Windscreen frame outer panel, CV

|

|

Windscreen frame outer panel, CV

|

Certain welded joints on the car may be MIG brazed with bronze as the filling material. A MIG brazed seam may be recognized from the gold colour of the joint. A MIG brazing must always be replaced by a new MIG brazing.

Warning

Warning

|

|

Repairs to MIG brazing using conventional welding methods and normal filler material are forbidden. Cracks can arise which can impair performance in a collision.

|

|

|

|

|

|

|

1.

|

Position the car in an aligning bench and cross-measure if necessary.

|

|

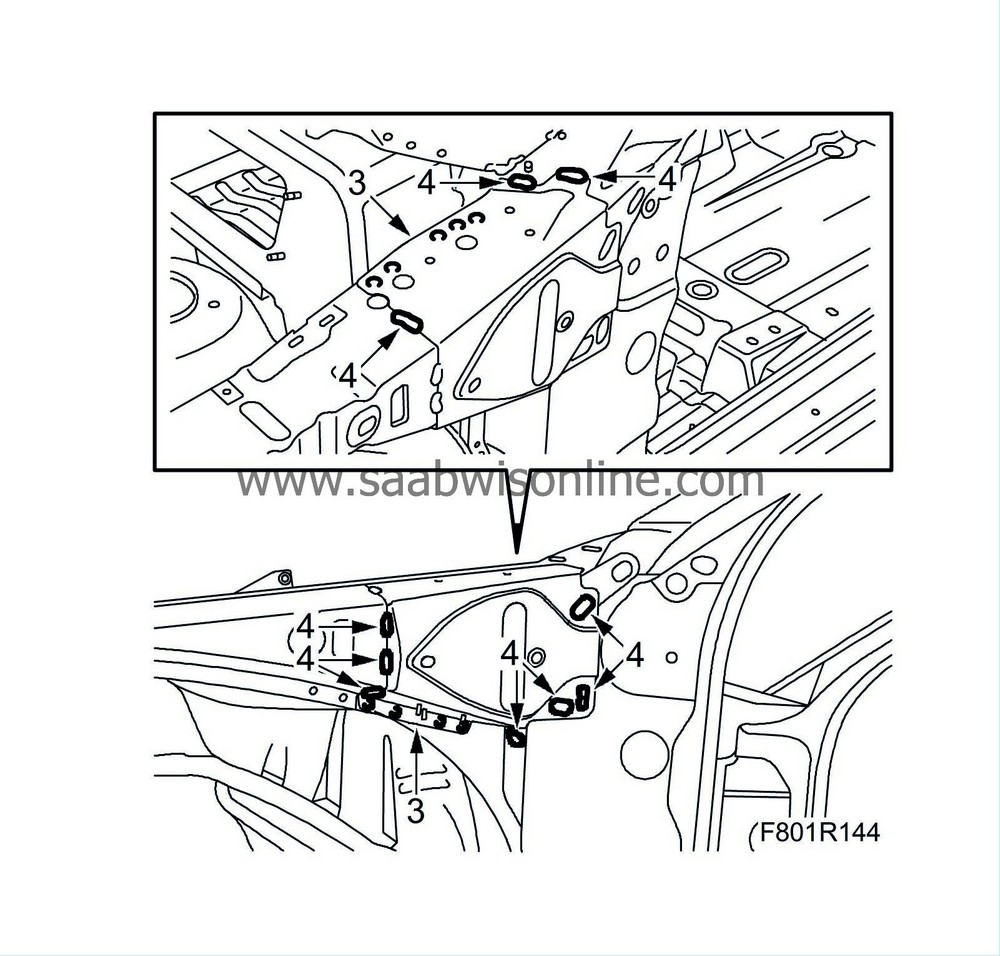

3.

|

Drill out the spot welds as illustrated. Drill out the upper welds only so that the nut piece follows.

