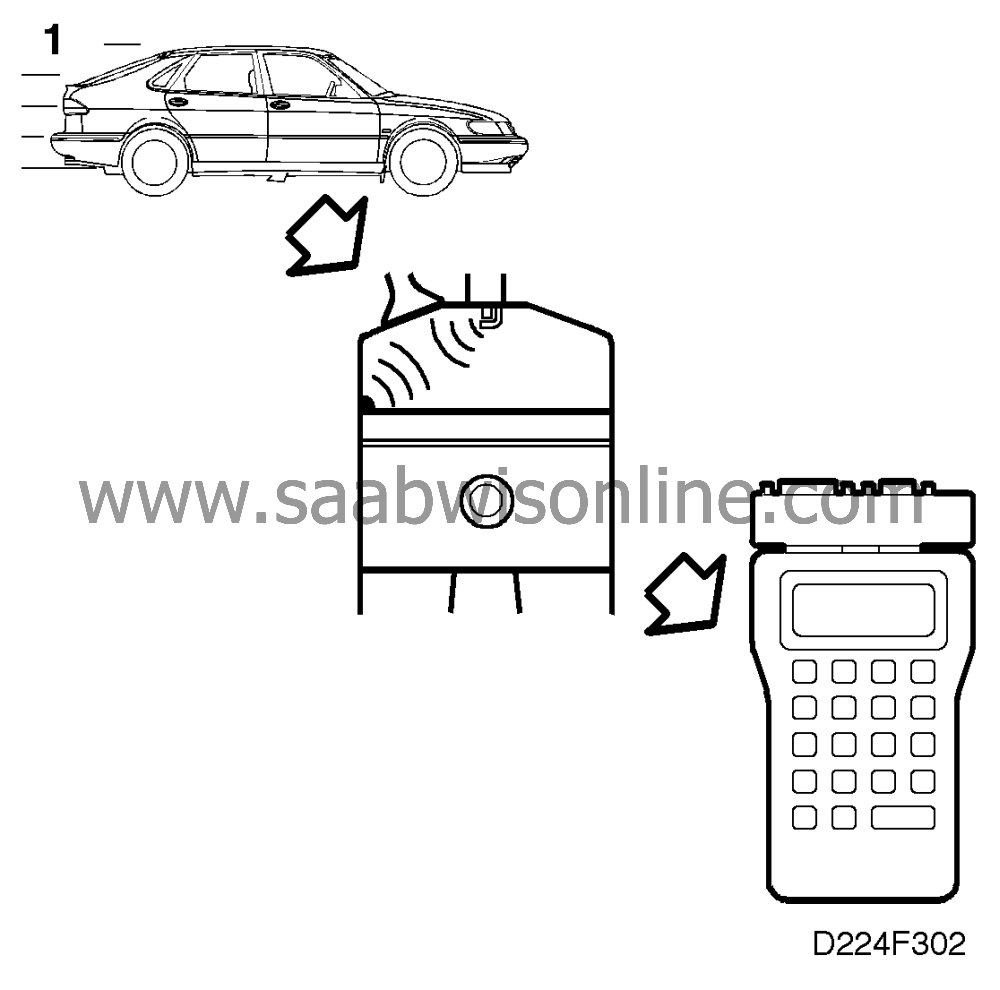

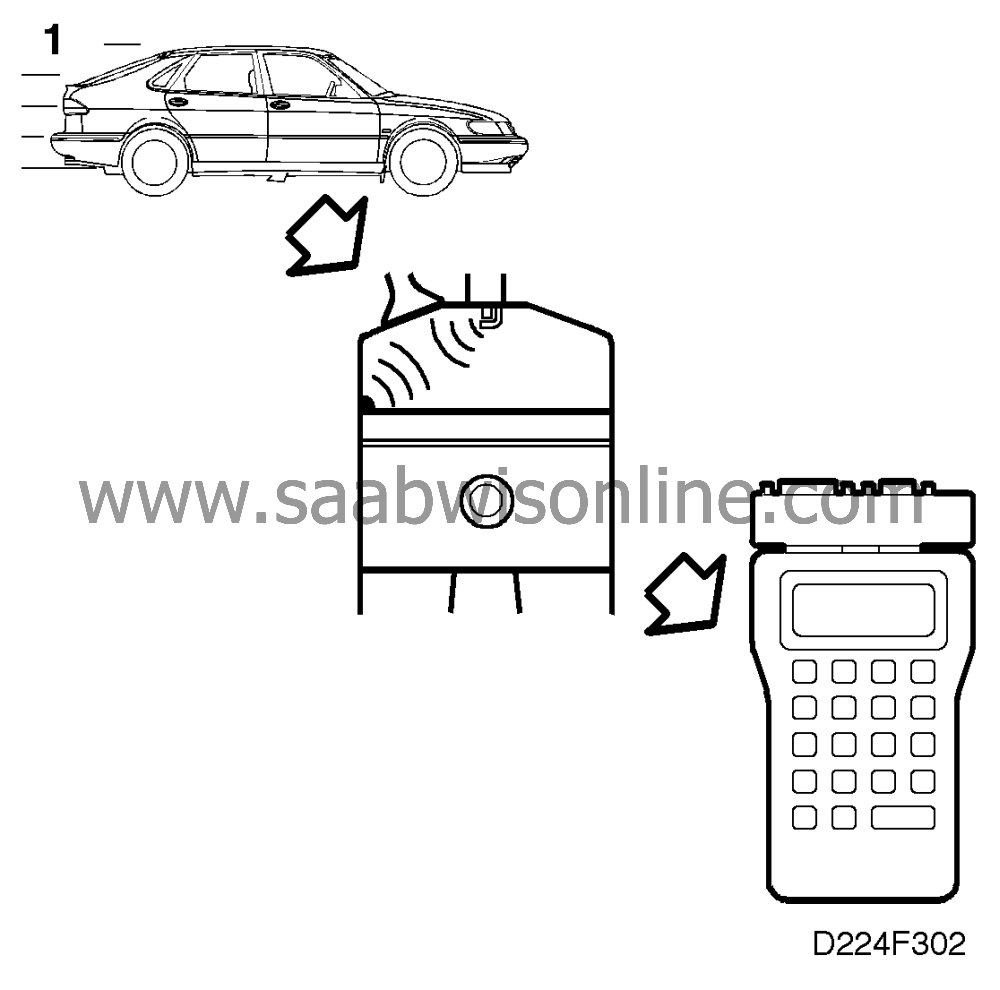

Connect an ISAT scan

tool.

|

|

-

|

Select

"BOOST PRESS. VALVE".

|

Checking the wiring.

Intermittent faults may

occur as a result of occasional short circuits and breaks in the wiring. Jiggle the leads and in-

line connectors at several places and in different directions to reveal faults in the wiring

harness. Observe the multimeter, ISAT scan tool or test lamp while carrying out this check.

Diagnostic procedure

1. Investigate the cause of basic boost pressure

If the control module initiates basic boost pressure for any reason, there may be

many reasons for this.

|

-

|

Select

"READ FUNCTIONS".

|

|

-

|

Select

"BASIC CHARGE PRESS.

|

When the car is driven at wide open throttle the ISAT scan tool will show the

cause of the fault.

Does the ISAT scan tool shown "BOOST PRESSURE"?

Continue with point 2.

The ISAT scan tool shows "KNOCK CONTROL" as the cause of the fault. The

trouble could be due to a poor grade of fuel or a defective ignition discharge module.

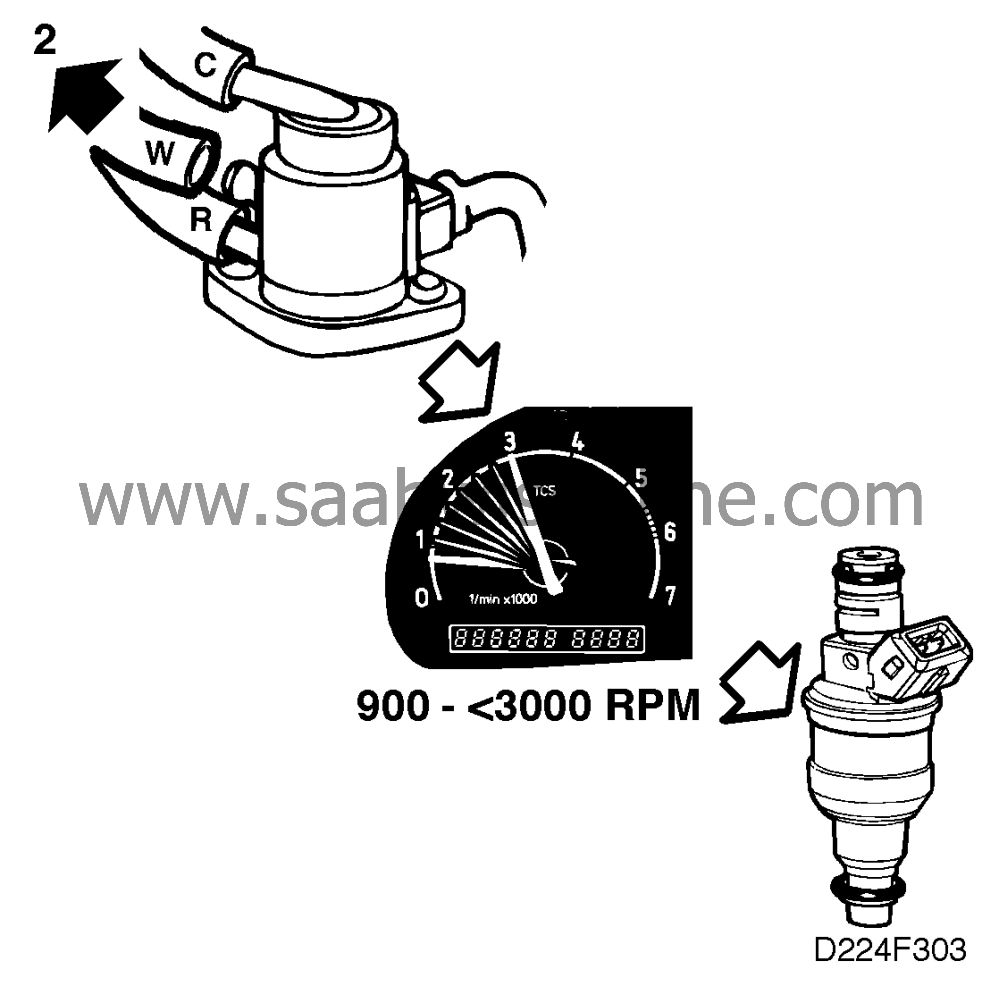

2. Investigate the cause of the fault

In the following it will be determined whether the fault is a control fault or a basic

engine/turbo fault.