|

|

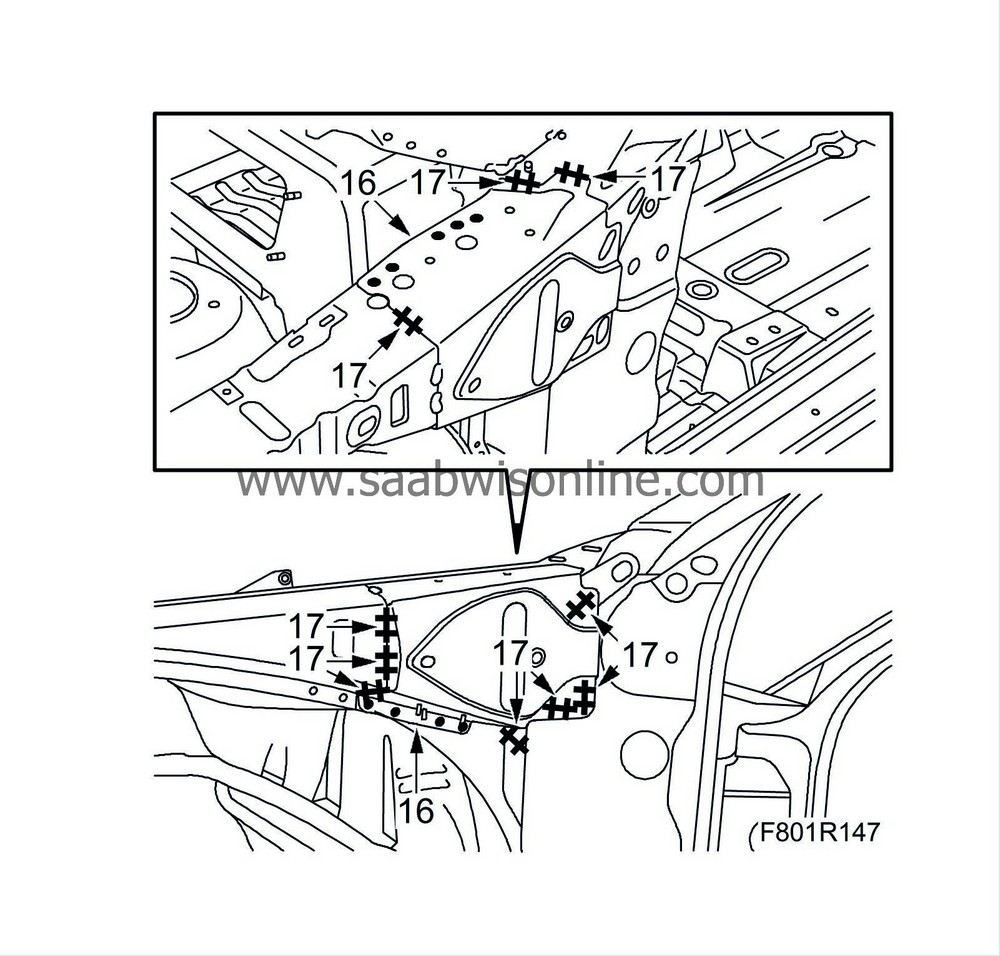

4.

|

Grind down the welds, according to the illustration. Note that the seam welds are MIG brazed.

|

|

5.

|

Tap the reinforcements loose.