|

-

|

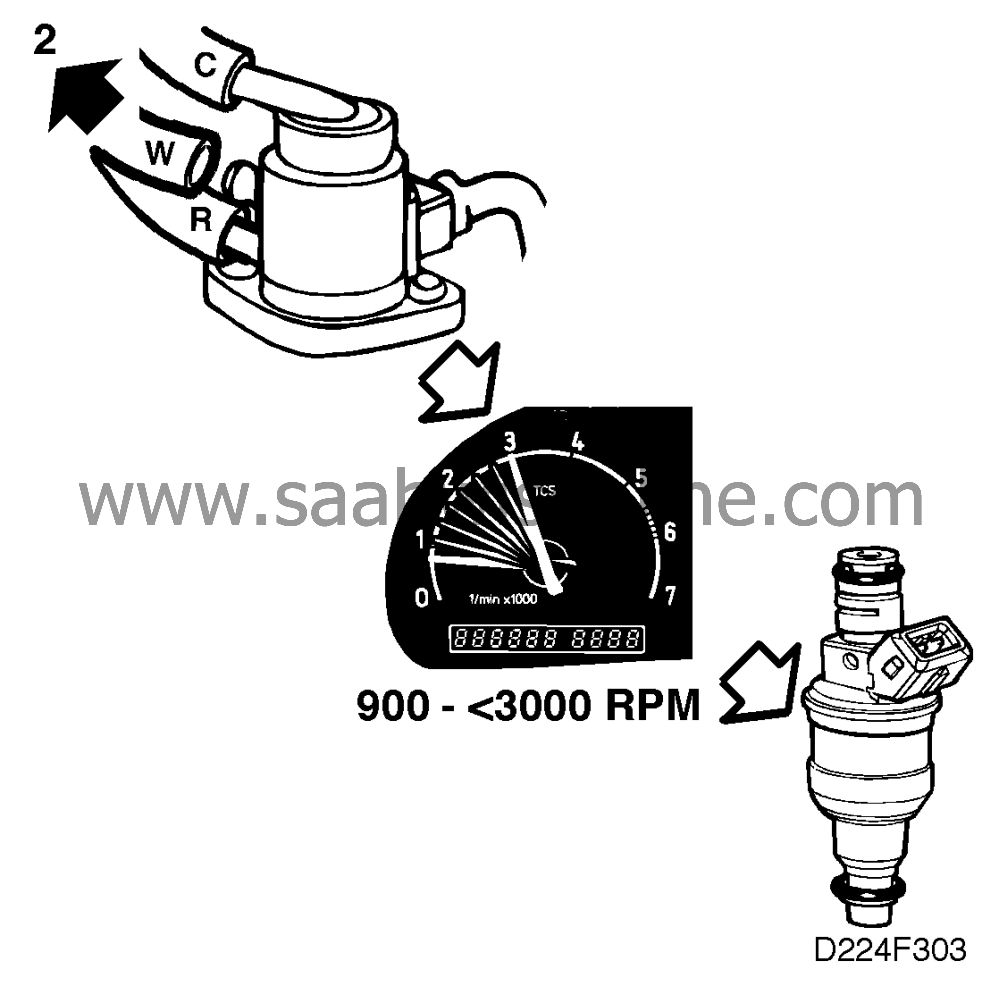

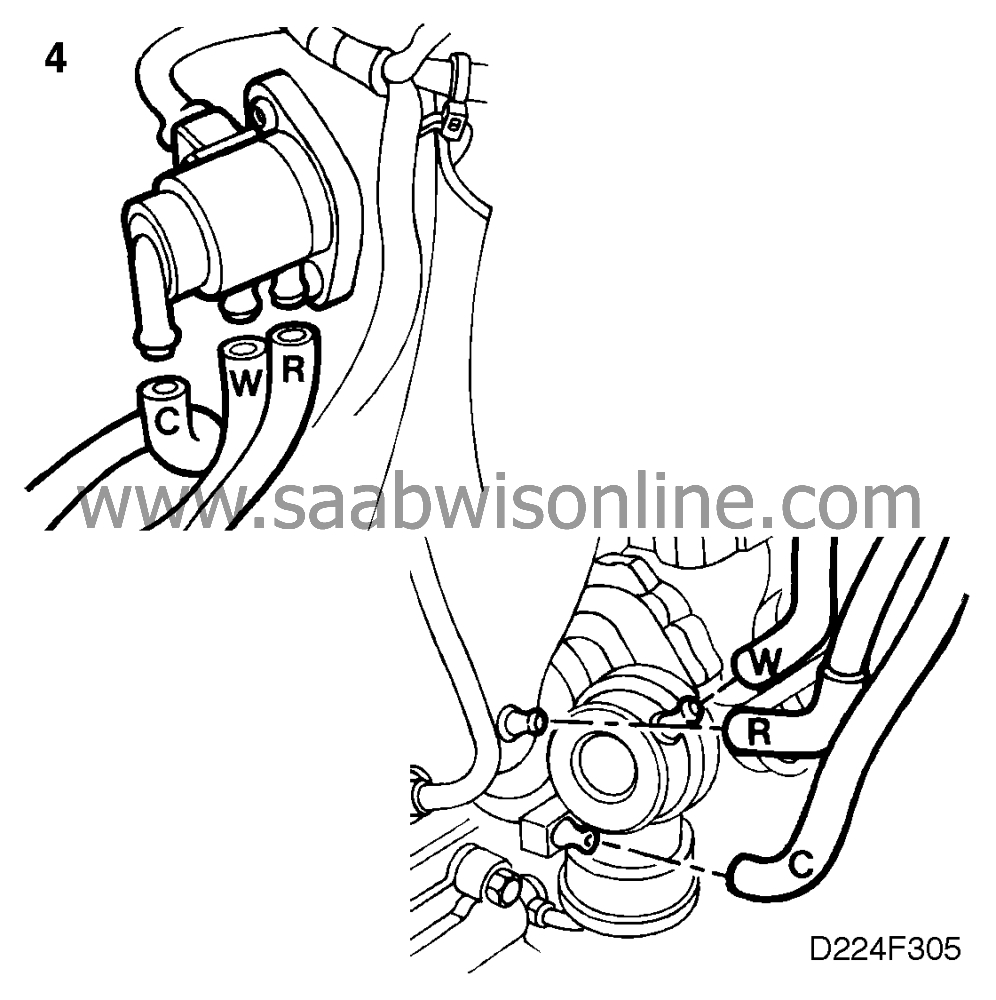

Disconnect the air hose marked

"W" from the boost pressure control valve, checking at the same time that it is connected to

the wastegate.

|

When accelerating at wide open throttle from low engine revs, the pressure

switch should open before 3000 rpm.

Does the switch open?

Continue with point 3.

Check and, if necessary, rectify the following:

|

•

|

Leakage in the intake system

between the turbo unit and throttle body (in the bypass valve, for instance).

|

|

•

|

Incorrectly adjusted basic boost pressure.

|

|

•

|

Clogged exhaust system.

|

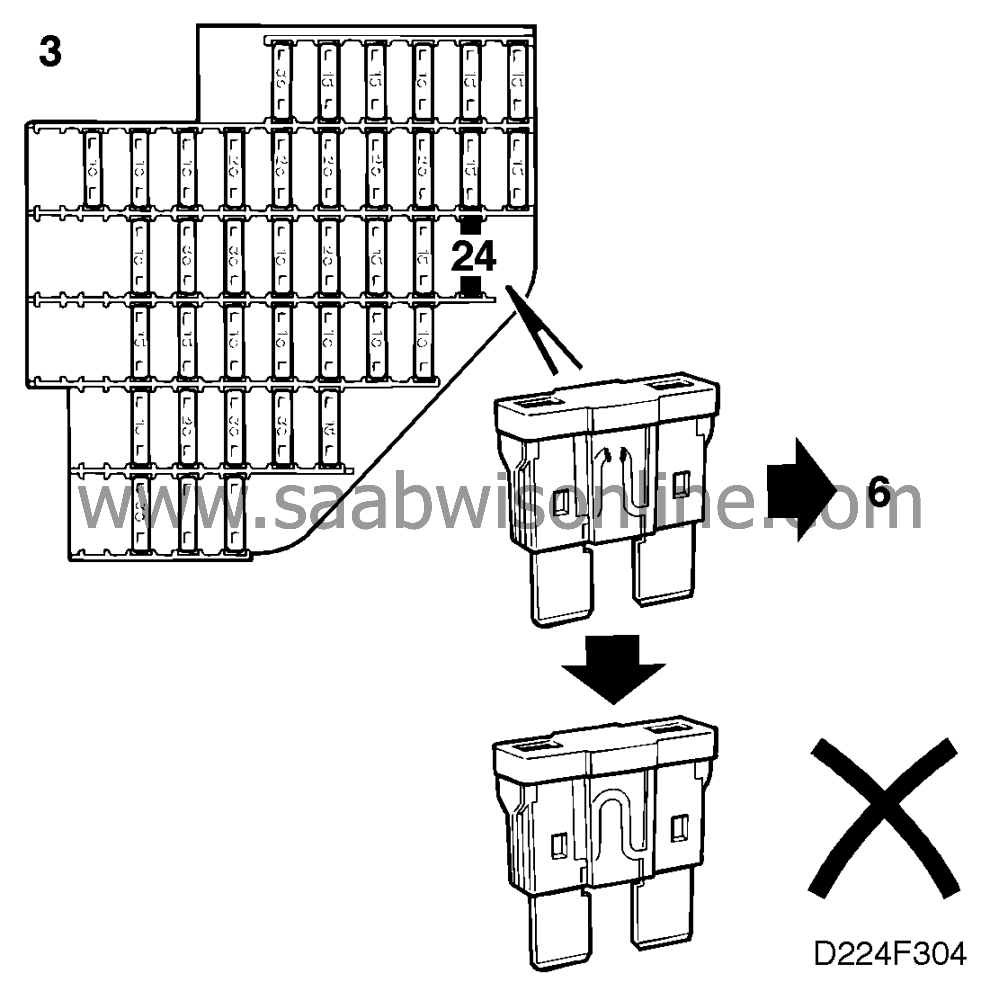

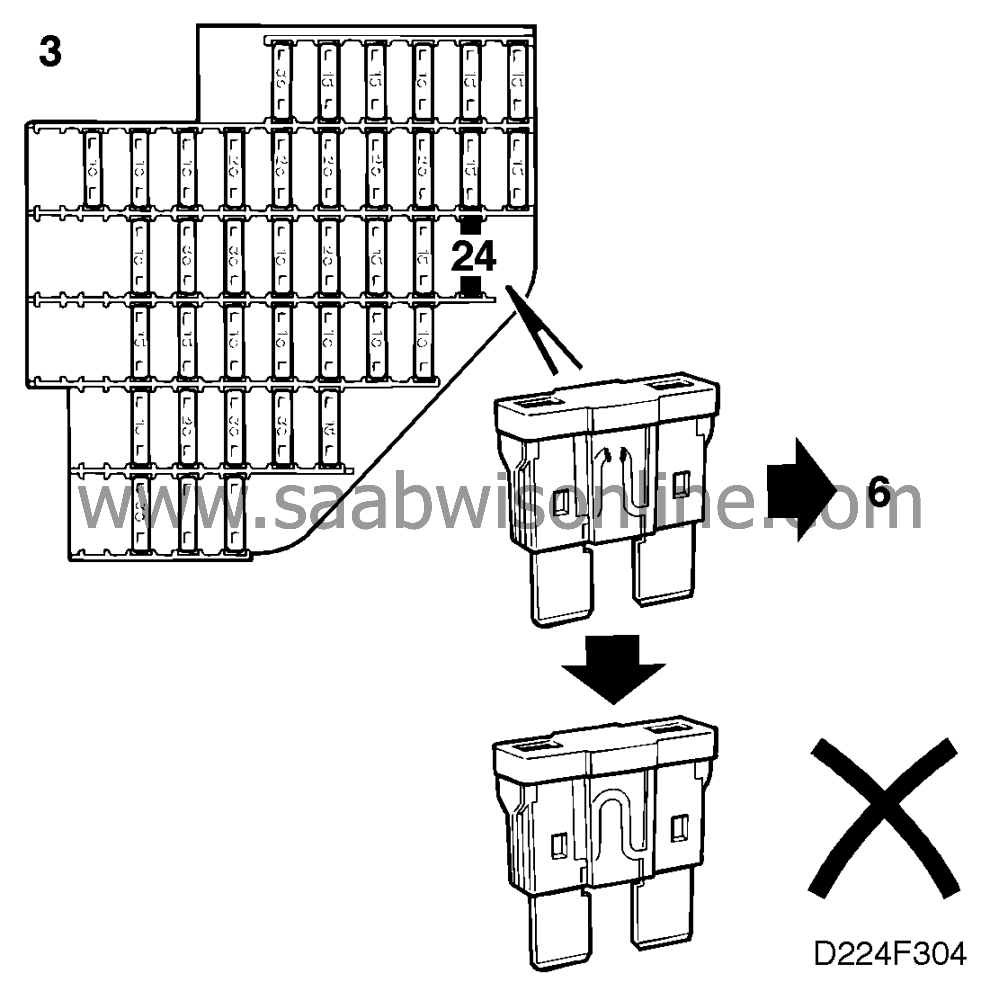

3. Check fuse 24

Is the fuse OK?

Continue with point 4.

Continue with point 6.

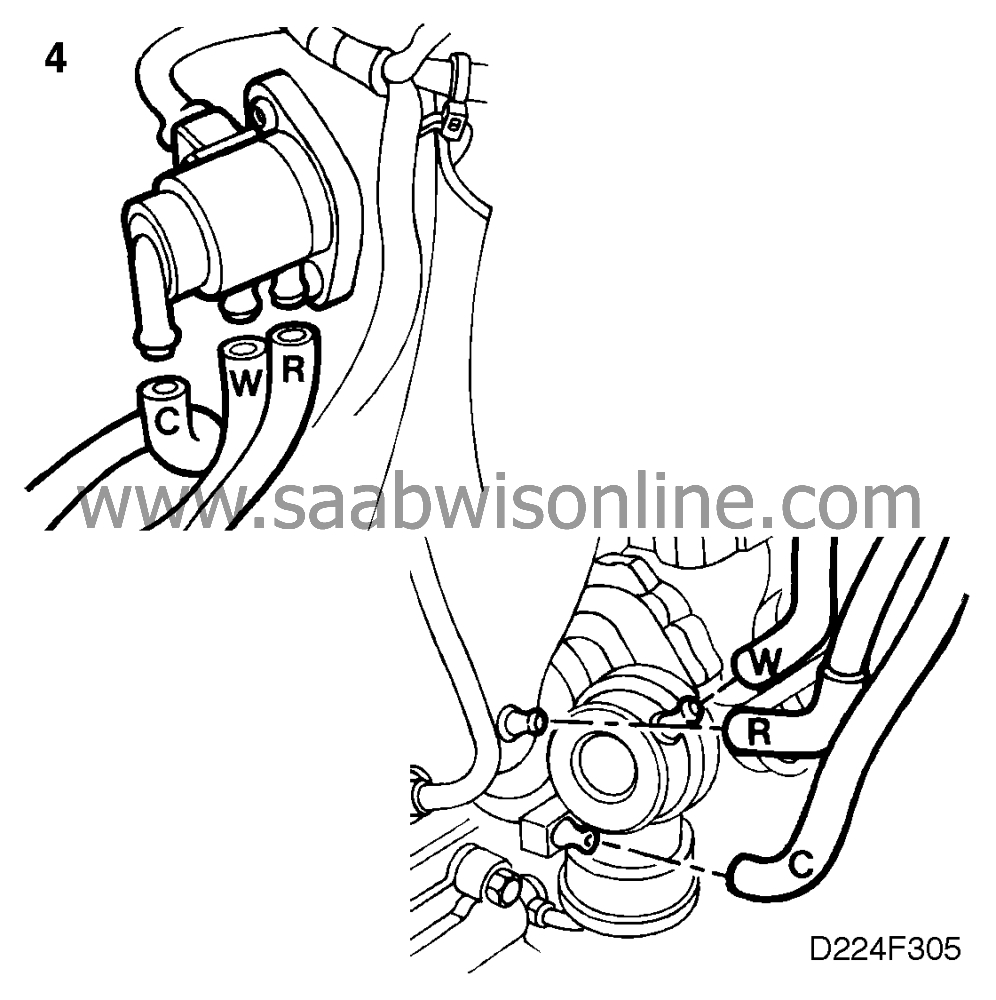

4. Check the air hoses

Inspect the valve's three control hoses, making sure that they are in good

condition and correctly connected.