|

|

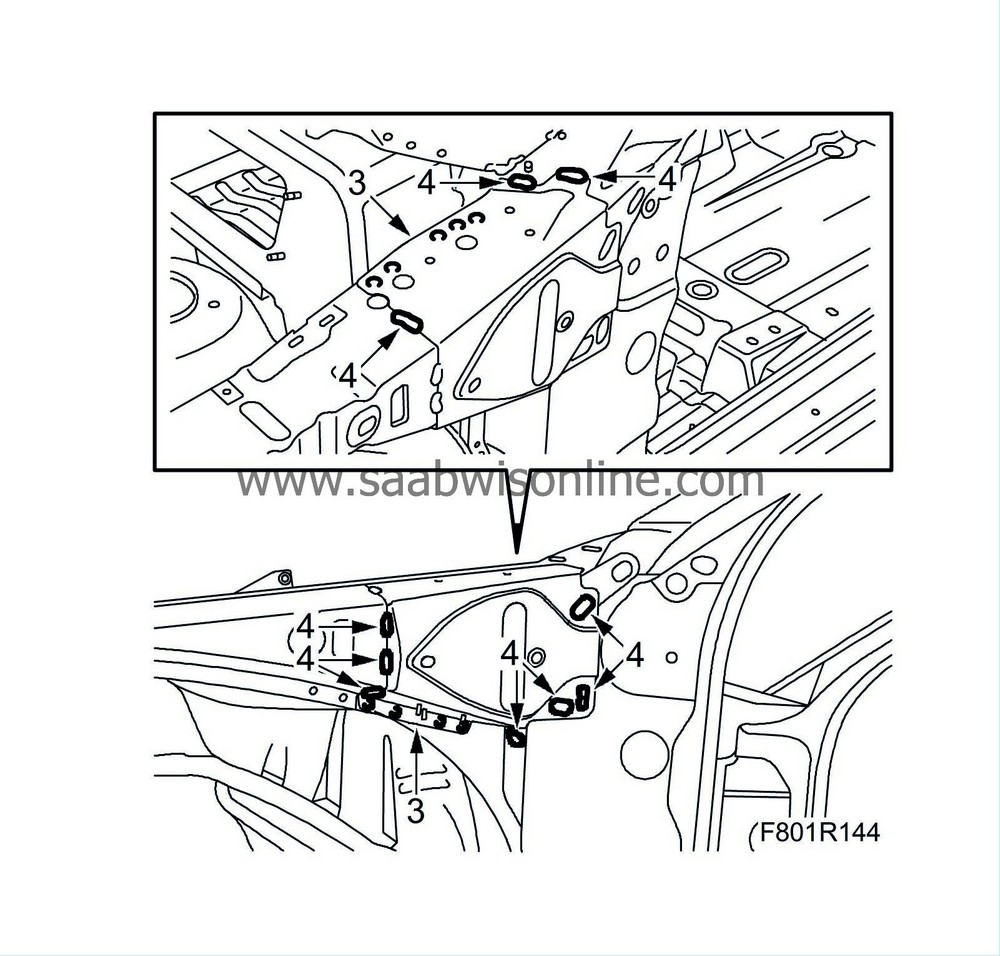

6.

|

Grind down the seam welds as illustrated. Note that the welds are MIG brazed.