Are the air hoses OK?

Continue with point 5.

Rectify any fault discovered.

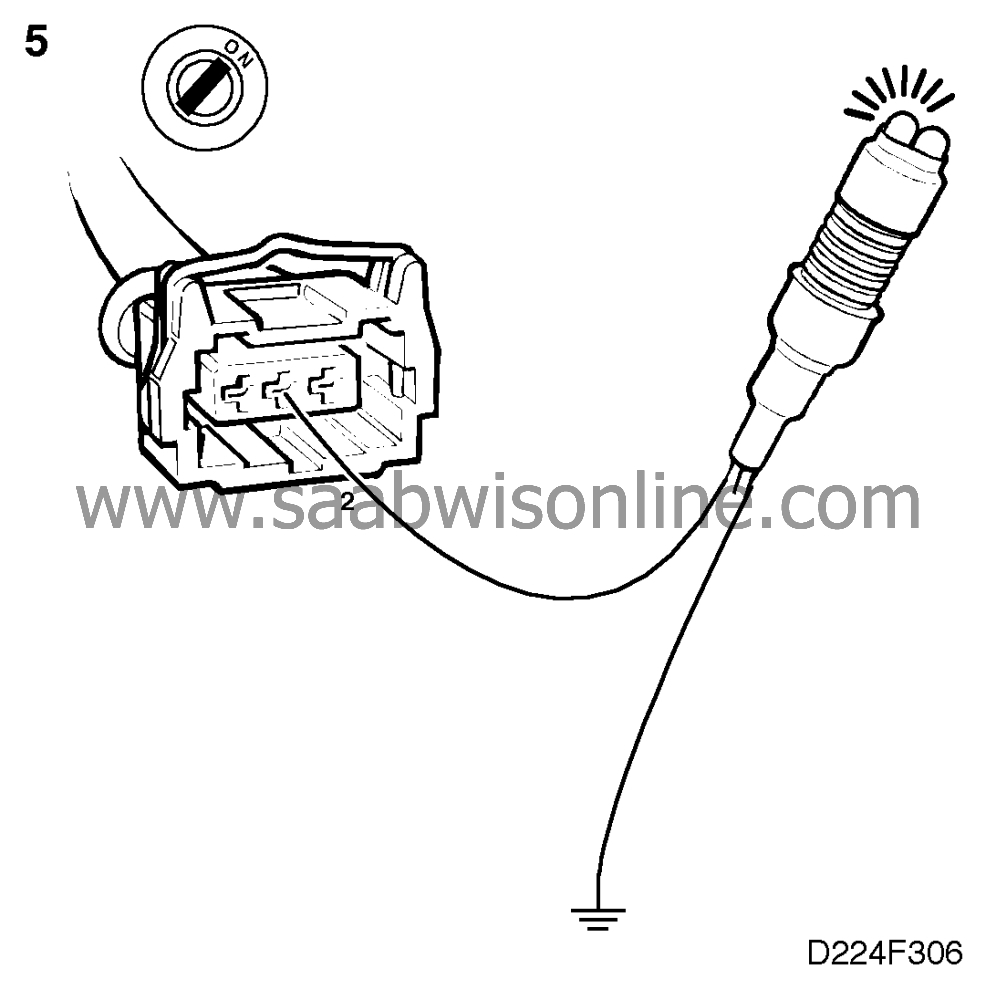

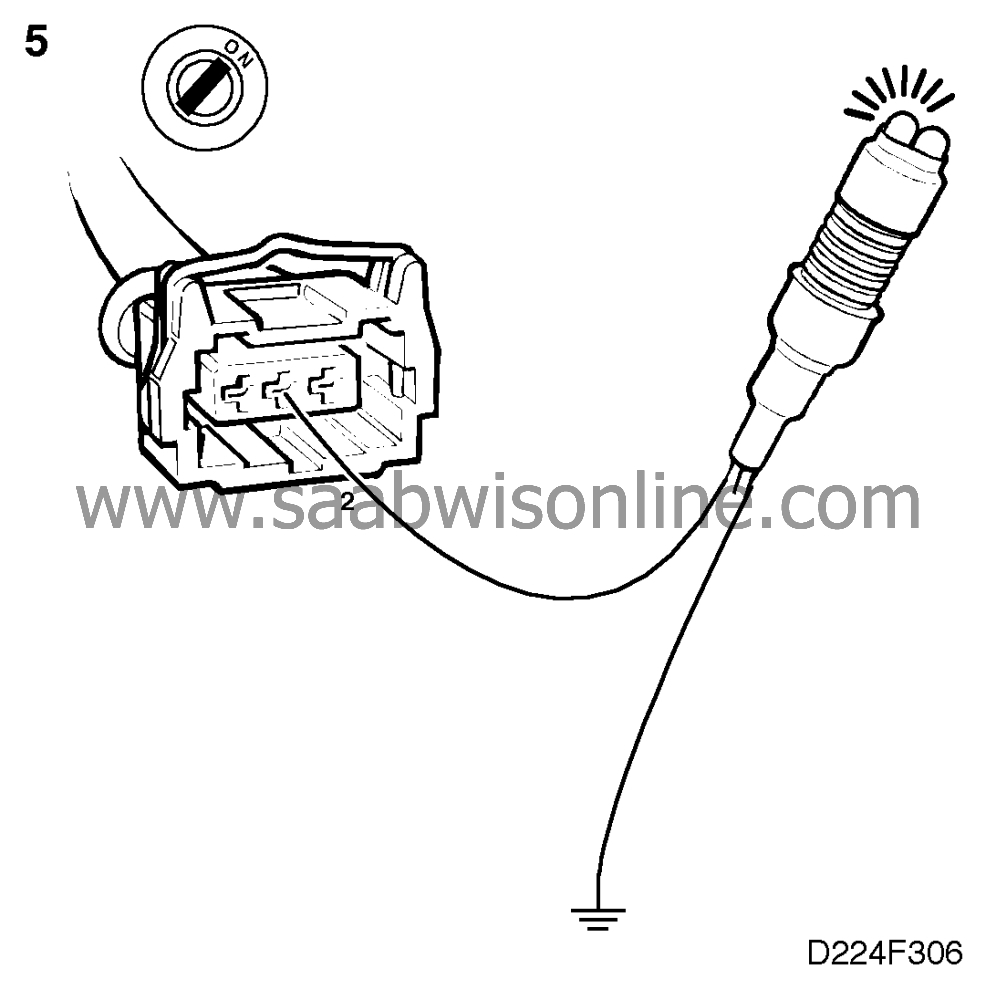

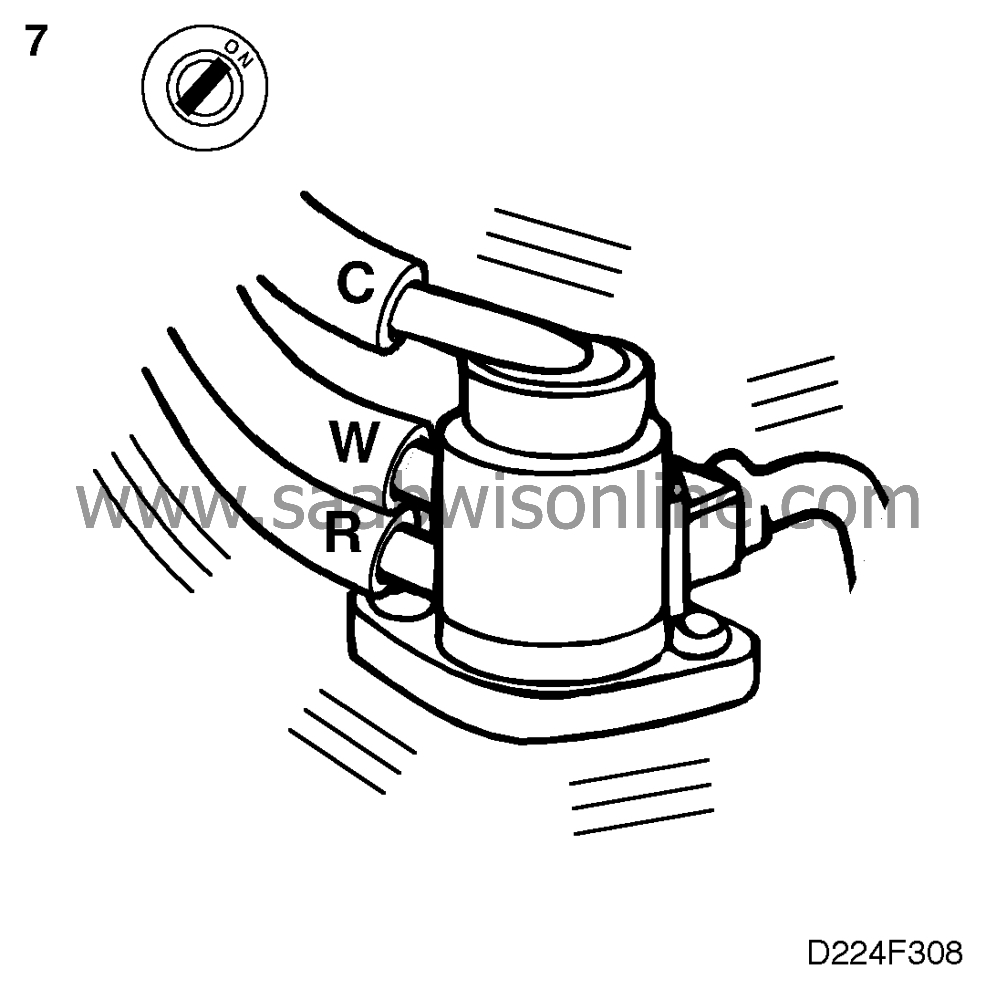

5. Check the power supply

|

-

|

Ignition switch in ON position.

|

|

-

|

Check that the valve is supplied

with power (+54 circuit) by connecting a test lamp to pin 2 of the valve's connector and

a good grounding point.

|

The test lamp should light up.

Is the test lamp on?

Continue with point 6.

Repair or replace the lead between pin 2 of the connector and fuse 24.

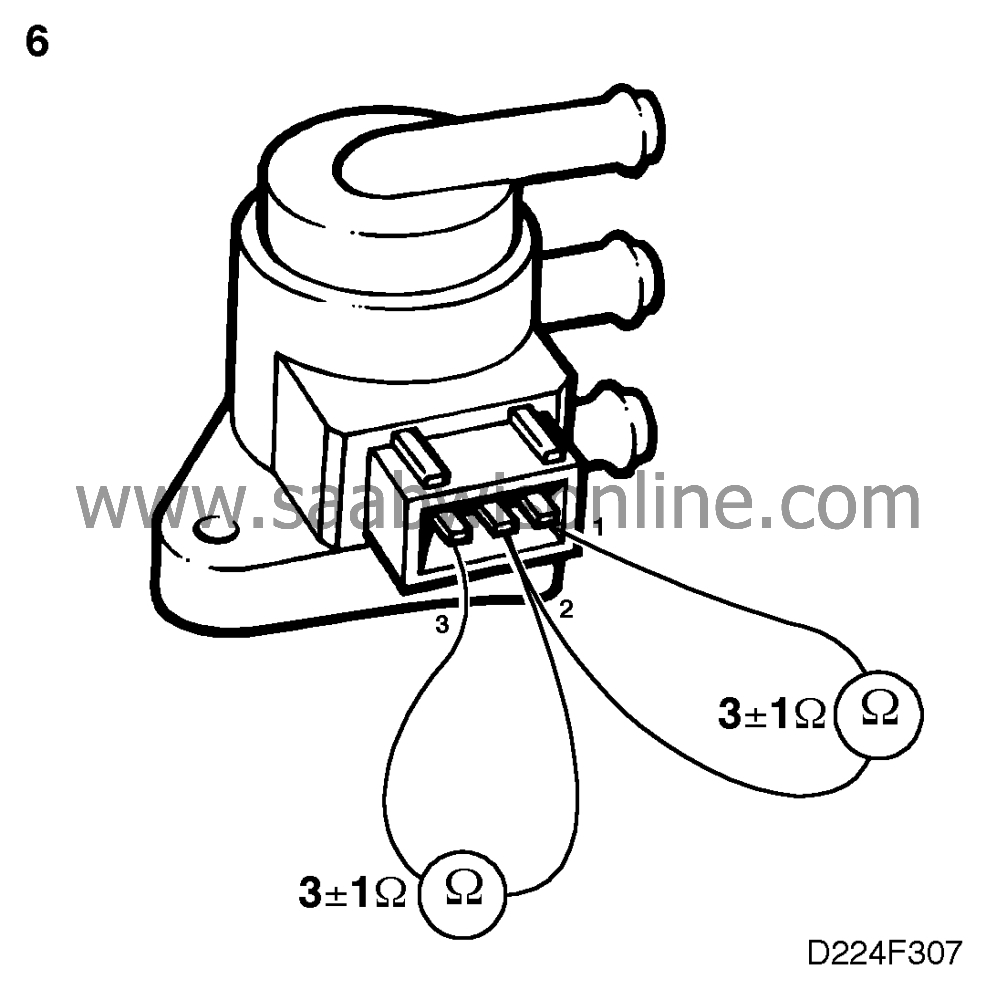

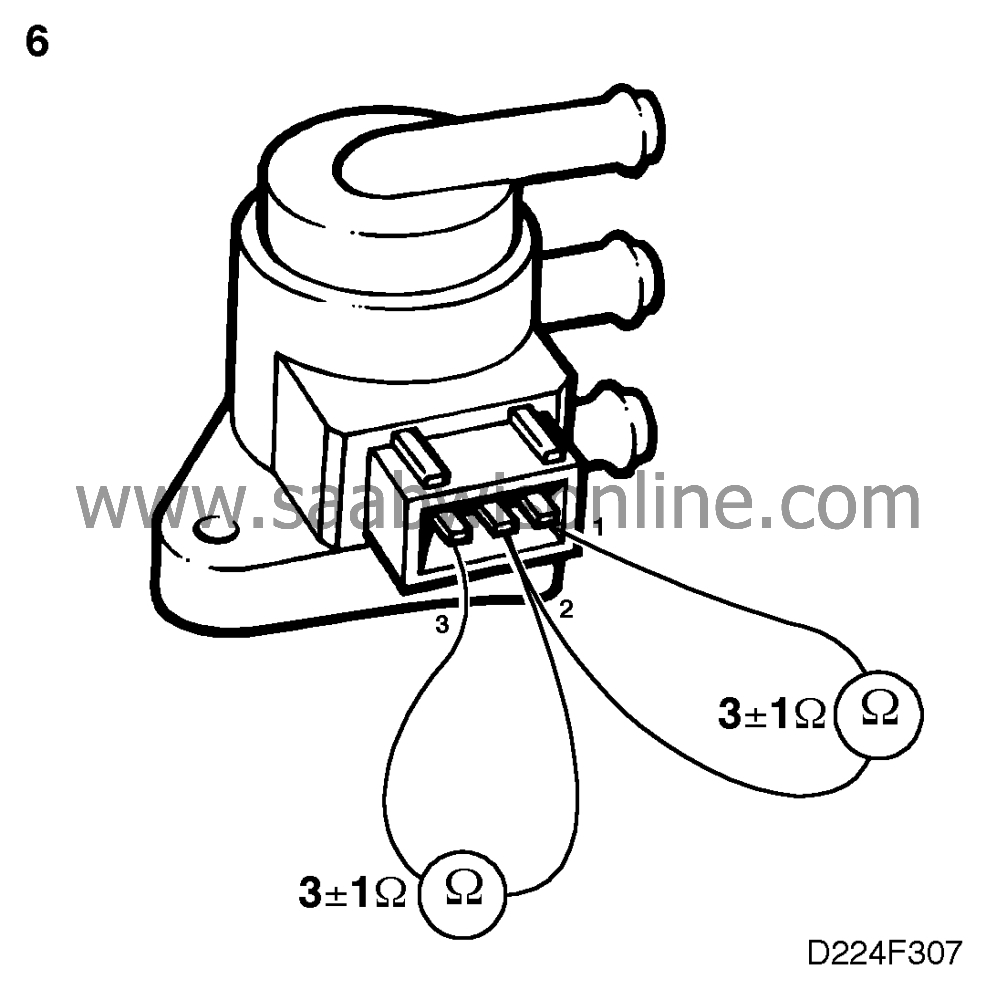

6. Check the resistance of the valve

|

-

|

Take resistance readings in the

valve's connector across:

|

Nominal resistance is 3±1 ohms in both cases.

Are the readings OK?

Continue with point 7.

Change the boost pressure control valve.

|

Important

|

|

If there is a short circuit in any winding the control module will probably also be

damaged. If a new valve is then fitted, it will inevitably be rendered unserviceable. In the event