|

|

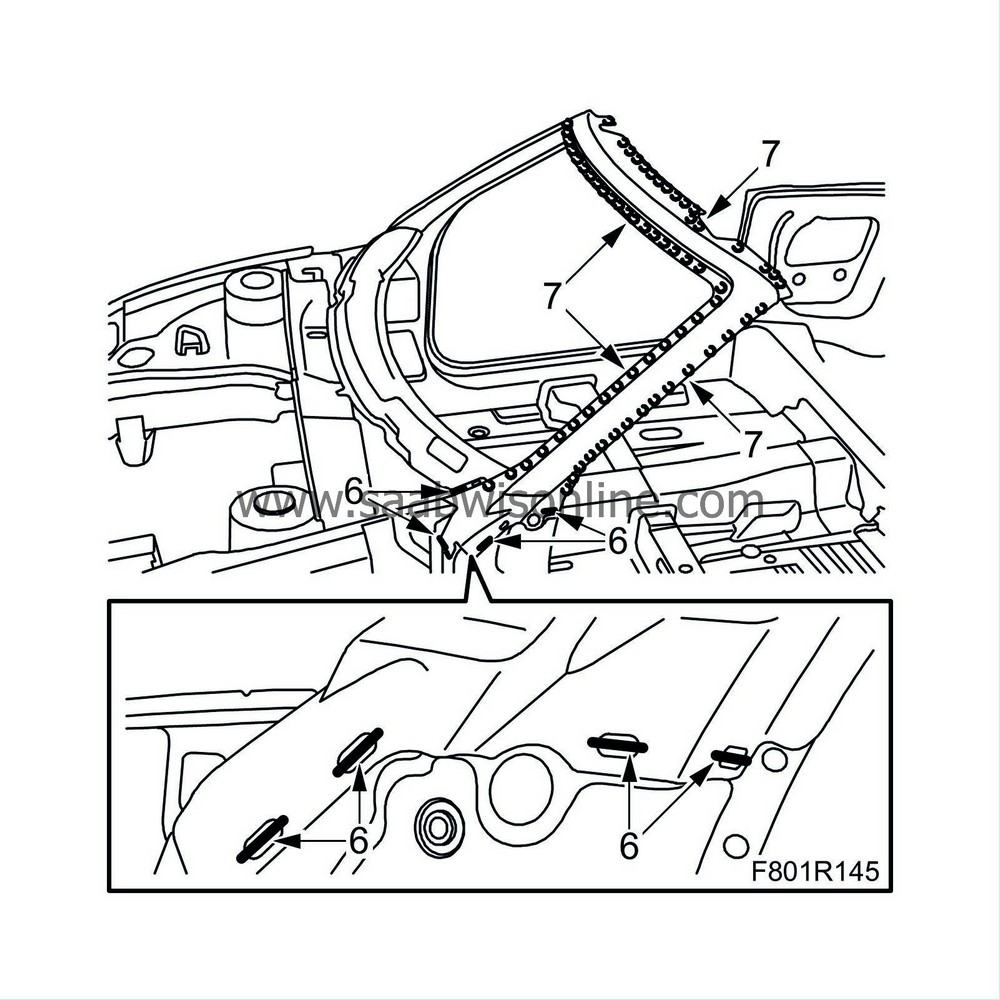

7.

|

Drill out the spot welds securing the windscreen frame outer panel.

|

|

8.

|

Tap the windscreen frame outer panel loose and align any deformed sheet metal or panels.

|

|

9.

|

Grind clean the surfaces that are to be welded.

|

|

10.

|

Drill holes for plug welding on the new windscreen frame outer panel.

When body adhesive cannot be used between the panel sections, reduce the distance between the spot welds. Spot weld distance max. 25 mm.

|

Important

|

|

The outer panel of the windscreen frame is only to be plug welded as the total material thickness is too great for spot welding.

|

|

Make sure the holes for plug welding are not positioned over the underlying spot welds. Otherwise, there is a risk of the existing spot welds coming loose.

|

|

|

|

|

11.

|

Apply welding primer on the surfaces to be welded. Use Teroson Zink spray.

|

|

12.

|

Place the windscreen frame outer panel in fitting position and secure it with welding clamps.

|

|

13.

|

Align the windscreen frame outer panel exactly.

|

|

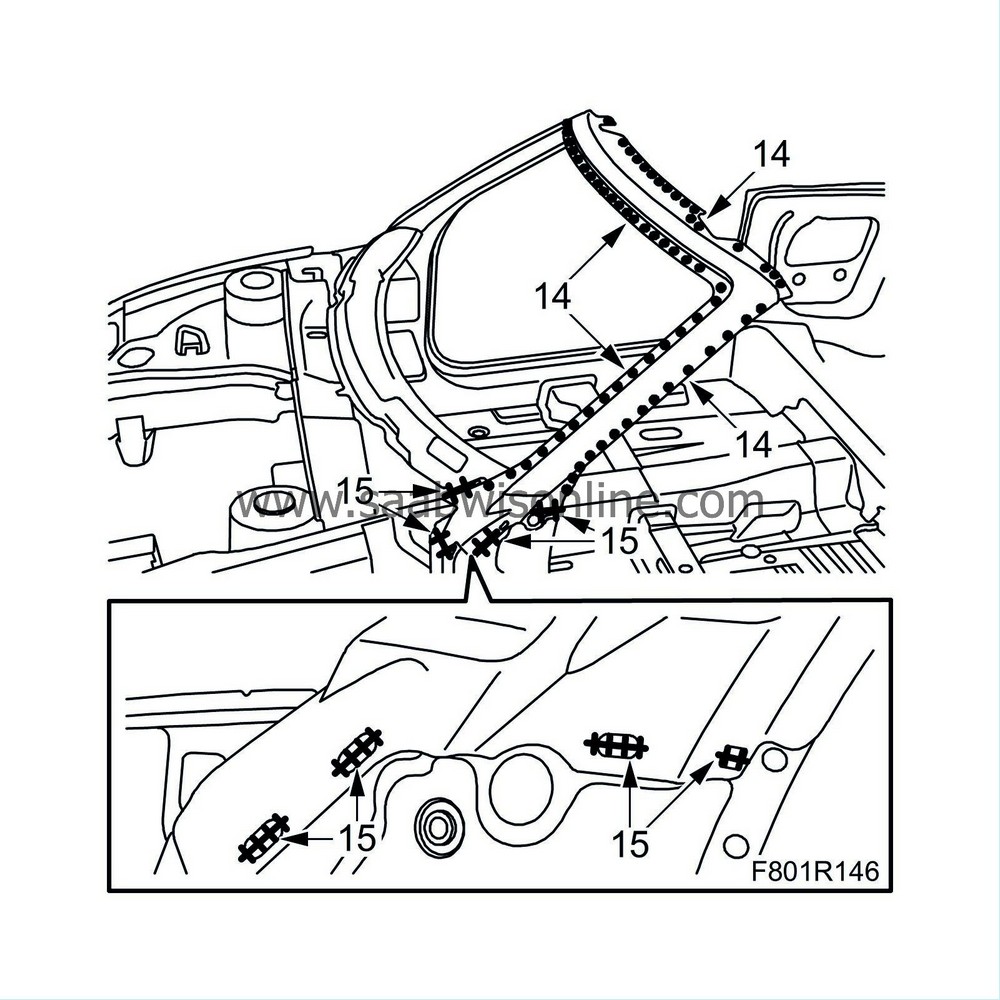

14.

|

Plug weld the windscreen frame outer panel.

|

Important

|

|

Do not perform all welding in one go. Allow the metal to cool from time to time to avoid heat displacement.

|

|

|

Warning

Warning

|

|

Repairs to MIG brazing using conventional welding methods and normal filler material are forbidden. Cracks can arise which can impair performance in a collision.