of a short circuit, both valve and control module must therefore be changed at the same

time.

|

|

|

If necessary, change fuse 24 afterwards.

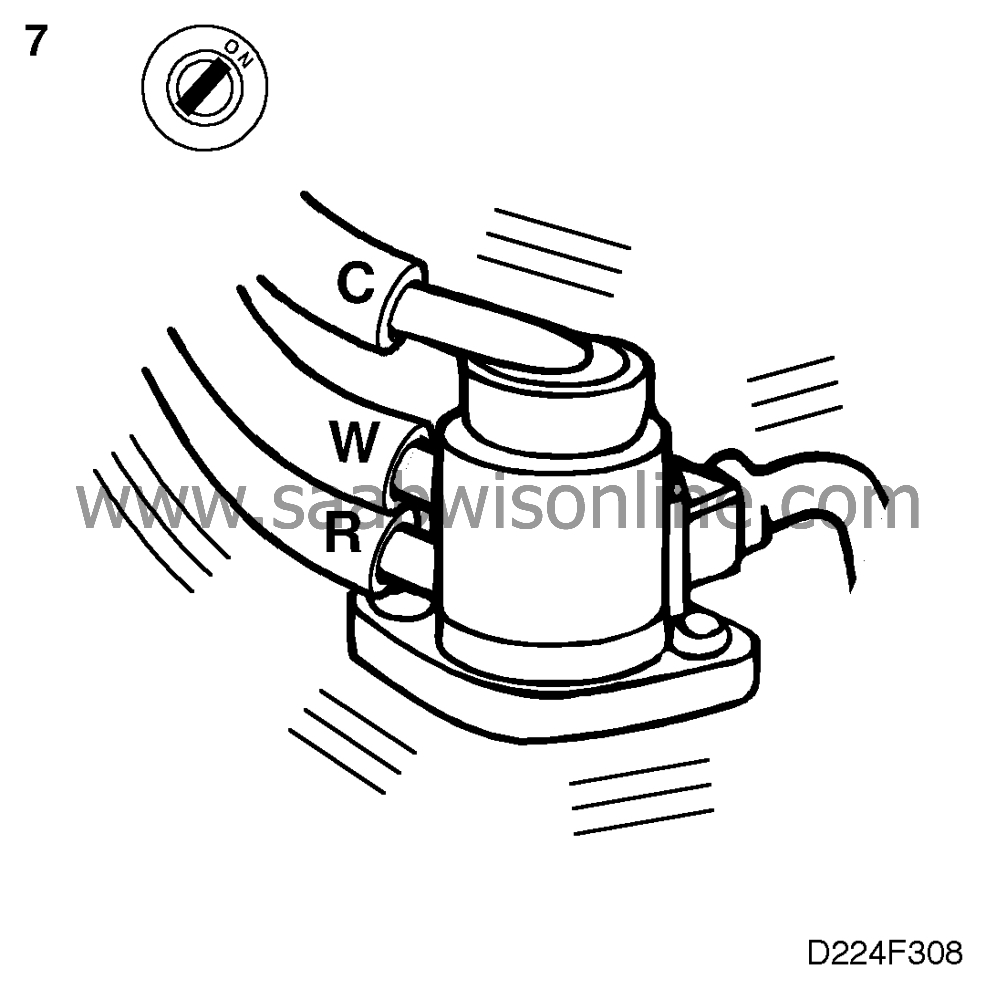

7. Check the lead connected to pin 3 of the

valve

|

-

|

Ignition switch in ON position.

|

|

-

|

Plug in the valve's

connector. A weak buzzing sound should be heard.

|

Can a sound be heard?

Continue with point 8.

Check the lead between pin 3 of the valve's connector and pin 2 of the

control module. Repair or replace the lead if necessary.