|

|

|

|

|

|

|

|

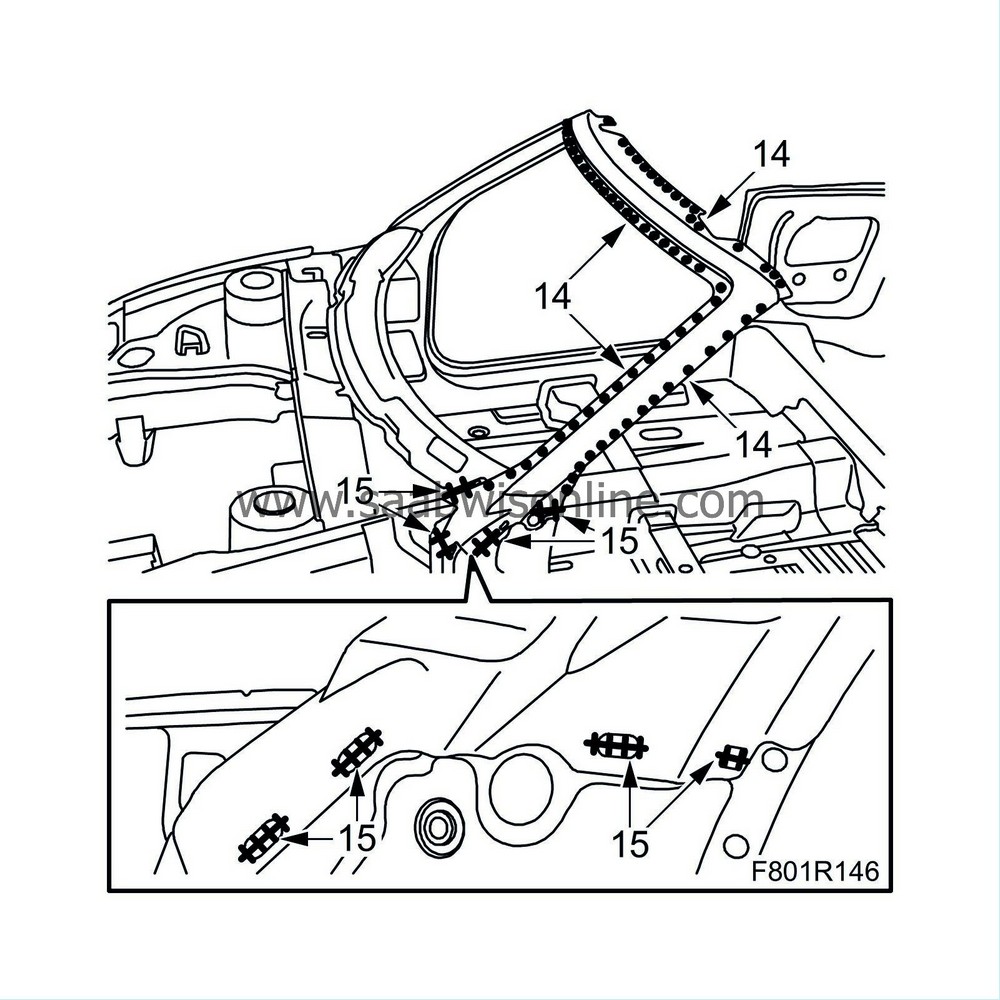

15.

|

Seam weld the outer panel of the windscreen frame. Replace the MIG brazing.