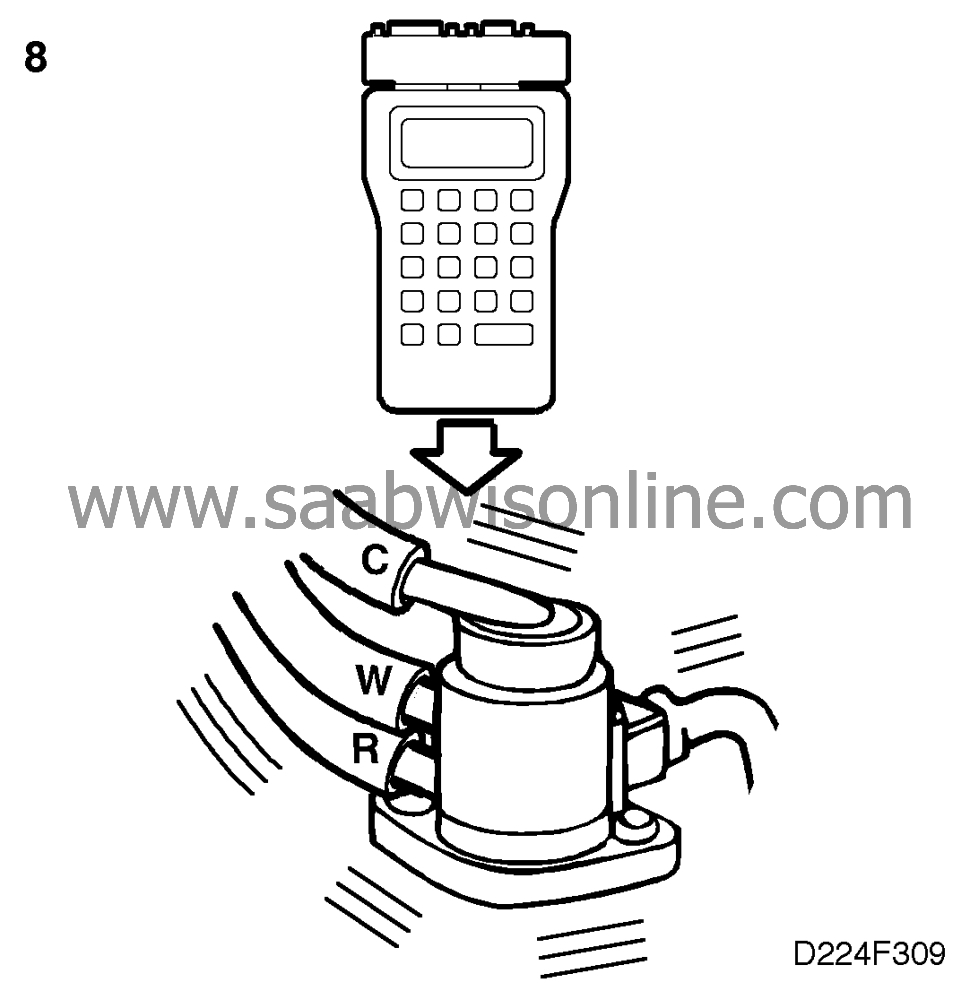

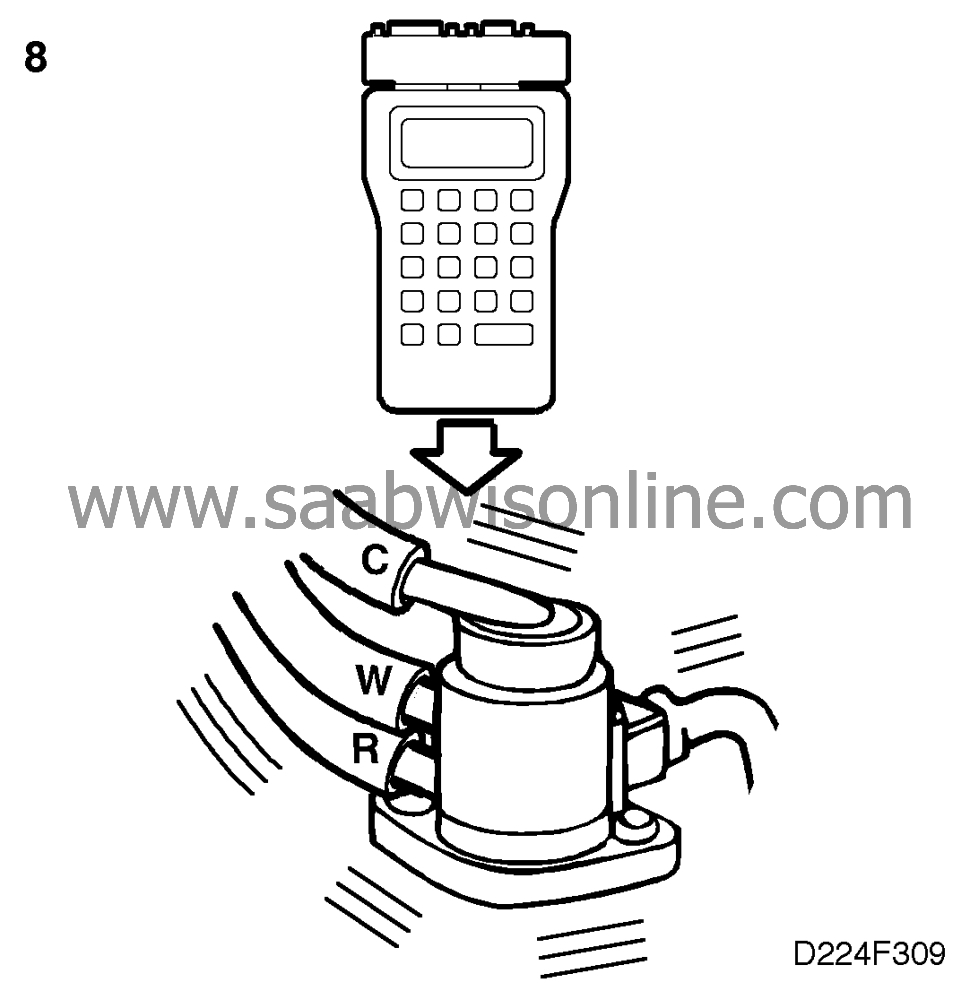

8. Check the lead connected to pin 1 of the

valve

|

-

|

Ignition switch in ON

position.

|

|

-

|

Plug in the valve's

connector.

|

|

-

|

Select

"BOOST PRESS. VALVE".

|

A loud buzzing sound should be heard.

Can a sound be heard?

Change the boost pressure control valve.

Check the lead between pin 1 of the valve's connector and pin 26 of the

control module. Repair or replace the lead if necessary.

9. Check functionality

|

-

|

Drive the car on test and check

whether the fault symptoms persist.

|

Do the fault symptoms persist?

Proceed to

.

.

The remedial measure taken was correct.