|

|

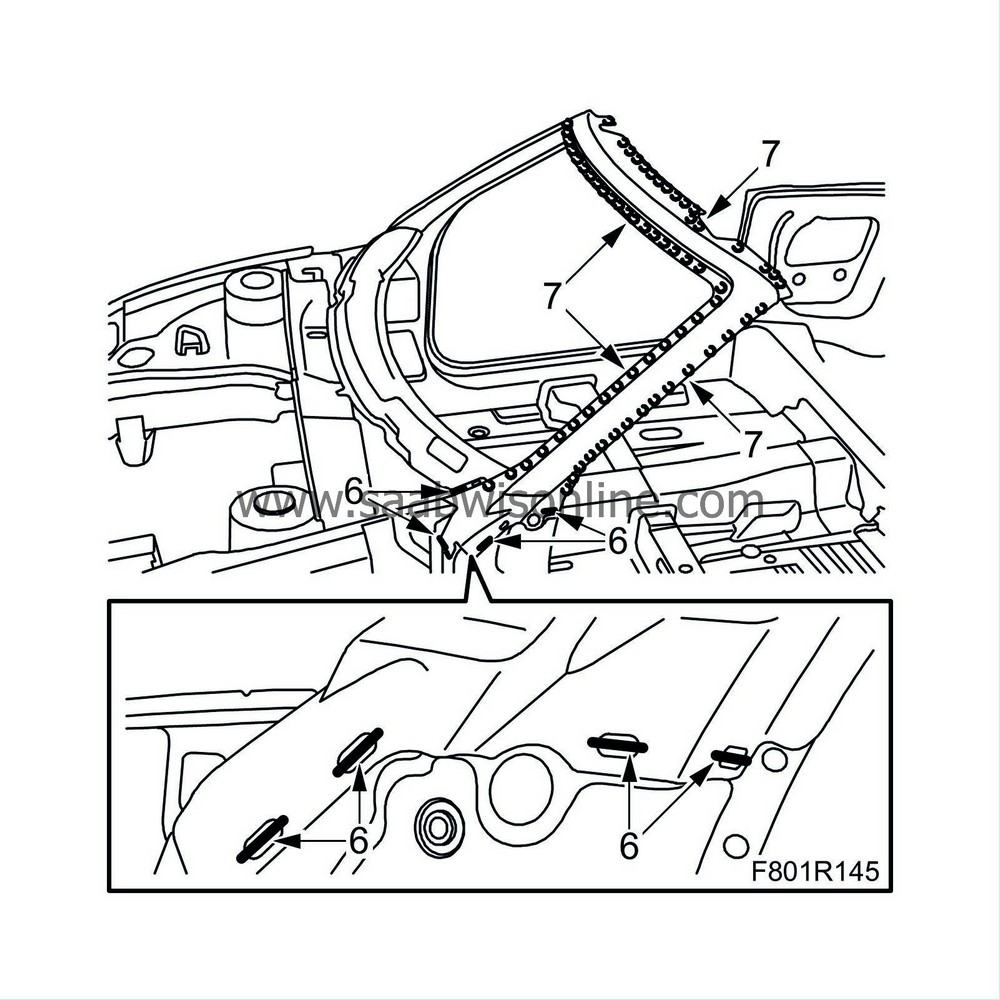

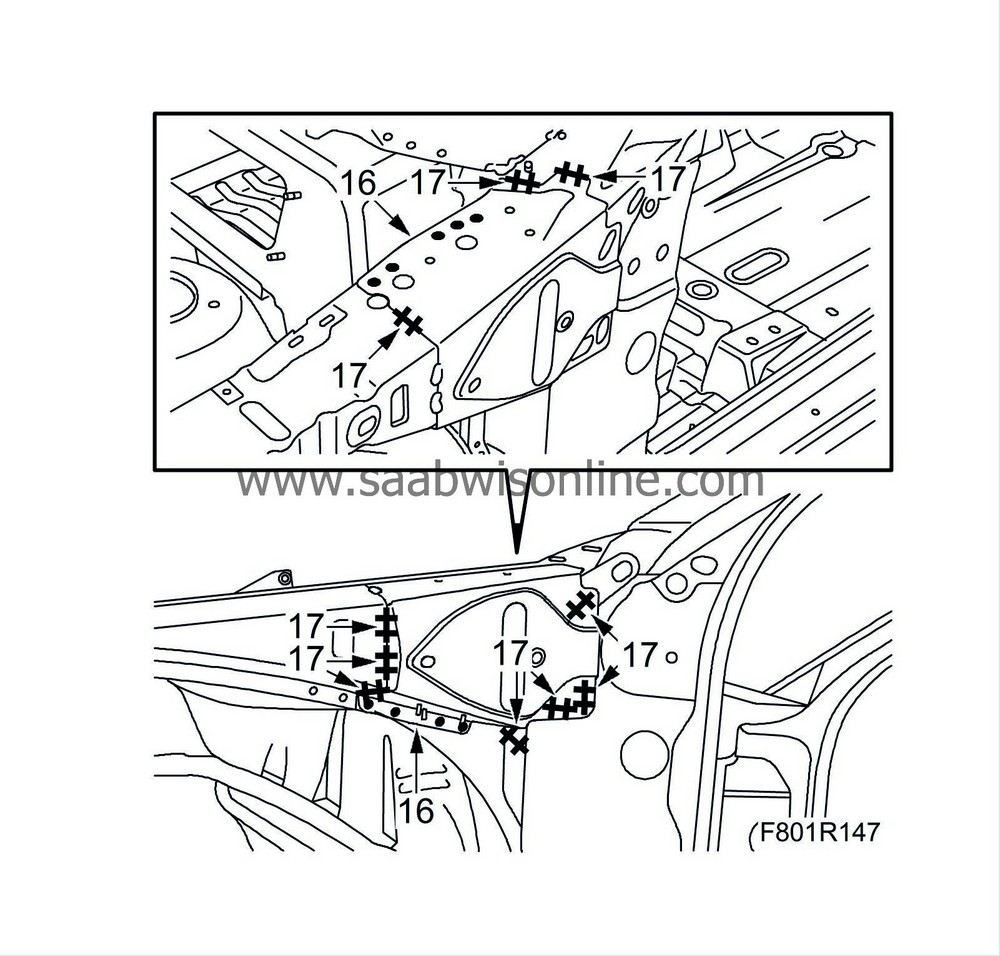

16.

|

Place the reinforcements into position against the outer sides of the front wheel housings. Spot and plug weld.

Warning

Warning

|

|

Repairs to MIG brazing using conventional welding methods and normal filler material are forbidden. Cracks can arise which can impair performance in a collision.

|

|

|

|

|

|

|

|

17.

|

Seam and continuous weld the reinforcements of the front wheel housings' outer side. Replace the MIG brazing.

|

|

18.

|

Wash away surplus welding primer. Welding primer reduces the adhesion of paint, filler and sealant.

|

|

19.

|

Apply primer to all bare metal surfaces. Use Standox 1K.

|

|

20.

|

Use Terostat 1K-PUR to seal joints and metal folds.

|

|

21.

|

Apply anti-corrosion agent to internal surfaces after painting. Use Terotex HV 400.

|

Warning

Warning